The main criteria for choosing a tool

Specifications

Dimensions. Compactness is appreciated.

The weight

It should be relatively small, since it is important to use the tool conveniently in any position, otherwise what kind of efficiency can we talk about.

Length of the power cord (for power tools).

The location and dimensions of the "Start" key. It should be at hand, and the dimensions should be adapted as much as possible for a comfortable press.

- Engine power. One of the fundamental parameters when choosing a jackhammer. Fluctuates within 500-2000 W. The more power, the higher the level of performance of the device, the more powerful the impact, the number of impact movements per minute.

- Maximum strength of a single blow. Measured in Joules. The functionality of this or that model of the instrument depends on the strength of the blow. In total, this figure can be at around 3-60 J or more.

- The number of beats per minute. Depends on the previous specification.

Equipment

- Suitcase. It contains the hammer itself and additional gear that come with the set.

- The presence of an additional handle. Can be straight or D-shaped.

- Nozzles. The more attachments, the wider the range of work performed.

Functionality

- Possibility of setting the frequency of beats. This indicator can be adjusted in several ways (depending on the specific model): according to the degree of pressing the key, with a special regulator, if it is possible to fix the "Start" button.

- Standby support - the ability to disable the idle shock function in automatic mode.

- Protective system. It is activated when the unit starts up. Limits inrush currents, which completely eliminates the possibility of a jump in energy consumption.

- Anti-vibration system. Designed to combat noise and vibration, aimed at reducing them. The latter is achieved thanks to the built-in dynamic counterweight. Also, in order to reduce vibration, the tool can be equipped with special handles with a spring suspension and damping inserts, rubberized pads and foam gaskets.

- The presence of built-in control devices (displays, indicators). Allows you to timely identify brush wear, cord and plug condition or need for service.

- Gearbox housing. Can be made of plastic or metal. If metal was used in the manufacture of the hammer, a large weight will become a distinctive characteristic of the hammer, which is disadvantageous for the user. You should not be afraid of the plastic case - it is lightweight, durable and wear-resistant.

- Possibility of adjusting the corresponding rigging mode. In the overwhelming majority of cases, 12 positions are used, which can be fixed every 30 degrees.

Useful Tips

-

In order to spend as little time as possible on possible breakdowns, you need to periodically check the product for its serviceability. The list of mandatory checks includes the air distribution mechanism, firing pin, valve and spring. Other parts are much less likely to break.

Each detail requires a special installation. Incorrect distribution of elements after repair can lead to complete malfunction of the tool, when it can no longer be repaired.

- Electric ones very often break down due to a malfunction or wear of the electric motor brushes. Usually, when a part is partially destroyed, a fuse comes out, but in some models this function is not provided.

- Pneumatic valves suffer most often from clogging of valves with dirt. In this case, the unit must be completely disassembled into its component parts, the equipment must be cleaned from the outside, and all the inner sides must be blown through.

Repair makes it easier to know the signs of breakdowns and installation rules. Before you start disassembling parts, you should diagnose for defects, malfunctions.

Application, operation

The main areas of use of jackhammers include construction and mining.

In the first case, they serve to dismantle structures during redevelopment and demolition, cut metal, remove concrete and asphalt pavement, tamp soil in hard-to-reach places, build wells, loosen frozen soils, make holes and niches, remove ice.

In the mining industry, jackhammers are used when more powerful equipment is not available. So, the conditions of use in mines, consisting primarily of limited space, determine the need for compact tools. In addition, workings are processed along the entire radius. Therefore, a lightweight hammer is required that can be used upside down.

The scope of application is largely determined by the type of device: in what conditions and under what atmosphere to work, etc.

Some of the features of the operation of jackhammers were noted above. Regardless of the type of device, general rules are highlighted. Firstly, before starting work, the tip of the nozzle should be lubricated with any type of plastic grease such as lithol and grease. Secondly, it is recommended to add grease to the barrel of the tool when working from two times per shift in order to extend its service life. In this case, various oils are used for a jackhammer in accordance with the instructions. Some recommend I20A, others - gear oil 15W-40, etc. Thirdly, you should not allow dirt and water to get into the device, rinse the cartridge from lubrication with gasoline at the end of the work, after removing the nozzle. Fourthly, it is necessary to follow the provisions of the instructions, using the hammer as intended and without overloading. Fifthly, once a month it is recommended to carry out maintenance, which includes complete disassembly and flushing of all parts with gasoline or kerosene.

In addition, there are specific features of the operation of each type of jackhammers.

So, a pneumatic hammer after a long break before starting work is recommended to be disassembled and washed in detail with gasoline. Then, within two weeks, the barrel should be lubricated with pneumatic oil 3-4 times per shift.

For electric models, timely replacement of brushes is required. In addition, technological breaks of 10 - 15 minutes should be taken at intervals of 25 minutes to avoid overload.

On gasoline jackhammers, it is necessary to pre-prepare a fuel mixture that includes gasoline and oil of a certain concentration. The instructions indicate which oil to pour into the jackhammer, in what quantity, etc. Moreover, it is required to completely develop the fuel mixture or drain the residues. This avoids contamination of the battery with an oil film.

Each type of device under consideration is characterized by specific malfunctions.

The main reason for breakdowns of electric jackhammers is electrical circuit disturbances, which consist in breaking the button and erasing the brushes transmitting electricity to the motor. Replacing the brushes is easy. The repair of the button is more difficult due to the fact that in many cases it is necessary to disassemble the entire case, however, on modern models, taking into account this feature, it is equipped with a separate cover to simplify replacement.

For models with internal combustion engines, a clogged carburetor is typical. Finally, on any jackhammers, there is a jamming of the nozzle in the chuck.In this case, the cartridge is dismantled and the nozzle is squeezed out, after which the cartridge is washed from lubrication with kerosene.

Popular models

If you need to purchase a Bosch jackhammer or other analogue, you should study the characteristics of the units. Let's start our review with the popular TSS-GJH95 model, taking into account the opinions of users.

The tool is made in China and is equipped with a 2.3 horsepower two-stroke engine with one cylinder. The unit is started using a mechanical (manual) starter; about 0.8 liters of fuel are consumed per hour of operation. The TSS GJH95 demolition hammer optimally combines the price / quality parameters. To lubricate the working parts, graphite is used in combination with a special oil.

Manufacturers

Some models of equipment are manufactured by the Tomsk Electromechanical Plant named after I. Vakhrushev. Pneumatic hammers and concrete breakers in Russia are produced by 2 factories:

- LLC "Tomsk Kuznetsov Plant".

- OJSC Tomsk Electromechanical Plant named after Vakhrushev.

The first one specializes in the production of models MOP-2, 3, 4 and BK-1, 2, 3. The second manufactures MO-2B, 3-B, 4-B and B-1, 2, 3. Similar equipment is also produced in China. ... Enterprises are distinguished by their capacities, and are also capable of forging all available brands of instruments. Uncertified mechanisms often suffer from a number of defects and a short service life.

Each product is equipped with a quality certificate and a conclusion on sanitary and hygienic control, as well as a passport indicating the guarantee, instructions for use. The serial number in the papers repeats the engraving of the bumper barrel. Official companies representing factories work in other countries. In Ukraine, it is.

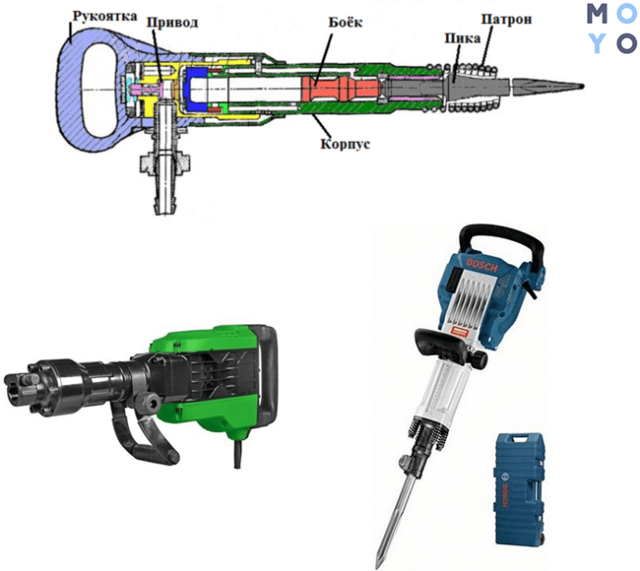

Device

The main structural elements for any type of jackhammers are represented by a striker, a nozzle, a chuck, etc.

Pneumatic piston models are arranged according to the scheme of piston systems based on the shock principle. The main structural elements are represented by a start valve, a striker, represented by a piston, a fitting for a compressor hose, a cup with a ring valve and a valve box, a muffler. In addition, the jackhammers include two springs, a shock absorber, a retaining ring, a handle, and a body.

The named parts are combined into several nodes.

- The impact device, also called the launcher and air distribution mechanism, includes the firing pin and the barrel.

- Vibration protection of the handle is represented by a glass and sealing sleeves.

- The anti-vibration chisel protection includes a manipulator and a spring-loaded bushing.

- The handle housing includes a housing, an aerodynamic noise suppressor and a trigger.

The shock system has two main functions: supply, distribution and removal of air, converting its energy into work.

Electric models are equipped with such specific units as an electric motor, a gearbox that converts the rotation of the shaft of the latter into a reciprocating movement, a crank mechanism with a piston that provides pressure in the cylinder acting on the firing pin.

Components specific for jackhammers with internal combustion engines include the carburetor, fuel tank, starter, ignition system, and fuel pump. In addition, taking into account the increased vibration of these devices, the handle and control elements are separated from the body by a spring suspension.

In addition, there are additional accessories for the hammer. It includes the following four attachments. An automatic speed governor, called soft start and idle speed limiter, serves to extend engine life by avoiding overloads and gradual acceleration. The principle of its operation is based on adjusting the speed in accordance with the load. The side handle increases ease of use by promoting proper hold and distribution of forces.The impact frequency adjuster increases tool control by allowing the breaker to be adjusted to suit different hardness materials. The latching button ensures that there is no need to hold it down continuously during operation.

The principle of operation of jackhammers is to create reciprocating movements of the striker located in the barrel, which is not kinematically connected with other parts. This is done by different mechanisms depending on the type of hammer.

So, in piston pneumatic models, the air supplied by the hose from the compressor overcomes the resistance of the valve spring when acting on the handle. As a result, the valve moves, opening the opening of the percussion mechanism. Alternately, in the lower and upper parts of the cylinder, a vacuum and excess pressure are created due to the bypass of compressed air between them by the valve system, generating reciprocating movements of the striker.

The operation of the pneumatic turbine hammer is based on the drive of the energy generated by the rotating air of the turbine wheel.

Gas powered hammers are also commonly equipped with pneumatic hammers. The piston, by changing the pressure in the cylinder, leads to the movement of the hammer piston with the tip attached.

Electric jackhammer

This power tool is powered by an electric motor - it drives the rotor, which, in turn, the firing pin. The striker sends mechanical impulses to the working body - the pike.

Electric hammers have such advantages as high power with low weight, better value for money. However, it should be borne in mind that this tool is not intended for use in high fire hazard conditions, as the engine can spark. Another disadvantage is the dependence on the power supply. Its best field of application is interior decoration.

Main Features of Electric Demolition Hammers

A device such as a jackhammer has a very powerful impact force. It is the impact energy that is the most basic characteristic of this device. It is determined by the number of blows that the considered jackhammer is capable of performing within a minute, and the energy generated by the apparatus during the same time. The device of such instruments is extremely simple. The striker is located inside the jackhammer body. It is driven by a drive. The striker has a mechanical effect on the lance, which is the executive element of the jackhammer. The pike makes very frequent reciprocating movements, due to which the destruction of the processed material occurs.

Electric jackhammer device.

It must be remembered that very rough energy is generated during the operation of the device. The operator is constantly exposed to strong noise and powerful vibration. Therefore, it is only possible to start working with the jackhammer if the safety regulations are observed and the appropriate protective measures are used.

As for the device of an electric jackhammer, such a unit is equipped with an electric motor. Thanks to him, the rotor is set in motion. It affects the striker. The latter sends mechanical impulses to the peak. Devices of this type are very popular, but they have a number of different disadvantages. Due to the fact that the motor sparks during operation, the use of this jackhammer is not possible in premises with a fire hazard. In addition, the disadvantages include the fact that the device depends on the power supply. It simply won't work without it.

The main characteristic of the electric breaker is the impact energy.

The user needs to understand the peculiarities of supplying electricity to the device drive.This information will come in handy when performing various minor repairs. A fairly common reason for the failure of an electric jackhammer is trivial and simple electrical circuit violations: brushes are erased or a button breaks. More often than not, the problem lies in the brushes. The device of the tool is such that, due to the brushes, electrical energy is transmitted to the motor. If they wear off, the bump stop simply won't turn on.

A pair of plastic plugs can be seen at the place where the motor is installed. To fix the breakdown, it is enough to unscrew the plugs, remove the remnants of the used brushes, replace them with new ones and return the plugs to their place.

In the case of replacing the start button, everything happens in almost the same way. But in this case, it will be necessary to disassemble almost the entire body of the device. However, modern manufacturers try to provide for such breakdowns and assemble devices so that the start button has a separate cover. This greatly facilitates the replacement of this element.

Care

Every technically sophisticated tool, including a jackhammer, will last much longer with proper care. To do this, the following general rules must be observed:

- before starting work, be sure to lubricate the shank of the lance with grease, lithol or any other type of plastic grease;

- during operation, add lubricant to the tool barrel, which will prevent its premature wear, this must be done at least twice per shift, industrial oil I20A diluted with kerosene or diesel fuel (25 - 40%) should be used as a lubricant;

- do not overload the fender with excessive load for it, use it as much as possible, according to the instruction manual;

- make sure that water and dirt do not get into the hammer when working, at the end of work, remove the lance and remove the contaminated grease from the chuck, rinsing it with gasoline;

- once a month, the tool should be serviced, with its complete disassembly and washing of each part in kerosene or gasoline.

Each type of jackhammer has its own specific maintenance rules. The gasoline tool requires that the filled fuel mixture is fully used up until the end of the shift and does not remain in the tank for long. Otherwise, it must be drained, this will prevent the carburetor from clogging with an oil film.

In electric bumpers, it is necessary to timely replace worn-out carbon brushes and not to overload the tool, making a technological break for 10-15 minutes after 25 minutes of work.

Pneumatic concrete breakers before starting operation after a long break, it is necessary to disassemble and wash all their parts in gasoline. After assembly, add 30 - 40 grams of pneumatic oil to the barrel to lubricate the barrel, and for the first two weeks, lubricate the tool in this way 3-4 times per shift.

Sharpening of the lance is not provided in high-quality jackhammers. This working tool is made by cross-wedge rolling with one heating, as a result of which the maximum strengthening of the upper layers of the peak occurs. Therefore, it serves for a rather long time, and when dull, it is simply disposed of, and a new peak must be installed.

The baffle peaks are made of steel. The technology of their manufacture makes the surface layer as strong as possible, as a result of which the sharpening of the tool is not provided.

Operating tips

When working with demolition hammers, it is necessary to use crowns of the greater strength, the harder the material to be processed. When processing asphalt or granite, use wide crowns. But penetration is strictly limited, otherwise there is a great danger that the tool will be blocked. If this does happen, the hammer will have to be rocked - then it will be possible to remove it quickly and easily. It is possible to hammer concrete of strong grades only with bumpers with special peaks.The extended working surface of these nozzles makes it easier to separate the layers of material. For crumbling rock or asphalt, a T-shaped handle is preferred, but when working at an angle to the surface, D-shaped holders are recommended.

It is necessary to fill in the lubricant in the recently purchased bumper three or four times during the shift until 2 weeks of operation have passed. Then you will have to pour oil twice in a standard shift.

Attention: the hammer must not bounce during operation. If this happens, something is clearly being done wrong.

The oil is usually added via a grease nozzle and, if not available, a nipple is used.

For information on how to use the jackhammer correctly, see the next video.

It is impossible to imagine a construction site, major or minor repairs, without first dismantling the surfaces, and of course, the pneumatic jackhammer is an indispensable tool here. The scope of activity in which this tool is used is not limited to this, it is quite wide. The pneumatic bump stop is widely used in various types of production, in various industries, including mining, road construction, its repair work, in places where preliminary destruction of structures and coatings is required.

How to use the device, safety precautions

Working with a jackhammer has a number of features associated with the impact of negative factors on the operator.

- increased vibration during operation;

- increased level of dustiness in the slotting zone;

- high noise intensity, hazardous to health;

- an abundance of small particles of solid material flying out at high speed from under the bit.

Protective equipment is required when working as a bump stop.

Therefore, safety requirements include the following points:

It is forbidden to carry out work without the use of personal safety equipment - earplugs or headphones, a respirator, goggles, as well as work without gloves and a protective suit made of dense fabric.

It is forbidden to use a known defective jackhammer. Before switching on, it is necessary to check the attachment of the chisel and the tightness of the bolts on the body.

During operation, following the safety rules, it is necessary to hold the bump stop only by the standard handles. It is unacceptable to work with one hand.

If there is an additional holder, use it for its intended purpose. The position of the body must be stable.

It is forbidden to entrust the instrument to minors and leave it switched on unattended. It is unacceptable to aim the point of the chisel in the direction of other people.

At the end of the work, do not touch the metal part of the case with bare hands. This can result in severe burns.

It is unacceptable to use the tool for other purposes, such as a crowbar or a shovel with the drive turned off.

The maximum period of work with a jackhammer is limited to 6 hours. Resumption of work is permissible only after a 1 hour break.

When using the tool outdoors during the cold season, the lubricant needs to be warmed up. To do this, you need to turn on the device, and within 2-3 minutes. warm up at idle.

Following these simple rules will protect the user from injury, and the bump stop from premature wear.

Often, when using a pneumatic breaker, some users increase the pressure of the compressor supplying compressed air to the tool. They proceed from a simple reasoning that the greater the pressure on the piston, the greater the impact force. This is indeed the case. But, unfortunately, for a very short time.

The compression level must correspond to the set nominal pressure of the unit.

All passport parameters of the hammer are indicated taking into account the nominal pressure - this is, as a rule, 0.5–0.6 MPa. (or 5-6 atm.).With an increase in pressure to 7-8 atmospheres, the load on the piston increases sharply (by 40-60%), and this leads to a halving of the resource of the parts. Therefore, the conclusion is simple - instead of "squeezing" the power uncharacteristic of the hammer, it is better to choose a tool with increased indicators of impact force.

How the tool works

The main feature of the bump stop is that it produces a large impact during the working process.

Impact energy is an important characteristic for this kind of tool. When calculating it, the number of blows carried per minute of working time is taken into account, as well as the energy generated over the same time period

Modern bumpers have a fairly simple design. The striker located inside the body makes oscillatory movements due to the existing drive. The mechanical impulses arising in the course of its operation are fed to the working body of the tool - the peak, which makes rapid reciprocating movements, due to which the destruction of the material is ensured.

When working with the tool, a rather coarse energy is generated, due to which the master has to feel strong vibration and noise. To reduce the manifestation of these effects, it is necessary to start working with a bump stop, having previously taken the necessary protective measures.

When working with the tool, a rather coarse energy is generated, due to which the master has to feel strong vibration and noise. To reduce the manifestation of these effects, it is necessary to start working with a bump stop, having previously taken the necessary protective measures.

The electric version of the bumper works a little differently. Here, too, the design has a firing pin driven by a rotor, which causes an electric motor to rotate. Mechanical movements performed by the striker are transmitted to the peak. Although this tool is one of the most popular not only among professional builders, but also for home craftsmen, it has a number of significant drawbacks. During the operation of the electric motor, it can give off a spark, therefore, it is forbidden to work with an electric bump stop in rooms with increased fire safety. Another disadvantage is the need for a power source.