1 Types of inventory

A fan rake works well on uneven and overgrown surfaces, straight rakes on difficult and heavy ground. And they owe their names to the shape, which is very reminiscent of a broom with the working bodies of the teeth, located in the form of a spread out fan.

Fan rakes are:

- metal;

- plastic.

Conventional fan rake

By the type and material of the teeth, they are made on:

- lamellar;

- wire.

A serrated rake is a tool with a series of narrow curved blades that are very helpful on uneven surfaces. The plates are springy without getting stuck in the bumps and pits. They are convenient for raking leaves from under bushes and trees. And tools made in the shape of a triangle are effective along fences and in hard-to-reach corners.

Fan rakes, metal and wire, are made, as a rule, of large wire, with teeth bending at an angle of 90 degrees. This arrangement of working elements does not damage the plants, and effectively copes with aeration of the soil and removal of debris from the beds.

They are convenient for thinning the lawn, combing before mowing or mowing. The blade of a metal instrument in this case is softer than the wire base and can sometimes break or bend. To prevent this trouble, expansion joints were invented. But more about them below.

Plastic rakes are less durable and functional, but they are lightweight. They are very convenient to use when cleaning small garden debris, even on uneven surfaces. The teeth are quite flexible and springy. The plastic tool damages the plants.

Plastic fan rake

It is very convenient if the rake is not just a fan, but also adjustable in the width of the working surface. For example, a tool with a handle up to 180 cm can taper to 30 cm. In general, the standard sizes of garden tools with a handle and a broom are:

- 130 cm;

- 150 cm4

- 50 cm panicle width.

1.1 Fan rake with compensator

This equipment is designed in such a way that, by installing a compensator plate, to prevent breaking of the working parts. Reinforced work surface plates will last longer than non-reinforced work surface plates.

Usually such a mechanism is placed on metal flat teeth. But, this model is not intended for adjustment. Installation of a regulating mechanism together with a compensating mechanism is technically (logically) impossible. Although, if someone succeeded - share your impressions and photos.

1.2 Fan blade rake 22 teeth

This is a fairly popular type of garden tool with 22 flat metal teeth, and usually a wooden handle. The reinforcing moment is made by a sector frame plate. The teeth are usually painted or treated with an anti-corrosion compound. This tool is convenient to collect not only fallen leaves or debris, but also small branches cut from trees.

1.3 Transformers

It is a multifunctional garden tool for a variety of purposes. The set, which consists of an aluminum telescopic handle and various attachments for it on the mechanism with a quick clamp, allows you to use it for any desired purpose.

Rake fan transformers

The plastic of the working area is not susceptible to corrosion, the set is convenient for transportation, and the adjustable handle length allows even very tall people to work comfortably with the tool. And the universal combined kits may include additional loosening attachments, and even a shovel or a hoe.

On the one hand - longer, rounded and sparse - for removing moss and leaves, shallow aeration. On the other hand, there are sharp and dense rows - for collecting small stones and loosening lumps of soil.

Views

Unlike tools with a metal working part, which are divided into plate and wire, the plastic version is available only with a plate working part.

At the same time, on sale there are both options with conventional plates, intended exclusively for cleaning, and reinforced models, which, due to the presence of a reinforcing compensator, can also be used for operations for the care of soft soil (for example, surface loosening).

Classic models with a metal working part are always designed for the use of a standard wooden handle with a diameter of 24 mm.

Plastic models can be equipped with a wooden or plastic handle, as well as supplied without a handle. The standard length of the handle for such equipment is 1.3 m.Options with a shortened handle of 1.2 m, as well as extended ones up to 1.5 and 1.8 m, are also available for sale.Some models are equipped with a telescopic handle, which allows you to adjust the length of the handle for the growth of the user.

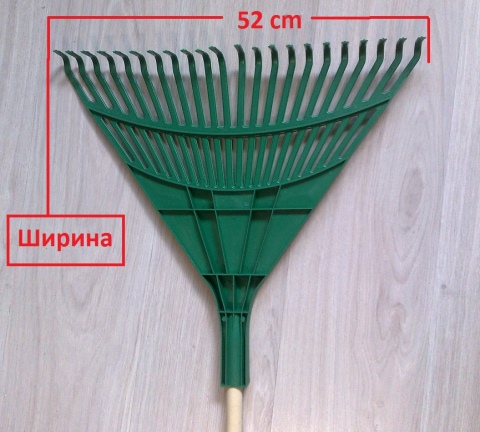

The standard span of the working part is 500 mm, and the number of teeth is from 20 to 25.

Other common formats:

- 200 mm, the number of teeth in such a rake is usually 15;

- 520 mm with 25 teeth;

- 560 mm with 22 teeth;

- 580x340 mm, usually products larger than this format have 26 teeth;

- 610 mm, available in both 26 and 30 teeth;

- 660 mm;

- 820 mm.

Unfortunately, unlike metal versions, plastic models with an adjustable width of the working part have not yet become widespread.

Which fan to choose - considering rake teeth

So, we know on what grounds models of fan nozzles for garden rakes are distinguished. Now it remains to figure out which option is preferable, and in what cases. The difference between the above two construction types is the degree of elasticity. Wire elements are made from wire, which is often coated with a polymer layer to increase tool life. Because of this, they are made as rigid as possible and are very convenient for working with flat surfaces and low, not too thick grass.

Fan nozzles for garden rakes

A completely different thing is the rake plate fans. They are made of very elastic thin plates that bend on any surface relief, repeating it with precision. As a result, it is convenient to work with such a rake on uneven terrain. However, it should be remembered that with high flexibility, such plates are quite vulnerable to excessive pressure, therefore, scraping along the ground with a tool of this type is not recommended, it can only be carried out in the thick of vegetation, sweeping away the leaves. However, the wire version has the same drawback, and if the elastic plates, bending, then take their previous form, then the wire is deformed irreversibly.

Plate fan rake

As for convenience, it all depends on what kind of debris you want to remove from the lawn, and what is the density of vegetation on the site. The fact is that wire garden models most often have a 90-degree fold at the ends of the raking elements, which provides excellent traction of debris and fallen leaves. Lamellar nozzles in dense elastic vegetation begin to bend upward, unable to penetrate between the stems, which is why most of the small twigs or the same fruit padanses can remain in the grass. When caring for a mowed lawn, the opposite is true - the hard wire nozzles begin to scratch the ground, and the plates do an excellent job.

Peculiarities

Traditionally, the rake is used for a wide range of daily tasks of the gardener, namely:

- cleaning garbage from the site;

- collecting fallen leaves;

- weeding;

- loosening the topsoil;

- aerating and leveling the soil;

- collection of cut grass.

Soviet summer residents mostly had access to metal models of this instrument in a standard comb form factor, while plastic products were found for a long time only in sets of children's toys. It was only in the early nineties that the first models of this product began to appear with teeth made of various plastics.

The fan-shaped shape of the working part allows the tool to capture a wider area, therefore, with such a rake it is more convenient to remove relatively light debris evenly distributed over the surface from the site, for example, dry leaves or freshly cut grass. At the same time, the accuracy and developed force of tools with a fan-shaped nozzle is lower than that of more familiar combs.

Outwardly, such a rake looks like a wide panicle, in which the lower part is made of plastic. The tips of the tines are curved to allow traction of the debris being removed.

2 How to make a fan rake yourself

First you need to decide on the main questions:

- goals;

- the size and length of the handle;

- cutting material;

- width of capture of the working part;

- type, length and density of teeth.

Since you will most likely be making your tool from steel or iron rather than plastic, consider making a quick rake. We cut off a steel strip of the required length, round off the edges and the future base of the working body.

Then we apply the required markings and drill holes with a diameter of about 5-6 mm. Cut off 11-12 metal rods about 8-9 cm in length and sharpen them from one end. Heat the prepared plate with holes and hammer into the holes of the rods, which, after cooling completely, will need to be welded.

Homemade fan rake

We take a pipe with a diameter of about 3-4 cm, and cut off a piece of about 20 cm from it to make an attachment to the base. To do this, we make a saw cut in the form of a slingshot about 7-8 cm long. We heat the pipe on fire until it is completely red-hot, we spread the cut, and fasten it to the base. We drill a hole in the pipe for the prepared handle, weld the base to the holder and fix the handle.

It must be remembered that if the pipe that you decide to use is already with a seam, then you can saw through the slingshot of attachment to the base only along the seam. Otherwise, during operation, the metal will undergo deformation and the fastening may disperse. Well, in conclusion: no one canceled the protection of homemade tools from corrosion. Therefore, if you paint or process an additional finished tool, it will serve you much longer.

What models can be purchased for the garden?

Owners of a large area should pay attention to the reinforced fan nozzles for a rake produced today. If conventional options have rather short raking elements, both wire and plate, in order to exclude their too rapid deformation during operation, then reinforced ones can be quite long

This allows you to capture a much larger number of leaves, sweeping them away in whole bales.

What is the reinforcement of the nozzle? Approximately at a distance of one third of the length of the elements from the place of their connection, a crossbar is installed, rigidly connected to each rod or to each rake plate. As a result, deformation of each individual element is eliminated, which greatly increases the reliability of the entire structure. It is especially worth highlighting the fan rake, 22 teeth of which provide maximum coverage of the surface in front of the operator. They are always sold together with a plastic or aluminum handle, which, among other things, can be telescopic, that is, it can be easily adjusted to your height.

It should also be noted that other fan rakes are reinforced with an additional element in the form of a movable transverse bar through which the wire elements pass.This option allows, by pulling a special wire lever towards the handle, to move the raking wires to the required angle, changing the intervals between the teeth. In some models, the control unit for changing the angle is more accurate. The cross bar is tightened by rotating a wheel installed under the handle, on the nozzle sleeve, which is connected to a shaft that tightly adjoins the lever and moves it along the base of the rake.

Dignity

The main advantage of models with a plastic working part can be called their greater flexibility and lower hardness compared to metal products. This makes it possible to handle significantly more complex and difficult-to-reach surfaces, for example, to remove debris in areas with rugged terrain or sweep it out from under fences, which is difficult to accomplish with a more rigid tool.

In the case when a solid obstacle is encountered during operation, the plastic teeth bend, and then, due to their high elasticity, restore their original shape, while fan models with a metal wire in such cases require subsequent alignment.

Of course, a rake with plastic teeth is completely devoid of such a drawback, since it is absolutely resistant to corrosion.

Another important plus of plastic equipment is its noticeably lighter weight and better balancing, since the plastic attachment weighs no more than the handle. Due to this, such a tool is much easier to work with than a metal one, in which the working part has a large mass, noticeably shifting the overall center of gravity of the tool.

Finally, a tool with a plastic working part is often significantly cheaper than similar products with a steel or aluminum tip.