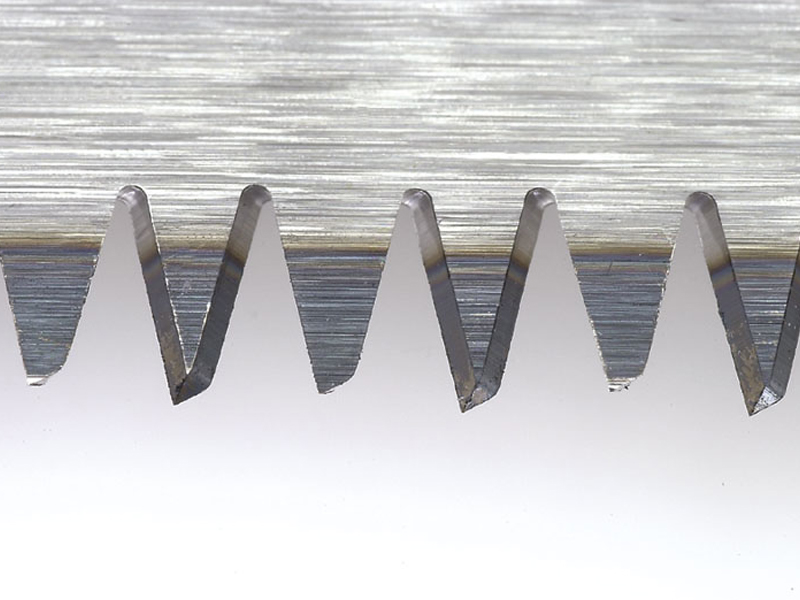

Sharpening teeth

These tools provide a standard triangular sharpening shape. It looks like a triangle with sharp angles and equal hips. Such a blade is used for cutting along and across, which, in turn, avoids coarse notches at the cutting site.

But it is worth noting that today there are more modern tools on sale. They have a significant difference from the classic ones, since they have hardened teeth, presented in the form of a trapezoid. The presented saws are much stronger and more durable, but the teeth of such a saw cannot be sharpened.

Possible malfunctions

Cut-off saws are famous for their high quality and reliability, therefore, in most cases, breakdown is caused either by improper operation, or by an illiterate selection of additional elements. Such tools have enough power, so you should use them correctly and choose the accompanying parts wisely.

Among the main malfunctions that can be observed with a cut-off saw, the following can be distinguished.

- Does not turn on or works intermittently. The problem is most likely a broken wire. Such a failure is eliminated very quickly by replacing the old wire with a new one.

- The saw sparks and smokes. This happens due to problems with the power unit, and it can be solved by replacing the motor bearings.

- The disc does not rotate well or does not rotate at all. The reason is the wear of the belt drive.

Thus, the metal cut-off saw is a unique device for processing this material. Products from many manufacturers are launched on the market, which are of high quality and reliability. This allows metal processing to be carried out at high speed and maximum safety.

The main thing is to choose equipment based on the tasks at hand. A review of the main manufacturers shows that it is the right choice that guarantees the longevity of the devices.

An overview of the Makita 2414NB metal cut-off saw, see the video below.

What is the principle of the device

Circular saws are not just hand-held power tools. They work with them on wood, sawn plastic or soft metal. Before it goes on sale, the tool is checked by the manufacturer's expert, and when it gets into the trade, companies monitor the sale of the product according to user reviews. Based on the results of research and a combination of both positive and negative indicators, a rating is drawn up, where the winner is the product most demanded by buyers and the general opinion.

According to the structural composition of the saws, which the society calls circulars, they consist of parts:

- hulls;

- engine;

- support handle;

- upper and lower protective casing;

- saw blade;

- support platform - the disk is held there;

- riving knife;

- angle regulating devices;

- toggle switch.

This is how the diagram of the main parts of the saw visually looks.

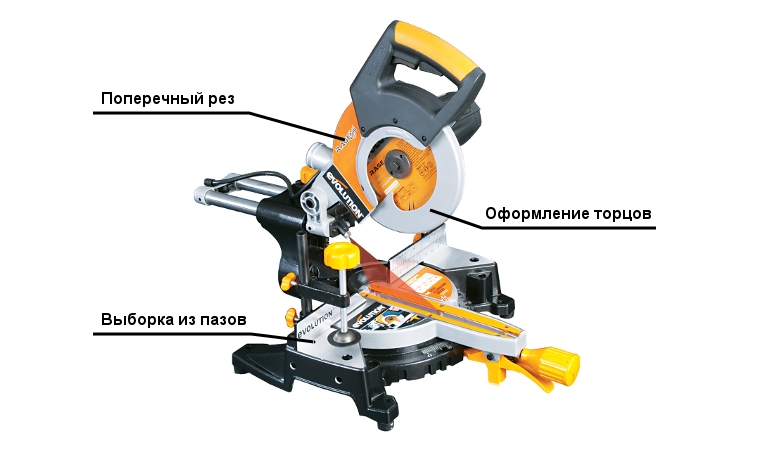

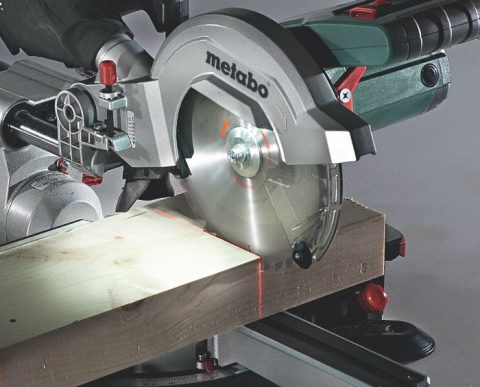

Circular saws should not be confused with miter saws, which cut material in a given angle direction.

Circulars are used to quickly cut a part in a straight line. The worker holds the device, directs the cutting along a conventional line, where the quality of the work done depends on the skills of the master. In the device, the shaft of the engine moves, which rotates the saw blade, and that, in turn, cuts the installed element.

One of the best devices from BOSCH

BOSCH

GKS 190 has been given the abbreviation for circular saw by the world famous manufacturer BOSCH.

If we consider the price for such devices in the range from 8,000 to 10,000 rubles, then this is the best model in this category.

The tool turns work into pleasure thanks to:

- deep cuts that provide the power of the device;

- even and clean cuts;

- reliability;

- convenience;

- long and strong power cord.

For some reason, the developers missed a smooth start, there is no fixation of an arbitrary angle. These disadvantages are compensated by the totality of the advantages of the electrical appliance, as well as:

- functions of constant and control electronics, which keep the speed at high loads or allow you to select their number;

- guide bar, it provides a precise cut.

When starting work for a minute, we must not forget about safety.

The instructions attached to the device contain the main points on precautionary measures.

Operating rules

Despite the fact that modern saws are characterized by a high degree of safety, in the process of using them you need to be extremely careful. Failure to do so may result in problems with device performance or operator safety.

Among the basic safety standards that should be adhered to when operating a metal cut-off saw, the following can be noted.

Before using it, it is imperative that you familiarize yourself with the instructions and safe work techniques. Failure to follow the manufacturer's instructions may result in serious injury.

If you do not have the skills to work with the tool, we recommend that you get the advice of a specialist or master.

Before starting work, you should definitely check the workplace for unnecessary items. In addition, you do not need to work alone: it is best to get an assistant who can provide first aid if necessary.

Visual inspection. Before each use of the saw, an external inspection must be carried out to ensure that there is no major damage.

In this case, close attention should be paid to the reliability of the fastening of the disk and other assemblies, as well as the fastening handle. A defective tool should never be used as this could cause injury.

electrical safety

Do not use such equipment outdoors or touch the tool with wet hands. If using an electric saw, make sure that it is double insulated.

It is worth remembering, however, that this kind of isolation is not a reason not to follow the usual precautions. That is why you need to be extremely careful when adjusting the speed of the collector motor.

Integrity of the structure

In order for the device to fully perform its functions and be safe for use, its configuration or design must not be changed. If some part is out of order, then you do not need to make changes yourself using homemade tables and other elements.

Peculiarities

In the process of processing metal materials, it is very often necessary to cut various workpieces to the desired size. Among the most popular materials, one can single out profile pipes, steel corners, etc. Of course, you can use a grinder for these purposes, however, an assembly saw is considered a more optimal solution, since it allows you to achieve a better result.

Among the features of such a saw, one can single out its safety and ease of use. The main advantage of the metal cut-off saw is that it has been specially designed for cutting metal blades. The rotation speed is selected in such a way as to ensure maximum safety during operation.

Replacing discs is also much easier than with grinders, using a socket wrench.

Machines that can provide a size of 50-65 mm are very popular today.Due to their small mass, such tools do not require physical effort.

That is why you should be extremely careful when choosing a particular cut-off saw so that it can fully cope with its tasks.

Popular manufacturers of saws for wood

If you focus on the reviews of specialists that can be found on specialized forums, then you can choose a high-quality and reliable tool for home and summer cottages if you first of all pay attention to:

- the reputation of the manufacturer;

- the price of the tool.

It is not worth buying cheap Chinese equipment for the sake of economy, because, in addition to the fact that it cannot provide a high quality of work, in some cases it can create dangerous situations for the user. It is most reasonable to purchase circular saws from well-known brands - Makita, Bosch and others. Although they are more expensive than their Chinese counterparts, their specifications are fully consistent with the manufacturer's price.

Saws Interskol

Over the years that Interskol has been selling circular saws to the Russian market, Interskol has built a reputation for being reliable and easy-to-use wood sawing equipment. The equipment produced under the Interskol brand is very popular in our country and abroad. First of all, consumers are attracted by the low price of this equipment, which can be purchased for 3000 rubles. Circular saws for wood from Interskol have many useful advantages. Long service life, ergonomics, as well as high quality of operations performed with these saws are relevant for buyers.

Over the years that Interskol has been selling circular saws to the Russian market, Interskol has built a reputation for being reliable and easy-to-use wood sawing equipment. The equipment produced under the Interskol brand is very popular in our country and abroad. First of all, consumers are attracted by the low price of this equipment, which can be purchased for 3000 rubles. Circular saws for wood from Interskol have many useful advantages. Long service life, ergonomics, as well as high quality of operations performed with these saws are relevant for buyers.

Due to the fact that today there are many models on sale that differ in technical characteristics, each buyer is able to choose for himself the model that is most suitable for him, taking into account the tasks facing him.

Saws Bosch

Circular saws from Bosch also have their advantages. If you believe the reviews of experts and consumers, they are distinguished by high convenience when holding the tool in your hands, and also create less vibration noise. Any user, regardless of work experience, can personally be convinced of the convenience when working with this tool, which was achieved by simply adjusting the speed of revolutions.

Reviews

I have been using the Makita 5008MG circular saw for a long time. I am completely satisfied with her, but if you work with her all day, you can feel how hard she is. I'm not entirely happy with the fact that the platform mount has some backlash. It becomes quite problematic to make a cut exactly at right angles, and in addition to this, she still "walks" a little more. Therefore, I would like to make a recommendation not to buy 2 mm discs for it. I used 1.8mm consumables and they bent quickly even under light load. As for the rest, I have no complaints about the quality of work.

Ivan

A couple of years ago I bought a Makita 5008MG circular saw. It suits me completely. It weighs a little, does not make noise, very reliable. She helped me build and complete all the finishing work in the house. This is a great tool for boards up to 50mm thick. I have been using it for 2 years now and have never had a reason to criticize it.

Sergey