Varieties of files for the intended purpose

The word "jigsaw" still evokes associations with wood. And although modern jigsaws are used with might and main for sawing plastics and metals, the main material for work is still wood and plywood. You also have to think more often about which canvases to choose for a jigsaw for wood.

By wood

For ordinary work on wood and its derivatives (plywood, chipboard, MDF), choose standard saws with a gray shank for simple or hard rocks. The dimensions of the blade, the setting and the size of the teeth are selected individually. But sometimes it is necessary to perform work that differs from ordinary sawing.

If speed is important, even to the detriment of the quality of the cut, then you need to choose long saws with large teeth and a large pitch. A bigger divorce is also desirable.

If you need to get an even and smooth cut without chips, then they take canvases with a small divorce or without it at all. Teeth are medium to fine. Materials that have a finished side (laminate, chipboard) have to be cut upside down. If you want to see the cut from the front side, then the files must be selected with the opposite direction of the teeth (the last letter of the marking is R).

For an artistic cut, there should be a narrow blade no wider than 4 mm, small teeth and a short length. Compliance with these conditions will make it possible to carry out shaped cutting at small turning radii.

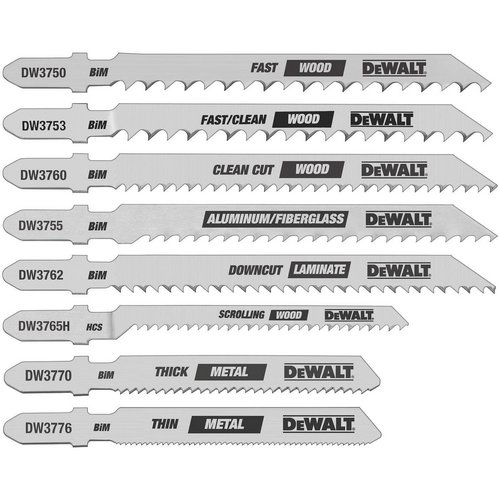

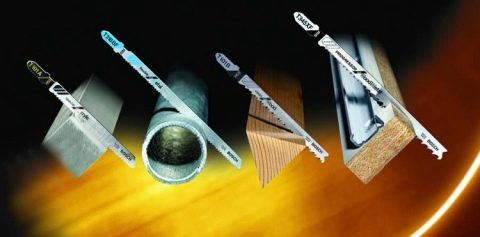

For metal

An electric jigsaw is still not the most suitable tool for cutting metal. But if necessary, he will cope if you choose the right file. The teeth of such files are very small and wave-shaped, the canvases are made of especially strong alloys, but they also quickly become dull. It is advisable to select files with markings exactly for the type of metal with which you have to work.

For polymeric materials

In the markings of the files there are designations just for working with such materials. Ordinary plastics and PVC products can also be sawn with saw blades on wood. In this case, the teeth should be chosen larger and with a large set. A fine tooth will not only cut but also melt the material. For plexiglass, it is better to choose a sheet for metal with a wavy pattern.

For special materials

For such options, their designation is provided. First of all, it is ceramics. Saws for it are made of special alloys, and the teeth are made with a special durable dusting.

Extra strong spray teeth are also required for cutting drywall.

But for soft materials, files are produced without teeth at all. Their cutting edge is a smooth blade, sharpened in a wave-like manner.

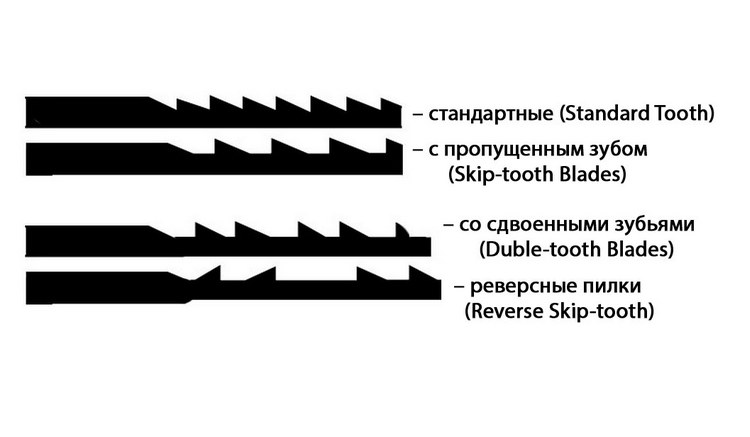

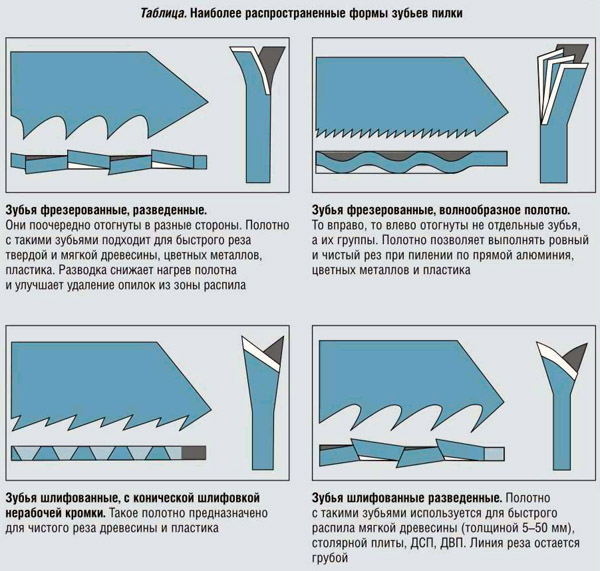

Varieties of files according to the geometry of the cutting edge

If you look closely at jigsaw blades, you will notice that they all differ in the amount of tooth setting and the geometry of the sawing edge. The more the teeth are set, the wider the cutting line will be, due to which the speed of work increases, however, at the cost of reducing the quality of the saw cut. Not only the cleanliness of the cut depends on the wiring method, but also what materials this equipment can be used for.

Milled with classic layout.

Peculiarities. Saws with a classic set, the teeth are alternately bent in different directions, like ordinary hand hacksaws. This setting helps to reduce the heating of the saw during operation, since the blade experiences almost no friction in a fairly wide kerf. It is almost impossible to get a neat cut with such a file, but the speed of work will be high.

Appointment. The purpose of saw blades with milled teeth and classic setting - fast cutting of hard and soft wood, as well as plastic and non-ferrous metals.

Milled with wavy routing.

Peculiarities. For rigs with such a setting, the teeth change direction not alternately, as in the previous case, but in groups of several pieces. At the same time, for each tooth, the deviation from the central axis is not the same as for its nearest neighbors - the working edge of the saw blade forms a wave.

Appointment. The purpose of the wavy cut files is a clean cut not only on wood, but also on chipboard or plywood, as well as working with non-ferrous metals and plastics.

Sanded with classic layout.

Peculiarities. The teeth of such blades are set apart and undergo a grinding process. The cutting line of such blades is wide enough.

Appointment. Saws with polished teeth, set in the classical way, are designed for quick but relatively clean cutting of wood and its derivatives - chipboard, fiberboard, etc.

Conical ground without set.

Peculiarities. The blades of such saws do not have a set of teeth, but their segments are polished, which provides a thin cutting line and an even cut.

Appointment. Allows for accurate cutting of wood, laminate, polymer materials.

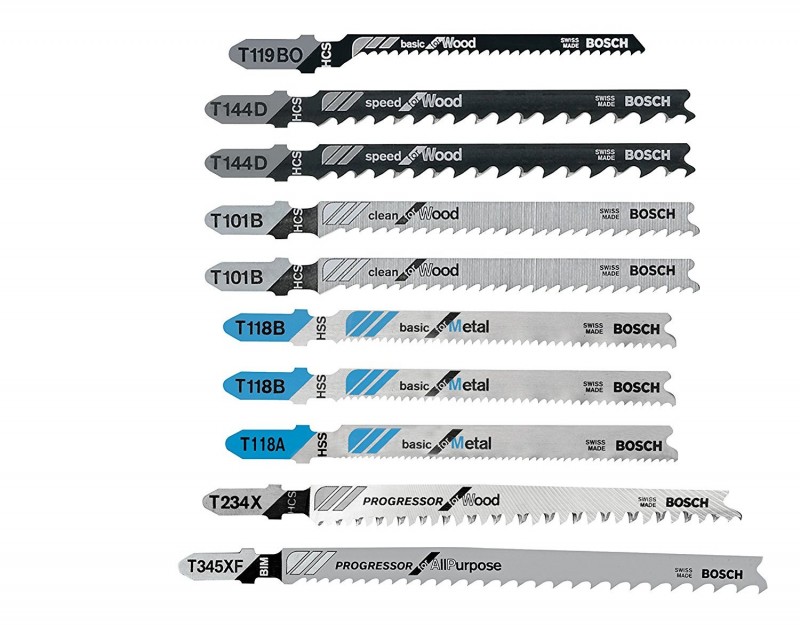

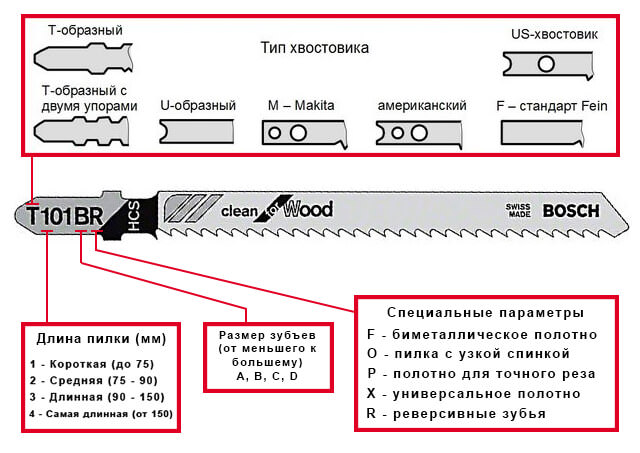

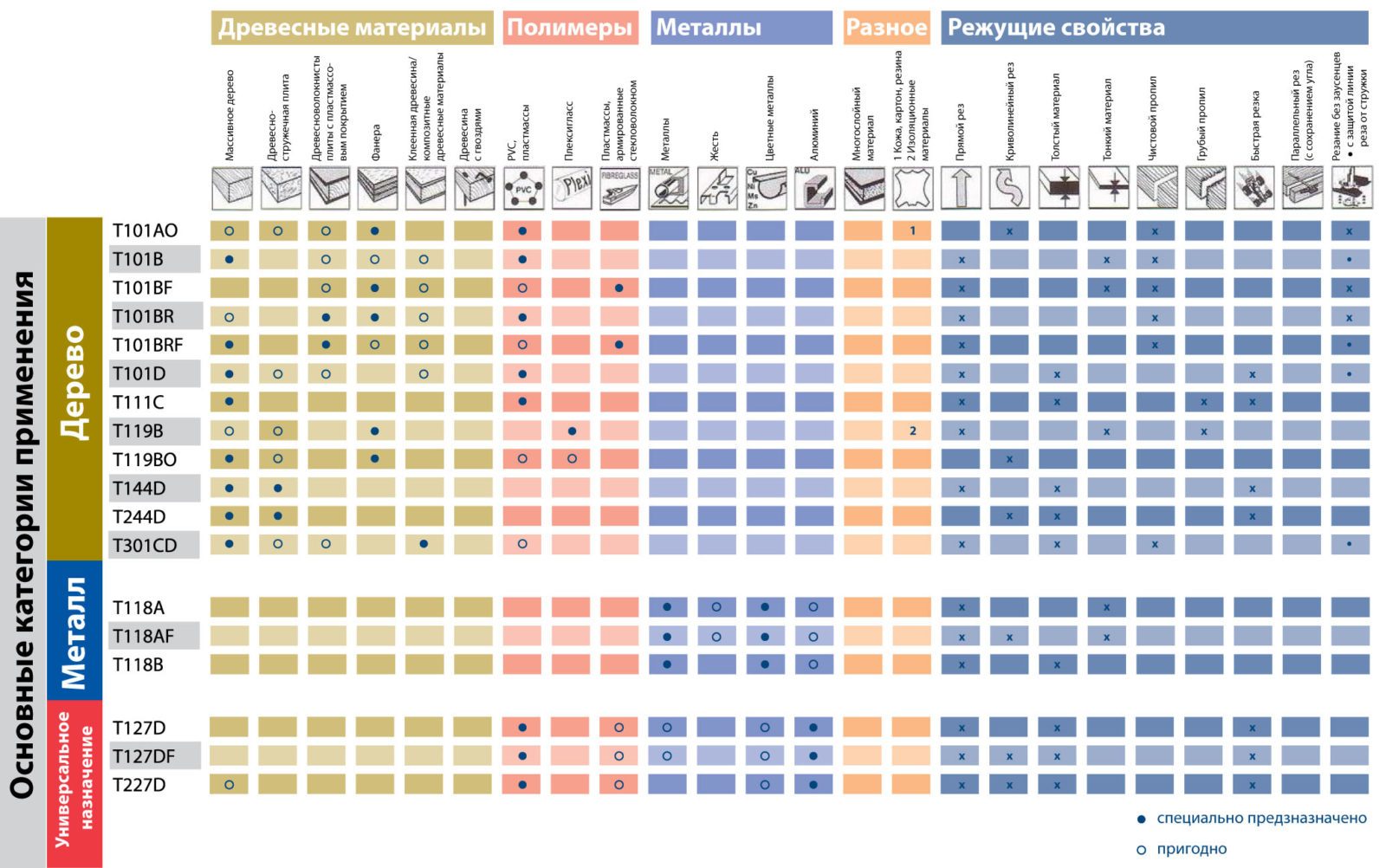

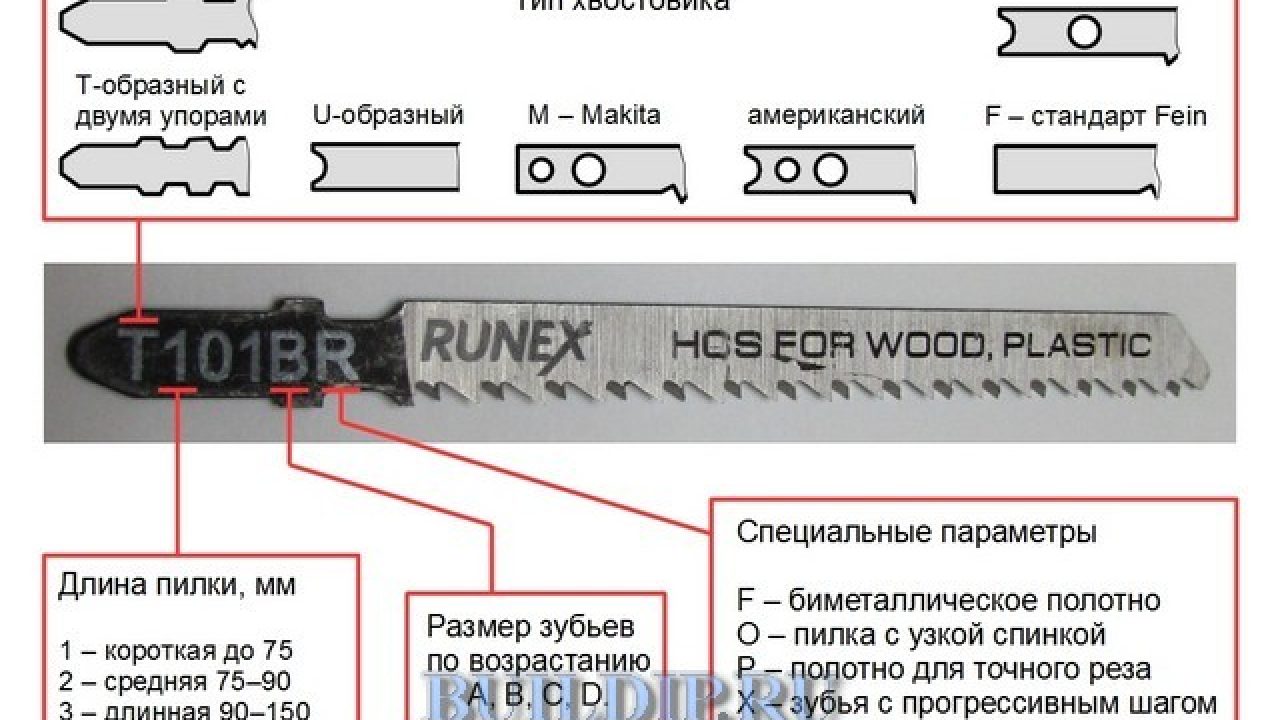

What does the marking on the files mean?

Even knowing all the intricacies of choosing a suitable jigsaw saw and having determined the necessary parameter values for yourself, you can get confused among the many products offered. Do not go to the store with a ruler and a caliper, measuring the dimensions of each blade and the pitch of the teeth!

On files from well-known manufacturers, various markings must be applied, giving approximate information about the parameters of this product. Of course, if you want to know the exact values, then you can measure it with a ruler. But it is better to do this not with every canvas, but with only one - pre-selected by marking.

There is no mandatory labeling standard. Most manufacturers of jigsaw saws adhere to the rules adopted by the BOSCH company. It is rare, but you can find markings that differ from these rules.

In accordance with BOSCH standards, alphanumeric markings are printed on the shank of the jigsaw blade. The first letter of the marking just denotes the type of shank: T-shaped or U-shaped.

The number following the letter refers to the length of the blade. But this is not the length itself, but the number of the corresponding length range.

1 - short files up to 75 mm long;

2 - average length: 75–90 mm;

3 - long: 90–150 mm;

4 - very long, more than 150 mm.

The next two numbers encrypt the purpose of the file (according to the manufacturers). This same information is usually found elsewhere on the saw blade in a more understandable way for the consumer.

The first letter following the numbers indicates the size of the teeth:

- A - small;

- B - medium;

- C and D are large.

The second letter (if any) gives additional information about files that are somehow different from the usual ones.

F - especially durable material of manufacture, bimetal.

О - small width, for curly cutting.

P - large thickness.

R - reverse direction of the teeth.

X - teeth of variable size.

Important information about the purpose is duplicated by marking twice: the color of the shank and the words on the blade itself.

For wood - gray; the words Wood (plain wood) and HardWood (solid wood and laminate).

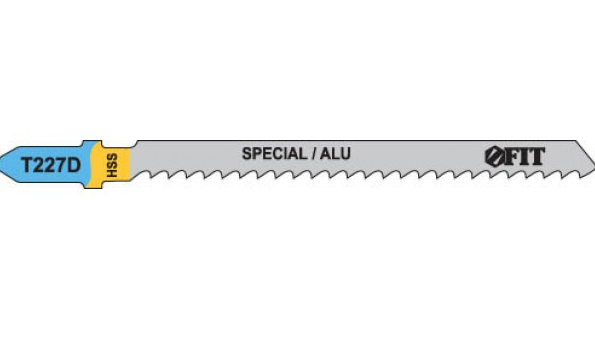

For metal - blue; the words Metal (metal), Alu (aluminum), Inox (stainless steel). Universal tool for wood and metal - white.

For polymeric materials - red; the words Acrylic and Fiber & Plaster (fiberglass).

For other materials - black; for example Soft-material (soft materials - rubber, foam).

For ceramics - Ceramics.

In another place of the canvas, verbal information about the method of application and special properties may be contained (usually in letters of a smaller size than about the material of application):

- basic - standard web type;

- speed - for fast cutting;

- flexible - with "wave" type divorce;

- clean - no divorce, clean cut;

- progressor - variable tooth size;

- special - highly specialized application (ceramics, durable plastic, etc.)

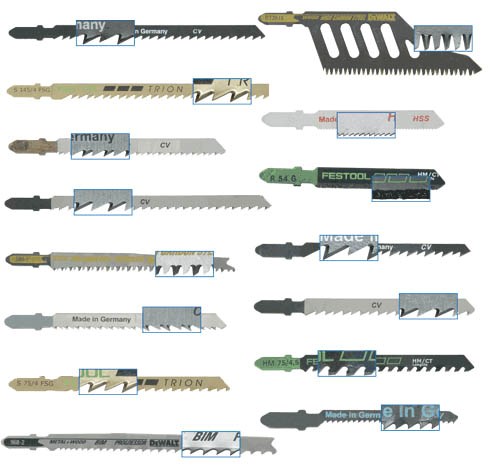

On the neck of the file (between the shank and the blade itself), letter marking is applied to the type of metal from which it is made:

- НМ - hard alloy;

- CV - chromium vanadium alloy;

- НSS - high speed steel;

- НСS - high carbon steel;

- ВМ or ВiМ is a particularly strong alloy.

Thus, by examining the markings on a jigsaw file, you can get comprehensive information about it.

Canvas dimensions

It is not only the size and shape of the cutting edge that determines the capabilities of jigsaw saws. The geometric characteristics of the canvas itself also affect the speed and quality of work. Plus, its dimensions must be selected based on the type and dimensions of the material being processed.

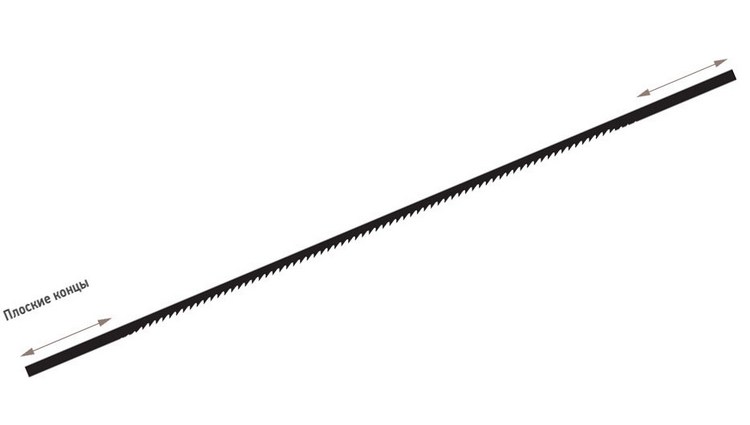

Length

The lengths of the jigsaw blades are in the range 40–250 mm. When choosing a specific length of a jigsaw file, you need to take into account the thickness of the material in the work. It is clear that for cutting thick wood pieces, a long jigsaw file is needed for wood. But if you cut thin sheet materials with a long blade, then due to the possible bending of the metal, it is difficult to get an even cut.

Width

You need to select the width of the saw blade based on the type of work to be done. For simple sawing where a straight and even edge is required, wide saw blades are used. When working, a narrow blade can walk, and a straight cut line will not work.

But when curly cutting of varying degrees of difficulty, you need to choose narrow jigsaw blades. It is easier to guide them to the side by drawing curved lines.

Thickness

When sawing thin sheet materials, the thickness of the file is not very important. But when working with thick workpieces, this size affects the quality of the sawn off surface. When working, thin blades will deviate from the perpendicular line, and the cut will turn out to be uneven. The thicker the web, the more even the cut it provides. But there is one caveat - too thick canvas is not suitable for all models of jigsaws. Jigsaws equipped with quick-clamping devices may not fit thick blades.

Marking

Whether a metal saw is suitable for a jigsaw for use in a particular case, and whether it is suitable for a tool made by a particular manufacturer, can be determined by the markings indicated on the blades. Gaining experience with a jigsaw, people easily begin to understand the symbols on the canvas. The first letter on it indicates the type of shank.

It can be identified with the letters T, U or M, although there are other standards depending on the selected tool. From the markings on the canvas, you can also read its dimensions. They are indicated immediately after the letter with the shank type designation. The shortest file is no longer than 75 mm. The average is considered to have a size in the range of 75–90 mm.

The longest are those whose lengths are from 90 to 150 mm. The digital designation is followed by an indication of the size of the teeth:

- small ones are indicated by the letter A;

- medium - B;

- large - C or D.

There is one more designation indicating the features of the saw:

- letter F indicates the use of an alloy of two metals in the file material, which provides the special strength of the product;

- the letter P indicates that the saw allows you to make an accurate cut;

- the letter O indicates that the back of the file is especially narrow, and such a product can be used for curved cuts;

- X: This blade is suitable for cutting various materials, including metal products.

- designation R - reverse, that is, the saw teeth are directed in the opposite direction.

The color indication on the shank also speaks volumes. To work with metal, choose products with a blue designation on it. White color indicates that the file is suitable for both metal processing and woodwork. And also special inscriptions can indicate the purpose of working with metal things.

Work rules

Some of these mini-machines are not designed for processing metal products that are thicker than 5 mm. Others make it possible to cut at least 10 mm metal. Much depends on whether the jigsaw is intended for home use or professional. In order for the jigsaw files to serve for a long time, you need to use the tool itself correctly.

- The correct setting of the jigsaw will ensure the normal operation of the tool and the trouble-free operation of the used file. It will allow the device to serve as long as possible and will not allow the cutting blade to become dull.

- When working, you do not need to put pressure on the jigsaw. This will not speed up the work, but the prospect of breaking the tool will become quite real. And also you need to choose the right speed of the file. At high speed, it can become very hot, becoming less sharp and less hard.

- No matter how skillfully the master may use an electric jigsaw, he should have at least a couple of spare saws at hand.

- If a jigsaw is often used for cutting metal, you need to have separate blades for aluminum, non-ferrous metals and steel on the farm.

- It is better to have a margin when using a hand tool, although an ordinary hand jigsaw allows you to continue using them until a certain length of the files is maintained, which makes such a machine quite economical. The jigsaw's clamping elements are designed so that you can always move the saw blade, ensuring its secure hold and keeping it in tension.

- Use protective goggles and gloves when working with any jigsaw. And also, one should not forget that a file is a very sharp tool and, if used incorrectly, a jigsaw can injure a person.

- You cannot "squeeze juice" out of a dull file, trying to use it as long as possible. From such treatment, the work can be performed poorly, and when using an electric unit with a blunt blade, the jigsaw begins to work under load and may break.

- When it comes to metalworking, nothing can last forever, and even more so for a jigsaw. But with proper selection and application of them, you can expect that they will not become frequently changed consumables.

In the next video, you will find an overview of Bosch basic saws for cutting metal products and metal surfaces.

Canvases for wood

The purpose of the jigsaw is to work directly with wood, well, with those materials that are made on its basis. Wood jigsaws come in many varieties. Jigsaws are distinguished, both by the size of the teeth, and by their sharpening, also by the shape of the file. There are two main types:

- Fine-toothed wood saws - Due to the shape of the teeth, this blade is called a "finishing tool" because it allows you to make a clean and precise cut.

- Dusty blades with coarse teeth - usually used for fast cutting of wood.

Jigsaws in this category are mainly made of carbon steel. It is for this reason that their cost is low.

Distinguish behind such parameters:

- File length. This parameter determines the immediate thickness of the cut.

- File width.

- The size of the teeth directly affects the cleanliness of the cut.

- The orientation of the teeth.

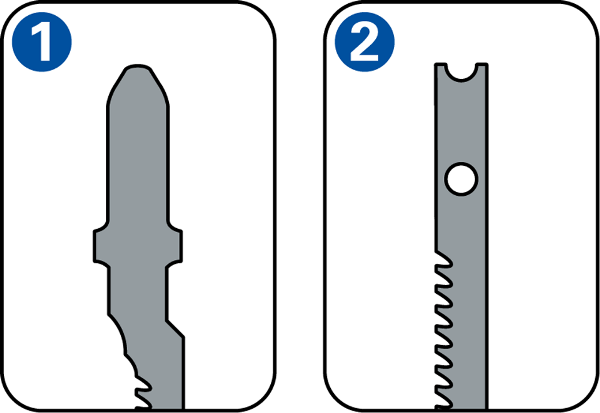

Types of jigsaw blade shanks

The first thing you should pay attention to when choosing a jigsaw file is the type of its shank. And this is logical: if your tool is not designed to work with such a variety, then you simply cannot use the new canvas.

There are actually not so many options:

T-shaped shank.

It is often called "Boshevsky", because it was this company that developed the files with this type of shank. Since BOSCH is the market leader in jigsaws and accessories for them, and other giants in the industry are trying to move to this standard, it is not surprising that T-shank files are currently the most common.T-shank fits most modern jigsaws - Bosch, Makita, Metabo, Hitachi, Skil, AEG, DeWalt, Sparky, Interskol, etc.

U-shaped shank.

The second most popular shank variety, the American standard. This is a universal shank for old models of jigsaws Skil, DeWalt, Wolf, Ryobi, Stayer, Black & Decker, etc. Such files are suitable for all jigsaws with shoe and screw clamps.

Makita shank.

Saws with this shank are only compatible with older Makita jigsaws.

Bosch shank.

It differs from the T-shaped shank only by the presence of the second stop. These files are only suitable for older Bosch models.

The last two types of shanks can already be classified as rarities. Finding such files in domestic stores today is almost impossible.

Conclusion

Have you already purchased a jigsaw?

Of course, not yet

Jigsaw blades are an extensive group of interchangeable attachments that allow you to cut different materials:

Each material has its own type of blade, which allows you to get the optimal edge quality

When choosing a blade, you should pay attention to the type of teeth, their size, blade length and width. All the necessary information is available on the side surface of the attachments

If you have any questions, it is recommended to consult with a sales assistant. As a rule, DIYers prefer to buy sets of different types of blades in order to have at hand all the most necessary cutting tools samples at once.

- Rechargeable reciprocating saw. How to choose a rating of the best models

- Cordless screwdrivers: model rating, tips for choosing

- LBM with speed control and smooth start. Model rating

- How to choose a secateurs? Review of the best and most comfortable models