The advantages of self-manufacturing and assembly

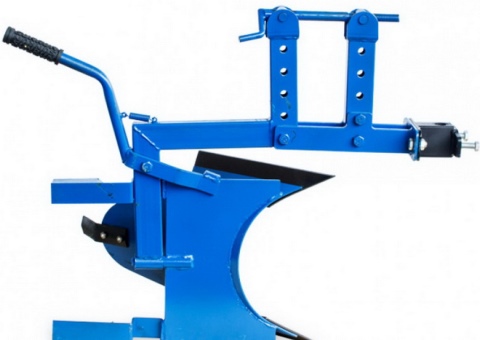

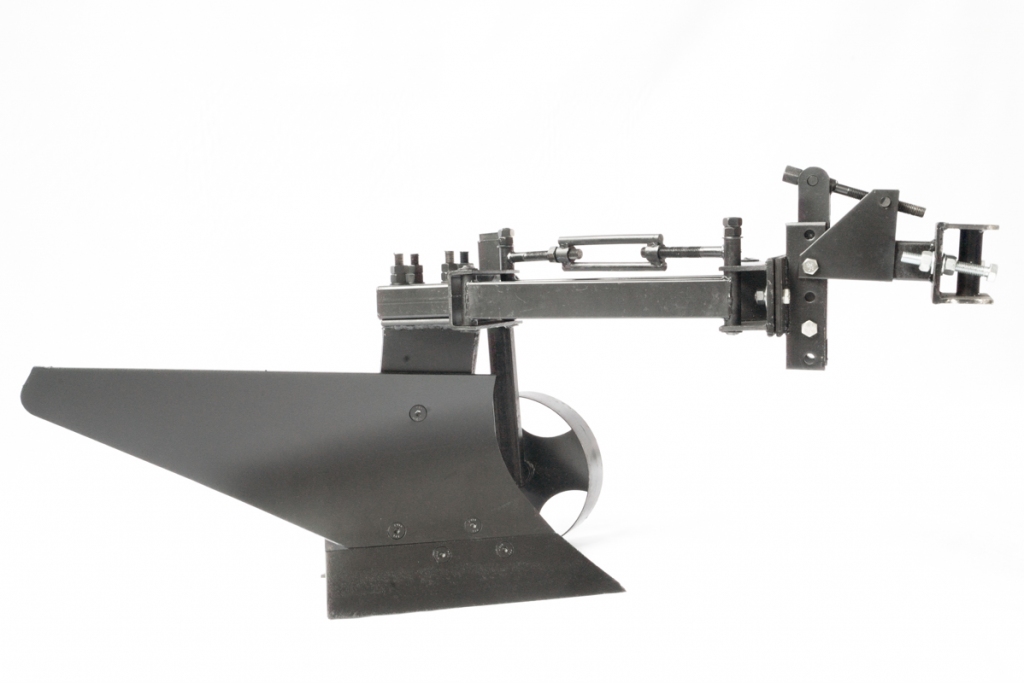

Plows collected by craftsmen from the remains of iron.

The main advantage of a self-produced plow is its low cost. You can make tooling from materials you already have, or use parts from old farm equipment. After the dissolution of state-owned enterprises, a lot of unnecessary equipment remained, which can be inexpensively converted to fit your needs.

The next advantage will be the practical compliance of the produced plow with your requirements for the processing of a particular type of soil and the necessary procedures for cultivating certain crops. You can make different working tools for different crops.

The use of materials known for their quality guarantees the successful use of hand-made devices. Shop counterparts often do not justify the specified technical characteristics and require revision and strengthening of the main elements. Spare parts and various metal structures accumulated on the farm will save you substantial finances when making a plow yourself.

It is more convenient to adapt self-made equipment to the existing agricultural equipment. The design of the plow is calculated for a specific mini-tractor in terms of power and productivity. It is also possible to complete the equipment with various tools for combined processing of a land plot.

Rotary plow: algorithm of actions

Rotary plow for walk-behind tractor with a support wheel is considered a complex type of canopy due to its design. It is necessary to work on it with special care so that mistakes do not negatively affect the quality of soil cultivation.

The rotary plow is manufactured according to a certain algorithm:

- The cutter is a working part. For manufacturing, you need to prepare a steel tube and metal plates. The latter are welded to the pipe for subsequent grinding of the soil and throwing it aside;

- Manufacturing of a frame for a gearbox. It can be of any shape, the main nuance is that the frame must protect the gearbox from moisture, debris, external damage;

- You will have to buy a gearbox. It connects to the gearbox of the unit;

- The rotary plow is quite large, so you need to install the wheels. Old wheels from motor vehicles will completely come off.

It is important to change the oil that lubricates the gearbox in a timely manner to prevent damage.

Varieties of plows

A plow for a tractor can be purchased ready-made, but there is an opportunity to make it yourself. Land cultivation is a complex operation that is performed before sowing crops and after harvesting.

Read also: Gasoline lawn mowers MTD: reviews

The models of plows are different, but they are united by the structure. The product has a ploughshare made of metal, it turns over layers of earth. The walk-behind tractor drives across the field, and the ploughshare stretches behind it, while the top layer of the earth turns over, weeds are destroyed. This is because their roots are cut with a ploughshare, as a result, after plowing, weeds are deep in the ground. They cannot germinate and die.

In the process of plowing, the soil is loosened, it becomes crumbly and is saturated with oxygen. There are different types of plows, so when choosing a tool, you need to take into account the area of the land plot, soil type and other indicators, then the quality of land cultivation will be high.

Installation and adjustment

After finishing work on the construction of the plow, it should be fixed on the walk-behind tractor. But before that, preparatory measures are carried out:

- moving the walk-behind tractor to the place where they plan to operate it;

- dismantling of the wheel drive - it must be replaced with special lugs (if they are not installed, then the plow will not work for planting the same potatoes - the equipment will slip and may "bury" in the ground).

After this stage, proceed to the installation of the plow.

- The plow is attached to the coupling of agricultural machinery using nuts. Thanks to this, it will be possible to independently set its performance characteristics.

- 2 securing pins are prepared. With their help, the couplings and the plow itself are attached to the earring.

After completing the preparation, they begin to adjust the installed plow. It is from this stage that it will depend on how efficient both the plow and the walk-behind tractor will be

For the correct installation of the structure, you need to pay attention to:

- width;

- plowing depth;

- incline.

The setup takes place step by step.

- On the extreme sections, the width is set. For this purpose, the edge should never move below or above the toe.

- The equipment is placed as steadily as possible on special stands so that it becomes possible to set the depth necessary for plowing. We must not forget that this parameter can vary depending on the time of year.

- It is necessary to carefully adjust the very attachment of the plow to the equipment.

- The bolting is carried out in such a way that the rear half of the plow is in line with the soil.

- The agricultural machinery can now be removed from the stand.

Homemade attachments

Almost any attachment for a tractor can be made independently. It can be a home-made potato digger, and a home-made rotary mower (or hay mower), and a rotary plow, cultivator, hiller. Sometimes you can redesign some equipment to make it more functional.

The most popular searches in the search engine are the design of an active plow on MTZ or DT and the question of how to make a cultivator with your own hands. After all, cultivators are faithful helpers to agricultural workers. The most difficult element at MTZ or DT is a rotary tiller. On a converted cultivator with a quality cutter, hilling can be carried out for a long time.

See »The device of the front axle of the Belarus MTZ-82 tractor

It is not difficult to understand how to make the installation of attachments, whether it be plows for tractors, a homemade cultivator, a potato digger for a tractor or other homemade products. The main thing is to act according to the given algorithms and check with the diagrams and drawings. Likewise, you can easily figure out how to set up a chisel plow on a wheeled tractor. Installing chisels on a wheeled tractor is a laborious process that can nevertheless be done by the tractor driver himself.

Which plow is suitable for mini tractors

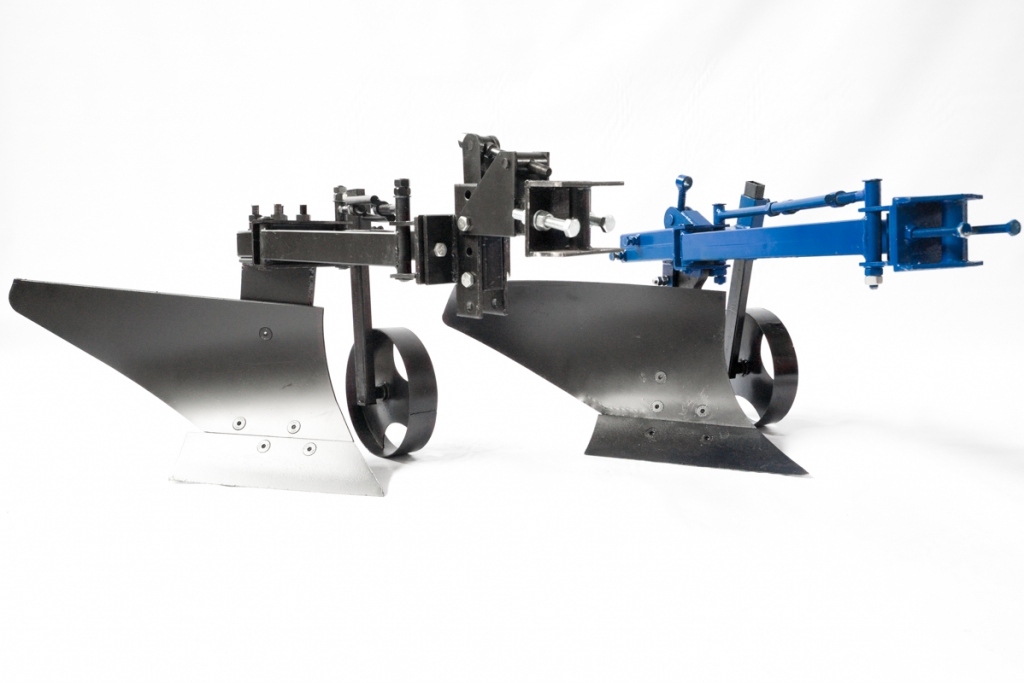

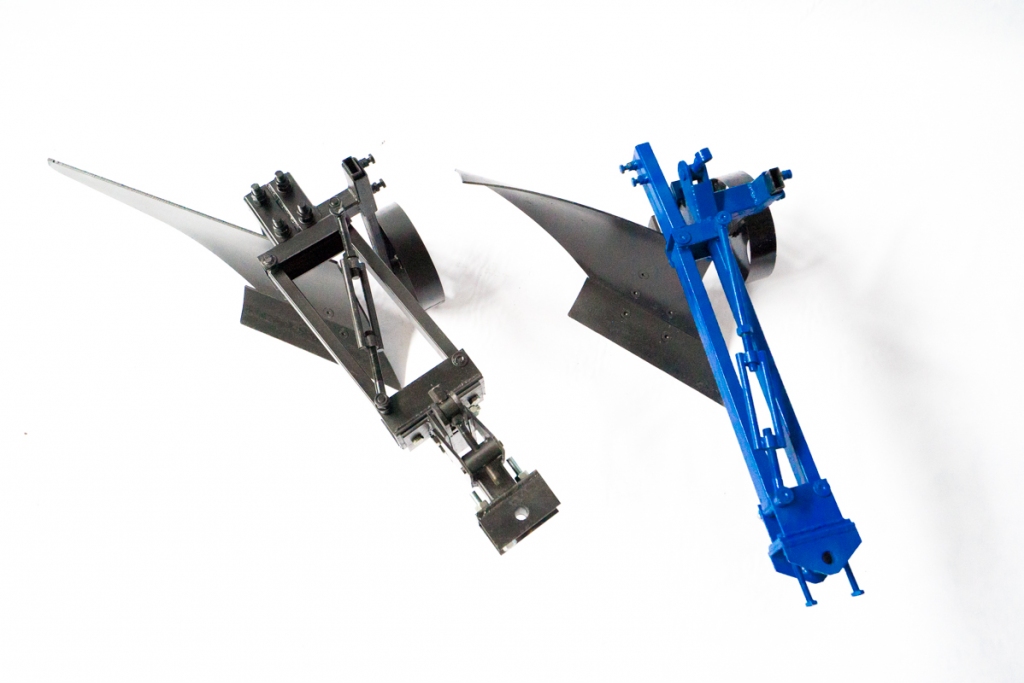

For an MTZ mini tractor or an imported model, a rotary plow of 1-2 sections is suitable. The best option is to purchase a 2 section plow. It consists of a frame and two working bodies - plowshares. Suitable for mini tractors with a pulling force of 3.5 to 6 kN. According to the shape of the working part, the plow is divided into types:

Rotary lightweight plow for mini tractors

Rotary - a modern plow. Has working blades installed in counterbalance to each other. In a flash, two work, and two hang over the ridge and compare the soil. The earth throws all the time to one side by active work with organs, passive blades raise and compare the ridges. When the mini tractor finishes a row, it does not turn around. The reversible plow turns itself and those plowshares that are suspended in the air become the workers. A burst of ground with such a plow leaves no ridges and the field has an even texture. There is no need to additionally use a cutter. This saves time and labor.

- Disc - the workers of the tribe are in the form of sharp discs. They are attached to a single frame by means of spindles on movable bearings. The tractor passes the lane while the discs spin and cut the soil into equal strips. The disc plow is suitable for heavy, clayey and heavily weedy soils.

- Plow blade - blades are wedge-shaped. On a two-frame, there can be from 2 to 4 blades. Works in a straight line. The most outdated and traditional model. Wedge-shaped plowshares go deep into the soil and plowing is carried out under the influence of the tractor's tractive force.

The two-body plow for mini tractors works the soil to a depth of 25 - 30 cm, the working width of one section is from 30 to 40 cm. Weight and dimensions depend on the selected model. You can buy a rotary reversible plow for your mini tractor from a company where agricultural assistants are purchased. Each model of the mini tractor has its own attachments. The models are universal for mini tractors with a similar aggregate system. So, the plow from Dofgan and Beoarus are coming up to MTZ. When choosing, two main criteria that play a decisive role are price and quality. Some people think that it is cheaper to make a plow for a mini tractor with your own hands. Of course, the price will be low if there are components. But if you have to purchase metal, fasteners, a welding machine, then the price difference with the finished factory model is small.

Plow types and their characteristics

Manufacturers produce several types of this equipment - rotary, disk and moldboard

Experienced farmers recommend paying attention to the two-body and three-body plows, which have two and three plowshares. The processing of small areas can be carried out using a single-body device, which consists of one share

By the method of plowing, the following types of equipment can be distinguished:

- furrowed;

- furless (even plowing);

- ridged.

There are several types of plows by the type of fixation.

- Attached - a tool that is fixed to the tractor using a single point hitch. The number of bodies corresponds to the type of tractor model. Advantages - low weight and simplicity of design, small turning radius. Disadvantages - inability to use equipment with a large number of bodies for a mini-tractor.

- Semi-mounted - equipment that uses not only special mounts, but also mounted wheels. For tractors with a pulling power of up to 3 tons, 6-furrow plows are suitable, and for mechanisms with a capacity of 5 tons, a 12-furrow attachment can be used. Advantages - high speed of work. The disadvantage is the presence of a large turning radius, the complexity of the design and the installation of auxiliary parts.

- Trailed is an unpopular device, for which only special wheels are used to move. Advantages - getting even and uniform plowing. Disadvantages - a large turning radius, the inability to use on small personal plots.

- Horse - an outdated type of equipment that is used only in single farms. Advantages - the ability to cultivate fertile soil in hard-to-reach areas.

Rotary

The rotor device is one of the latest developments of the manufacturers and consists of a movable shaft with several shares. This plow has a high speed and quality of soil cultivation. The main condition is the direction of the device strictly along a straight line. This design is indispensable for planting potatoes and other root crops. Manufacturers produce the following types of this equipment:

- drum - have rigid, springy or mixed pushers;

- bladed - consist of a movable disk, on which one or two pairs of blades are fixed;

- scapular - consist of fixed blades on a movable rotor;

- screw - have a working screw, which can be single-threaded or multi-threaded.

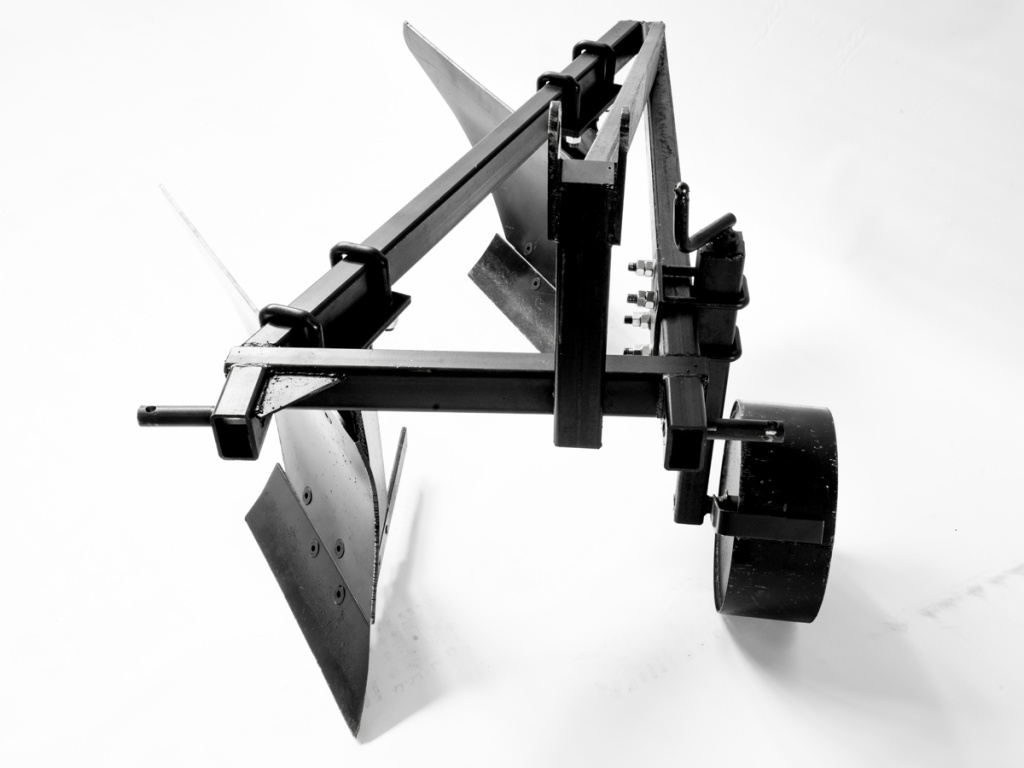

Plow-dump

Reversible (overhead) plow is made in the form of wedges, which are installed at a certain angle. After plowing, a curved dump with small pieces of soil is formed. The main feature is the implementation of the turn at the end of the furrow not of the tractor, but only of the plow. These mechanisms can have one or two cases. The furrow depth can be adjusted using the support wheel.

Disk

Disc attachments are shaped like a spherical disc that rotates on bearings. With the active, sharp working surface of the disc, the device easily cuts any kind of soil. Farmers use this plow to work on areas that have heavy, clayey and moist soil. The main feature of this model is the preservation of the integrity of the working surface of the cutting element in case of contact with a stone or metal object. The engine power on the tractor used must not be less than 18 hp. with

Particular attention should be paid to the versatile plow, which has a manual swivel mechanism on a standard hitch. The chisel mechanism performs moldboard-free loosening of the soil

The plow design has three planes, such as:

- lower horizontal;

- lateral vertical;

- front blade.

Rotary tine harrow

Appeared in domestic plant growing relatively recently. It is most often used in the cultivation of potatoes. After passing such a harrow, the farmer receives the correct trapezoidal bed. The harrow perfectly pulls out weeds, loosens the soil remarkably

Importantly, it can be used until the very bloom of potatoes - the teeth of the rotors practically do not damage the stems of plants

Another plus. After passing the rotor, the potatoes end up in the beds at an elevation relative to the general field level. Due to this, since the ridges are warmed up better, earlier and more friendly crop shoots are provided.

Types and classification of plows

There are several types of plows on the market today. Among them are the following categories:

- ploughshare;

- disk;

- rotary;

- combined;

- chisel.

The products of the ploughshare type are in the greatest demand. They were used by our ancestors, while the former popularity has remained unchanged to this day. As for disc solutions, most often such models are indispensable when processing heavy soil compositions and areas with high or insufficient moisture. In turn, combined and rotary devices are suitable for processing virgin lands.

The products of the ploughshare type are in the greatest demand. They were used by our ancestors, while the former popularity has remained unchanged to this day. As for disc solutions, most often such models are indispensable when processing heavy soil compositions and areas with high or insufficient moisture. In turn, combined and rotary devices are suitable for processing virgin lands.

The latter type is characterized by a complex design and narrow fields of application. With private farming, this option is ineffective due to the complexity of maintenance and other subtleties.

As for the types of traction, they are represented by the following categories:

- Tractor. It is considered the most popular type of plow. It is produced for various types of equipment, including compact mini tractors, as well as walk-behind tractors;

- For horse traction. The popularity of such a solution is much lower. It must be used in those areas where the use of a tractor is impractical or impossible due to lack of free space;

- Rope-traction. Most often they are used in places where a horse cannot climb. We are talking about wetlands with a steep slope, etc.

However, this is not the whole classification, there are two more categories according to the type of purpose. It is about general and special. Representatives of the first group are able to cultivate most of the existing types of land, while specialized models are suitable for:

- stony soils. They are equipped with protective mechanisms that provide reliable protection against damage due to the impact of large stones;

- revolving models. Supplied with two identical plows in mirror image.Most often they are used for smooth plowing when it is necessary to obtain the most even surface without any grooves and humps.

Preparation of tools and materials for work

DIY plow design requires a clear plan of action and the selection of the right tools and materials. It is advisable to familiarize yourself with the finished product drawings in advance. In addition, a home-made product for cultivating the land should be distinguished by its simplicity of design and efficiency of use. To make a standard version of a hand-made plow, you will need the following:

- ploughshare or steel billet;

- puncher;

- steel material for the manufacture of blade and field board;

- welding inverter;

- angle grinder;

- fasteners, in the form of a set of bolts and nuts;

- metal rack for the manufacture of the plow base.

When grasping a layer of soil over 25 cm, the surface and material of the plow are exposed to strong loads, the consequence of which can be a quick wear of the product. It is best to choose 9XC carbon steel or hardened 45 steel with a thickness of 4-5 mm as a workpiece material.

Next, we begin the manufacture of the working part of the plow body, which is responsible for lifting the soil and turning it into the furrow. There are several ways to make a moldboard. The contact surface of the moldboard side is in the shape of a cylinder. Using bending equipment, it will not be difficult to produce such a blank.

Another option implies the presence of a finished pipe with a diameter of 0.55-0.6 m and a wall thickness of 3-5 mm. A template is made from ordinary cardboard, covering the required area of the pipe, along the contour of which the desired shape is cut with the help of electric gas welding equipment.

Use a file hammer and file to eliminate bumps and burrs. The most difficult method of making a plow is considered to be the manufacture of a workpiece in a metallurgical furnace, followed by straightening with a ready-made matrix (sometimes a tractor plow blade is used).

After installation, do not immediately start plowing. It needs to be configured. This is necessary so that the tool can fully cope with its tasks. You need to check the serviceability of each element, lubricate with oil, tighten the screws.

- if you work on heavy soils, then the plow must be weighted with a special metal disc that is mounted on the frame;

- blades can be sharpened with a sharpening stone;

- during operation, dirt and plant roots can adhere to the blades. They need to be cleaned, as resistance increases and it will be extremely difficult for the tool to work;

- if you need to carry out any work with the raised plow, some kind of support must be placed under it. If the plow is lowered on a person, it can be dangerous to health and life;

- bearings are lubricated every day;

- after finishing all work with the plow and mini tractor, it must be thoroughly cleaned, washed from dirt, dried and lubricated with oil, thereby protecting it from corrosion and dull blades.

Many owners do not know how to set up the plow before work. It's easy enough to do, but the whole process plays an important role in the productivity of further work. So, the adjustment of the plow to the mini tractor is carried out in several stages:

- Depth adjustment. You can find the wheel adjustment bolt on the outside of the square tube. If you scroll it, you can control the plowing depth. So, clockwise - the depth increases, counterclockwise - decreases;

- Setting the width of the plowed area. The width can be increased by stretching the length of the transverse shaft control rod;

- Adjusting the level of the side of the frame. To align one side or the other, you need the appropriate barbell;

- Adjustment of the front and rear frame levels. To do this, you need to either stretch or tighten the front bar of the body.

Rotary equipment

A rotary or rotary harrow is usually used to cultivate the land after harvesting grain crops. Also, this type of equipment for a walk-behind tractor levels the ground surface well and removes weeds. The rotary harrow consists of six working edges, discs and a hub. The equipment has undergone changes and it has been revealed that for greater efficiency, the working blades must be set at an angle, which makes it easy to cut and level the soil during processing. A self-made harrowing device is installed on the unit instead of wheels or lugs. The video shows a homemade rotary harrow for a walk-behind tractor in operation on a site.

Looking at the presented photo, it may seem that making such a harrow with your own hands is not difficult, however, in order for it to work normally, it is necessary to correctly calculate the entire structure, namely the angle at which the working edges are installed.

The video shows the whole process of making a rotary harrow and working with it.

Dimensions (edit)

The dimensions of different types of plows may vary. You can consider the parameters of the parts using the example of a rotary instance. It is taken into account that the rotary view of such a device is assembled from the following bases:

- side vertical part of the runner;

- horizontal plane at the bottom of the runner;

- front moldboard part.

The most productive plow is considered to be the one in which the cutting edge at the bottom of the fixed share is 20 mm below the bottom of the horizontal runner. Another well-aligned part of the plow is the alignment of the cutting edge on the side of the fixed share with the cutting edge on the side of the plow. The share and the blade must not protrude more than 10 mm beyond the boundaries of the vertical plane on the side of the runner.

There is one more important nuance - fastening the frontal plane of the blade share without visible gaps and gaps, and in the same plane. If we consider these details in more detail, then they should be well polished and, like a mirror, reflect any surfaces. There should be no protruding fasteners under any circumstances.

As soon as the plow returns from excavation work, it is advisable to clean it from settled soil and foreign particles. Polished elements must be poured with oil or greased with grease. Next, the mechanisms need to be rubbed with a rag. Thus, it will be possible to protect the structure from aggressive external influences that can lead to the formation of corrosion on the plow surface.