Subtleties of choice

Basically, when choosing perforated metal panels, one should be guided by the place of their application, the amount of tools or material that will be stored on them, the microclimate of the room and the issue of price and manufacturer. If your workshop has a dry microclimate, then there is no difference between the choice of aluminum or steel options for you, since the risk of corrosion is minimal.

The loads that these panels can withstand are enormous, but most steel panels are coated with a protective paint finish that also allows for color matching, which is sometimes important for the overall design of the workshop. Aluminum models are often used in supermarkets or trading floors to create racks for goods out of them.

For information on how to make a perforated toolbar with your own hands, see the next video.

Perforated panels - description and materials

place and comfortably use

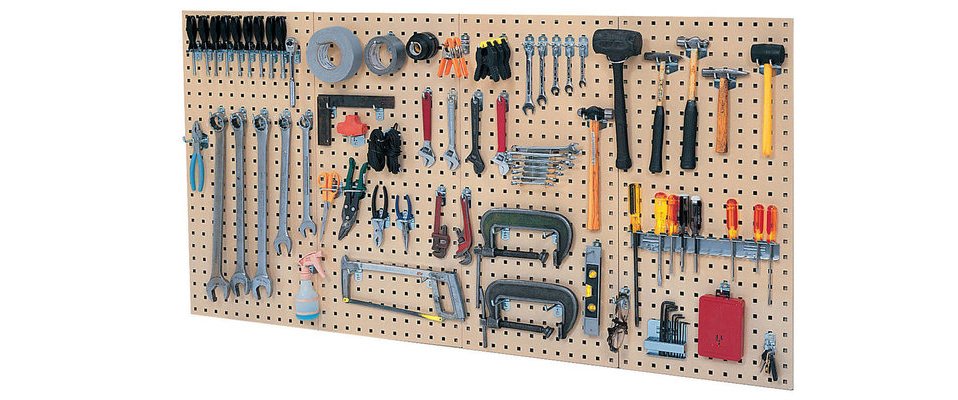

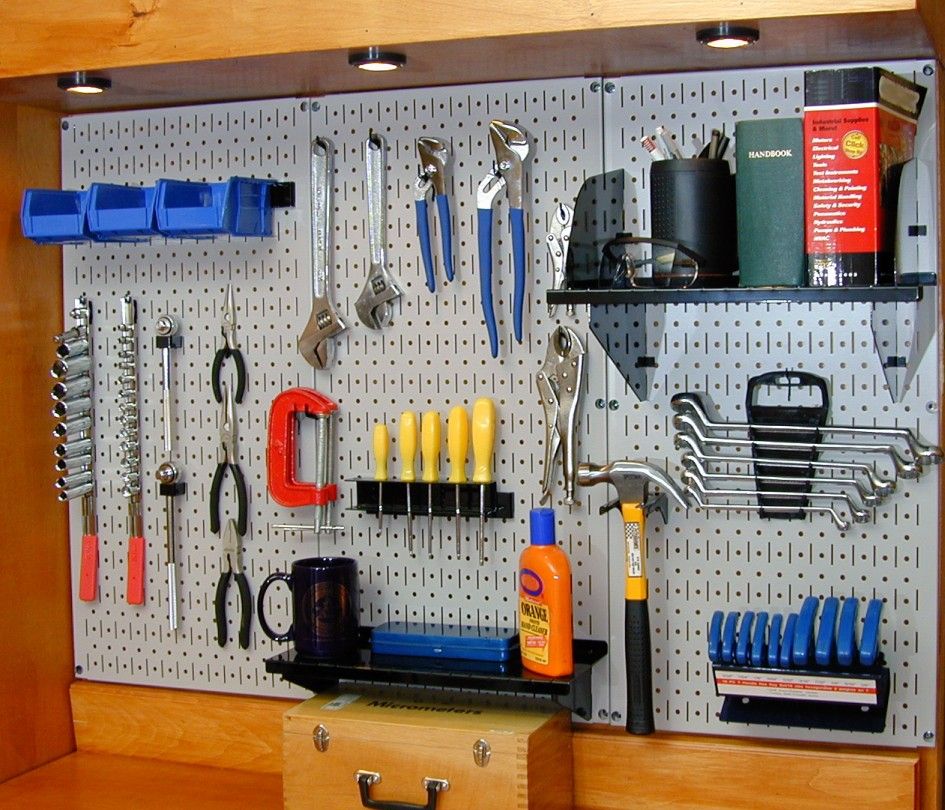

Perforated layouts allow you to save work space, keep the necessary tool always at hand and control its availability. A workshop equipped with such panels will have a modern look, and various working devices will always be at hand.

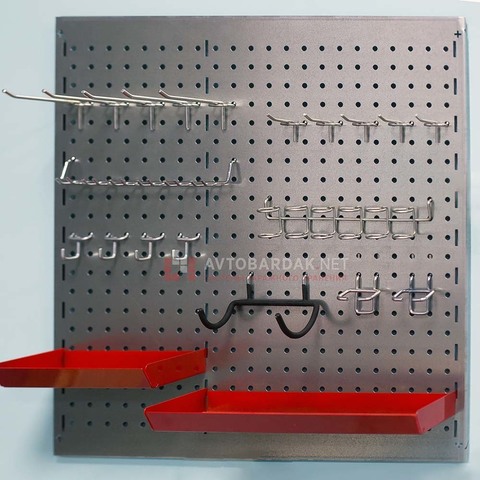

Perforated sheets are attached to special brackets, and tools are placed on them using holders, shelves and hooks. However, on sale you can find cabinet panels that are mounted without any fasteners.

Perforated sheet sizes:

- On average, the height of such products is 200 centimeters, and the width is 100 centimeters. Large sheet sizes can be produced for various workshops and garages. Their width can exceed more than two meters.

- The minimum layout size is 50 centimeters wide and 100 centimeters high.

- The thickness of the chipboard can be up to 7 centimeters, and metal - from 1 millimeter.

- The perforation diameter is 5 millimeters and the distance between the holes is 15 millimeters. This allows you to fill the panel as tightly as possible and at the same time it is convenient to arrange everything.

- The pitch between the centers of the hook attachment is 30 millimeters.

However, it must be remembered that the dimensions are calculated according to the overall dimensions of the product, while the working surface itself most often has rather modest dimensions. That is, with a structure height of 150 centimeters, only 50 or 100 centimeters can fall on the perforated surface used.

The building materials market offers many different standard sizes of panels, so there is plenty to choose from for arranging any workplace.

The areas of application of perforated layouts are unlimited, however, for each case, you should select a product with certain characteristics:

- durable metal structures are well suited for professional workshops;

- small-sized sheets will come in handy in a subsidiary farm or garage;

- multifunctional layouts in the form of screens and modules are widely used in manufacturing and industry;

- products with various additions have found their application in the arrangement of showcases in hardware stores.

Metal perforated panels

Affordable tool storage racks are easy to install and easy to use.

Advantages of metal products:

- perforated panels are resistant to humidity and temperature extremes;

- they are environmentally friendly, as they are produced without toxic compounds;

- there are practically no restrictions in the conditions of use and standard sizes;

- the gaskets made of galvanized steel are not subject to corrosion;

- with their help, you can service both small building structures and massive spare parts, and a weighty power tool;

- the outer laminated layer of products is resistant to minor damage;

- in metal sheets, you can create special perforations that allow you to attach various hooks and canopies to them.

Most often, perforated panels are made in two colors. They can be white or natural wood.

The disadvantages of metal layouts include:

- Mandatory fastening for fixing the sheet of horizontal strips.

- Compared to MDF models, the price is quite high.

Perforated chipboard panels

When choosing layouts from MDF, it should be borne in mind that in conditions of increased use, they are not able to provide adequate wear resistance.

Due to the low strength of the material, tools for storing tools are made in small formats. Their standard size is 60x60 centimeters. Such layouts are strong enough, do not deform or bend. In addition, they are easy to transport and install at the desired location.

Perforated MDF panels are designed to store only oversized tools. With their help, you can conveniently place and operate hammers, wrenches, screwdrivers, etc. At the same time, when choosing such products for your workplace, you must remember that at high humidity and high temperatures, their service life will not be long.

Toolbar composition

If the rack is purchased from a specialist store, it should include the following parts:

- Aluminum or steel perforated panel. This is the main element, which looks like a plate with symmetrical or randomly located holes made in it. If it is made of ordinary steel, then it must be covered with paint, since the instrument fixed on the site is not always clean or dry. When moisture enters an open area of metals, rust can form, and the appearance of the entire structure will lose its attractiveness. Aluminum does not corrode and therefore it is not necessary to paint it;

- Brackets for fastening the panel itself to a section of the wall. Sometimes this part is included, but most often it needs to be purchased separately, depending on the place of fastening and operating conditions. You can also make the bracket yourself from wood or metal, or use a regular bar;

- Hardware for fixing tools and other items. Such components are corners or frames specially made in the factory, as well as metal hooks on which tools are hung for a special suspension. Brackets can be both plastic and metal, but it should be borne in mind that their resource differs from each other. Metal is able to withstand heavy loads, so products made from it are much stronger than any others.

Aluminum panels with hooks

Perforated aluminum panels can most often be found in car services or carpentry workshops, as well as on trading floors, since their cost is slightly higher than steel ones, organizations engaged in commercial activities can afford such walls. During this operation, new products or tools are constantly displayed on the panel, the platform is scratched and worn out, so its base must be strong and reliable.At home, it is unlikely that it will be possible to cause significant damage to metal shelves, so their use is justified due to their low cost, compared to panels made of other materials.

Functions and advantages of metal panel

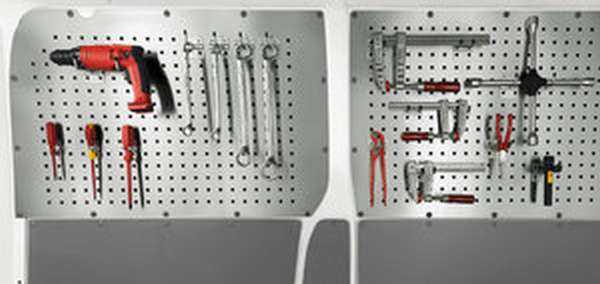

Perforated panels for tools at home perform the main function of placing the necessary items within walking distance and in plain sight, so that at any time you do not look for the right thing in cabinets and bedside tables, but simply remove it from the rack and use it for its intended purpose.

Also, the specified product can be used as a dividing partition between work areas to determine the sectors of activity. For example, if the workbench with the machines and the washing chamber are located close to the left or right side, you can place a perforated sheet on which the tool will subsequently be mounted. In this case, the panel plays the role of a storage area and at the same time blocks access to different work areas.

Commercial or domestic use of metal panels has several advantages, which include:

- Perforated metal panels perfectly withstand any loads and, due to stiffening ribs, do not undergo deformation, they are moisture resistant and resistant to temperature extremes;

- Their production is carried out from pure materials that do not have substances harmful to humans. All used metal is sorted and processed, and only chemically purified paint is used;

- These products come in a wide range, of any size and thickness of metal;

- The modular system allows the panels to be combined to create a variety of user-friendly storages;

- If aluminum or stainless steel is used, then the perforated panel serves for more than a dozen years, since moisture and corrosion are considered the main enemy of such elements, and non-ferrous metals are indifferent to this type of aggressive environment;

- High load-bearing capacity. When the platform is located on the wall using anchor bolts, any tool can be hung on the surface: from a hammer and screwdriver to a hammer drill or other large-sized equipment. Commercial equipment based on such panels is especially effective, since it is capable of supporting a large weight of goods;

Bracket types

- The painted surface can be of any color and even several colors. In addition, the paint protects the metal from minor scratches and damage;

- If there are not enough holes in a certain sector, they can be made at any time using a household drill or screwdriver;

- A variety of hooks and brackets that can be arranged in any order, depending on the size of the object being hung and its weight;

- The ability to make panels at home with your own hands. This requires a minimum of tools and only a few metal plates;

- To organize the sector for storing tools, it is not necessary to make many holes in the supporting wall for fastening various brackets and holding devices. All objects will be held on the plane of the panel without leaning against the base or damaging the surface.

But along with the listed advantages, there are two disadvantages to using perforated metal panels. First of all, this is the cost of the finished product and accessories for it. Since the factory production of such elements is quite laborious and requires some costs, its price is slightly higher than racks made of wood or plywood.

The second drawback is that for the correct installation of the structure, it will be necessary to remove the sheet from the wall by a few centimeters. This is necessary in order to securely fix the hooks and brackets on the site, and so that, if necessary, you can change the location of the suspensions without removing the panel from its place.

The perforated panels used as commercial equipment are much larger, so it is not always possible to mount such a product in a domestic environment, besides, the principle of their fastening is slightly different. Installation of these products is carried out by fixing the panel to the wall with an anchor system and fixing the lower cut on a special platform bolted to the floor. This design allows you to reduce the load on the wall by transferring the weight of objects on the plane to the rack.

Choosing a perforated panel of factory or own production, the workplace will always be in order and cleanliness. Also, the appearance of the room will look more attractive and filled with functionality.

Garage toolbox

In order to build a panel for the instrument, you do not need to have professional skills. This task is easily solved by purchasing perforated panels (tin or HDF can serve as the material) or economy panels (MDF frame with a groove around the entire perimeter of the product).

Since we are talking about the independent manufacture of options for mounting a tool in the garage, we will analyze the option of making a panel from MDF sheet or plywood. Here, first of all, you need to measure the place above the workbench and decide on the size of the product itself. Then lay out a piece of plywood on the floor and lay out everything that needs to be laid on the selected panel on it. The final step is to drill holes in the selected mounting locations and secure the equipment with screws. As a result, professional panels with tools in the garage are made quickly and easily - all that remains is to place them on the wall in the room.

It's important to know! Often, hooks are installed on a tool board panel in a garage without a rigid fixation. This raises many questions for garage owners, because it is difficult to fix any things on them.

You can only use hooks on the wall for junk in the garage.

Methods for mounting perforated layouts

The panels can be placed on various surfaces.

Wall sheets are the most popular type of designs. They are fixed directly to the wall and fastened with special screws. With the help of such layouts, you can save room space and, at the same time, comfortably use the work tool.

Wall sheets are the most popular type of designs. They are fixed directly to the wall and fastened with special screws. With the help of such layouts, you can save room space and, at the same time, comfortably use the work tool.

Perforated panels for the locksmith's workbench are manufactured according to the length of the machine. Their size can be matched to a double-pedestal, one-pedestal or bastumbov workbench. Structures are fastened using special brackets and racks. In addition, two panels can be installed on the workbench at once.

Modular screens or systems can be placed in the middle of the room. They will also perform the zoning function.

Rear spacers can be conveniently positioned on pipe stands or other suitable profiles.

It is worth noting that the placement of various additional elements depends on where and with what the panel is installed.

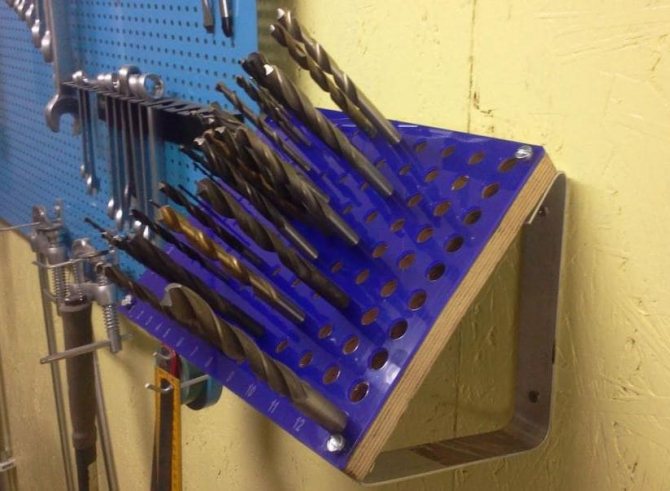

How to store drills correctly?

Separately, we focus on the nuances of storing drills. It is advisable to do this based on the purpose (for metal, for wood) and according to the diameter of the tool. For example, very small drills (up to 1 millimeter) must be placed separately from the rest due to their low mechanical strength. So, if you put tools 0.8 and 10 together, without fixing them in any way, the larger part, if accidentally moved, will break the smaller one under the action of gravity.

The second point - the most convenient is the location "from smallest to largest".

The third aspect is reliable fixation, which prevents breakage of the working edges and products in general. That is, it is necessary, if possible, to exclude their mutual contact with each other.

The fourth factor is usability. Any instrument should be within reach, but located so that adjacent samples do not interfere.

Making a perforated panel with your own hands

DIY soft panels for walls

Metal sheet 3 mm

In order to save personal funds, some craftsmen try to make the above products on their own, for this it is necessary to act according to the following algorithm:

Sheet metal of the required thickness is purchased, which must correspond to the planned load. In retail outlets, metal is sold with a thickness of one millimeter to 5-7 millimeters.

It is important to take into account here that the thicker the sheet, the higher its nominal weight, therefore, the fastening mechanism for fixing it on the wall must be reinforced;

The markup of the future product is made. It is not necessary to know the exact location of the hooks and brackets here, as it is very difficult to predict.

Many craftsmen do first install a metal sheet to the wall, and only then make holes in the right places;

Drilling a sheet

- The edges of the sheet are bent around the entire perimeter. This is necessary to remove sharp corners and give additional rigidity to the entire structure. You can bend the metal on a special machine or by clamping the edge in a stationary vise. The height of the bend should correspond to the thickness of the future bracket;

- Wooden bars or a metal corner are screwed onto the resulting product, which are inserted into a niche formed along the entire length of the sheet. It is this block that will be the basis for fixing the entire panel on the wall surface;

Anchor installation

- With the help of anchor bolts through the drilled holes in the bar, the panel is mounted on the wall. Due to the thickness of the wood, the perforated sheet will be removed from the surface by a few centimeters, which is enough for the installation of fastening hooks;

- Bearing brackets are bent from thick-walled wire or sheet metal remnants, which will subsequently be inserted into the holes;

- At the final stage, the entire assembled structure is painted with acrylic or alkyd enamel, including the supporting hooks.

After the panel is completely dry, it can be used, tools and other devices can be hung on the brackets, as well as, when adding small cabinets to the surface, organize boxes for storing screws, bolts and other small elements.

Of course, prefabricated perforated panels purchased at retail outlets have a more acceptable appearance, but their cost is also much higher than making such platforms yourself.

Stiletto heels

Suspended shelf with stiletto heels will help to save free space in the room. To make it you will need:

- plywood and fiberboard sheets with a thickness of at least 2 cm for the manufacture of flooring;

- 4 large anchors;

- 4 hex nuts;

- 12 regular nuts;

- 4 hairpins;

- 8 flat washers;

- 4 Grover washers.

Of the tools you will need:

- drill;

- puncher;

- spanners;

- jigsaw;

- screwdriver;

- level.

The process of making a suspended shelf on stiletto heels is as follows:

- A shelf of the required dimensions is cut out of plywood or chipboard.

- To give the material strength, a metal profile with internal stiffeners is fixed at its ends.

- Holes for studs are made along the edges of the shelves.

- After that, the product is applied to the ceiling and the markings for the holes are made on it. This will prevent distortions from forming.

- Next, holes are made for the anchor, they are driven into the concrete and twisted until it stops.

- The studs are connected to the anchors on the ceiling and the connections are fixed with nuts - sleeves.

- After the major fixing of the studs on the ceiling, you can proceed to the installation of the shelf.

This type of shelf will help you save space in your garage. To prevent the mobility of the structure, you will need to use a metal corner. One edge is attached to the wall, the other to the shelf.

How to do it?

The shelves and shelves in the workshop are irreplaceable. Since they contain spare parts, components, tools, fasteners, bolts, nuts and much more. With the right approach, shelves can even become an original piece of furniture that combines practicality, ease of use and a certain elegance.

Before you start making a shelf with your own hands, you need to think over important nuances:

- Product dimensions. They will depend on the size of the room, personal preferences and the type of activity of the master.

- Manufacturing materials. These can be structures made of metal, plastic, wood.

- Construction type. This can be a hanging shelf attached to the wall, a floor version, a shelf located on a workbench. The main thing is that the structure you have made is securely fixed, there should be free access to it, and it should not interfere with the work process.

After you have decided on the design and type of shelf, selected the material of manufacture, stocked up with the necessary tools and materials, you can start working:

- First, a drawing of the future rack is created, which indicates the exact dimensions, joints, and appearance. Here you can either come up with a design on your own, or find a ready-made version on the Internet.

- Next, a place is prepared where the product will be installed. If it is a wall structure, check that the wall is flat. Remove all irregularities and minor defects from the surface. If the product will stand on the floor, check it for evenness and strength.

- Now we start making the components, cut out the shelves according to the drawing, make holes and grooves in them.

- The next step is to assemble the product. The most difficult process is the installation of the drawers. Here you need to correctly set the guides and make sure that the surfaces do not rub against each other.

After assembling the shelf, the finishing is carried out:

- Wooden surfaces are cleaned with a grinder or sandpaper, stained and painted with varnish or paint in several layers.

- In the presence of metal elements, they are treated with anti-corrosion compounds, primed and painted with water-based paint.

Applications of metal panels

Most often, perforated panels can be found in enterprises, retail premises, garages or workshops, but there are also non-standard options for the location of these products, for example, in the kitchen or children's room. In addition to tools, the panel can store kitchen utensils, hygiene items and even plates, and in the children's room - toys, various educational posters and other items.

It is important with such an arrangement of the panel to keep the brackets clean and safe, for example, in order to protect the child, you should not use hooks and other sharp brackets, it is better in this case to use a regular magnet in the form of numbers or letters

Trade racks

Trading racks and equipment do not require strict safety measures, so they are simply painted by the manufacturer in a certain color and allowed to work. The only condition for the safe operation of the specified product is that the paint and the metal itself are refractory and self-extinguishing. This is necessary to prevent the spread of fire in the event of a fire or poisoning of people with combustion products. In such rooms, the rack is not mounted on the walls, but is located on special racks in the sales area.

Sometimes you will find mobile panels for use outside the workspace. Such panels are equipped with special wheels, if necessary, they can be moved to the desired sector of the room along with the parts on them.These products are most often used in car service shops, since the area of such premises is significant and, in order not to waste time on trips to fetch the tool and back, the entire module moves into the working area.

Tool stand in the garage

A stand made of any material will become a convenient way to fix equipment on the wall in a garage box. The most important thing is to understand that it will not be possible to place heavy parts and tools on such a panel. But he's perfect suitable for storage small items that you want to have at hand at all times. Moreover, any of the owners of garage boxes from scrap materials can make a stand for keys in the garage with their own hands.

Now all stand designs are divided into the following types:

- Horizontal stands,

- Vertical panels,

- Inclined structures.

Standard vertical stands are recognized as the most convenient garage owners. With their help, you can provide a tool device on the wall in your personal garage right above the workbench and workplace.

Classification and purpose

The organizer is designed to conveniently store tools of a given size in one place and in a specific order, which provides quick access and maximum efficiency.

There are many variants of execution, the main of which are stationary and portable.

Stationary fixtures can be in the form of drill boxes built into the workbench or wall-mounted fixtures. Their advantage is a large storage volume, that is, you can arrange products of various diameters and types.

There are also portable options in the form of boxes, but more compact, cases, various holders. They are easy to transport, take up little space, but hold a limited amount of tools. Therefore, you need to plan in advance the types and volumes of work performed in order to take with you only the most necessary.

The most compact in the portable category are drill cases and cases. The first are folding products of the "book" type, made of soft polymers, leatherette or natural leather with stitched or glued inside pockets-holders. The diameter of the instruments in this case does not exceed 3 millimeters.

The second type of product is, as a rule, cylindrical containers that can accommodate 15 - 20 drills of various diameters.

For convenience, on the surface of both types, you can stick paper with the listed diameters and types of tools (for example, like this: 0.8; 1.3; 2.7; 3.2; 3.6 - for metal).

The best option is a box for prefabricated drills, where the grooves for the parts are cast and marked.

You can also purchase or make your own stand and drill box. How this is done is described below.

Homemade shelving in the garage

The tool rack is installed either in the workshop or in the garage. When placing the rack in the garage, it should be done above the roof of the car. As for the width of the shelves of the rack, they should accommodate a small box with tools (screwdrivers, wrenches, etc.), a plane, emery and other items.

When constructing a shelf, it should be borne in mind that it must withstand heavy loads. Since most of the instruments are quite heavy in weight. Therefore, the structure of the rack must contain metal reinforcement from the reinforcement.

The manufacturing process for such a shelf will look like this:

- All components are prepared first. Reinforcement is cut and evenly distributed along the entire length of the future hinged structure.

- A drill is selected according to the diameter of the pins, and holes are made in the wall.

- Further, the reinforcement is hammered into the wall and leveled in length.

- You will need metal corners to fix the shelves.

- Markings are made on the metal for welding along the edges of the protruding pins.

- Further, metal strips are welded under the boards and holes are drilled in them for fixing the boards.

- The final touch is the installation of tailored wooden shelves that are bolted to the metal.

After completing the assembly of the structure, it can be primed and painted in any color. This option for making a tool shelf is suitable for men who like to tinker with their hands.

Mobile

A mobile shelving unit in a garage or workshop is best made of metal. This structure must be installed on wheels, which will facilitate the movement of the shelf around the room.

Despite the mobility and ease of use of the mobile structure, it does not have a large carrying capacity. As a rule, such products are designed for a maximum weight of up to 100 kg.

For light tools, you can build a metal island rack with your own hands, which will consist of several shelves.

In conclusion, it is worth noting that you can make shelves racks in a garage or workshop with your own hands. To do this, you will need to select consumables, tools, make a competent drawing of the future rack and stock up on free time. As a result of diligence, you will get versatile, multifunctional, durable and reliable shelves for storing various tools.