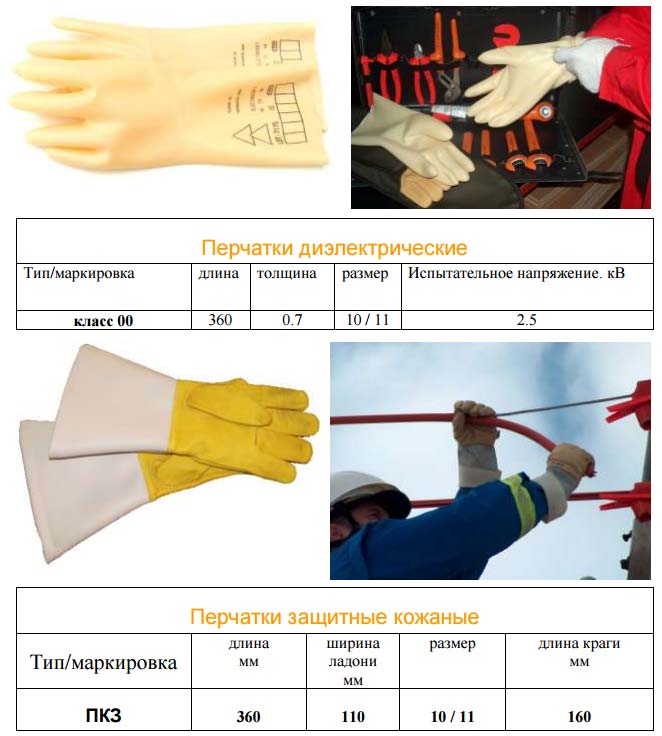

Length of dielectric gloves according to GOST

It is worth remembering that any dielectric medium must be monitored periodically. Electrician gloves are made most often from the following materials - rubber and latex. In some installations, gloves with a special mark “Ev

"Made in accordance with GOST. This sample allows you to work under a voltage of more than 1000 V. What should be the dimensions of the gloves and what is their length?

Also, the dimensions of the gloves depend on the type of purpose:

- For sophisticated work;

- Regular;

- For tough jobs.

In terms of wall thickness, for hard (rough) work, there should not be an excess of 0.9 cm, and for thin - 0.4 cm. Ideally, they should be easily put on over outerwear (sleeves). The minimum permissible length has been set - at least 35 cm.

Service life and features of use

Before the very beginning of electrical work of all types, it is necessary to carefully inspect the protective equipment for any mechanical damage: cracks, punctures.

Inspection of gloves for electrical work for breaks and punctures should be carried out not only before starting work, it has a frequency determined by standards - in particular, it is carried out during regular tests. At the same time, it is not difficult to determine the presence of damage - for this they just need to be filled with water or twisted in the direction of the fingers, most of the defects are immediately striking.

During work and operation, it is strictly not allowed to roll up the edge of the gloves - this requirement will help protect the skin from injury.

Additionally, you can put on top of the gloves any other products made of tarpaulin or leather.

Seamless gloves

Thanks to their design, seamless dielectric gloves allow you to work in more dangerous situations, because they are made of rubber that is strong enough and simply cannot be poured so that there are no seams left. Again, no one is interested in design in this situation, and the main task is to protect the fingers and palms of the worker from electric shock, they cope with this task very well.

This version of gloves is in great demand due to its reliability and strength of the design, since the thickness of the rubber here is really decent and this allows you to work even in those locations and situations where other types of protection do not withstand or are simply not allowed for use.

There were no particular flaws, these gloves are heavier, but the difference is not so great that you feel an extra gram in the design. There are many more advantages here.

How to use protective gloves correctly

When using dielectric gloves, you must act in accordance with the rules of use:

Before purchasing gloves and before starting work, be sure to pay attention to the expiration date.

Only dry products can be used.

It is necessary to carry out a visual inspection and determine if there are any cuts, dirt, punctures on them.

To test the tightness, the gloves must be filled with air.

Check for the presence of a dielectric gloves verification stamp;

They must be worn to the full depth, the edge of the gloves must be worn over the sleeve of the workwear. Do not wrap the hem of the gloves!

To protect products from mechanical stress, you can wear gloves made of leather or tarpaulin over them.

Do not clean gloves with gasoline, acid solution or alkali

For this purpose, you can only use water, soap or soda.

Storage rules are not allowed to store products near open fire, heating appliances. The storage temperature should be from 0 to +25 degrees. WITH.

Important! Danger to life to use expired dielectric gloves!

The material from which the gloves are made can dry out and become brittle. As a result, the level of protection of the gloves will be significantly reduced. Fragile material can collapse at the wrong time.

How to check the strength?

Since dielectric gloves are an important element in protecting a person from injury and sometimes death, regular checking of their quality is one of the most important safety factors. Even an imperceptible puncture, a tiny defect, can cost a human life. It is checked by simply twisting the glove towards the fingers - any damage becomes noticeable.

They check the protection for the presence of moisture or dirt - in this case, the products become electrically conductive, useless as a security tool.

Safety requires laboratory testing of dielectric protectors every 6 months. There is an approved test where personal protective equipment is tested with a high voltage of 6 kV for one minute. High-quality PPE pass no more than 6 mA, otherwise they are subject to write-off.

- The gloves are immersed in a tank of water so that the edges protrude 0.5 cm above the surface. The gloves are filled with water, the protruding edges must be dry.

- There is an electrode inside the glove, it is connected to ground using a milliammeter. In this way, it is known whether the glove is passing current.

- From the transformer, the current flows through a wire connected to the water tank.

Such a check allows you to accurately determine the marriage: gloves are rejected not only if an excessive amount of current is passed, but also when the milliammeter needle vibrates. The date of the next test is marked on the product and recorded in the logbook. Protective rubber products can only be dried at room temperature, without subjecting them to additional heating.

Peculiarities

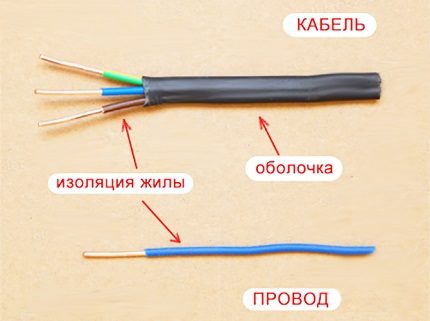

Dielectric seamless gloves are part of the electrical equipment. They are used when working with electrical appliances and electrical cables. Protective equipment is needed when you need:

- disconnect / connect a pantograph with a voltage of more than 800 V;

- replace the high voltage fuse;

- replace the lighting device;

- disconnect the terminals of the transformer;

- work with a reversible valve element.

Dielectric seamless gloves make the work of electricians who maintain electrical installations, power lines, and electrical equipment safe.

If they are sized to fit, they retain their full user experience.

These PPE are subject to the developed safety requirements. Gloves made by the method of seamless casting are comfortable to work with. They are used by professionals, performing work of different levels of complexity. The range of products is small, however, the choice requires special care. The slightest mistake can result in injury due to electric shock.

Dielectric gloves are tested twice a year. The tests are carried out in a laboratory under special conditions. At the same time, special containers with liquid are used, immersing gloves in them so that the water is not only outside, but also inside. Moreover, the straightened upper edge of each pair should not be immersed in water by at least 5 mm. Within one minute, a voltage of 6 kV is applied.

In this case, the leakage current should not exceed 6 mA.After the test, the gloves are dried in a special chamber, then they are stamped with the indication of the period of use until the next check. On average, the cost of testing one pair can be 195 rubles, provided that it is carried out within 5 days. If you wish, you can check the pair in 1 day by paying 295 rubles.

Test Principles for Dielectric Gloves

When using rubber dielectric gloves, it is necessary to follow the rules of operation, and before that it is necessary to carry out a certain test on them: place the gloves in a bath of water, filling them with water from the inside.

Voltage should be applied between the body of the bath and the electrode immersed in the water. If a breakdown occurs, the gloves are discarded. Gloves can also be tested in the laboratory. After verification, write off all data to the protocol. The bot can be checked in the same way.

This type of verification has its advantages, the main of which are:

- High precision due to electronic equipment.

- A developed interlocking scheme that will secure electrical tests.

- The presence of a regulator to control the tests.

This product is a must-have when working with electricity to protect against step voltages. They are worn on ordinary clean and dry shoes, in addition, they must be at least 160 mm long, consist of a rubber upper and a grooved sole, inside which there must be a textile lining, and reinforcing parts must be located inside the bot.

Check before use

Dielectric gloves are tested according to the following criteria:

- The presence of a stamp (date of testing and expiration date).

- Mechanical damage.

- Humidity.

- Dirty gloves.

- No punctures or cracks.

The expiration date of the gloves is determined after a preliminary test. If they pass the test, then they put a stamp on which the date of the next test should be indicated.

Gloves should be inspected for external damage, they should not be. If there are any, then the gloves must be replaced without fail.

Dielectric gloves must be clean and there must be no moisture on their surface, this is unacceptable!

If there is visible contamination, they should be washed and dried before use. In the room where gloves are dried, the temperature should be room temperature.

Many punctures or cracks in the eye cannot be seen. To identify such damage, the following steps should be taken: put the glove on a flat surface, and then twist it towards your fingers. If it is damaged, then air will be released from the holes.

- In order to protect gloves, it is allowed to wear gloves over them, which can be either canvas or leather.

- It is strictly forbidden to wrap the edges of the gloves, as the safety of the worker is impaired.

- Before use, it is allowed to disinfect gloves, it can be either soap or soda solution. But after that, you should dry them well so that no moisture remains on them.

- The entire check should be done by yourself and just before putting on gloves. Do not entrust this procedure to someone else.

- Last but not least, do not ignore safety regulations. Dielectric gloves are used to protect workers' hands and fingers from electric shock.

Quality check

If you do not know how to test dielectric gloves, then there is a whole instruction and special mechanisms working exclusively for this task. Naturally, at the factory itself, where the device is manufactured, testing and detailed inspection of the product is carried out, only after verification can the protective equipment be sent for sale.

But, as I said earlier, even with a service life of one year, gloves must be checked for suitability for work twice a year, only in this case the employee has the right to use a protective device and work with tension. The requirement is quite logical, because the work is carried out with such stress that a faulty glove can become a very serious problem for the worker's health.

To test protective gloves, special equipment is used - a volumetric tank with water, into which gloves are immersed approximately half the length. Inside each glove is a sensor that detects voltage. Voltage is applied to the water in the tank and it is checked if there are any vibrations inside the glove.

If they are present, then it is immediately handed over to the scrap, since these products cannot be repaired or upgraded. It seems to be nothing complicated, but such an installation is quite expensive and is not available at all enterprises.

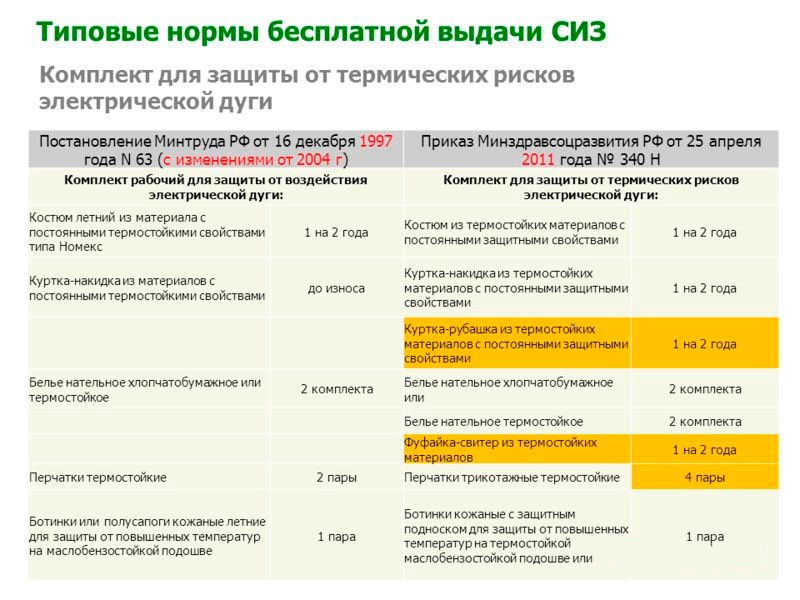

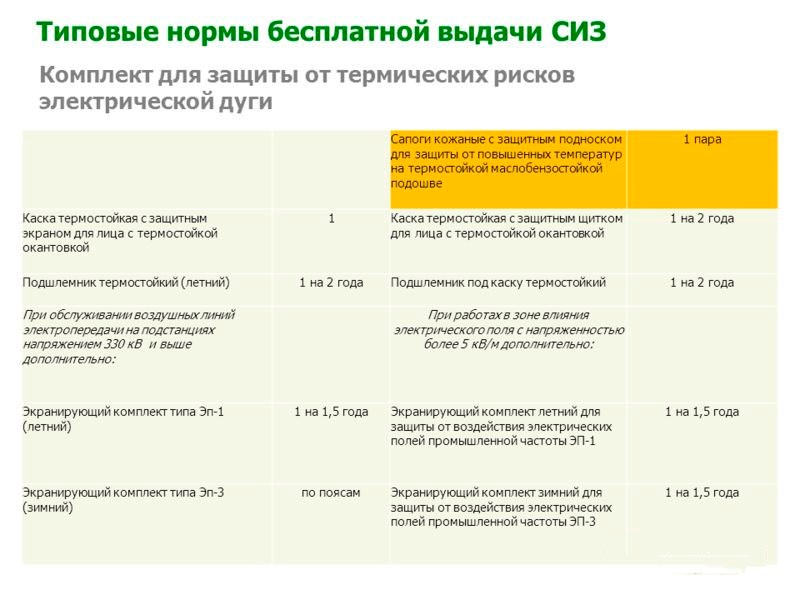

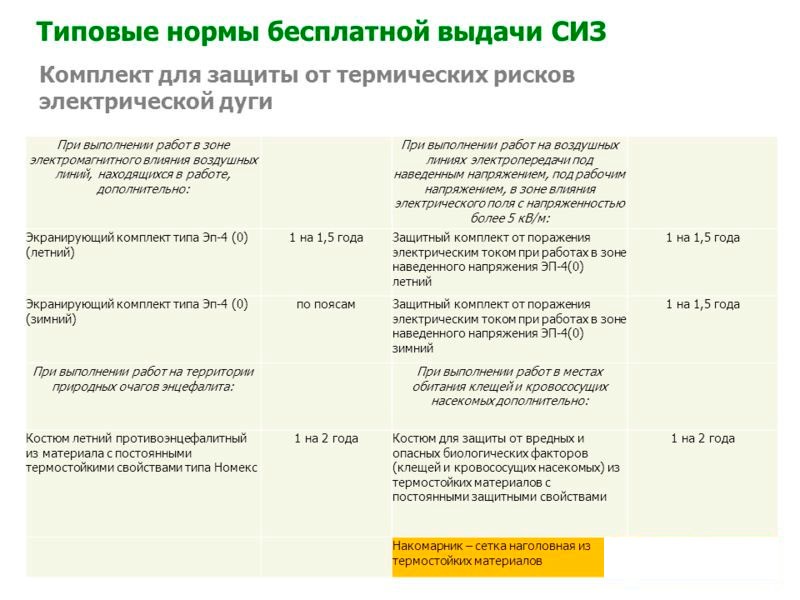

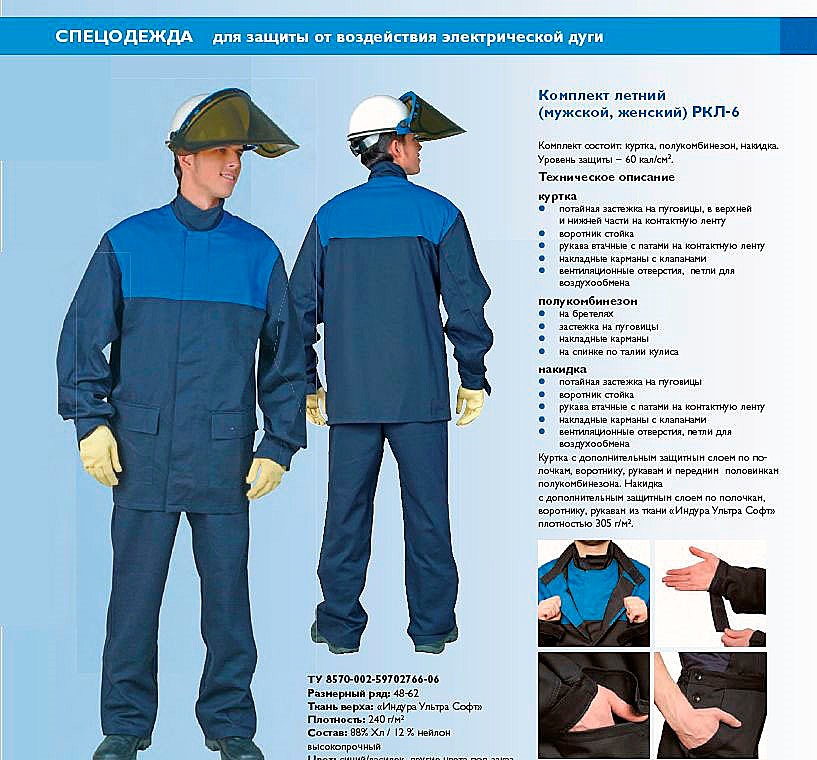

Protective equipment against electrical fields

To protect the worker from electric fields, shielding devices or a set of personal equipment are used.

Important! If a person enters the zone of influence of electric fields, then he must apply the main protective equipment regardless of the available voltage or the number of volts. The shielding device is designed to reduce the voltage of electric fields to an acceptable level

After that, the employee will be able to stay in a specific area without risk to health. Allowable indicator - no more than 5 kV / m

The shielding device is designed to reduce the voltage of electric fields to an acceptable level. After that, the employee will be able to stay in a specific area without risk to health. The permissible indicator is no more than 5 kV / m.

Important! Each shielding device must be grounded. All shielding devices must also have a connection to the various mechanisms on which they will be installed.

If the electric machines themselves are grounded, then this element can not be used on PPE when working in electrical installations

All shielding devices must also have a connection to the various mechanisms on which they will be installed. If the electric machines themselves are grounded, then this element may not be used on PPE when working in electrical installations.

The personal protection kit is divided into several types:

- for operation at ground potential, if the electric field voltage is no more than 60 kV / m;

- for working on the potential of live parts with possible touching them.

An electrician is a dangerous profession, and therefore you need to take care of your health. To do this, you need to get special equipment that will protect a person from electric shock. It is also advisable to know exactly which PPE is used by workers serving electrical installations in order to control the issuance of the correct form. If an employee notices that any part of a protective suit is damaged, he should demand that he be given a new kit, as his life may depend on this.