For metal work

Modern jigsaws are capable of sawing a variety of metals, including black steel. However, the productivity of the tool when working with such materials drops sharply, the depth and cutting speed decrease, at the same time, the wear rate of the saw blades sharply increases.

Saws for metal processing are made of high-quality grades of high-strength steel and are distinguished by fine teeth (up to 1 millimeter) with wavy sharpening. If you often work with metal parts, we advise you to buy several files: separately for steel, for aluminum, for bronze and other non-ferrous metals.

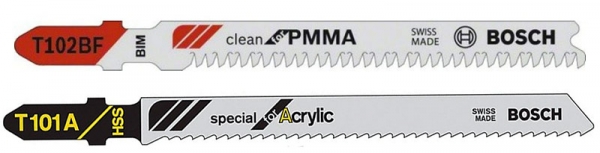

For sawing other materials, such as plastic, polymers, plexiglass, drywall, manufacturers develop unique types of blades that are suitable specifically for a particular material. When processing particularly hard surfaces, we recommend purchasing tungsten-coated files.

Helpful tips for choosing

The durability of the file depends not only on the skills and accuracy of the master, but also on the quality of the steel. Buying cheap products "made in China" is unlikely to save money. They break down rather quickly, and if we compare the total cost of the samples consumed for a certain technological operation (and even the time spent on replacing them, possibly on going to the store), then the benefit is very doubtful.

On sale there are files that are positioned as special, "for tiles." Yes, they can cut ceramics. But how advisable is it to do it with a jigsaw, especially at home? Not to mention that the work will go slowly, so much dust will be generated that it is unlikely that there will be a desire to continue cutting. For these purposes, you should not spend money on a file, no matter what famous manufacturer it is and at what attractive price it is sold. To work with ceramics, instead of a jigsaw, you should use a glass cutter - both faster and cleaner.

Judging by the advertisements, there are files on the market that provide an almost perfect cut. They are highly recommended to us, for example, for cutting laminate, parquet boards. And many believe that this is exactly the modification, without which "well, nothing". How true is this, especially if we compare the cost of a jigsaw (about 2,200 - 2,760 rubles) and these files (from 550 rubles to 1,100)?

Judging by the advertisements, there are files on the market that provide an almost perfect cut. They are highly recommended to us, for example, for cutting laminate, parquet boards. And many believe that this is exactly the modification, without which "well, nothing". How true is this, especially if we compare the cost of a jigsaw (about 2,200 - 2,760 rubles) and these files (from 550 rubles to 1,100)?

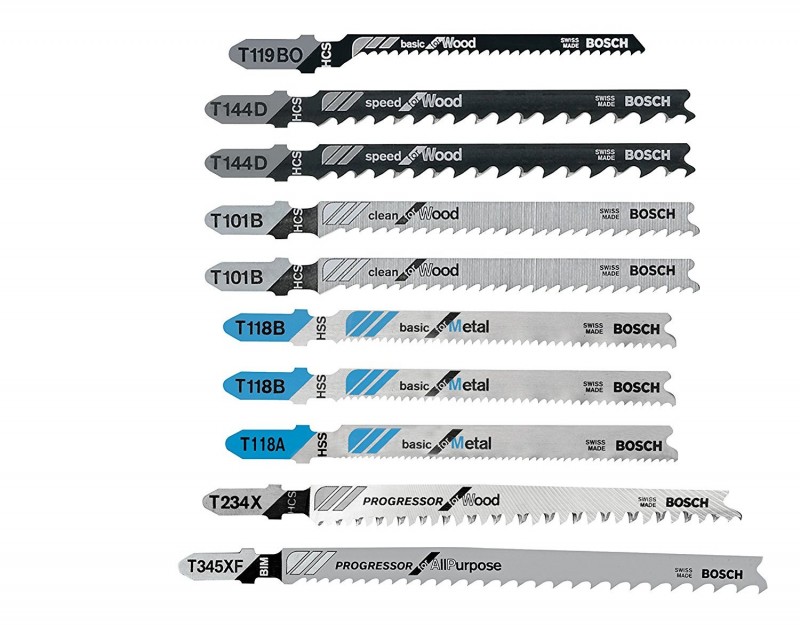

For “DIYers” who do not have sufficient experience in working with this e-tool, the author gives a hint - all this is a myth. In the sense that such files are “the only possible option for a clean cut”. Firstly, products, for example, of the same "Bosch" (series "T101" AIF or AOF), give minimal chips. If you are careful, then the best is not needed, especially since the price is acceptable - within 330 rubles. Secondly, the end parts of all the blanks obtained during cutting are sealed with something (at the joints) or closed during the installation process (for example, when arranging the finished floor - with plinths). The question is - is it worth paying the same 550, 780 or 900?

Universal jigsaw blades are not the best choice. Manufacturers claim that they can cut both wood and metals. But, as you know, there is no remedy "for everything". The plus, which gives multifunctionality to such files, is complemented by the minuses - a decrease in the quality of a cut, a slowdown in the speed of work, and a number of others. They are suitable only for performing elementary operations with a jigsaw, when neither accuracy, nor productivity, nor the condition of the edges of the fragments are important.

For a curly cut with a jigsaw, for example, in wood, you need to choose saws with a narrower blade.

Web width

The higher the value of this parameter, the more accurate the cut will be when working with thick samples.

When choosing a file, you need to look at its markings. The HCS symbol indicates that this product is designed to work with sufficiently soft materials (plastics, wood). But for hard files, you need to choose files with the designation "HSS". There are also more expensive samples with increased strength ("BIM"). They are made of bimetal and allow you to work with almost any alloys, ceramics and other materials with a particularly dense structure. But for domestic use, the expediency of purchasing them is rather doubtful, given the simplicity of homework and the high price of files in this category.

Cutting opportunities

The market offers saws for almost any material - from soft (wood, plastics) to hard (metals and artificial stones). But sawing concrete and "iron" in domestic conditions, as a rule, is not done with an electric / jigsaw. There are other tools - a "grinder", a hacksaw for metal. And the professionals know the criteria for choosing special files, so a few comments about this are below. But with samples for performing everyday, homework, it is worthwhile to figure it out in more detail.

The market offers saws for almost any material - from soft (wood, plastics) to hard (metals and artificial stones). But sawing concrete and "iron" in domestic conditions, as a rule, is not done with an electric / jigsaw. There are other tools - a "grinder", a hacksaw for metal. And the professionals know the criteria for choosing special files, so a few comments about this are below. But with samples for performing everyday, homework, it is worthwhile to figure it out in more detail.

A good owner always has a kit - for wood (and products based on it), plastics, plexiglass. Depending on the thickness of the samples and the specifics of cutting, the home set should have 2 - 3 files of each type. How to choose them?

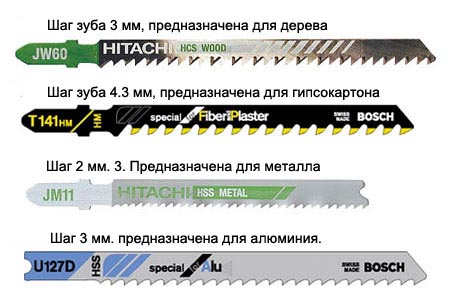

- The shank of the metal saw is blue in color and has small teeth.

- The wood tool is distinguished by its modification. Saw blades with large teeth, between which there is a significant gap, are suitable for fast (preliminary, coarse) cutting of material. Products with small teeth are used when cutting sheet materials or small-section bars, when one of the main quality criteria is cutting accuracy with a minimum of chips.

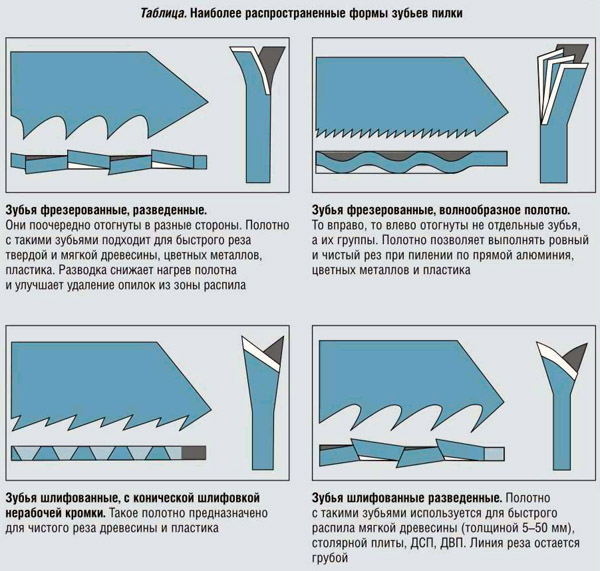

Something else should be explained on the configuration and location of the teeth. This will help you choose the right file if you intend to perform "delicate" work with a jigsaw.

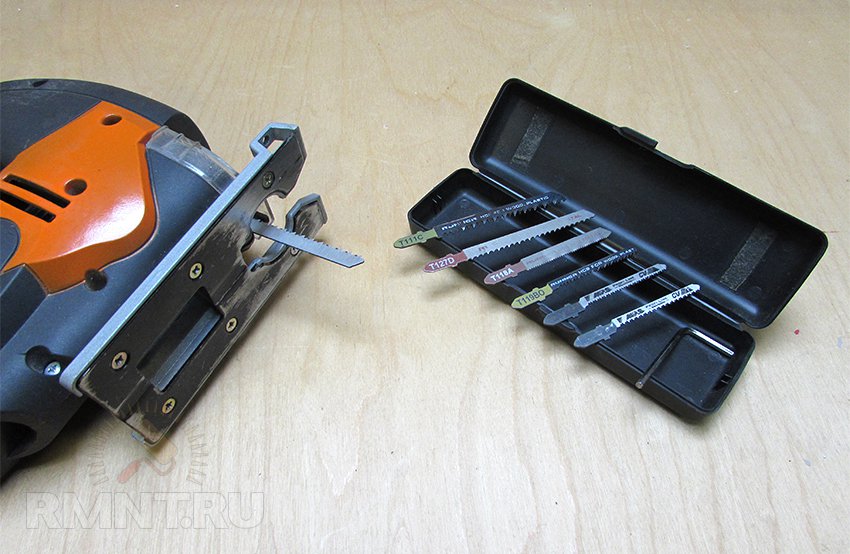

Photo of jigsaw files

We also recommend viewing:

- What are aluminum rivets

- Best screwdriver bits

- Which polyurethane foam is better

- Choosing a blade for a hacksaw for metal

- Overview of drills and drills for rock drill

- Overview of diamond core bits for concrete

- The best concrete drills for drills and hammer drills

- How to choose a good diamond blade for concrete

- Which abrasive disc is better to choose

- Wood milling cutters for hand router

- How to find the right grinding wheel

- Which drill chuck is better

- Choosing good wood drills

- Types and sizes of staples for the stapler

- Why do you need a unipack

- Metal brush for grinder and drill

- What and how to choose a line for a trimmer

- Which drills for metal are better

- Which chainsaw oil to choose

- Cut-off wheels for grinders

- Metal pipe clamps

- How to choose a galvanized bucket

- How to choose a circular saw blade

- Varieties of petal circles

- What is tow

- Nylon ties

- Types and application of electrical tape

- Choosing a light plastic bucket

- How to choose safety glasses

- Why do you need masking tape

Help the site, share on social networks

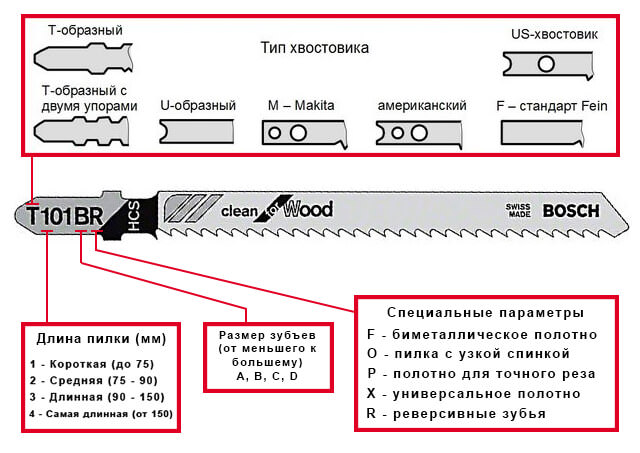

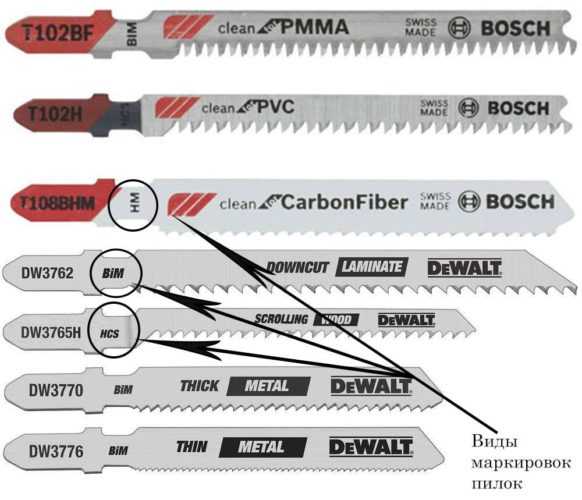

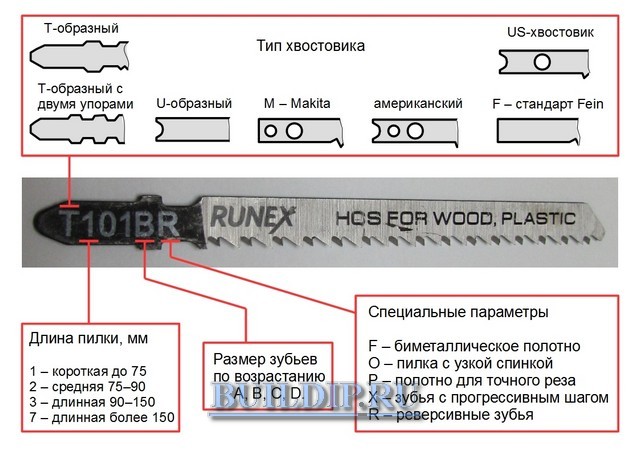

Features of marking

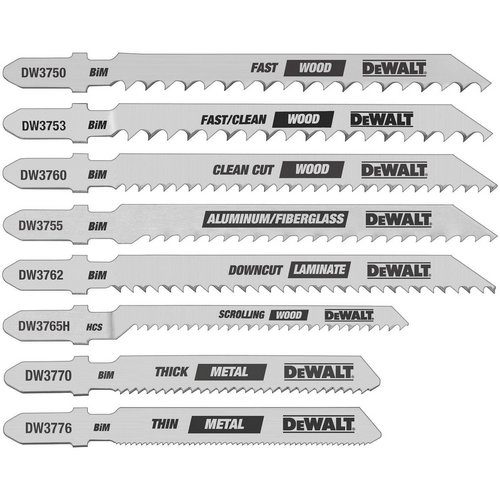

By studying the offers of different manufacturers, in stores you can find many different types of attachments, differing in the configuration of the teeth, base thickness, length and width. Naturally, for a novice craftsman who buys a jigsaw attachment for the first time, it is extremely difficult to choose the right file for the job. To make the right decision, you must first look at the marking.

By studying the offers of different manufacturers, in stores you can find many different types of attachments, differing in the configuration of the teeth, base thickness, length and width. Naturally, for a novice craftsman who buys a jigsaw attachment for the first time, it is extremely difficult to choose the right file for the job. To make the right decision, you must first look at the marking.

In order not to make mistakes when choosing a nozzle, you must first get acquainted with the existing types. To date, there are 4 main classes of jigsaw saws on sale:

- nozzles with a gray tail - allow you to work with any wood;

- nozzles with a white tail - designed for working with wood and metal;

- nozzles with a blue tail - for working with metal;

- nozzles with a black tail - for working with plastic, cardboard, tiles.

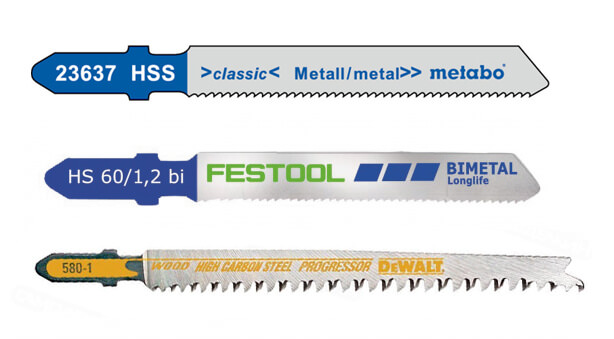

You can also find out from the marking what metal the proposed nozzle is made of. This is indicated by capital English letters. If the abbreviation HCS is used in the marking, then it can be concluded that the nozzle blade is made of high carbon steel. If the marking contains the letters HSS, then it means that in front of you is a nozzle that was made of high-speed steel. There are also BiM and HM markings. The first means bimetal, and the second means hard alloy.

If you need a nozzle for cutting plywood, soft fiber wood, laminated chipboard and chipboard up to 30 mm thick, and in addition, plastic, then it is best to purchase the HCS nozzle. Her teeth have a pointed shape and a conical grinding. Due to their high flexibility, they have excellent wear resistance.

HSS saws are mainly used for working with metals. They have a curvature in the lower part, which is necessary to prevent metal scuffing. Although these saws are thinner than saw blades for cutting wood, they have a higher hardness.

If the master needs to purchase a wear-resistant canvas, then it is best to opt for metal nozzles. The high strength characteristics of these nozzles are ensured by the laser welding technology used in their manufacture. High-carbon steel is used as a material for their production. The rear part is made from it, and high-speed steel is used for others. This type of file is the best choice when you want curved lines and a perfectly straight cut.

HM canvases are used mainly for specific work when it becomes necessary to cut lightweight concrete, fiberglass or tiles.

If you have to work with laminate flooring, it is best to choose a blade with a reverse tooth system. When using these attachments, the cut will be carried out in the opposite direction, not away from yourself, but towards yourself. This layout allows you to cut parts of any length and at the same time get a clean line without chips. Files of this type are suitable for working not only with laminate, but also with veneer boards. If the home craftsman knows what information is contained in the marking for a particular model of the attachment, then he can easily choose a file for himself that will help him effectively and with less effort to complete the task.

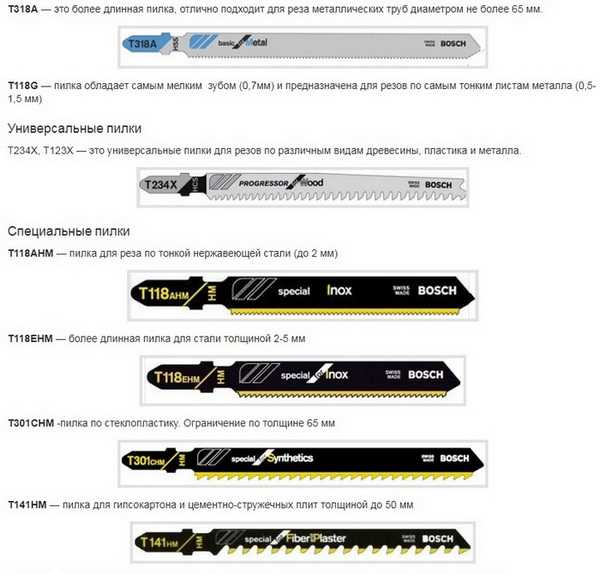

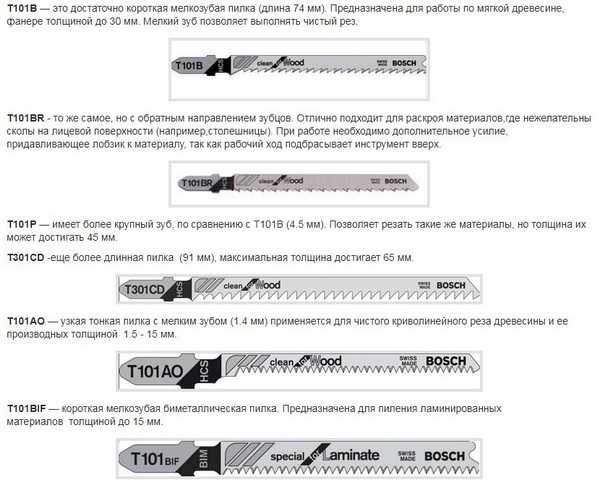

Types of canvases - decoding of inscriptions

Some manufacturers use the European standard from Bosch to classify products, others indicate it in addition to their marking.

The inscriptions indicate the purpose of the file for any material:

- Wood - Medium density softwood and composite boards.

- Hardwood - laminated hardwood.

- Fiber, Plaster - fiberglass products.

- Acrylic - polycarbonate, plexiglass.

- Metal - galvanized profile, sheet metal, pipes.

- Inox - stainless steel.

- Alu - aluminum.

- Soft-material - cardboard, rubber, carpets, polystyrene.

Inscriptions indicating the grade of steel used in the manufacture:

- HSS is a high quality grade for fast cutting of hard materials.

- HCS - alloy steel for cutting wood and composites.

- Bi-Metal (BM) is a blade consisting of the previous two grades and is suitable for most applications.

- HM - carbide saw blade for cutting blocks and ceramics.

Marking specifying the type of work:

- Clean - for a clean cut.

- Basic is a common file suitable for a variety of tasks.

- Speed - for fast and straight cutting.

- Flexible - flexible metal file.

- Progressor is a versatile blade with teeth of different shapes.

- Special - canvas for plastic, ceramics or other specific materials.

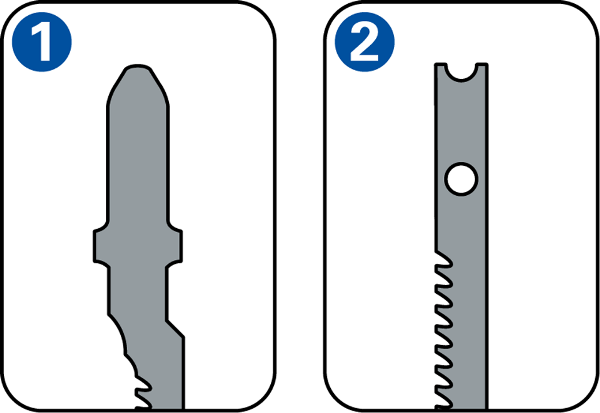

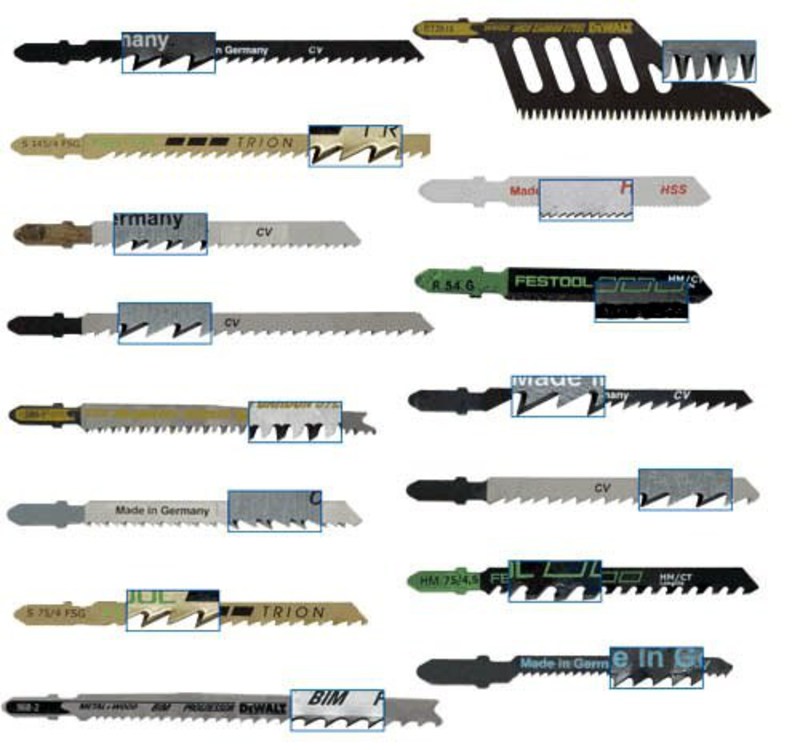

Views

To work with jigsaws of different companies, files with a shank of one form or another are used. T-shaped - the development of Bosch. Today, such shanks are used by other manufacturers for their tools. There are saws with a similar base on the market very often. The U-shaped shank is more suitable for jigsaws that have been on the market longer than those made by Bosch. They fit together with a tool that has pad-type clamps. There are also old-style shanks that fit Bosch and Makita tools.

It should be borne in mind that in addition to files for working with metal, there are those that make cuts on wood, plastic and other materials. In particular, jigsaws powered by electricity were originally intended for wood processing. If for working with wooden products, saws made of an alloy of chromium and vanadium are used, then blades for working with metal are made of steel, capable of quickly sawing strong metal sheets and other things from such a hard material. The stronger the metal being cut, the finer the teeth on the blade. The width of the web also varies.

It all depends on what kind of work is supposed to be done. The wide one allows you to make a straight cut at high speed without fear of getting off the chosen path. This will also depend on the thickness of the web. The thicker it is, the more likely it is to cut the metal in a perfectly straight line. For curly cutouts, narrow blades are suitable, allowing you to easily make intricate turns.

The shape of the teeth on a file designed for cutting metal is also important. Some instruments have very shallow and wavy cutouts, allowing you to make even cuts, making small turns if desired. Such blades are intended for cutting materials with a thickness of 1-3 mm. To cut various metal products or pieces of metal with a greater thickness, blades with set teeth help, the number of which increases by an inch towards the edge. They are capable of cutting materials up to 10 mm thick, such as brass, copper and aluminum products and sheets.

Files are also distinguished by the distance between their teeth. The calculation is based on how many teeth are in one inch. This is evidenced by the TPI indicator. Jigsaw blades are distinguished by the fact that they can be easily adjusted to the size of a specific tool, for example, set it to a length of 150 mm. For jewelry hand jigsaws, depending on the thickness of the metal product being processed, you can choose the file number from 8/0 to 8.

The width of such sawing devices is very small. From a distance, the delicate canvas looks like a string. This allows you to easily make bends on the metal, creating an especially thin pattern with their help. Among all the variety of jigsaw files available in circulation, you can find universal ones. It is believed that they are suitable for working with wood, and with plastic and metal. But, as practice shows, their use, including on metal objects, does not provide a good cut quality.

Length (mm)

It varies in the range of 50 - 150. Quite often, when it comes to household tools, the file is purchased "for everything." In this case, practitioners advise focusing on the length of 100. As a rule, this is quite enough for homework.

When choosing a file, you should also take into account the power of an electric / jigsaw (how to choose a jigsaw, read here). What is the point of buying too long, focusing only on the thickness of the sample for cutting, if the tool simply "will not pull" it. And the price of such a file is higher than for a short analogue. If you intend to work with a jigsaw only with chipboard, laminate, plywood, then it is advisable to choose the last option (within 50 - 80).

Classification of jigsaw files according to the type of material being processed

For wood and wood materials

The jigsaw was originally designed to work exclusively with wood. Modern tools have learned to saw both metal and plastic, but their main purpose is still cutting wood and its derivatives. That is why most of the saw blade assortment is designed to work with these materials. "Wooden" files are divided into groups according to the type of work for which they are intended.

Fast cut.

When carrying out some types of work with wood, it is often not the accuracy that is important, but the speed of the process. Saw blades for fast cutting of wood are capable of providing high performance. They are easy to recognize by the following characteristic features:

- long blade (from 60 mm),

- large teeth (up to 6 mm),

- large amount of divorce (about 1 mm).

Clean cut.

Operations such as cutting furniture boards from chipboard or trimming parquet boards require a smooth and accurate cut. When solving such problems, where the quality of work comes to the fore, and not productivity, blades for a clean cut are used, having:

- average size of teeth (no more than 3 mm),

- minor divorce.

Most saws have their teeth pointing towards the jigsaw. So that the front side of the material after cutting the chipboard or laminate is as accurate as possible, without chips and scoring, the workpiece is placed with the back side to itself / the tool. To cut from the "face", you need to use a blade with a reverse tooth. True, working this way is more difficult than usual - you have to overcome the pushing force of the tool.

Figured cut.

It is almost impossible to cut a curve with a small radius with an ordinary wide blade. For a figured cut, specialized files are used, which, due to their size, easily pass rounded sections:

- narrow canvas (no more than 4 mm),

- fine teeth (up to 2 mm),

- small length (up to 40 mm),

- beveled back.

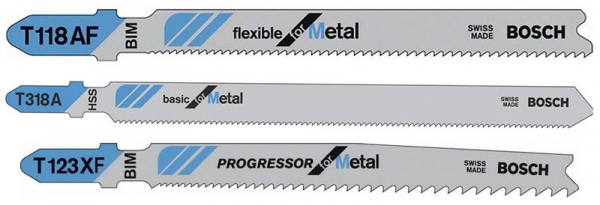

For metal

I must admit that a jigsaw is not very suitable for cutting metal: the tool can hardly cope with the load, the process is very slow, the files quickly become blunt. However, sometimes this extreme method is justified.

Saws for metal differ from saws for wood: they are made of extra strong steel and have fine (up to 1 mm) teeth, set in a wave-like manner. If you often use a jigsaw and at the same time perform a wide variety of work with it, we recommend keeping at hand three metal blades at once - separately for aluminum, other non-ferrous metals and steel. If you have to cut metal only from time to time, it will be enough to have only a file for steel - it will certainly cope with cutting non-ferrous metal products.

For polymer materials

For cutting pipes and other PVC products, large-toothed blades designed for cutting wood or metal are suitable.

Fine-toothed files will also cope with the task, but you will have to cut at the minimum speed, otherwise the plastic sawdust softened from the high temperature will clog the teeth of the file. For thin sheets of plastic and plexiglass, fine-toothed metal blades are excellent. To cut thick plastic, you can take a file on wood and cut at low speeds.

For specific tasks

Files for glass and ceramics are made of extra strong alloys and have diamond or tungsten carbide spraying on their cutting edges. It makes sense to use a jigsaw to cut ceramic tiles or glass only if you need to cut curly elements; there are other, more suitable tools for cutting these materials directly.

Drywall and other building materials containing abrasive particles of gypsum, cement or sand will quickly blunt any files. An exception is the carbide-tipped saw blades specially designed for these materials.

A file designed for cutting cardboard, rubber and other soft materials is more like a knife. It is "toothless", and its cutting edge is made in the form of ground waves.

Universal

Universal saws, made, as a rule, of high-speed steel, are used to work with various materials - wood, plastic, metal. You should not expect a high cut quality when using them.