2 How to make a hiller for a walk-behind tractor with your own hands?

Do-it-yourself hiller can be made using fairly simple designs. This is not difficult. To create a traditional unregulated hiller, you need to cut the halves of the product from 2 mm thick metal using a template.

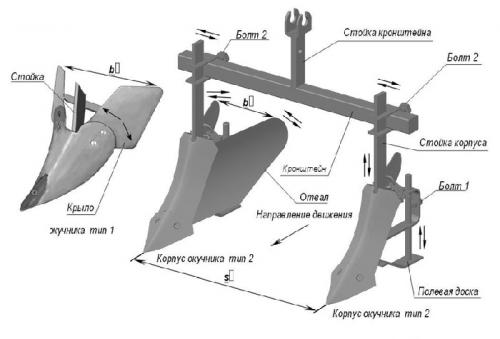

Drawing of a hiller plow for a walk-behind tractor

Next, bend these parts until the radii coincide, then weld in 3 passes. The seams are processed with a grinder. Ultimately, you should get an even layer of metal.

A do-it-yourself disc hiller can also be made. To do this, you must select the type of wings. Plowshares, dumps, or discs, are steel sheets with a thickness of 1.5 - 2 millimeters, whose lower edges are bent.

The main thing is that the disks are symmetrical. Otherwise, then the structure will lead to the side, which will greatly complicate the work. To create the unit, you can use the plowshares, which served as a seeder.

It is necessary to install the plowshares at an angle, maintaining a distance between the lower points, which corresponds to the width of the wheel track, equal to the width of the row spacing.

To connect the elements together, a bolted connection or welding is used. The discs are connected using adjustable adapters.

In addition to the disk, the main parts of the tool are: screw lanyards, stands and a T-shaped leash. Lanyards are needed to adjust the vertical axis of rotation of the disc. A homemade hiller is attached to the walk-behind tractor with your own hands using a beam with wings.

The manual disc hiller is made on the basis of the drawing, while it is very important to provide for the ratio of the fastening structure and dimensions. The tool can be made in two ways: with variable wing width and fixed

In the first method of arrangement, the distance between the discs can be changed due to the symmetrical rearrangement of the racks

The tool can be made in two ways: with variable wing width and fixed. In the first method of arrangement, the distance between the discs can be changed due to the symmetrical rearrangement of the racks.

To facilitate the work with the tool, it is necessary to arrange the plain bearings. To increase the reliability of the product, you can install bearings, rather than sleeve bushings.

Hilling potatoes with a hiller to a mini tractor

The use of a disc hiller for a walk-behind tractor with your own hands will facilitate the work and help to increase yields.

To attach a homemade hiller to a walk-behind tractor, a bracket is used to a hitch without a bead. The unit leash is attached to the bracket using a stopper and bolts with washers. A corkscrew is inserted inside the square tube and pressed tightly against the outer surface.

After that, the do-it-yourself hiller for the walk-behind tractor is ready to work. The traction of the walk-behind tractor can be increased by working in first gear. If the wheels slip during the hilling process, they must be paired.

The mini tractor hiller is installed to huddle your potatoes. For the tool to be really effective, the potatoes must be planted in the correct rows, the distances between the plants must be equal.

In order to process agricultural crops in a mechanized way, a high-performance hiller for a tractor is used. Its main purpose is inter-row cultivation of potatoes from weeds and hilling of tubers to increase yields.

2.1 Making a manual hiller at home (video)

Home / Equipment / Do-it-yourself manual disc hiller for potatoes

When growing potatoes, there are techniques that can not be ignored and even less overlooked. One of them is the hilling of grown potato bushes, the purpose of which is to create air exchange in the soil. If the area occupied for planting potatoes is small, then many manage on their own and with a hoe, but when the area is large enough, then a mechanical assistant is already required to facilitate physical labor and reduce processing time. Learn how to make a hand-made potato ridger with your own hands according to drawings and videos.

Instructions

I would like to start by considering the process of making a disc hiller, because this type of device is the most in demand today.

By setting disc sizes of different diameters, it is possible to huddle potato bushes of various lengths.

Disc hiller

Many people ask the question - how to make a hiller for a walk-behind tractor with their own hands? At home, this is quite possible if you follow certain recommendations. So, we will describe the manufacturing process in stages (for example, take a disk hiller for the Neva walk-behind tractor):

- For manufacturing, we need cutters from an old seeder, or metal sheets 2 mm thick. They are fastened using bearings with oil seals.

- You need to put them at an angle to each other. The distance between the lower parts of the discs must correspond to the track width of the walk-behind tractor. They are connected by welding, or using ordinary bolts.

- Here you need to follow a strict recommendation - the disks should be symmetrical to each other. Otherwise, the walk-behind tractor with a hiller will move to the side, which will significantly complicate the whole process of work.

- In addition to the discs themselves, the design of the hiller includes screw turnbuckles, a T-type leash and stands. Lanyards, in this case, perform the adjusting function of turning the discs along the vertical axis.

- A do-it-yourself hiller for a walk-behind tractor, the drawings and photos of which you see below, must be made in strict accordance with the dimensions. There will certainly be improvisation, but with the first assembly experience, it is best to use other people's best practices.

- Depending on the possibilities, it is possible to make a fixed and adjustable working width. The second method is more convenient, because you can change the disc spacing by simply rearranging the racks.

- To aggregate the hiller with the walk-behind tractor, you need to use the hitch bracket, on which there is no bead. The hiller leash is attached to the hitch with a stopper, connected with bolts and washers. The stopper itself is inserted into the square tube and then tightened.

The disc hiller for the Salute walk-behind tractor is made in the same way, because the design itself and the method of connection with the walk-behind tractor are completely identical with the Neva.

Active hiller

To make such a hiller, we need exactly the same list of materials and tools that we used in the manufacture of a disk hiller:

- welding machine;

- sheet metal;

- Bulgarian;

- fastening connections.

Using a similar toolkit, you can make an active hiller for the MTZ walk-behind tractor, Plowman, Champion, Carver, Huskvarna, Lifan. The manufacturing principle is in many ways similar to the disk version:

- The axles also need to be adjusted to the parameters of the walk-behind tractor, and the parts themselves are welded using a welding machine.

- As previously reported, this type of hiller makes certain requirements for the walk-behind tractor. It must have two forward gears, as well as a PTO - a power take-off shaft. Many sellers of walk-behind tractors, speaking of the fact that a walk-behind tractor has two gears, mean one rear and one front.

- So when buying, you need to clarify this point.

- It would be expedient to manufacture several bushings with brackets, as well as additional blades made of metal.

Double row hiller

A double-row hiller is the same lister type of a hiller, but in a double volume. Let's consider the whole process of work in stages:

- For work, we need a sheet of metal about 3 mm thick. From this material it is necessary to weld the base of the hiller.

- A 4 mm steel strip can be used as a bracket. The field board is made from a 5 mm thick sheet of steel.

- The stand of the hiller takes the brunt of the work. Therefore, you need to make sure that it is the most stable and reliable in comparison with the rest of the hiller.

- The hiller wings can be made from a sheet of steel with a thickness of 2 mm. They need to be bent slightly using a pipe of the desired diameter.

In principle, this is where the process of making a two-row hiller ends. You can also make an adjustable system of hiller wings, which are attached to the base using hinged technology. In the tail of the structure, there are rods that regulate the angle of inclination of the wings.

Otherwise, the manufacturing principle is completely identical to that of the fixed Lister version.

Manual hiller. Manual potato ridger

Potatoes have always been considered one of the staple vegetables in the kitchen. It is used to prepare first and second courses, desserts, etc. Growing this vegetable is associated with high labor costs, because in order to obtain a good harvest, it is necessary to huddle potato bushes several times per season.

Thanks to hilling, oxygen access to the roots is improved, channels in the ground are destroyed, as a result of which moisture evaporates less, and the number of tubers also increases.

Hilling bushes is carried out in summer cottages mechanically using a hoe. However, this is a long and arduous process.

To help farmers and gardeners specializing in growing potatoes, a special tool called a hiller has been created.

Advantages and disadvantages of hillers

The use of mechanisms always allows you to increase labor productivity on farm and summer cottages.

Manual hiller

Advantages:

- reduces labor costs and increases the efficiency of the farmer;

- can be a multifunctional tool that can be additionally used for loosening the soil, planting potatoes, as well as during harvesting;

Disadvantages:

- in order to use the device, it is necessary to purchase it, which means that material costs for the purchase and further maintenance will be required;

- when working with the device, you must comply with the safety regulations.

Types of potato growers

Depending on the design, the following types of devices are distinguished:

- listeric;

- disk;

- propeller.

Disc hiller

The propeller mechanisms allow you to move the soil between the rows into the grooves.

The most common are lister and disk devices.

Lister mechanisms

Interesting! Attachments of this type are available with a fixed working width. Otherwise, they are called plows, as they look like a plow.

They are produced with an adjustable angle of attack (the angle of inclination of the cutting part of the hiller to the ground) and fixed.

Adjustable ones allow you to change the depth of loosening and, accordingly, the coverage area.

Advantages of the device:

- consumes less power compared to disk devices;

- simpler in design;

- the price is less than for a disk device;

- has a low weight, therefore it works perfectly on low-power mechanisms (walk-behind tractors and cultivators).

Lister hiller

Disadvantages:

- does not work well on wet and heavy soil;

- planting potatoes should only be flat, with a strictly fixed row spacing.

Disc hillers

Structurally, they consist of two discs with a sharpened edge. When the hiller moves, the discs rotate and crush the soil. They have a convex shape. Due to this shape, the soil is simultaneously loosened and an earthen roller is formed.

The discs are attached through ball bearings to the racks, which are located on a horizontal holder frame.

Note! They can be adjusted vertically, less often horizontally. With vertical adjustment, the angle of rotation of the discs changes, due to which the amount of soil that is needed to form the ridge also changes.

Horizontal adjustment moves the discs vertically (up or down). Thus, the angle of attack is adjusted.

Advantages:

- better performance of hilling, the ridges are smoother and higher;

- can be used with different row spacing;

- allows hilling on heavier soils.

The disc hiller can be used with different row spacing

Disadvantages:

- higher price;

- higher fuel consumption.

Depending on the volume of work performed and the degree of mechanization, the potato tiller can be:

- manual;

- automated.

Fact! Manual - designed to perform only hilling, automated - used to perform several types of work: hilling, loosening, planting, harvesting.

Manual - moves due to the fact that a person pushes or pulls the mechanism.

The automated potato bucket is an additional suspension device for a walk-behind tractor, cultivator or tractor.

Manual potato ridger

Allows you to process potato beds, regardless of the presence of a walk-behind tractor or a tractor. For manual types, the most common designs are lister and disc mechanisms.

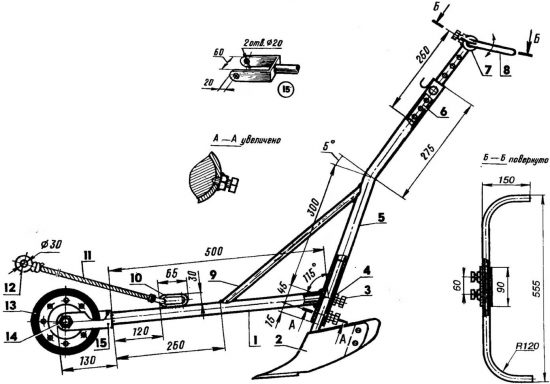

Manual plow hiller: instructions and drawings

Here you will need a set of materials.

- pipes with a diameter of 32 and a thickness of 2.5 (L 1000 millimeters and 700 millimeters);

- steel pipe with a diameter of 45, 6.5 (L 1000 millimeters);

- pipes with a diameter of 21, 2.5 (L 1000 millimeters and 1700 millimeters);

- sheet iron 3 mm thick, electrodes, bolts and nuts, lanyard.

Next, you need to make a rack:

- bend a steel pipe with a diameter of 45 and a length of 1000 millimeters in half, while making an angle of 30 degrees;

- on one side, drill 5 through holes with a diameter of 12 and with an interval of 50 millimeters;

- on the second side, you need to weld 2 brackets for the handle and lanyard.

After the rack, you need to start making the plow itself:

- make markup according to the drawing;

- cut;

- sharpen knives;

- weld two dumps and weld everything with a rack.

Next, the turn comes to the rear handle:

- bend a steel part with a diameter of 32 and a length of 1000 millimeters on both sides into a perpendicular, observing a distance from the edge of 150 millimeters;

- it is necessary to drill 5 through holes with a diameter of 12 with a distance of 50 millimeters from each other in a pipe with a diameter of 32 and a length of 700 millimeters;

- then cook it all.

Types of hillers for a walk-behind tractor

Conventionally, a hiller for a walk-behind tractor, according to its constructive solution and principle of operation, can be divided into several main types:

- disk type;

- listeric;

- propeller (active).

Lister

The device of this type has the simplest constructive solution. Such hillers have a strictly fixed working width and resemble butterfly wings in appearance.

The structure of this device consists of two branched iron sheets attached and fixed to each other. When working, the hiller must lift the soil up from a flat surface, overcoming the resistance of the soil and creating the necessary ridge. The tip of the pointed attachment must drop below the surface of the soil to a predetermined depth. It loosens the soil and raises it, and guide planes serve to direct the soil to the base of the plant, which create the collapse of the soil on both sides.

Since the wings in such a hiller are fixed motionless, when working with it, you have to adjust the row spacing to the size of the device, and not vice versa. Therefore, given that the optimal width between the rows when planting potatoes is considered to be 60 cm, the working width of a factory hiller of 25-30 cm is considered not very convenient when growing potatoes. Constructive improvements for the hiller concern the size of the wings and the angle of their installation to reduce soil resistance and change the working width and height of the furrow ridge.

Variable width attachment

Such a device is the most convenient because it has an adjustment mechanism that provides a convenient and quick change in the position of the wings. It is thanks to this constructive solution that the hiller can be easily adjusted to different sizes of beds. One unpleasant drawback of such a mechanism is associated with the fact that when the process of loosening is carried out, the wings push the soil apart in different directions, but not a very large amount of it falls back into the furrow. But, despite this inconvenience, such a hiller model is more popular with many farmers.

Disk

From the very name of the device, one can understand that it uses discs, the thin rims of which enter the required depth with little soil resistance. For high-quality and easy operation, this design requires precise adjustment of the take-off angle and the angle of inclination of the discs vertically. The distance between the working discs is set on the frame according to the required size of the processed row.

This type of tool has a number of advantages:

- It goes well with a walk-behind tractor. When using such a tool in a low gear of the walk-behind tractor, its power increases. Therefore, the efficiency of digging the soil increases significantly, and also has a beneficial effect on the tool's working cycle.

- Very comfortable to use. When loosening and digging up the soil, a large expenditure of physical strength is not required. A properly configured device does not require additional support from the back, but moves along the ground as if independently.

- Versatility of application. Such a tool is convenient to use for loosening the soil both during the potato planting period and during the growing season of the plant.

Propeller

This type of hiller is also called active, because the principle of its operation includes both the rotational movement of the working elements and their translational movement. The use of such equipment is possible only on walk-behind tractors with two forward gears and a power take-off shaft. The design resembles a home fan in appearance.

The use of such equipment is much more effective than other models, but due to the complexity of manufacturing and the high cost of components, they are used much less often.

The entire technological process of the propeller elements is carried out in one turn of the active disk. First of all, the soil is dug up and weeds are cleaned out, and then the beds themselves are loosened.

At maximum power, this device can be used not only for hilling the soil, but also for transferring the earth to another place.

Principle of operation

Gardeners know that potatoes should be hilled several times per season. If the soil on the site is well-cultivated, loose, this contributes to a better oxygen exchange process. The air entering the soil has a positive effect on the development and growth of plants. Timely loosening increases the yield by 30-60%. Due to the design of the working body of the hiller, furrows with the required depth are obtained. The loosened soil falls off on both sides of the resulting ditch. Tubers are laid in it, and in the future, the grooves are covered with earth. In the process of growing, the potatoes must be sprinkled with a thick layer on top. This promotes the formation of a large number of tubers.This filling is provided again by loosening with the formation of a groove along the planted seedlings. This is achieved by the fact that the working parts of the hiller, when moving in the aisles, cut off the top layer of the earth.

In addition to potatoes, other crops that are planted in rows and require hilling can be processed with the hiller, for example, tomatoes, eggplants, peppers. Tool designs differ in working width, manual or mechanized operation. The first option is quite primitive, requiring two operators, one of which grabs the front handle, and the other presses on the rear rod. As a result of efforts, the device goes deeper into the ground, cuts the soil, and when moving inside the seam leaves a noticeable trail of earth. The automated version clings to a tractor or walk-behind tractor and is controlled by one operator.

Manual and automated hillers can be subdivided into the following types:

disc is a simple tool suitable for one person;

The garden plow is a versatile plow that requires two operators.

It is clear that the disc options are easier to use, they are often automated by linking them with motor vehicles. The ridges of the earth after the disc hillers are higher. There is also a negative point in these devices - the price. In comparison with the plow hiller, it is four times higher. Externally, the tool looks like a frame with wheels on which the disks are suspended. The distance between them can be changed in accordance with the row spacing. The discs are set at a certain inclination, which is not recommended to be adjusted in relation to the vertical. Without a constant equal distance between the circles, the tool will pull sideways.

The simplest type of hand plow has a predetermined working width, wings (plows), shifted relative to each other, which are stationary. This is convenient if the row spacing has already been determined, and the tool fits them. Another advantage of the fixed width hillers is the possibility of using light cultivators weighing up to 30 kg. The advantage lies in compactness, and the negative side is hidden in the limited work in wet areas. This is where the tool will stick in the soil.

A variable width furrower is the most common option. The adjusting mechanism is simple, but it allows you to move or extend the wings, adjusting them to the desired width for the row spacing. The tool can also be automated, but only with heavy walk-behind tractors. The wings of such a hiller move the earth in both directions at once. After the tool passes, the piece crumbles back into the line that it cuts. For a more efficient harrowing process, a more powerful walk-behind tractor is required, otherwise it will seem harder to pull the hiller than to work with a hoe or hoe.

1 What types of hillers are there?

After the winch and plow, the hiller is the second most important unit. It helps to cut furrows for planting, which are then covered with planting material. There are several options for this tool:

Measurements of a lister hiller for potatoes for a walk-behind tractor

- listeric;

- products with variable gripper bus;

- disk models;

- propeller-type hillers

1.1 Lister hiller

The lister unit is the simplest type of tool, it has a fixed working width. The design of this apparatus consists of two connected and spread wings, which are fixed to each other.

The tool wings are stationary, therefore the working width cannot be adjusted. The hiller cannot be adjusted to the row spacing. In this case, when working with the tool, the aisles are adjusted.

The width of the lister hiller is 25 - 30 cm, this is not the most convenient option, because for growing potatoes, a row spacing of 50 - 60 cm is recommended.

A feature of such a device is the presence of thin racks, in this case the cultivator does not reboot at the moment the hiller is buried in dense soil. Some lister hillers have a streamlined shape that is more practical.

1.2 Attachments with variable working width

The machine with a variable working width is convenient for tilling, because it is equipped with an adjusting mechanism. It allows you to change the position of the wings.

It can be adjusted to suit the row spacing. The disadvantage of the apparatus is its high energy consumption. This is due to the work of the wings, which move the soil to the side, after passing by the hiller, the earth crumbles back into the furrow. As a result, the arms and back get tired faster and the engine is wasted. Despite this, such hillers are one of the most popular among gardeners.

1.3 Disk devices

Disk models have the following advantages:

Diagram of a disc hiller for potatoes

- easy to use (to work with these tools you need a minimum of effort, they move forward by themselves, do not require additional pushing from behind);

- universal (they can be used to hilling after planting tubers during the period of active growth of the aboveground part of the plants);

- successfully combined with a walk-behind tractor (if you use a disc hiller at a reduced speed of the cultivator, its power increases. This increases the efficiency of cultivation and improves the operation of the unit).

When choosing from a huge assortment, it is advisable to choose those models that are made of alloy steel, equipped with rolling bearings with a large thickness and disc diameter.

1.4 Propeller-type hillers

Propeller-type hillers are used for cultivators and walk-behind tractors, which have two forward gears. This is necessary so that in second gear with a power of up to 180 rpm, it is possible not only to loosen, but also to transfer the soil into the beds from the row spacing. Such a do-it-yourself potato hiller will perfectly cope with the tasks.

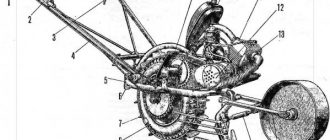

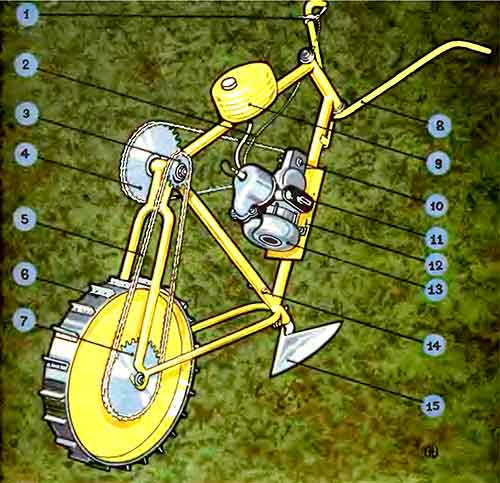

Description of a walk-behind tractor with a chainsaw engine

So, we have a chainsaw that is not used very often or is completely lying around. In this case, after making some calculations and preparing the necessary materials, our saw turns into an excellent walk-behind tractor. The principle of assembling homemade agricultural equipment, depending on the manufacturer's brand, may vary, but the general principles are as follows:

- The most important step is the preparation of the drawing, guided by which, you will assemble the required structure. Drawings and diagrams of a walk-behind tractor from a chainsaw with your own hands can be made both by yourself and by downloading ready-made calculations from the Internet. It will not be difficult to find them, it is enough to drive a request into a search engine and select the assembly option you like.

- The drawings have been found, which means it's time to assemble the frame for our motor-cultivator.

- Once the frame is ready, the saw motor and its gas tank are attached to it.

- In the last turn, additional elements of the system are installed, which are responsible for controllability and other functionality.

Note! As a motor, not only a motor from a chainsaw is suitable, but also an engine removed from a motorcycle or moped. In this video, we will consider a motorcycle cultivator from a chainsaw friendship:

In this video, we will consider a motorcycle cultivator from a chainsaw friendship:

To implement the idea, prepare the following materials:

- Motor from any existing chainsaw. The Druzhba and Ural saw is best suited for this.

- A handlebar removed from a moped or motorcycle.

- Welding machine.

- Pipes and sheets of metal, in the amount necessary for assembling the frame of the walk-behind tractor.

- Wheels from non-working equipment.

- Transmission.

Having prepared all structural elements and assembled them in accordance with the drawing, you will receive a device with the following characteristics:

- Powerful. Some homemade designs have 9 horsepower.

- Lung.

- Small-sized.

- The motors used in chainsaws have a large margin of safety, which allows you to work on a home-made installation for a long time.

- Economical.

As an example for assembly, consider 2 options for engines removed from Druzhba and Ural chainsaws. They are considered the most suitable for our venture, and here's why.

friendship

Chainsaw friendship has the following characteristics:

- 3.5 horsepower motor.

- Weight - 7 kilograms.

- The volume of the gas tank is 0.55 liters.

- The volume of the oil tank is 0.26 liters.

It is recommended to use the 4th generation Friendship model for assembly.

Products manufactured under the Ural trademark have characteristics that differ from Druzhba. The differences lie in the following details:

- The power of the Urals is higher than that of Friendship, and amounts to 5 horsepower.

- The engine generates a lot of soot during operation.

- The gearbox installed on the saw tends to wedge from time to time.

- Small specks, getting into the engine of the Ural saw, burn out without causing any special damage to it.

As you can see, each model has its own pros and cons. Making a walk-behind tractor from a Ural chainsaw motor or constructing a home-made walk-behind tractor from parts of a Druzhba chainsaw is up to you.