How to choose?

When choosing nitrile gloves, it is important to understand what tasks are set for this personal protective equipment.

In addition, the following should be considered when selecting.

- Size range. This point is especially important where one-piece nitrile gloves are used - in medicine, cosmetology, in chemical production. The product should fit snugly around the hand, not fall off it. The cuff area of properly fitted gloves always covers the wrist.

- Brand. Medical and cosmetic nitrile gloves of good quality are produced by large companies such as Sempercare, Benovy, NitriMax. Household ones can be found at Freken Bock, workers at Ansell, Kraftool Expert. The Euronda brand focuses its products on the chemical industry, HoReCa - on restaurants and the service sector.

- Type of. Poured gloves with a cotton or nylon base are the most comfortable for long-term work. It is better to choose models with a high knit density, then the products will not stretch too quickly. Products with leggings are needed if you want to protect the skin as much as possible from contact with an aggressive environment. Medical and cosmetic products are sterile, must have disposable packaging, such requirements do not apply to household items, they are most often suitable for repeated use.

- Coating thickness. Two-layer nitrile gloves in a douche design really effectively protect hands from contact with oil products and other chemically aggressive liquids. But the thicker the polymer layer, the less flexible the products will be, the worse the tactile sensitivity. For small jobs, it is better to choose single-layer nylon-based products. In cosmetology, mainly powder-free options are used, rather thin, but durable.

Given these points, you can choose the right nitrile gloves for household work, medical work, industrial production.

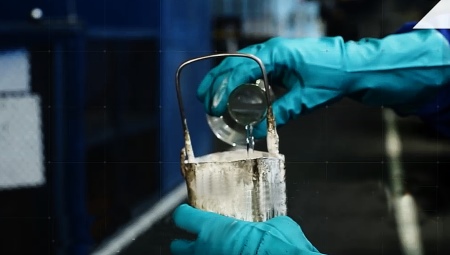

The following video introduces the fun process of making nitrile coated gloves.

Advantages and disadvantages

Nitrile gloves have their own list of obvious benefits. The pluses include such characteristics.

- Lack of potential allergens in the composition. Unlike natural rubber, artificial rubber is completely safe.

- Increased safety margin. The nitrile coated surface of the glove better withstands mechanical friction, contact with cutting or piercing objects.

- Good contact with various types of surfaces.

- Wide operating temperature range. They range from -40 to +130 degrees.

- High protective properties. Nitrile does not come into contact with phenols, alcohols, animal fats, aldehydes, oils, petroleum products and other potentially hazardous substances.

The disadvantage of such gloves is low elasticity.

What is it and what is it for?

The use of protective equipment in production and in other areas of activity is of great importance. Gloves with a nitrile coating are made on the basis of synthetic rubber, which completely repeats the properties of its natural counterpart. This material is hypoallergenic, highly chemical resistant and durable.

Nitrile products are made from a mixture of 2 components: acronitrile and butadiene. The compound undergoes a polymerization process, turning into a cast material - it is from such a base that gloves are formed. Their use is due to the properties of the material.This type of work accessories can be disposable or reusable, it is used in medicine (when examining patients), in the food industry, in cosmetology, when cleaning, at production and construction sites.

Views

All nitrile gloves are usually divided into types according to their design features. Medical products are always whole, do not require special dusting with corn starch. In cosmetology, in food production, nitrile gloves are also used, most often disposable. Products in black with a textured finish are used in tattoo parlors, allowing you to securely hold tools in your hands.

There are reusable all-polymer nitrile gloves. They have high mechanical strength, withstand heating up to 130 degrees, and have antistatic and dielectric properties. Such products are in demand in the chemical industry.

Powdered and powder-free nitrile gloves differ in their ease of donning. In the first case, corn starch is used internally, which prevents the layers of material from sticking together. Powder-free products are used where the ingress of foreign substances is undesirable. They are also chosen by people who are allergic to this starch. Powder-free gloves are coated with polyurethane for easier use inside.

Nylon garments with nitrile-doused fingers and palms are reusable and washable. They stretch well, especially if the polymer coating is partially applied. This is a convenient option for work equipment for builders, installers. They are often used in garages and tire shops because of the high durability of the gloves combined with their high grip.

Knitted work gloves are also doused, but the coverage area on them varies. It can be just the palm and the inside of the fingers, or the entire hand. In addition, for industrial purposes, working with petroleum products, oils, chemical reagents, nitrile one-piece gloves are produced, on which the cuffs of the leggings have a solid structure. The inner part of the product is knitted, cotton.