Common types of equipment - we study the characteristics and design

Before choosing a plow for a walk-behind tractor, you will need to study the types and characteristics of equipment

As a rule, the buyer has to pay attention to the equipment of three main types:

- Single-hull;

- Reversible;

- Rotary aggregates.

Before deciding which is the best of the proposed options, you need to familiarize yourself with the characteristics of various types.

Single-hull inventory

Single-body equipment is equipped with one share, which is why it is considered the simplest.

If you want to make a plow for a walk-behind tractor with your own hands, you should choose this particular prototype. For this, there are many schemes that differ in hinges and other details, so everyone can choose the most suitable drawing for themselves.

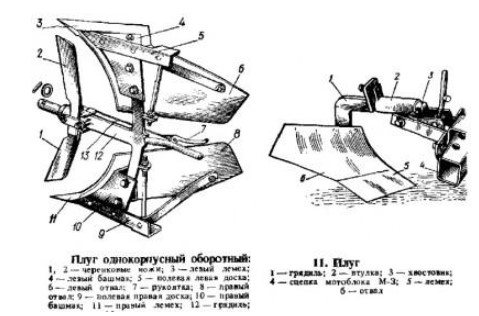

Reversible plow working principle

Reversible, or reversible plow, refers to more complex two-body equipment.

It is equipped with a curved nib at the top of the body. Due to this, during processing, the soil layer is turned over, which makes it possible to use it in areas with solid ground. Such a plow lends itself to disassembly for the purpose of sharpening a knife or upgrading.

This kind of universal plow for a walk-behind tractor differs from conventional units in that it is supplied with a ploughshare that turns over in the ground in one direction. Thanks to this, he processes the area several times faster. The plow hitch is standard, which makes the soil much more efficient.

The plow has 3 planes: a horizontal bottom rail, a vertical side rail and a front dumping mechanism. To purchase a quality plow of this type, be sure to study the advice of experts:

The lower horizontal runner of the unit with the dismantled blade and the share, placed on the table, must coincide with the table surface;

The lower edge of the share, intended for cutting, can be set 2 cm below the horizontal slide;

The position of the side edge of the blade and the side edge of the share should be in a straight line. In this case, the elements themselves should be 1 cm outside the side vertical runner:

- The surfaces of the fixed share and plow are at an angle of 15–20 °;

- The working part of the ploughshare with its front part adjoins the blade body without visible gaps;

- There must be no fasteners and the surface of the elements must be polished.

Having carefully studied the description of all types of plows, it will be much easier for a beginner to decide on the most suitable option for him. Next, let's look at how to make a homemade plow for a walk-behind tractor.

Do-it-yourself plow to a walk-behind tractor from an equestrian cultivator

An equally viable idea is to recycle an old horse plow into a walk-behind tractor. A full description of the process is given in the video.

An equally viable idea is to recycle an old horse plow into a walk-behind tractor. A full description of the process is given in the video.

A feature of all horse plows, without exception, is considered to be their heaviness, created by a bulky blade. If such a plow is installed on a walk-behind tractor without alteration, the earth will not tilt.

This is a big plus, since the plow share of the horse plow will not undergo any changes.

To make a plow from a horse for a walk-behind tractor you will need:

- independently make a blade, which is cut out according to a pre-drawn drawing from a steel billet (3 cm thick). For accuracy, it is advisable to make a cardboard template;

- after cutting, a special shape is given to a stainless dump;

- remove the horse blade and install a homemade one instead;

- remove the handles that were on the vertical axis;

- instead of them, weld metal fasteners through which the plow will be hung to the walk-behind tractor.

- If, during field trials, it turns out that the converted horse plow does not throw well, you should bend the share slightly so that it can cut more into the soil.

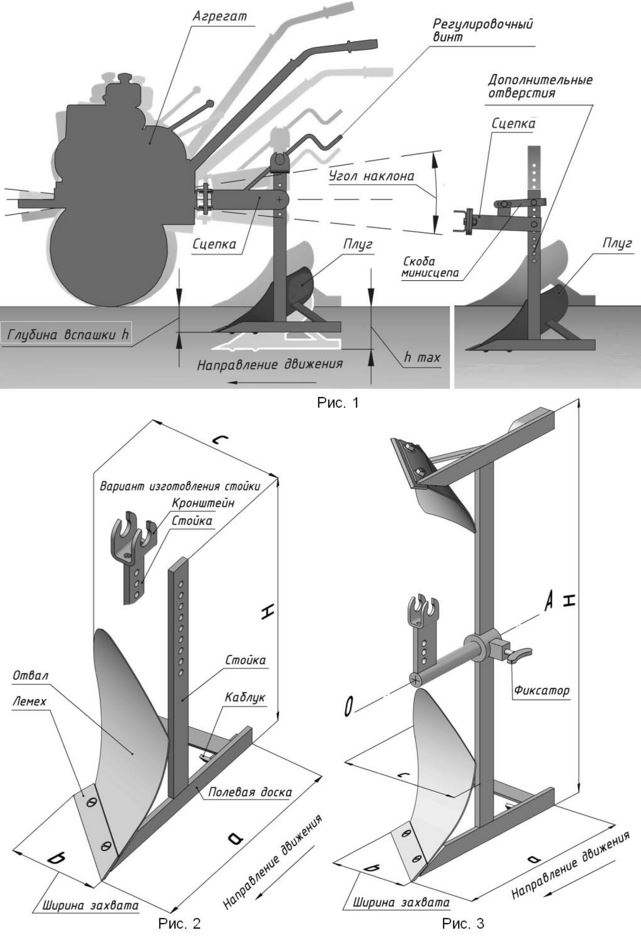

Installing a plow on a walk-behind tractor

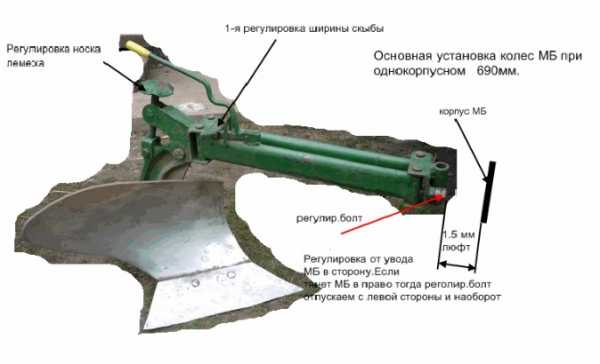

Regardless of the design features of the plow, its size and shape, it is attached to the walk-behind tractor with a special hitch. It can be of a universal or stationary type. The first option is optimal because of the great possibilities for configuring the device.

The type of hitch does not affect the features of mounting the structure on motor vehicles.

You can hook the plow to the walk-behind tractor following a simple scheme:

- The unit is installed on a raised platform. You can use bricks or logs;

- The plow hitch is attached to the hitch. Both holes on the devices must match exactly;

- The clutch on the towbar must be secured with a bolt.

Do not tighten the bolt forcibly when attaching the attachment. A too rigid connection will negatively affect the quality of plowing the soil. When creating resistance during the operation of the plow, it will be thrown a little to the sides. To avoid this, it is necessary to leave a horizontal gap of approximately 50.

Types and their design features

When making a plow, they take a special metal that is able to withstand the load during operation.

Single and double hull

Single-furrow plowshares are ideal only for soft ground, their design does not include more than one share. The advantage of such equipment is that it is easy to assemble and has a low weight.

The double-furrow plow is suitable for working on any soil, as long as there are no stones. With the help of such attachments, you can create furrows, huddle plants, and clean the area from weeds.

The width of capture can be adjustable or fixed on such equipment.

Dump and dump

Among the varieties of plows there are non-moldboard and moldboard plows. The latter are more popular as a means of cultivating a small plot of land.

They have their own classification:

- furrowed;

- without furrows;

- plowing smoothly.

On the dump structure, the share is at a special angle of inclination, so the earth layer does not just turn over - the earth becomes loose.

Reversible

Reversible plows are used on soil that is difficult to cultivate.

The required power of the walk-behind tractor is taken into account when choosing a share of greater or lesser weight. It is rather difficult to make such equipment on your own, since the pen is bent at an exact angle.

This design helps to turn the soil as soon as the plow lifts it.

Rotary

The blades are installed on a rotary or rotary plow, and if you compare such a unit with the others, then, from a constructive point of view, it is very different. It is sometimes compared to cultivators.

There are several plowshares in the design, which are specially given a curved shape. They are mounted on a common axis, it is set in motion when the equipment is turned on, then it turns the ground over. It is this feature that distinguishes the rotary plow from the cultivator.

Even a novice operator can easily work with such attachments. The walk-behind tractor easily moves along a given trajectory, it may not necessarily be straight, as in other cases. Summer residents most often use the rotary view when processing the garden and the area from the grass.

Disk

A disc-type plow is used for hilling, processing of wet soil. It differs in a small depth of processing.

Choice

Choosing the right plow is essential for this type of work. This tool can be of several types: The single-body plow has the simplest design, clear fasteners and small dimensions.

It is great for standard excavation work

The single-body plow has the simplest design, clear fasteners and small dimensions. It is excellent for standard excavation work.

The reversing tool features a curl at the top of the feather that helps to flip over seams of earth. This design is intended for processing heavy types of soil.

The rotary plow has the most complex structure. It has several plowshares, and depending on this, it can be two- or three-body. Its distinguishing feature is its low operating speed (compared to milling cutters) and shallow working depth. Such a tool is well suited for loosening already developed land.

The disc plow is used for wet or very wet soil. But its processing depth is the smallest of all types.

After choosing the type of plow you need, you need to pay attention to a few more details. First of all, this is the type of fastening

It must be suitable for the cultivator. Further, it is worth checking with the seller whether the existing machine has enough power to work with this type of attachment. If the power of the unit is low, then there is a risk for a short period of operation to significantly wear out or completely overheat the cultivator engine.

About, how to plow properly with a mounted plow, see below.

How to make a hitch for a walk-behind tractor yourself

During operation, the device will be subjected to a heavy load, therefore, the recommended dimensional and strength characteristics of all assembly elements should be adhered to. In this case, the following coupling qualities will be guaranteed:

- Ensuring reliable fixation with the walk-behind tractor.

- Attachment to attachments.

- Ensuring the declared operational qualities of equipment.

- Affordable price.

- Reliability, long service life.

When choosing a model, you should check the dimensions that the hitch of the walk-behind tractor and attachments (plow, trailer, harrow, etc.) have. The task of the wizard is to ensure complete compatibility of elements, ease of use and the ability to easily configure equipment for a specific task. The main part of the hitch is a U-shaped bracket. Through the holes on one side, it is attached to the walk-behind tractor with pins, on the other side, the rack of the necessary attachments is fixed to the body of the device.

Required tools and materials

A person engaged in economic activities on the land usually has a sufficient set of equipment for the manufacture of a coupler. To work, you need the following tools:

- Bulgarian.

- Drill, drilling machine.

- Measuring tool: ruler, tape measure, square.

- Welding machine.

- A set of keys.

It is important to choose the right drill for the diameter of the studs and bolts. The absence of backlash will extend the life of the attachment

The body can be cut from sheet metal or a suitable channel can be used.

Preference should be given to a hitch with an adjustment mechanism. In this case, you can use attachments of different classes, from different manufacturers, achieving maximum efficiency in work.

The photo below shows a universal hitch with a threaded adjustment mechanism. A simple but effective device that is not difficult to make with your own hands:

Working with a drill for metal will be easier and more productive if you make a preliminary hole with a smaller diameter when drilling. For example, a 5 mm drill is used first, and then a 12-16 mm drill for the size of the bolt.

Making a universal connection

You need to do the work on a flat surface. A table of the right size or workbench will do. The order of work is as follows:

- Markup. According to the drawing, the contours and dimensions of the elements are indicated.

- Drilling. The operation is performed with a drill or on a machine.The accuracy of the holes is checked with a vernier caliper, as well as a pin or bolt, inserting them into the seat. Both backlash and jamming of parts are excluded. To facilitate work and to avoid injury, the holes are machined with a countersink.

- Welding. It is preferable to use electric welding. The metal heats up only at the junction and does not critically lose its properties. If a suitable channel is not found, then a structure is made of sheet steel of the required quality.

- Assembly. The bracket is bolted to the channel. If an adjusting mechanism is provided, then it is also fixed to the structure.

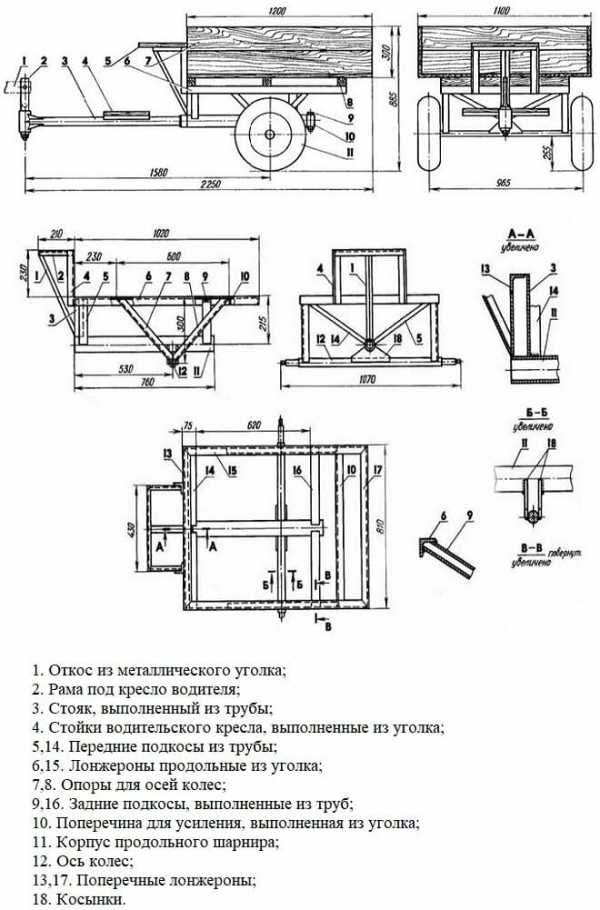

Improvement of the undercarriage

The first thing that users of a walk-behind tractor think about is how to make a cart with a seat for it. The use of equipment in a normal mode with the use of levers involves the application of great physical effort. However, the use of a trailer reduces the stability of the vehicle. This problem can be eliminated by expanding the wheelbase. This is done using extension cords that are attached to the axle shaft with pins or bolts. Having solved the problem with stability, the operator is faced with another question: the unit is poorly controlled. helps to give him good maneuverability. This device is made by analogy with the nodes of cars. Homemade unblockers for a walk-behind tractor are made using ordinary household tools - a grinder, welding and a grinding machine.

The light weight of the walk-behind tractor is the reason for poor adhesion of the wheels to the ground. Slipping is common when picking up virgin soil, working on wet ground, or driving on snow. To avoid slippage, weights are attached to the walk-behind tractors.

These devices are categorized as follows:

- Wheeled. They are discs that are mounted on wheels or hubs. Discs are made monolithic from metal, concrete or hollow filled with sand. The weight of the wheel weights can be 30-70 kg.

- External. They are made of any heavy material (steel, lead, concrete). Attached to the body with hooks or bolts. Some craftsmen weld a frame from a corner to the body. Sandbags, bricks, scrap metal and other heavy objects are placed in it.

You can improve the passability of the walk-behind tractor by installing lugs. The easiest way to make lugs is to make a rim from a strip of metal and weld the blades onto it. The rim diameter should be larger than the rims and smaller than the tires. Fitting the rim is carried out with the tires flat. After the lug is installed, the wheel is inflated.

You can improve the transmission by installing a homemade variator on the engine. The system of belts and disks will allow you to smoothly change the speed of the unit, without jerking and vibration.

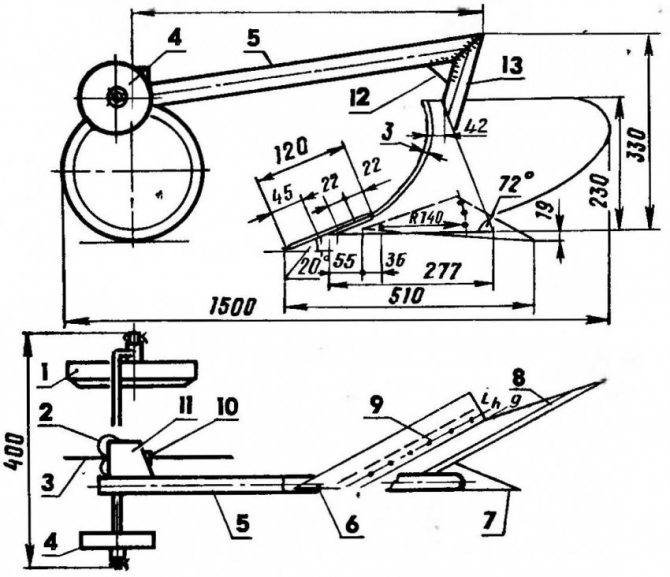

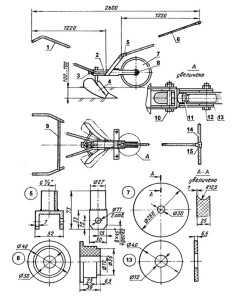

Structural elements of the plow

Making a hand plow yourself is not a problem today. Moreover, there are many drawings of various designs on the Web.

So, to make a tool for plowing the land, you will need the following:

- pipe handle - 2 pcs;

- fixing the rack with an M 10 screw;

- frame;

- fastening fork of the hinge to the frame;

- plow;

- wheel;

- drawbar;

- nylon bushing for bearing;

- hinge axle made of M 10 bolt;

- jumper between the handles;

- axis;

- lock-nut;

- distance washer;

- tee;

- drawbar handle.

The main thing that you need to be guided by in the manufacture of a plow is strict adherence to the instructions and adherence to the parameters of the selected drawing. Even a seemingly insignificant detail can greatly affect the performance of the tool or negatively affect its performance later on.

Assembly

The first is the frame, which can be made of a metal pipe with a cross section of 40 × 52 mm and a wall thickness of about 7 mm.To form the fork, the wide sides of the frame are cut, which are located opposite each other. Then the middle is marked on the frame, where the transverse traverse will be installed and the lugs are welded to which the drawbar is attached. At the beginning of the fork (at the front of the frame) there is a hole that is welded tight to prevent dirt from entering.

Mount the stand

To secure the plow stand in the wide part of the pipe used to create the frame, 16 × 31 mm holes are drilled or cut on both sides. Through holes Ø10.2 mm are also made in the narrow walls of the frame for attaching the handle using M 10 bolts. The handles are made separately from a tube with a diameter of approximately half an inch. You can use an old water pipe for this purpose, which is flattened on both sides with a sledgehammer. In the resulting planes, holes Ø10.2 mm are drilled and bolted to the frame. For greater rigidity, a cross member is welded between the handles.

Plow coupling

The hitch is an important element that ensures a secure attachment of the mounted plow to the Neva. The most popular is the U-shaped mount from the channel, which is installed under the steering wheel of the walk-behind tractor. When the hitch is created, holes are drilled to secure the mounting pin and bracket. The mounting bracket is located at the top or bottom, so as not to interfere with hanging.

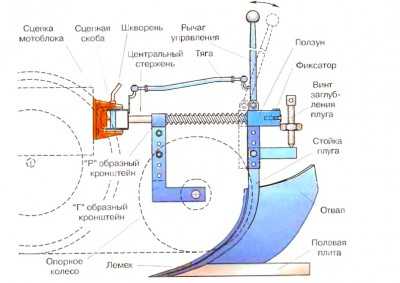

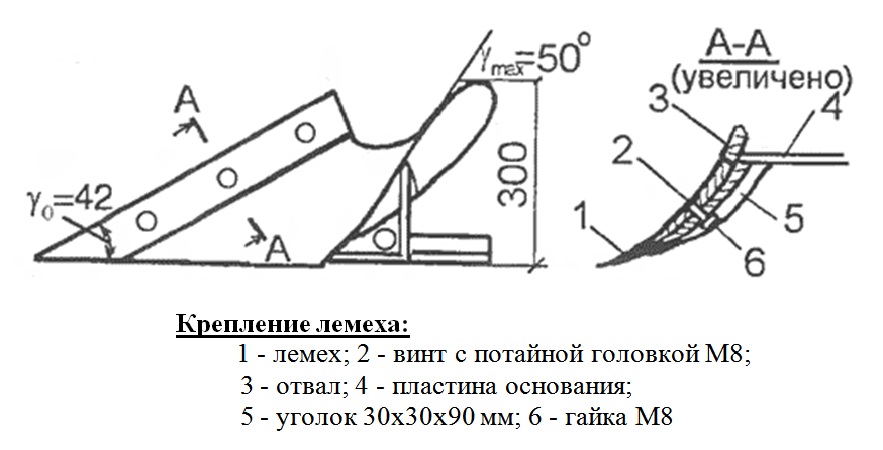

Manufacturing and fastening of working elements

The main elements of the single-body design are the share and the blade. For their manufacture, durable sheet steel with a thickness of 3-5 mm is needed. The share is made first, for which an old circular saw blade made of high-strength steel is used. To sharpen the cutting edge of the ploughshare, it is beaten off on an anvil. Next, a dump is made from a metal pipe Ø50-60 cm and a wall thickness of about 5 mm. A template is made of cardboard or thick paper, which is applied to the metal and outlined with chalk along the contour. On the lines obtained, a workpiece is cut out by gas welding, which is brought to the required size with a "grinder" or with a hammer and emery.

The final stage

After creating all the metal parts of the plow, the final assembly requires a 50 × 50 cm metal sheet, as well as an electric welding machine. To the sheet, with strict observance of the angles, the elements of the future plow are lightly tacked by welding: the side shield and the share, to which the blade is tried on. If there are discrepancies, the blade is brought to the required condition with a hammer and welded to the rear of the share.

If no flaws are noticed during inspection, you can proceed to capital welding. The metal sheet on which the assembly was carried out is detached from the structure with a "grinder" or with a hammer and chisel. Next, the welded seams are thoroughly cleaned, the share and blade are sanded with sandpaper. When the structure is assembled and almost ready to use, it is painted, especially the places of welded joints. This will add aesthetics and protect the metal from corrosion, which means that it will significantly extend the service life of the product.

Since it is not very easy to make a plow for a walk-behind tractor with your own hands, at least minimal experience with locksmith tools is required. It is imperative to adhere to the working drawing and all required instructions during manufacture. We add that making the plow on your own will save you money, because most of the materials can be found on the farm.

Care

When using a plow, regardless of its type, it is imperative to monitor the cutting elements. After each operation, the metal is cleaned of adhering dirt and washed. Over time, the sharpness of the knives is lost and it is required to sharpen them. It takes experience to do this right. You can use a grinder or sharpen by hand.

But this is not the only care the attachment needs, polishing is just as important.It can be sanded with sandpaper or polished using specialized equipment. The main thing is that the surface is shiny, even and smooth.

Recommendations for use

As practice shows, "Niva" goes for sale already assembled, but after purchase, before installing attachments, it is required to perform the correct adjustment of the main units. Competent preparation of equipment allows you to perform full-fledged work with the maximum use of characteristics.

For the full operation of the engine, the valve system must be adjusted. For this purpose, the carburetor is disassembled, as well as all screw connections on the upper and lower housing are unscrewed, followed by cleaning the elements. The next step is to adjust the valves using the adjusting screws.

In order for the equipment to serve as long as possible and maintain its performance, the following operating recommendations should be adhered to:

in the process of installing cultivation sheds, it is necessary to control the direction of the knives in the direction of the movement of the equipment; if in the process of agricultural work the wheels slip, then it is recommended to install additional weights; it is very important to control the quality and purity of the fuel used in the walk-behind tractor; when starting up a cold device, it is necessary to close the air supply by means of a special valve; after starting the throttle is set to position XX, and the engine warms up for about three minutes; it is strictly forbidden to set the speed to maximum values at the stage of engine warm-up; It is especially important to prevent oil from entering the surface of the air filter element during operation. Before starting to work with adapters and walk-behind tractors, it is very important to familiarize yourself with the instructions supplied by the manufacturer.

Before starting to work with adapters and walk-behind tractors, it is very important to familiarize yourself with the instructions supplied by the manufacturer.

How to make a plow for a walk-behind tractor with your own hands from an equestrian one?

The horse plow, in comparison with other types of attachments, can be completely wooden. The only metal element can be a ploughshare.

Step-by-step instructions for making a horse plow for plowing the land yourself is given below:

- The handles are made of two wooden beams, the thickness of which is about 10 centimeters. The upper part of the handles is supplemented with rubberized pads;

- The handles are connected at right angles, so it will be more convenient to hold on to them with both hands;

- The lower parts of the elements are connected with self-tapping screws;

- A 20 cm thick beam must be bent so that its ends are parallel;

- The lower end of the bar is attached to the share;

- At the upper end, the plow is attached to the walk-behind tractor. For manufacturing, you can use small wooden blocks;

- A double handle is installed in the middle of the mount.

The structure of the horse plow is very simple, but it is highly efficient. It cannot be used when processing wet soil, so as not to break the wooden parts.

The method of making a plow for a walk-behind tractor can be selected for yourself. Each self-made canopy can be used with units of popular brands Neva, MB-1 and MB-2, MTZ, Krot, Salute.

Plow dimensions

The swivel-type plow consists of three main planes:

- Side vertical plane of the runner.

- The lower horizontal plane of the runner.

- Front moldboard plane.

If, after dismantling the blade and the share, the plow is placed on top of the table, close at the same time pressed against the wall, and its side plane is moved to the vertical wall, then the table cover will coincide with the horizontal lower plane of the runner, and the vertical wall with the vertical side plane of the runner.

A plow is considered good if the lower cutting edge of the installed share is 20 millimeters below the horizontal lower plane of the runner.

The second correct plow design is to align the side cutting edge of the installed share in a straight line with the cutting side edge of your plow. Also, the blade and the share do not protrude more than 10 millimeters beyond the vertical side plane of the runner.

The third correct condition is the connection of the working front plane of the share to the blade without a gap and in the same plane. Ideally, they should shine like a mirror, respectively, be well polished and protruding fasteners should not stick out.

After the plow has returned from work on the site, it is recommended to clean it of soil and foreign objects, pour oil on the polished parts or grease it with grease, then rub it with a rag. This will protect the surface from environmental influences and corrosion.

The fourth correct design is the rear level surface of the share, which makes an angle of 20 degrees with the flat side of your plow, which is equal to the rear angle of the mounted share.

The mouldboard and share cutting edges also have 20-degree clearance angles to the side of the furrow, but your mouldboard cutting edge may be rounded.