Selection Tips

To choose a saw blade for a reciprocating saw, it is necessary to take into account not only its belonging to work with a certain material, but also pay attention to the following factors

- Reciprocating saw power. On average, the value fluctuates around 600 W, such saws are hand-held. A hacksaw with a power of 800 W or more is used for gardening and construction work, and is not considered a universal power tool. The power of cordless saws depends on the supply capacity, it also affects the duration of the work performed.

- Sawing system. The pendulum system reduces wear on the working surface, improves productivity. When performing work with increased accuracy, the power tool must be equipped with a vibration frequency regulator.

- Number of strokes per minute. The higher the number, the less time it takes to cut hard materials. The number also indicates the density of the products that the tool can handle. It is advisable to purchase saws with the ability to adjust the stroke.

- Types and type of teeth on the cutting surface. Blades with fine or wavy teeth provide better, cleaner cuts. The types of saw teeth are also selected based on the material being processed. Blades with carbide teeth work better on dense materials: metal, stone, and others.

- Saw shank compatibility with the chuck. In the sets, the saws are mainly presented with a universal shank, they are suitable for electric hacks, hand saws. Specific connectors are labeled with a letter designation and are intended for use with professional equipment.

- Manufacturer. It is recommended to purchase files from trusted brands such as Bosch, DeWalt, Metabo.

- Ease of use. Comfort depends on the type of handle, the presence of an anti-vibration system, a switch for the speed of the saw movement, the possibility of replacing the cutting blades without using special tools, and a battery charge indicator.

Potential problems and tool repair

When working with a reciprocating saw, problems may periodically arise associated with a broken tool or a jammed blade. What to do if the blade gets stuck or flies out, how to pull it out and sharpen it? Use the following guidelines to correct and identify the problem.

Canvas problems

The reason for the emergence of a flyout or a jam of the file is the wear of the retainer. This problem is found in cheap tools, it rarely appears in professional units. If no problems with the retainer have been identified, it should be remembered that the shank of the blade may not hold in the groove due to a counterfeit consumable. The hole diameter and blade shank do not match the original, which causes the file to fly out and jam. The solution to this problem is to replace the saw retainer. The jammed blade can be pulled out with pliers after lubricating the saw shank and the retainer with oil. If it is impossible to reach the blade, the tool should be disassembled.

Vibrations during tool operation

The cause may be the appearance of a backlash. The bushings that drive the rods are usually made of brass and will wear out over time. Elimination of the malfunction is possible only by replacing parts.

Noise while the tool is running

This is due to bearing wear due to insufficient or no lubrication of the parts. The solution is to change the lubricant or parts.

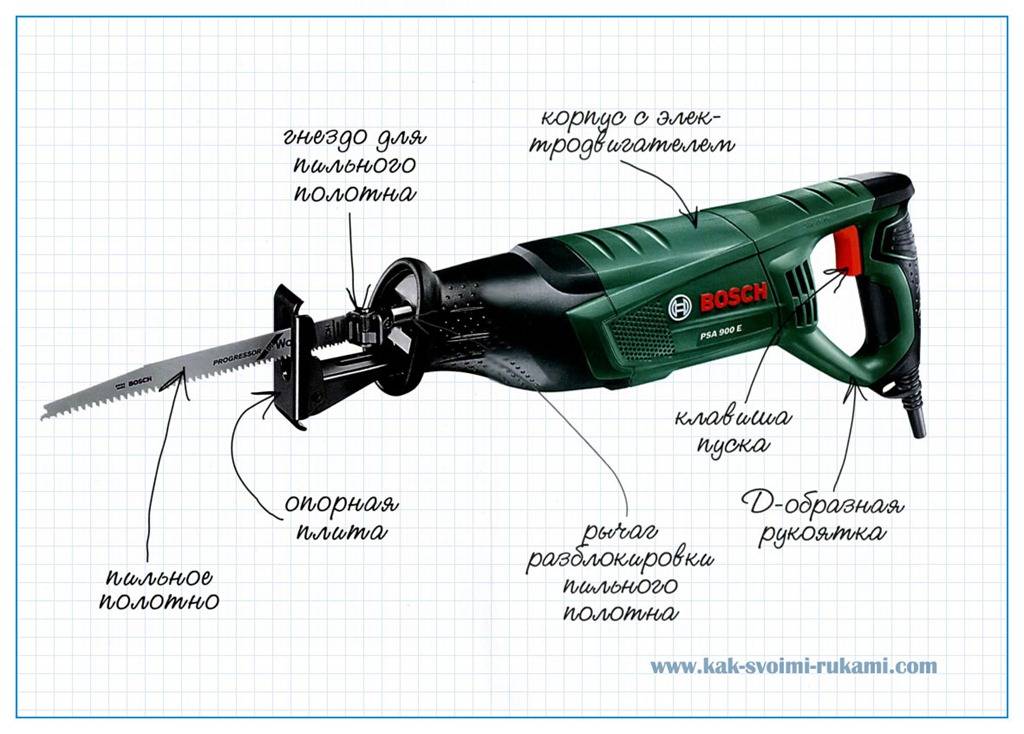

Features of the reciprocating saw device

Reciprocating saw device

Reciprocating saw device

A reciprocating saw or an electric hacksaw is a hand-held tool for cutting concrete or other materials, powered by the mains, with a cantilever fastening of the working body, which looks like a hacksaw blade that performs reciprocating fast movements during work.

An elongated gearbox, an ergonomic handle, a cantilever blade allow you to cut through the material in the most inconvenient places, cut its parts that are flush with the wall. The tool can be operated while holding the workpiece suspended.

The main advantages of reciprocating saws are:

Device characteristics:

- Equipment power 0.5 - 1.5 kW. Most models are designed for a power consumption of 0.9 - 1.2 kW.

- The number of strokes of the working blade is 2.5 - 3 thousand rpm.

- There is a speed adjustment that allows you to change it when the web is moving.

- The blade travel ranges from 19 to 32 mm.

- Some materials have limitations on the maximum cutting depth;

- Pendulum stroke. In this case, with the reverse movement of the blade, it must be slightly deviated from the cutting line. This allows you to effectively remove sawing waste, the blade heats up less, and the productivity of the tool increases. Not all have a pendulum movement, but only the most popular electric hacksaws;

- Canvases. The functionality of the equipment depends on the blade used. Its complete set includes several blades for different materials, which differ in pitch size, shape and size of teeth, knife material, whether or not there is diamond dusting.

Blades are produced with variable pitch and tooth sizes - they grow from the tool shank to the end of the blade. Their convenience is that when using different sections of the blade, one saw can provide different parameters when processing concrete;

Support shoe. It allows the tool body to be securely fixed by pressing it against the work surface, which increases the speed of concrete sawing, improves the quality of the cut, and the process becomes more convenient and easy. The shoe can move with its fixation along the web, while ensuring that the required sections of the web are put into operation.

In addition, the support surface of the element can be rotated, and the blade cuts the material at the desired angle.

Attaching the file to the tool

Attaching the file to the tool

The principle of operation of a reciprocating saw for concrete

With saber saws with your own hands, you can cut materials such as:

- Aerated concrete: aerated concrete and aerated concrete blocks, aerated concrete, aerated concrete blocks and other similar building materials;

- Lightweight concrete: expanded clay concrete, pumice concrete, perlite concrete, arbolite, polystyrene concrete and stony concrete;

- Heavy concrete based on Portland cement, slag cement, asphalt and polymer cement;

- Red, silicate and karmic bricks, clinker bricks, foamed concrete;

- "Wild" stone, porcelain tiles, gypsum plasterboards, artificial stone, limestone, shell rock and chalk.

Most often, a reciprocating saw is used for efficient, fast and relatively inexpensive work.

These include:

- Dismantling of partitions, walls, concrete floors, crossbars, columns, pilasters and other types of concrete building structures;

- Redevelopment of any premises in the house, office;

- Arrangement of door and window openings in the walls, adjusting the size of existing openings;

- Finishing of corners, which were processed by disc machines;

- Cutting holes and niches;

- Cutting to the required size: reinforced concrete, concrete and foam concrete blocks and other building and finishing materials.

Using a hacksaw for hollow blocks

Using a hacksaw for hollow blocks

Electric hacksaw

Electric hacksaw

Useful Tips

A chain saw, although you can't call it a hacksaw, is in many ways more effective than saber counterparts.

A chain saw, although you can't call it a hacksaw, is in many ways more effective than saber counterparts.

The instruction supplied with the instrument recommends following a few tips:

- Reciprocating hacksaws for concrete are the only effective cutting tool for cutting hard material in hard-to-reach areas;

- The use of such a tool is cost-effective when carrying out a small amount of work;

- It is not recommended to use the unit for cutting reinforced concrete materials.

The processing of concrete blocks of various types of concrete is a fairly often used operation when performing construction or repair work. In this case, you need a special concrete hacksaw, which has increased strength and can withstand the abrasive parts of the material. The video in this article will help you find the information you need on this topic.