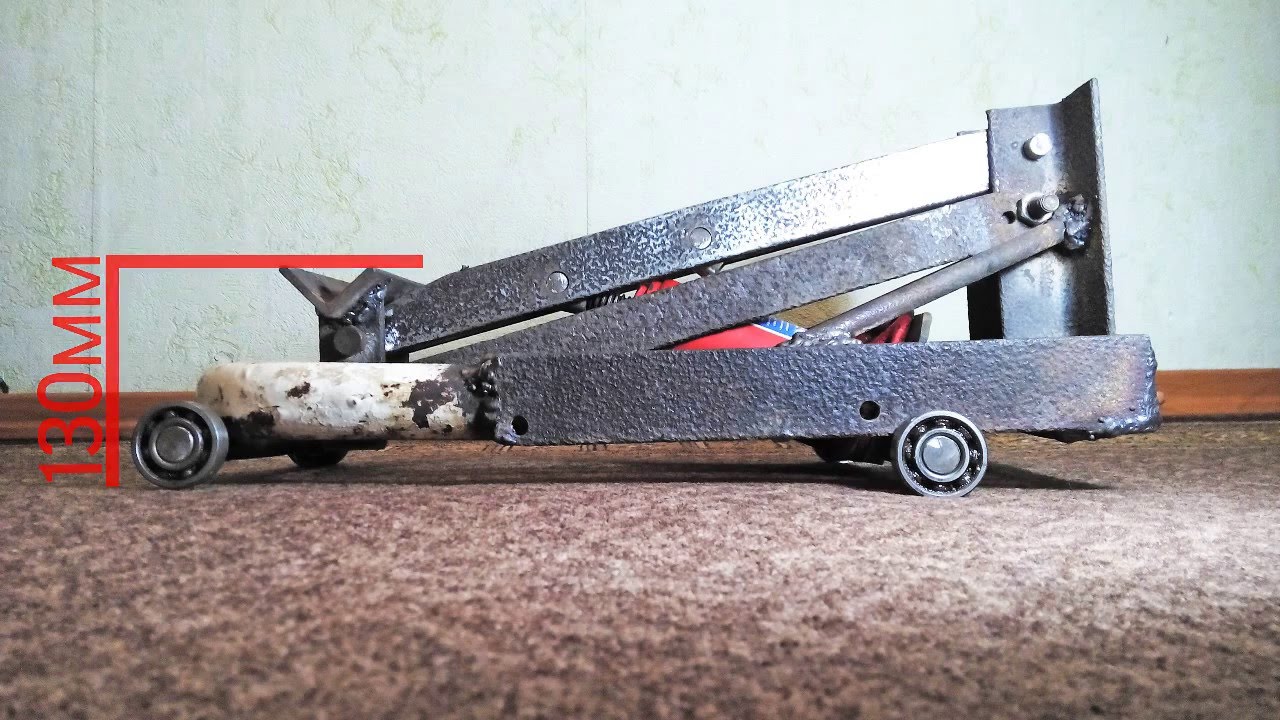

Option number 7. DIY screw jack

This structure consists of the following elements:

- screw mechanism;

- base;

- emphasis;

- shoulders - 2 pcs.

Screw jack design

The jack is assembled on the basis of a sheet of steel with a cross-sectional area of 2.63 cm2. 4 holes are drilled in the corners, necessary for the installation of fasteners, through which the base will be fixed.

The rotation shaft is made of metal rods with a diameter of no more than 12 mm. At one end of the element there must be a retainer (with the possibility of attaching a pin), and at the other - a thread.

Making a screw jack

The last one is the axis, thanks to which the shoulders - lower and upper - will rotate. Pins with flat cylindrical heads are additionally placed on the sides. Elements are attached with cotter pins. The last step is to install the retainer.

An example of using a screw jack

Recommendations

After completing the work, it is recommended to relieve the hydraulic jack from loads. Store the device in a dry and warm place. Due to the penetration of excess moisture, the mechanism can become covered with corrosion, and the cold will negatively affect the quality characteristics of the working fluid. It is advisable not to use the jack in severe frost. The loads on the lifting mechanism must not exceed those for which it is intended.

With continuous operation, the replacement of the working fluid (pumping) should be done once every 2-3 months. Then, in order to maintain the hydraulic jack in working order during the "downtime" period, there is no need to change the oil in it - 2-3 working movements of the rod once every 3 months are absolutely enough.

Summarize. In case of failure of the hydraulic jack, it is necessary to check 3 components:

- quantity and quality of oil;

- the presence of air bubbles in the system;

- how tightly the valves sit in the seats, pollution.

In the overwhelming majority of situations, to resolve all difficulties with the jack, it is only necessary to clean and change the working fluid.

How to repair a rolling jack in 10 minutes, see below.