Peculiarities

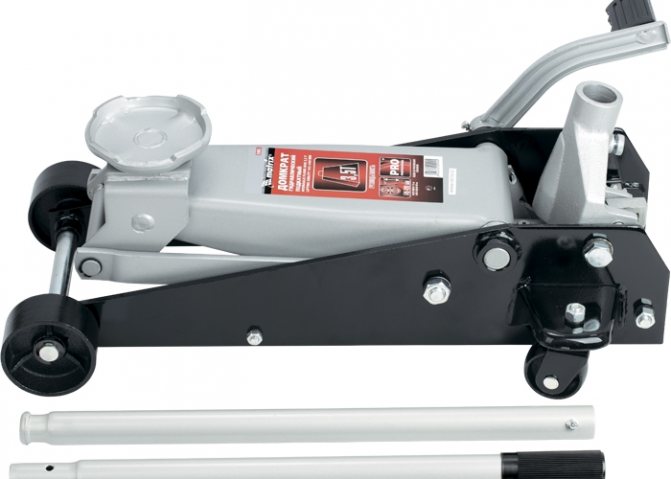

A rolling jack is a very useful and necessary thing in every garage. It should only be remembered that he needs a flat, solid surface to work. This tool is a long, narrow cart with metal wheels. The whole structure is rather weighty.

It makes no sense to carry such a jack with you in the trunk, since it is not always possible to find a flat shoulder for its use. At the same time, it is heavy and takes up a lot of space. This tool is indispensable for workshops that carry out minor quick repairs without the need to fully raise the machine on a lift. Tire centers simply cannot do without such equipment.

It will always find its use in a simple garage, since it is not always handy for a car owner to get through the entire trunk for a small jack that comes with the car. In addition, now on some brands of cars "native" plastic jacks, and car owners do not always want to check their strength and play Russian roulette.

In the raised state, the trolley jack is low, but very stable, which allows, if necessary, to shake some parts of the car a little, to open the doors and trunk.

The mechanism of the device includes a shut-off valve, which allows you to fix the stem in a certain position with a load. Some models are equipped with special grips to expand the capabilities of the device.

There are jacks that do not work from a hand pump, but from a pneumatic tool. For such a lifting mechanism to work, it is necessary to have a compressor. This type of jack is not practical for home use and finds its place in service stations for trucks.

Rolling-type jacks have their own advantages, which are worth noting:

- ease of use with the necessary free space;

- having wheels, it is not necessary to carry it in your hands, but you can simply roll it to the right place;

- thanks to the ability to work with a lot of weight, such a jack will be able to lift the entire side of the car;

- no special places are needed for lifting, that is, you can lift the car at any safe place;

- the make and type of vehicle are absolutely not important, as long as the weight does not exceed the permissible values.

In addition to all its obvious advantages, there was still a place for disadvantages, and they are as follows:

- high price for this type of instrument;

- large weight and dimensions.

The need for such a device should be obvious, unless it is a nice addition to your toolbox. In other cases, a simple hydraulic bottle-type jack can be completely dispensed with.

Bottle jack device

Today, there is a hydraulic lift in almost every car repair shop, since with the help of a 5-ton jack of the old model, cars can be raised to a predetermined height for repair work. Due to their high carrying capacity and ease of use, bottle-type lifts are popular.

Bottle hydraulic jack

Bottle hydraulic jack

Even 50 years ago, it was possible to lift a car or any other load only with the help of a mechanical device, but over time, experts have established the fact that the capabilities of such a device are limited. Mechanical lifters were unable to generate high pressure even when the craftsman tried his best.As a result of the tests carried out, a modern lifting mechanism was invented, for the operation of which oil was required. The working fluid helps to create the required pressure, and the jack gradually raises the load to the required height.

Note!

With the help of bottle jacks, it is possible to lift vehicles weighing more than 2 tons, from which it can be concluded that these mechanisms are used to lift concrete columns or foundation slabs.

It is worth noting that hydraulic lifts are used not only by workers in service stations, but also in large oil refineries. These designs are indispensable in hydroelectric power plants, and over the past 10 years they have been preferred by most motorists, both experienced and beginners. For optimal operation of the device, both vertical and horizontal planes are suitable, which makes it popular even in the construction industry.

DIY hydraulic bottle jack repair

The most frequent and widespread breakdowns of a bottle jack are the failure of oil seals and gaskets, as a result of which fluid flows out of the working cylinder. Also, another popular malfunction is represented by jamming of the stem during its reverse stroke.

As soon as the first oil leak is noticed, it is necessary to immediately start repairing the lift, and if you ignore this problem, then the stem can jam.

You need to start repair work by draining the oil, after which the structure is disassembled, the oil seals and seals are changed, new and high-quality oil is poured in, and then the device is pumped.

Often, dirt accumulates in the working fluid, which entails jamming of the lift rod. To repair a jammed rod, the tool must be completely disassembled using the prepared repair kit and thoroughly rinsed every part. If corrosion is found, the outer walls of the lift should be repaired.

It is always worth remembering that improper operation (exceeding the loads indicated in the technical document) and untimely maintenance of the bottle hydraulic structure leads to breakdowns, which are not always easy and possible to eliminate. The lifting telescopic piston may come to a complete stop or extend slowly and jerkily.

Hydraulic Jack Service

If the reason is found on time, the tool can be disassembled and repaired, after which you can make a nozzle for a bottle jack with your own hands. But if mechanical damage appears, such as a malfunction of the piston or the body of the lift, it is recommended to write off the jack and purchase a new, high-quality adapter for bottle jacks with a rubber pad.

Main characteristics

When choosing a jack, you should pay attention to the following parameters specified in its specification:

- Lifting height. It is desirable that the indicator exceeds 450 mm - such jacks are more versatile and are used to service any type of light transport

- Pickup height. The standard figure ranges from 120-150 mm, however, there are also special low-profile models (70-90 mm).

- Ascent speed. Accordingly, the higher it is, the faster you can end the unpleasant repair procedure and continue your journey.

- Carrying capacity. The main parameter of any jack. The standard rolling jack reaches up to three tons, but there are more expensive modifications with a lifting capacity of 5 tons. However, they are rare.

- Convenience. It is difficult to call this a parameter, since it does not have a fixed value and is determined by the buyer himself. Depends on the size of the device, type of handle, chassis, etc.

- Transfer type. There are few options - gear or cardan.It is recommended to choose the second one, as it is more reliable and durable.

- Stem and body material. The load capacity, stability and weight of the device depend on it. For example, aluminum jacks withstand less load, but they themselves weigh much less than similar steel jacks.

Hydraulic trolley jack 3 t Inforce T83003C

A universal lift of Russian-Chinese production, widely used by motorists and service workers and service stations.

- Carrying capacity - 3 tons

- Lift height - 410 mm

- Pick-up height - 130 mm

- Weight - 19 kg

Professional trolley jack AE&T T31203

Chinese jack, often used when working in tire shops. The reinforced body makes the device quite heavy, but more stable, which allows it to be used on any surface. Convenient steering with the chassis swivel wheels. The warranty is 12 months.

| № | Useful information |

|---|---|

| 1 | Carrying capacity - 3 tons |

| 2 | Lifting height - 495 m |

| 3 | Pick-up height - 135 m |

| 4 | Weight - 36 kg |

Hydraulic rolling jack 3 t STELS SUV 51134

Russian product, popular among drivers of cars and SUVs due to its relatively small dimensions. The improved locking system allows you to keep the load at a height for several hours. Chassis on steel wheels; comfortable ergonomic handle. The warranty is 6 months.

- Carrying capacity - 3 tons

- Lift height - 535 mm

- Pick-up height - 190 mm

- Weight - 21 kg

Rolling jack AIRLINE AJ-3F-390P

The cheapest model presented. Medium reliability design, optimal for use in the middle lane. Reliable load securing system. A flat platform is required for work; Comes with a detachable carry handle and a sturdy bag. The warranty is 6 months.

- Carrying capacity - 3 tons

- Lift height - 390 mm

- Pick-up height - 135 mm

- Weight - 12 kg

Model overview

When choosing a jack, it is necessary to take into account such points as the country and make of the manufacturer, as well as the model of the vehicle.

It is also important for car owners how mobile this device is, so you need to find out about its weight and dimensions.

Having considered the popular brands of manufacturers and the most commonly used jacks, several of the best models can be identified.

Matrix Master 51028

It is a hydraulic trolley jack, which is easy to operate, compactly placed in a special case. Designed for lifting passenger cars. The jack is equipped with a valve-shaped safety device that prevents overloading of the tool. It can be used both in workshops and on the road for repairing cars.

Hobbyline jack

These low grip bottle jacks are designed to handle heavy loads. But due to their rather large dimensions, they are difficult to transport, so they are usually used in service stations. The comfortable handle allows you to fix the mechanism in a convenient place for work, without any special effort.

DA5P120K

The model is considered one of the best among the low-lift jacks. It was developed for fixing and lifting oversized cargo during installation and repair work. Designed for stationary use in workshops or garages. The design includes grips for lifting weights, springs with the ability to return the rods to their original position, as well as pumps that create fluid pressure in the chamber of the working cylinder.

The support part allows lifting loads up to 5 tons, and the side parts are capable of only 2 tons. A hydraulic cylinder complete with a built-in pump and a control panel makes it possible to work in almost automatic mode.

Take off

Donut ° Ром:

- please. Saucer and saucer. Burgundy, burgundy 2, 3 line 5 line. Sowing stems - 5 saps 10 saps.Side by side, side by side 20 side by side.

- Good luck. On the floor. Bottom line Flare (flare) flare 65 min. Burgundy: bark and bark of bark and bark of bark 140-200 bark

- Good luck. Rose, Rose, Rose, 350, Rose, 350, Rose, 350, Rose Tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting, tilting tilting tilting tilting tilting 500 tones

Peculiarities

Rolling jacks are the most popular and frequently used type.

The mechanism is widely used in auto repair shops, car garage repairs, tire fitting works. With the help of a rolling jack, you can easily smoothly raise the car to a predetermined height and just as smoothly lower it down.

The main structural elements of such lifting equipment are:

- rigid base on which 2 wheel pairs are located;

- 2 cylinders, in each of which pistons are installed;

- heating and suction valves;

- lifting platform.

The rolling jack is characterized by:

- a large working stroke - it has a low level of pickup and a fairly high lift (it can serve a car, the suspension of which is less than 10 cm, but the mechanism can lift the load by 50 cm);

- mobility - design features allow you to move the mechanism anywhere without much effort;

- productivity.

Taking into account all the features, it is not at all surprising that the trolley jack is a priority for car owners. With the advent of this type of lifting device, mechanical jacks are a thing of the past.

Views

There are several types of jacks.

Hydraulic devices operate on liquid, differ in their design, can be single or double-plunger, and can also differ in the type of drive. The design of such options consists of a body, a piston and a working fluid. The guide cylinder is a housing with an oil reservoir. After pressing the drive handle, the force is transmitted through the lever to the pump. During the upward movement, oil enters the pump cavity. Due to the fact that the piston and cylinder have different diameters, the applied force is minimized. Oil under the piston pushes it out and lifts the weight underneath. Such devices have high efficiency, operate very smoothly, and have high structural rigidity.

Bottle devices have the same principle of operation as hydraulic ones, differ only in a more powerful design. They can work in all weather conditions, since the liquid in the cylinder is not subject to freezing. They are stable due to their vertical construction and wide support shape. They must only be used and stored in an upright position, otherwise oil may leak.

The most adapted and demanded are rolling jacks. They can be used in any conditions. Thanks to the hydraulic principle of operation, they provide a smooth ride when lowering and lifting the load. Due to the peculiarities of the shape, they can lift the load from almost zero height, which is very convenient when working with cars that have a low stance. They are easy to use, but, like bottle counterparts, must be upright.

Rack jacks have one distinctive feature - the bent end of the rack at 90 degrees. Thanks to this design, it is possible to lift the load even from the lowest point. Such devices can be used both vertically and horizontally.This ability is in great demand, as it provides a more comfortable work. The principle of operation of such devices consists in the interaction of a rack and a ratchet mechanism. The body has a lifting arm and a load support. During the lifting of the load, the body moves along the toothed rack. The device is protected by a metal casing from dust and dirt. If a metal cable is connected to this type of jack, then the device can work on the principle of a winch.

Hook or two-stage jacks have two hooks, which are at different heights. Such mechanisms of the bottle type are two-level and combine two types, low-grip and bottle. A characteristic feature of such devices is the pick-up arm, which catches the load at the bottom edge.

Home

Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, and Rose Service. Rose, Rose, Rose, Rose, Rose, Rose Quick and easy:

- bottle;

- power supply;

- flare;

- l ± bl »loc;

- bank;

- luclocal;

- bunker;

- burgundy;

- red and white (red).

Tint, tilting, tilting Lol lokl lokl lokl lokl. ÐÐ »Ñ кР° жÐ'ого конкÑÐμÑного виÐ'Ð ° ÑÐ ° Ð ± оÑÑ Ð¿ÑимÐμнÑÑÑ ÑÑ Ð¼Ð¾Ð'Ðμл Ñ, коÑоÑÐ ° Ñ Ð¿Ð¾ конÑÑÑÑкÑивнÑм оÑоР± ÐμнноÑÑÑм и ÑвоÐμÐ¼Ñ ÑÐ ° l ·

Rules for the selection of lifting mechanisms

You need to be very careful when buying a floor lift

Important aspects that a buyer should pay attention to when purchasing:

- Choose a jack only tied to a specific type of car.

- The most important factor here is ground clearance. Ground clearance is determined by how high off the ground is the place where the jack contacts the vehicle when it is lifted. Vehicles with low ground clearance are easier to lift with conventional hydraulic floor jacks. They can be used in low-profile versions for sports and racing cars. They are also favorites for most sedans, SUVs, vans, coupes, and trucks.

- All floor jacks are designed for a specific maximum lifting capacity. You need to make sure that the maximum power on the jack exceeds the lifting weight of the machine and possible load and will allow it to be used for a long time. Typically this rating is given in tonnes, with 2 ton and 3 ton devices being the most common. Most compact and fuel efficient mid-range vehicles can be safely lifted with the 2 tonne device. For luxury full-size cars, vans, minibuses and mini-trucks, three-ton mechanisms are suitable.

- Build quality. A well-built jack has predominantly metal parts, while a cheap one has a lot of plastic parts. In addition, the quality of the finish is often an indicator of the strength of the material. If the metal has a polished surface with nicely painted areas, this means that the manufacturer is openly showing reliable parts of the devices, and when paint is carelessly applied with visible overspray, the manufacturer may try to hide the poor quality metal under it. High quality devices are heavyweight and run very smoothly.

Main selection criteria

The main criteria for choosing a rolling jack

- Maximum height.A rolling jack for an SUV or crossover should accept this parameter from 450 mm, due to the large travel of their suspension. If the lifting height is insufficient, then it will simply not be possible to remove the wheel.

- Minimum height. Typically, the minimum lift height is between 125 and 140 mm. For lovers of low clearance, there are low-profile rolling jacks with a pick-up height of 75 - 90 mm.

- Ascent speed. The presence of an additional pedal significantly increases the lifting speed.

- Carrying capacity. It is selected based on the weight of the serviced vehicles. Hydraulic sliding jack 2t, the price of which is quite low, can be suitable for a garage with a small car. And the owner of more serious equipment, an inveterate "jeep", needs to pick up a rolling jack of 3 tons. It will cope better with the task at hand. And this is provided that the weight of the car does not exceed the boundary value.

- Convenience. The presence of a rubber stop on the lifting platform and protection on the handle to prevent damage to the coating on the car.

- The mechanism for transmitting force from the handle to the shut-off valve (gear, cardan). The cardan transmission is optimal. It is more reliable, durable and cheaper to repair in the event of a breakdown.

Also note the presence of the caps on the plunger. They provide additional protection for the mechanism from dirt, corrosion and reagents and are highly desirable

The presence of additional grease nipples on heavily loaded assemblies is also encouraged.

After purchasing and before using the jack, read its instructions. Subsequently, this can save you from many problems in the process of its work.

The already mentioned latch, inserted into a special bore, significantly increases the safety of work when the load is raised

Although safety precautions explicitly prohibit non-stop operation, this requirement is often not met.

The presence of a retainer is guaranteed to avoid sudden folding of the jack, which may be the result of a malfunction of the hydraulic lift mechanism, but does not exclude its mobility.

Pay attention to the lever as well. It can be long or short, it can have specific shapes of the handle, which makes it possible to lift more comfortably

An important characteristic is the length of the jack lever handle. It is unlikely that anyone will deny that a 3.5 ton trolley jack is easier to operate with a long handle, since it is easier to lift a heavy car with such a lever.

For cars, a shorter handle is practical.

Although, many manufacturers have provided for the option of compound lever handles that have the ability to adjust the length based on the situation.

The material of the case and its thickness also play an important role.

An aluminum rolling jack will withstand less load than a similar steel one, but at the same time it will have much less weight.

The choice can also be greatly influenced by the manufacturer - a trolley jack of Russian production or foreign. The jacks of our Chinese comrades pass separately.

Jack maintenance

The long-term service of any device is achieved through timely maintenance. The main indicators of the required repairs are intermittent ascent, reduced travel speed. In order to avoid large financial costs for repairs, it is required to carry out maintenance in accordance with the manufacturer's regulations.

The main maintenance of the hydraulic type rolling jack is oil level control... Over time, the seals give a slight leak, the oil level is close to the minimum mark. The process is carried out on a flat surface with the mechanism inoperative, when adding oil, it is necessary to check the existing one, intensive operation may entail a complete oil change. Oil is used only from high quality manufacturers, it is possible to use any type, depreciation, industrial, for automatic transmissions. There is no need to mix different types of oil, only one type of oil should be in the design.

The rubbing parts experience constant loads, it is necessary to constantly lubricate the mechanisms with grease or other grease. Storage is allowed in a dry, ventilated place to avoid oxides of compounds, rust on the structure itself.