disadvantages

Due to the fact that the perforators of the Kuibyshev brand belong to the budget price segment, most models are not equipped with a rotational speed switch, which reduces their versatility. A noticeable drawback of the tool is the need for strict adherence to the operating modes recommended by the manufacturer. Long-term use of hammer drills without pauses (on average, about 10 shallow holes in a row) leads to noticeable overheating of the body in the area of attachment of the side handle.

Finally, a common problem with this tool is the relatively poor quality of the plastic used to make the body. Overheating of the product is often accompanied by an unpleasant odor, and with prolonged operation in shock mode, cracks and chips may appear on the case.

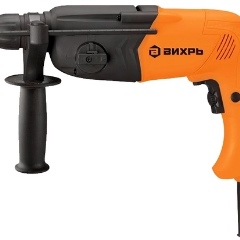

Features and models

As of the current year, the company supplies the Russian market with 7 basic models of rock drills, differing in power consumption and impact energy.

An important feature of all models is the use of the SDS fastening system, developed by the famous Bosch company. For all models, except for P-1200K-M, where the SDS-max mount is used, the SDS-plus system is characteristic

Also, all perforators of the company are distinguished by the presence of two handles, one of which is stationary, and the other can rotate in a range of up to 360 degrees. Let's consider the assortment of TM "Whirlwind" in more detail.

- "P-650K" - the least powerful and the most budgetary perforator of the company. With a power of only 650 W, this tool develops a blow rate of up to 3900 bpm with an energy of 2.6 J, and a spindle speed of up to 1000 rpm. These parameters allow him to drill holes in concrete with a diameter of up to 24 mm.

- "P-800K" has a power of 800 W, which allows it to develop a frequency of impacts up to 5200 bpm with an energy of one blow of 3.2 J. But the speed in the drilling mode for this model is not too much higher than the previous one and is 1100 rpm min. The maximum drilling diameter in concrete is 26 mm.

- "P-800K-V" differs from the previous model in more compact dimensions, ergonomic handle-guard (which significantly increases its convenience and safety) and increased impact energy up to 3.8 J.

- "P-900K". Structurally, this model hardly differs from the "P-800K". The increase in power consumption to 900 W allowed the impact force to be increased to 4 J at the same rotation speeds and impact frequency. Such a powerful impact allows this model to be used for making holes in concrete with a diameter of up to 30 mm.

- "P-1000K". A further increase in power to 1 kW allows this device to develop an impact energy of 5 J. The spindle speed for this model does not differ from the previous ones, but the impact frequency is even slightly lower - only 4900 beats / min.

- "P-1200K-M". Despite the significant power (1.2 kW) and ergonomic design, it is not very efficient to use this model in drilling mode, because the speed in this mode is only 472 rpm. But the impact force of this model is 11 J, which makes it possible to make holes in concrete with a diameter of up to 40 mm.

- "P-1400K-V". Like its predecessor, this powerful rock drill is designed for construction use only and not for household drilling in relatively soft materials. With a power of 1.4 kW, its impact force is 5 J, the impact frequency reaches 3900 beats / min, and the drilling speed is 800 rpm.

Usage Tips

To avoid overheating of the tool structure, pause during drilling, and also periodically transfer it from impact and combined modes to drilling without impact. Failure to comply with this rule is fraught with breakdown.

Before inserting the drill into the hammer drill, be sure to inspect it. The presence of noticeable deformations and damage can lead to breakage of the drill during operation, which can lead to serious injury.Loss of sharpening also leads to negative consequences, in particular - to increased wear of the used rock drill. Therefore, use only drills that are in good technical condition.