Choosing a tool and working with it

When choosing a method for drilling concrete, it is worth choosing the right tool. A quality drill with a nozzle will drill the wall quickly and accurately. Not every tool is equally well suited for this purpose. A low quality concrete drill is time consuming and may not be up to the task at all.

A quality drill with a nozzle will drill the wall quickly and accurately

When choosing a tool, pay attention to:

the presence of a speed controller

It is important to be able to adjust the speed for accurate drilling. Working exclusively at maximum speed will result in reaming of a large hole and surface damage;

the ability to set the percussion mode of the drill

Useful for punching through thicker layers;

drill installation depth adjustment;

the presence of an auxiliary handle in the kit. A professional and powerful drill belongs to heavy power tools, it is better to have a built-in handle for two-handed operation;

satisfactory power indicators, so that it is convenient to drill concrete, brick and other materials, because the drill is a universal tool.

Choosing a tool and working with a drill are important procedures, otherwise the wear of materials increases and the wall collapses.

After selecting the best option for the drilling machine, it is important to decide which drill to drill the concrete wall with. In all stores there are nozzles with victorious tips for stone, they are optimally suited for concrete

Before starting work, it is better to get used to using the selected tool. It should be comfortable for both one-handed and two-handed use. One hand rests on the handle and the other on the detachable handle or side of the case.

Choosing a tool and working with a drill are important procedures

Any device of an electric type is vulnerable to temperature changes; it is recommended to wait until it warms up or cools down to room temperature before turning it on. With sudden changes, there is a risk of condensation. If there is no need for drilling temporarily, it is better to disconnect the power tool from the mains.

Drilling features

When using a drill, it is important to select the equipment and drill with the required technical parameters. It is recommended to use an electric device with a speed regulator and an additional shock mode

The use of the side handle speeds up drilling and reduces the burden on the operator, the drilling depth regulator will not be superfluous.

Drill device and drill installation

The drill uses an AC brushed electric motor. The design of the motor provides a speed controller, which is displayed on the power button. To reduce the speed and increase the torque, a gearbox is used, a tool with a 2-stage gearbox is found.

A cam chuck is attached to the output shaft of the gearbox; a latch chuck is used in rotary hammers. The perforator gearbox is equipped with a separate unit, which ensures the formation of the translational-rotational movement of the drill.

Before drilling the concrete surface, the drill must be secured. The tool is placed in the chuck, the cams ensure the alignment of the drill and the axis of the chuck. The drill is placed inside the chuck for the entire length of the shank; it is prohibited to lengthen the working part of the tool by pulling the shank out of the chuck. To tighten the chuck, use a wrench (included with the drill).

Power selection

To make holes in concrete surfaces, a tool with a power of at least 600 W is required. The rotational speed is selected depending on the diameter of the drill and the characteristics of the processed material. The employee independently selects the speed, reducing the emission of dust into the air and reducing the likelihood of chipping off wall fragments when drilling a hole.

Drill errors

The main mistakes when operating an electric drill:

- Do not hold the equipment by the chuck when working. Protective gloves and clothing must not sag or have loose parts, as there is a risk of material being wrapped around the rotating drill.

- Do not point the tool at an angle or apply excessive force as the worker may fall off a ladder or ladder and cause injury.

How to insert and remove a drill or drill

Rotary hammer models can be equipped with three types of cartridges:

- quick-clamping;

- cam;

- SDS systems.

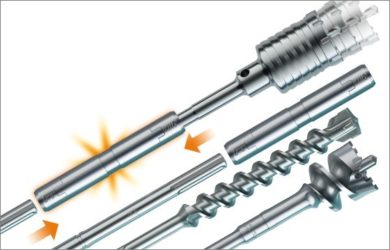

The vast majority of rotary hammer drills are equipped with an SDS system chuck, therefore, the operation of installing a drill is considered using this chuck as an example.

Drill installation

The SDS system chuck is a keyless chuck. A drill (drill) with a corresponding shank is installed in such a chuck in three steps:

- Pull down the chuck sleeve.

- Insert the cutting tool into the slot.

- Release the chuck sleeve.

The SDS mechanism is reliable, prevents the drill from falling out and saves time when changing drills. It is used for hammer drills for industrial and domestic purposes of low and medium power.

To work with drills with a conventional cylindrical shank, a special chuck with an SDS shank is required. Such a chuck adapter allows you to work with a hammer drill in electric drill mode with standard drills. However, drills with SDS shanks can be found commercially.

Jaw chuck with SDS shank for drilling with standard drills

Removing the drill

To remove the drill or drill from the SDS system chuck:

- Wait until the rotation of the chuck has stopped completely.

- Secure the lower sleeve of the chuck by hand.

- With the other hand, unscrew or pull off the upper sleeve.

- Get a drill or drill.

Drill for metal

There are also different types of tools for working with this material. But it is worth remembering such a nuance as the quality of the nozzle. It is determined quite simply: if the drill is of an inconspicuous gray hue, then it is made of low-quality materials. This will affect the period of use and the accuracy of the holes created.

The black nozzle is considered to be the highest quality and durable. The hue is acquired by steam processing at the end of production. The titanium nitride coated drill has a bright golden hue. It belongs to a more expensive category, but the period of use and its characteristics compensate for all costs.

Drills for metal for a hammer drill can be of different types. For example, spiral tools are used to drill holes in non-ferrous metals, cast iron and steel. Such borax can differ in their appearance and structure. They can be tapered or cylindrical, a little less often use hex drills. Tapered models are inserted directly into the machine, and cylindrical drills require an additional chuck.

Drilling concrete

Required tool

Due to the nature of concrete, you will need a special tool to drill it:

- Perforator (hammer drill) - provides rotary-translational movement of the drill.

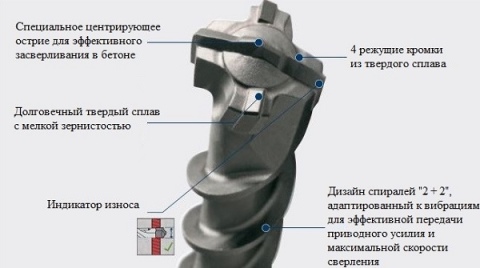

- Concrete drills for impact drills made of hard alloys. Their shank and screw part are made of tool steel, and the cutting working area is a carbide metal plate, sharpened at 60 degrees, which is soldered into the groove of the cutting part of the tool.

- Punch (needed when drilling with a conventional drill).

It must be said that it is possible to cope with the task at hand with a tool without a strike function. Below we will take a closer look at how to drill a concrete wall with a drill.

Solid Carbide Concrete Drill Bits

Drilling procedure with a hammer drill

The procedure for drilling a wall using a punch and a special drill is quite simple:

The concrete drill should be switched to hammer drilling mode and the operation should be started. The drill should be positioned strictly at a 90 degree angle to the wall, unless the drilling is specifically done at a certain angle.

Perforator

- After a while, the drill must be moistened in cold water and continue to work.

- If the tool rested on something solid and stopped going deep, then you will have to try to drill the wall in a different place.

- After the desired immersion depth has been reached, pull out the drill without turning off the drill. To clean the hole from dust, it is necessary to deepen and pull out the drill a few more times.

This completes the procedure.

Drilling with a drill

Many home craftsmen doubt whether it is possible to drill concrete with a drill? Of course, this procedure will take much longer than when working with a hammer drill, however, it is quite possible to make a hole.

To perform this operation, you will need a special punch. This tool is a bar with a pointed hard end. It is used to break the surface in the drilling area.

Punch

The instructions for doing this work are as follows:

- First of all, to the place where the future hole will be located, you need to attach a punch and hit it several times with a hammer.

- Then, a drill is inserted into the resulting funnel and a hole is drilled. As with the hammer drill, care must be taken to ensure that the tool does not overheat.

- If the drill stops deepening, you must again use the punch and insert it into the hole and hit it hard with a hammer several times.

- In this way, drilling is carried out until the desired hole depth is reached.

As a result, although an ordinary drill for concrete is not suitable, in the absence of a perforator, it can also be used to drill a reinforced concrete wall.

In the photo - working with a punch

Diamond drilling

Finally, we must talk about another effective drilling method that allows you to successfully make holes in the walls. With its help, you can quickly cope with the task and at the same time not dust the room. We are talking about diamond drilling. (See also Concrete Dusting: Features.)

This technology implies the use of special equipment, which is a set of the following elements:

- Electric motor;

- Rack, which is fixed to the base;

- Drill bits.

With this design, water is fed directly to the drill to cool the tool. Therefore, there is no need to interrupt the process. In addition, water washes away dust, so that it does not have time to get into the surrounding space. Often, such an installation includes a water vacuum cleaner that allows you to remove the mixture of water and dust from the surface.

Diamond drilling

Of course, it makes sense to use diamond drilling of holes in concrete only for industrial purposes, where it is necessary to make a large number of holes, especially of large diameter. For domestic purposes, the equipment is unlikely to come in handy.

In addition, the price of the kit, like any other professional tool, is quite high. Therefore, if it is necessary, for example, to fix a shelf on the wall, it is more expedient to use a puncher. (See also the article Concrete Putty: How to Make.)

Which ones to choose?

It all depends on the type of device with which you will use the existing drills.

- Cutters for conventional drills. The shank will be in the form of a simple cylinder or polyhedron.The drills are suitable for working with bricks or foam blocks. A drill with a high power is selected for the drilling process.

- Rotary hammer cutters usually have more solid dimensions. You will definitely find the SDS max mark on the drill body. Products of this kind are needed for drilling the most durable surfaces - reinforced concrete, for example.

You may not be able to drill a wall of concrete with an ordinary home drill. If you are not able to do this, just take another tool, for example, a hammer drill, because it has significant power and excellent impact force in any drilling. The hammer drill is often referred to as a concrete drill by many craftsmen. There are 3 types of this popular tool:

- auger - used to create the deepest and widest holes possible without any problems;

- in the form of a spiral - ideal for producing medium-sized holes;

- shallow - used in order to get small holes.

Qualitative use of this kind of drills for a hammer drill or professional hammer drill will require them to be firmly fixed in the device. To simplify this task, in the very design of the device there is a certain thickening at the very end.

The crown product can be of two types.

- Diamond. The drill is similar to a tube or bit, which is fixed on a rod and has diamond dusting along the edges.

- Pobeditovoe. The attachment is very similar to the one described above. The difference is that there is no sputtering, it is replaced by small victorious teeth.

When choosing a good drill for working on concrete, you should carefully examine it from all sides.

- The product must be free of defects, scratches, chips or bruises.

- The color of the product should be uniform, by this criterion you can determine the quality of the finishing. For example, steel color will mean that such processing has not been performed at all, black color will indicate that the product has been hardened with superheated steam. The yellow tone will indicate the excellent quality of the product, since it has clearly undergone a special treatment to reduce the stress of steel. But it is still better to purchase drills that are carefully covered with the thinnest layer of protection made of titanium nitride, then they will have a golden color.

- A large assortment of drills is represented by both foreign trade marks and our companies, their price will directly depend on the "promotion" of a particular brand. The difference in cost between products for a single use and a tool for professionals is quite significant, this applies to both the quality of the product and its characteristics.

- It is not very profitable to purchase ready-made kits, it is best to choose 1 good drill with suitable parameters. The cost will depend on the diameter, but not significantly. Sometimes a 0.8 cm rod that has undergone high-quality processing will cost more than a 1.2 cm punch drill bit, but from a Chinese company.

- Among the best foreign manufacturers, the brands Bosh and Metabo, as well as Stayer and Makita, are most often distinguished. Their cutters are well known for their increased reliability and long service life. Among our manufacturers, the products of the Zubr, Enkor and Interskol trademarks have proven themselves in the best way.

Surface preparation

If you need to quickly make a deep hole in the wall, you should first make sure that there is no wiring in the place where you will start drilling, there are no built-in pipes (for example, heating) or an electric cable. The easiest way to quickly detect such elements in the walls is to use a conventional metal detector (call a specialist with this device at home). There are almost always fittings in the walls of residential buildings, so you will need to install the device to search for non-ferrous metals (wiring), and then to steel.If you do not take this condition into account, you run the risk of stumbling into the reinforcement when drilling, and then the drill from the win will be damaged.

Before starting drilling, a point is put on the wall. To prevent the tool from sliding, a small depression is made with any durable metal object or the drill itself at low speeds. After this procedure, the drill will easily enter the wall. It should be borne in mind that a facing material is usually installed on top of the cement, it is much softer than the walls themselves, and therefore at first the drill will go easily, and then suddenly it will rest against a harder material.

Types of attachments

Construction work on the processing of concrete slabs or walls is carried out, as a rule, using a perforator, which is often called a drill by craftsmen. This multifunctional tool is sold fully equipped with attachments. Their sizes vary. The main drill bits include a chisel, drill, bit, diamond drill and lance. The longest drill bit available.

The drill is characterized by a spiral shape and is used to drill cylindrical holes. The chisel allows for dismantling, it removes old tiles, plaster and other finishes. The pike has a large diameter and, unlike a drill, is capable of quickly punching holes in concrete floors. The channel drill is designed to create grooves in concrete during the installation of communication systems. The crown is used when it is necessary to drill holes of a certain diameter for switches and sockets.

Boer

This type of attachment differs from conventional drills in that it has the shape of a "tail". Drills are classified as disposable tools, since after long-term use they are practically not subject to renewal and sharpening. The main advantage of the drill is that it is able to clean concrete chips from the holes when drilling. It is recommended to choose this nozzle for drilling deep holes; for drilling through and blind holes in concrete, a drill with a diameter of 6 to 32 mm is suitable.

Drill

When choosing drills, it is important to look at their “tail”. This is due to the fact that the design of the chuck and the apparatus often does not correspond to the tail of the drill.

The Speed X SDS-max drills work well on concrete surfaces. They are durable, equipped with additional cutting elements and guarantee fast drilling. Most drills also have special channels for removing dust, they are located in the head of the bit, provide accurate direction of shock waves and evenly distribute the impact force.

To quickly and efficiently drill concrete, use drills with a diameter of 12 to 52 mm. Their length is different and ranges from 200 to 1200 mm. The choice of this or that drill size depends on the complexity of the work and the depth of the holes. The main feature of the drills is that their spiral part is placed at a certain angle. Thanks to this, the nozzles quickly form holes and remove waste material from them.

Chisel

This tool can have various forms and purposes. The pointed chisel looks like a pyramid with a sharp end or a cone. They dismantle the old finish and punch holes in the concrete floors. The spatula chisel has a curved shape and resembles a screwdriver, only its cutting edge is thin and wide. It is recommended to use it before drilling holes, as the chisel cleans the surface of old concrete layers.

There is also a flat chisel, it differs from the previous types with a pointed tip. A flat chisel is considered the most common in construction work; its cutting edge can be from 1 to 4 cm in size. Moreover, the smaller it is, the more effort will have to be made when drilling. To punch channels in a concrete wall, chisels of a special shape are used, which are called a strober.This nozzle is equipped with special wings, they rest on the surface and allow you to adjust the depth of the hole when drilling.

Milling cutter

It is a special type of nozzle, with the help of which you can easily make a hole of any complexity and size, including for socket outlets. If work is carried out on reinforced concrete, then you need to purchase cutters with a diameter of 68 mm

However, it is important to consider the surface density and the desired hole depth while drilling. For large and deep holes, cutters with a diameter of 100 to 150 mm are often used.

Recommendations

When working with a puncher, it is important to take into account certain rules. When drilling concrete, experts recommend using a coolant or special lubricant

Before starting work with a long drill, it is advisable to work with a shorter drill. Often the concrete surface has a loose structure, therefore, in order to prevent it from crumbling, processing is recommended in the "drilling" mode. At the end of the work, the tail of the drill must be cleaned of dust, for this it is wiped dry with a soft cloth and lubricated with machine oil or grease.

To prolong the life of the rock drill, it must be used according to the instructions provided by the manufacturer. In addition, regardless of the amount of work, you should take short breaks to cool the case. If the gearbox overheats, the device will quickly fail. The cooling device must not be immersed in water. Increased pressure on the concrete being processed is also not allowed, this will help increase the impact force of the device, but can lead to quick breakage of the nozzles.

In the next video, you will find tips for using the punch.

Let’s block ads! (Why?)

Useful tips for working with a concrete drill

It is important not only to choose the right device for creating holes in concrete surfaces, but also to have an idea of how to use it.

- Even before drilling, it is advisable to prepare a set of drills that will differ in their performance characteristics. You need to know that for an effective solution to a particular task, you should use concrete drills for a drill or hammer drill for a specific purpose. Thus, in the arsenal of a home craftsman, there must be drills for working with concrete, ceramics, stone and other hard materials. However, a situation is possible when, at the beginning of drilling, the owner is forced to stop working due to the fact that the drill has reached the metal reinforcement. To cope with this obstacle, it is necessary to change the concrete fixture with a metal drill at this stage of the work. With its help, a hole is created in the reinforcement, and then they continue to drill the hole with a drill again. At the same time, individual craftsmen approaches to solving this problem a little differently: they simply perform a special sharpening of the drill, which allows using it to work not only with concrete, but also with metal. However, this can only be done by those who have sufficient experience and special skills.

- Do not overheat the drill when creating a hole in the concrete surface. To do this, it is necessary to take a break every 15 seconds of continuous drilling. The drill must be cooled naturally. In this case, the use of water or other liquid is considered unacceptable.

- There are situations when, entering the thickness of the concrete surface, the drilling device collides with an obstacle in the form of a hard stone, which it cannot cope with. To eliminate it, it is advisable to have a bumper available. With its help, you can crush a stone, and then again continue to work with a concrete drill.

- Sometimes it happens that you have to create a hole in a load-bearing wall or ceiling. It is undesirable to work here with a hammer drill; it is best to change it to a hammer drill.If you neglect this advice, then it will not lead to anything good, because, despite the efforts and the time spent, you will not be able to create a hole in this structure.

- When working with ceramics, a concrete product should be used. In this case, you must turn off the hammer drill mode. Otherwise, there is a risk that the tiles will crack.

- If during operation the drilling device is dull, then a grinder is used in combination with a diamond disc to return it to its performance. However, you can initially avoid such situations if you prepare a high quality expensive tool.

Preparing the tool for work

Correct use of the rotary hammer requires strict adherence to the instructions and instructions for use. Violation of these rules will lead to an early breakdown of the tool without the possibility of repair.

The most common mistakes when working with a puncher:

- exceeding the permissible load on the tool;

- long-term continuous operation, in which the elements of the drive and gearbox overheat and may fail;

- neglect of the requirements and terms of maintenance of the tool;

- violation of lubrication regimes, the use of low-quality lubricants;

- performance of work not provided for in the operating manual.

Before starting work, the tool should be inspected. It is necessary to make sure that it is complete, in the absence of mechanical damage to the body of the tool and the chuck. Check the integrity of the insulating layer of the mains cable. Make sure that the working tool (drills, drills, crowns) has no cracks or chips, the cutting edges are sharply sharpened.

After that, a test switch-on and idle operation should be performed. It is imperative to check the functionality of the buttons and toggle switches for controlling the speed and direction of rotation of the cartridge.

To work safely with a hammer drill, you will need personal protective equipment:

- transparent glasses;

- gloves;

- closed shoes;

- overalls;

- headphones or earplugs.

Personal safety rules cannot be neglected when working with such a powerful power tool. Shards of solid material and dust can be harmful to health.