Making a lister plow

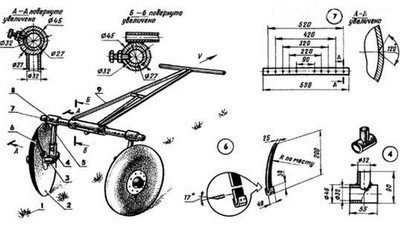

Such agricultural equipment for motor vehicles is a classic unregulated device that is most often used. For its manufacture, it is necessary to sketch or use ready-made drawing documentation, according to which it will be easy and simple to carry out all the activities.

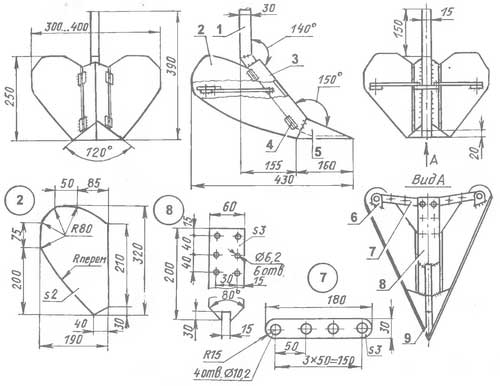

- We build the base from an iron sheet 3 mm thick. She will face the opposition of the soil, therefore, must be extremely strong.

- The holder is made of a metal strip, 4 mm wide, the spare part must be hardened.

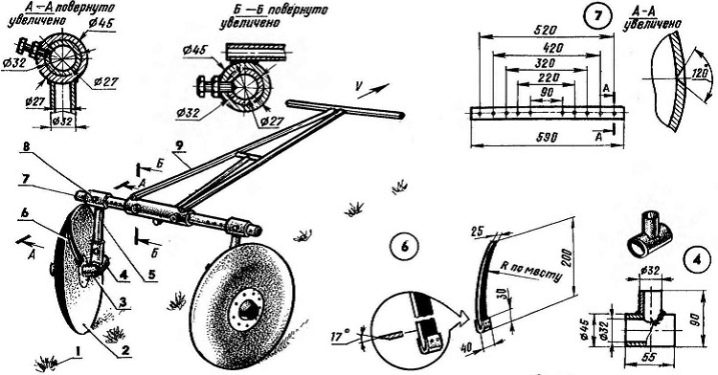

- The field board is made of 5 mm thick steel. It is hardened in several steps by means of a gas burner.

- The rack is made of iron with a thickness of 8 millimeters, since it will be the component on which the entire load will fall.

- The wings for the gun are made of iron 2 millimeters thick, they must be consistent with the parameters of the chosen scheme, since this is the only way to dock them to the base.

- Then they bend a little and cook to the base.

If you need to adjust the row crop, you need to fix the wings to the base by means of hinged joints. The rods for setting the angle are mounted in the tail of the base. You can also create a 2-row attachment that doubles the pace of work. In this case, it is necessary to add traction mechanisms to the constructed structure, and create the fasteners movable, which will make it possible to adjust the size of the rows.

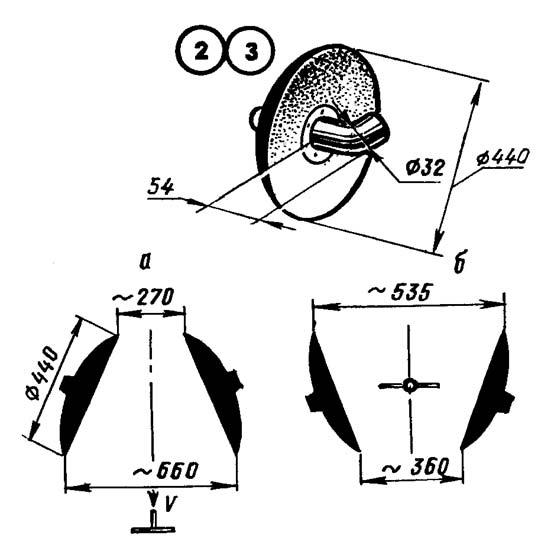

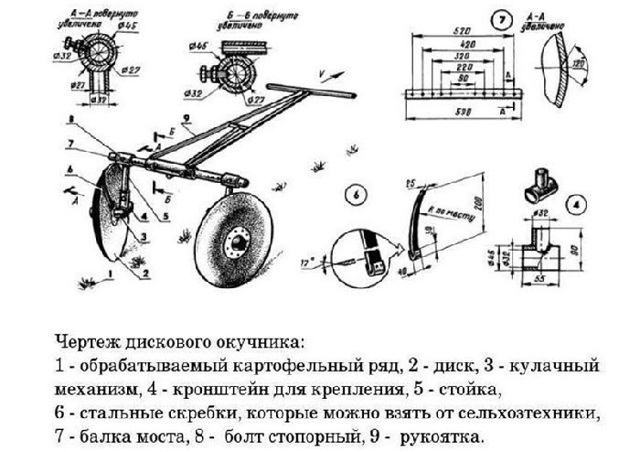

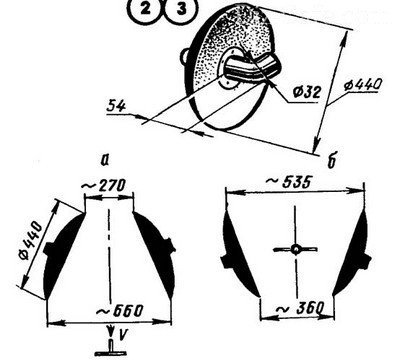

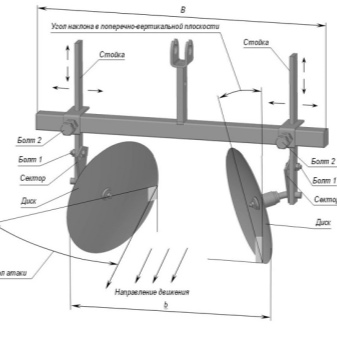

A simple model of a disc hiller for a walk-behind tractor

To make the tool, you need to choose the type of wings. Discs, or plowshares, dumps, are steel sheets 1.5-2 mm thick, with bent lower edges.

When arranging the structure, you can use plowshares taken from an old seeder.

Plowshares are installed at an angle, keeping the distance between the lower points corresponding to the width of the wheel track, equal to the width of the row spacing

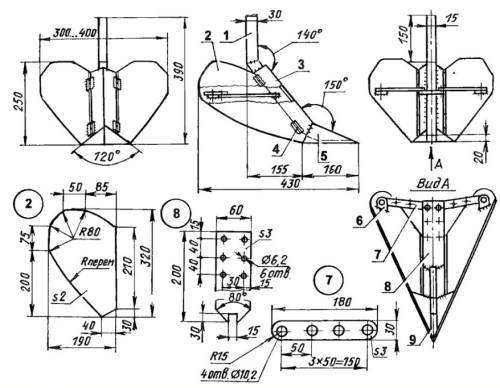

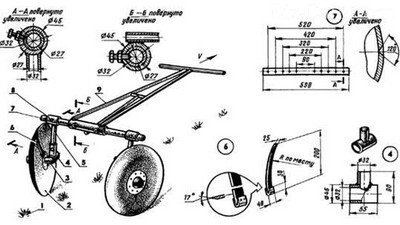

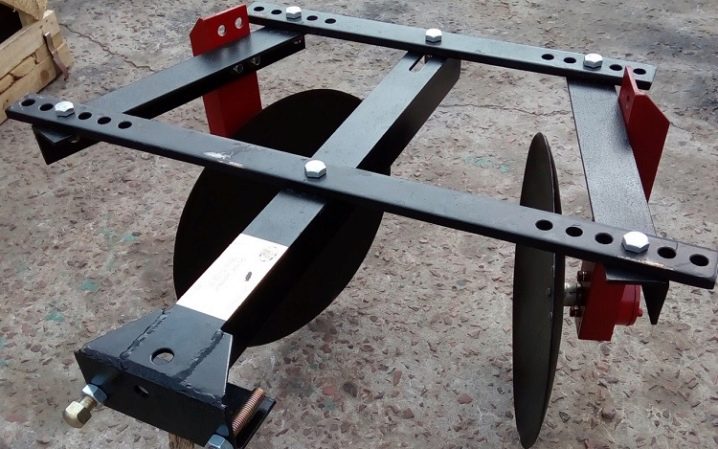

The elements are connected to each other using a bolted connection or by welding. The disks themselves are connected using adjustable adapters. In addition to discs, the main elements of the tool are: a T-shaped leader, screw lanyards and stands. Lanyards are needed to adjust along the vertical axis of rotation of the discs. The tool is attached to the walk-behind tractor using a beam with wings.

When manufacturing and assembling parts based on the drawing, it is important to provide for the ratio of dimensions and the design of the fastening. There are two options for making the tool: with fixed or variable wing width

In the second method of arrangement, the distance between the disks can be changed by symmetrically rearranging the racks.

Main assembly elements: 1 - processed row, 2 - disc, 3 - fist, 4 - T-shaped bracket, 5 - post, 6 - steel scraper, 7 - bridge beam, 8 - locking bolt, 9 - beam handle

To facilitate the work with the tool, it is necessary to provide for the arrangement of plain bearings. By installing bearings rather than sleeve bushings, product reliability can be improved.

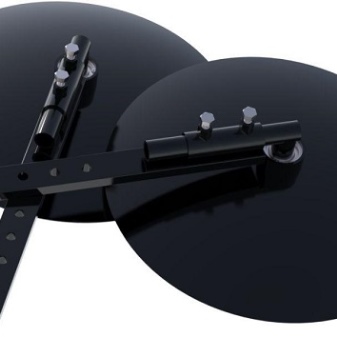

In the process of assembling the structure for attaching the tool to the walk-behind tractor, a hitch bracket without a bead is used. To do this, a hiller leash is attached to the bracket using a stopper and bolts with flat washers. The stopper is inserted inside the square pipe and pressed tightly against its outer surface.

The hitch bracket itself is turned with bolts, and the leash is placed along the longitudinal axis of the walk-behind tractor

The unit is now ready for operation. Working in first gear, by reducing the forward speed, you can increase the traction of the walk-behind tractor. If the wheels slip during the hilling process, they must be paired.

How to mount a hilling tool on a walk-behind tractor?

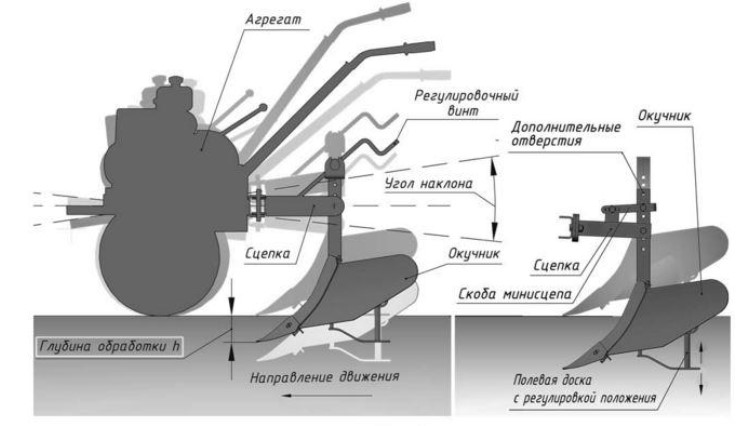

Mounting the hilling tool on a motor-cultivator presupposes competent adjustment of the slope of the field board and the immersion depth, which must be smaller than that of the plow. Before you start using the hiller, you need to do such activities.

- Mount the hitch and wheels on motor vehicles, then add the hiller.

- The tiller is installed on an equal plane, and the hilling tool is lowered to the ground and fixed on the hitch.

- When installing the equipment, make sure that the rack of the agricultural implement is in an upright position. This will allow you to adjust the pitch of the board as needed.

- Then the equipment lands or sinks slightly into the soil so that it is below the lug support plane.

It is necessary to do a test hilling and take a look: if the equipment is buried in the soil, move the rack forward, slightly lifting the toe. When leaving the ground, the stand is retracted by lowering the toe

The main thing is to take into account the width between the rows by adjusting the existing structural elements

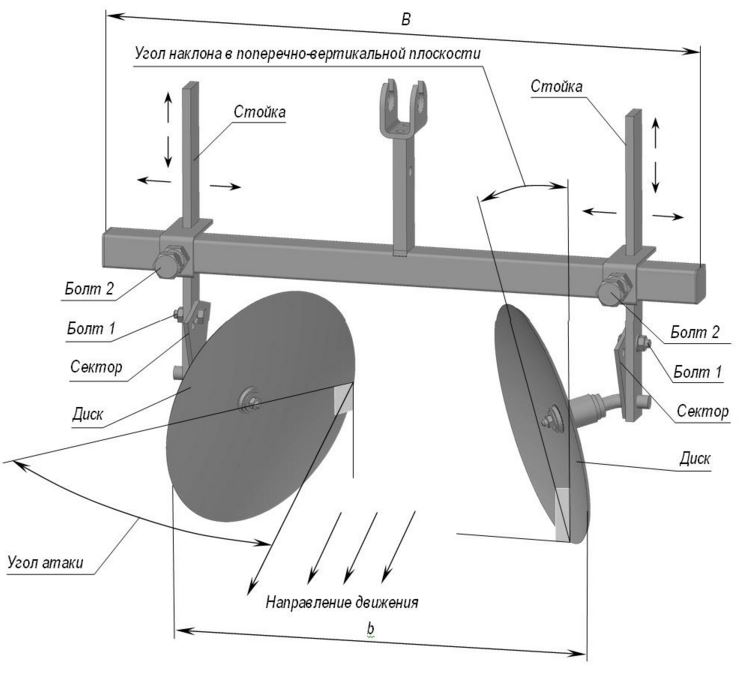

Device

The main components of the device are:

- T-shaped axis;

- screw connections that regulate the angle of inclination of the discs;

- racks in the amount of two pieces;

- discs in the amount of two pieces.

The paired discs should be in the ground at a given depth with little or no resistance. They rotate in the ground, excluding human effort. Thanks to the adjusted angle of inclination and the angle of takeoff, the parts create a ridge. It is customary to set the discs to a value corresponding to the row spacing. Pairs of discs must be of the same diameter and weight. This is the only way to achieve the evenness of the ridge and the smooth running of the device. The required profile is leveled by the angle adjustment system.

The mounted hiller is not included in the standard set with walk-behind tractors and cultivators. Items are sold separately or manufactured in-house. The high cost of hillers pushes people to self-manufacture

When buying, you should pay attention to the compliance of the hiller with the capacities of the main unit. The cost of the hiller is associated with the variety of materials used in its manufacture.

2 How to make a hiller for a walk-behind tractor with your own hands?

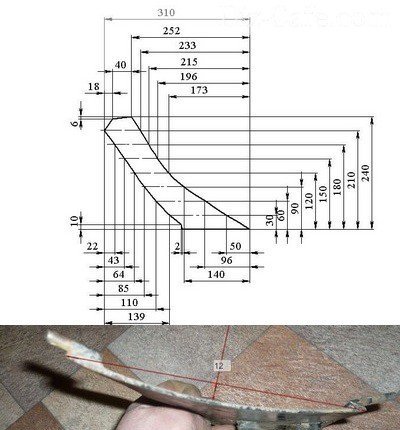

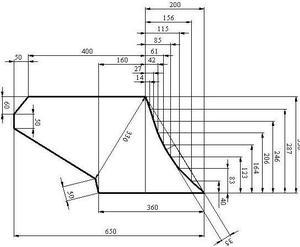

Do-it-yourself hiller can be made using fairly simple designs. This is not difficult. To create a traditional unregulated hiller, you need to cut the halves of the product from 2 mm thick metal using a template.

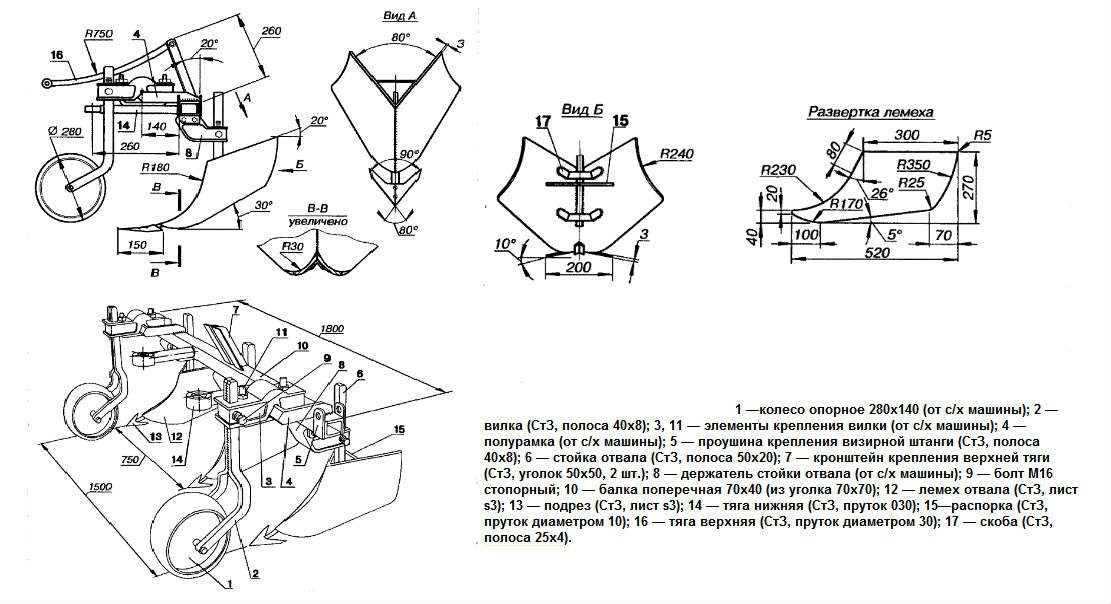

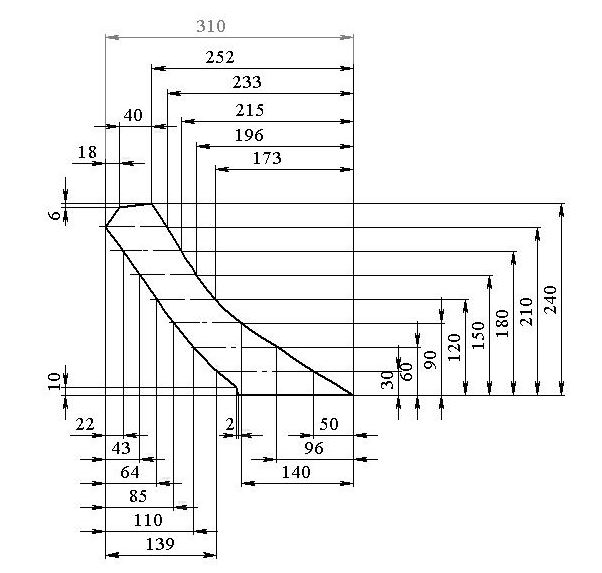

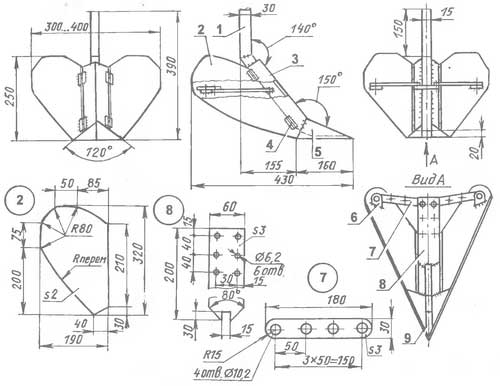

Drawing of a hiller plow for a walk-behind tractor

Next, bend these parts until the radii coincide, then weld in 3 passes. The seams are processed with a grinder. Ultimately, you should get an even layer of metal.

A do-it-yourself disc hiller can also be made. To do this, you must select the type of wings. Plowshares, dumps, or discs, are steel sheets with a thickness of 1.5 - 2 millimeters, whose lower edges are bent.

The main thing is that the disks are symmetrical. Otherwise, then the structure will lead to the side, which will greatly complicate the work. To create the unit, you can use the plowshares, which served as a seeder.

It is necessary to install the plowshares at an angle, maintaining a distance between the lower points, which corresponds to the width of the wheel track, equal to the width of the row spacing.

To connect the elements together, a bolted connection or welding is used. The discs are connected using adjustable adapters.

In addition to the disk, the main parts of the tool are: screw lanyards, stands and a T-shaped leash. Lanyards are needed to adjust the vertical axis of rotation of the disc. A homemade hiller is attached to the walk-behind tractor with your own hands using a beam with wings.

The manual disc hiller is made on the basis of the drawing, while it is very important to provide for the ratio of the fastening structure and dimensions. The tool can be made in two ways: with variable wing width and fixed. In the first method of arrangement, the distance between the discs can be changed due to the symmetrical rearrangement of the racks

In the first method of arrangement, the distance between the discs can be changed due to the symmetrical rearrangement of the racks

The tool can be made in two ways: with variable wing width and fixed. In the first method of arrangement, the distance between the discs can be changed due to the symmetrical rearrangement of the racks.

To facilitate the work with the tool, it is necessary to arrange the plain bearings. To increase the reliability of the product, you can install bearings, rather than sleeve bushings.

Hilling potatoes with a hiller to a mini tractor

The use of a disc hiller for a walk-behind tractor with your own hands will facilitate the work and help to increase yields.

To attach a homemade hiller to a walk-behind tractor, a bracket is used to a hitch without a bead. The unit leash is attached to the bracket using a stopper and bolts with washers. A corkscrew is inserted inside the square tube and pressed tightly against the outer surface.

After that, the do-it-yourself hiller for the walk-behind tractor is ready to work. The traction of the walk-behind tractor can be increased by working in first gear. If the wheels slip during the hilling process, they must be paired.

The mini tractor hiller is installed to huddle your potatoes. For the tool to be really effective, the potatoes must be planted in the correct rows, the distances between the plants must be equal.

In order to process agricultural crops in a mechanized way, a high-performance hiller for a tractor is used. Its main purpose is inter-row cultivation of potatoes from weeds and hilling of tubers to increase yields.

How to do it yourself?

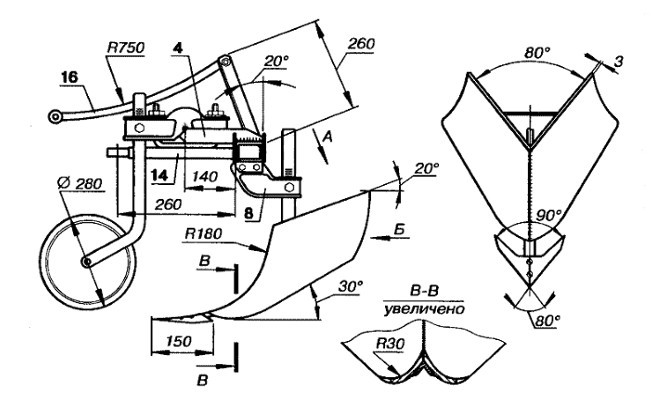

Any equipment is easier to manufacture if there is a corresponding drawing with specified dimensions. The tool making algorithm is required first:

- draw drawings on paper;

- make a template in full size, which will then be used to cut out steel parts;

- bend the blanks of the discs along the level until the parallel lines of the radius are reached;

- organize welding work, with an apparatus with the appropriate power for the metal used;

- clean the welding edges with emery;

- fasten the racks and turnbuckles with bolts;

- weld structural elements;

- adjust the position of the discs.

The required steel thickness for the discs is 2-3 mm. The distance between the elements can vary from 35 to 70 cm. The racks and brackets are made of ordinary water pipes with a diameter of up to 20 mm and a steel thickness of about 2 mm.

Required materials and tools

As discs, it is allowed to use ordinary lids from kitchen utensils with a diameter of 40 to 60 cm. These parameters are selected experimentally and are associated with the power traction of the walk-behind tractor. Too heavy a device, the unit may simply not be pulled. The elements of the connectors will be replaced by a hollow pipe with a diameter of at least an inch, with a meter size.

The pulling force is assigned by a 3⁄4-inch hollow pipe. For the leash, you need to choose T-shaped steel products. Adjustable adapters are useful for clutching disc elements. Bolts will play the role of fasteners. The elements are fastened with welded seams, bent with a turbo bend or with a gas lamp.If the structure is made for a walk-behind tractor, a bracket should be provided. Hand tools need comfortable grips.

Manufacturing

It is possible to make a hiller for the popular motor-blocks "Ugra", "Belarus 09N-02", "Motor Sich" according to the same principle. The main axles on which the disks are hung are adjusted to the parameters of the walk-behind tractor. Parts are connected by welding. The main condition for the disks is a symmetrical arrangement. Both elements are mounted at an angle, and the best connection option would be an adjustable one with an adapter. The holder elements are bent with a turbo bender and then welded to the axis. The reliability of the fasteners must be checked, and the edges of the welding must be cleaned.

The elements are attached to the axis with the letter T. The assembled structure is installed to the walk-behind tractor using a bracket. The stopper can be inserted into the profile tube and pressed firmly. The hiller is revised before planting the potatoes. This will allow you to eliminate shortcomings in a timely manner and not spoil the harvest.

In the process of work, you can set the optimal speed that will match the power of your walk-behind tractor. Hand-made mechanisms allow not only to save on attachments for the walk-behind tractor, but also to facilitate manual labor. Even if there is no unit with a power device on the farm. A self-made manual disc hiller will be a good helper, besides, it will save money on the purchase of equipment.

Assembly

The basic elements of the manual disc tiller remain the same. The assembly of the product is easier, since the two disks of the tiller are connected to each other by a conventional sleeve or by welding through a pipe, which will act as a jumper. Manual models do not imply adjustment of the connection angle, therefore, work with them is possible along row spacings with a standard distance. The free rotation of the discs around the axis will be assisted by the hub. Due to the rotation, the tool will easily enter even in heavy, dense soil.

Elements with discs are connected to a beam, for which a welding machine is useful. Anchor bolts can be selected as connectors. Such fasteners make it easy to disassemble the garden tool.

A handle is useful to control the device. As which you can choose a handlebar from an old bicycle or other similar inventory. It is fixed on the beam and aligned with the height of the person who will control the hiller.

By the way, wheels from an old bicycle can also be adapted to a manual tiller. Attached to the frame at the front will significantly reduce operator stress. Some craftsmen also use a bicycle frame in the assembly, installing hiller discs instead of pedals. The steering wheel and one wheel remain in the design.

Types of attachments for a walk-behind tractor

The hiller demonstrates efficiency when planting potatoes. This attachment is used on walk-behind tractors, which reduces labor intensity and potato planting time. Tillage tools come in a variety of designs to suit all planting conditions. Hillers for potatoes for walk-behind tractors are not included in the standard equipment of the unit, but you can make them yourself.

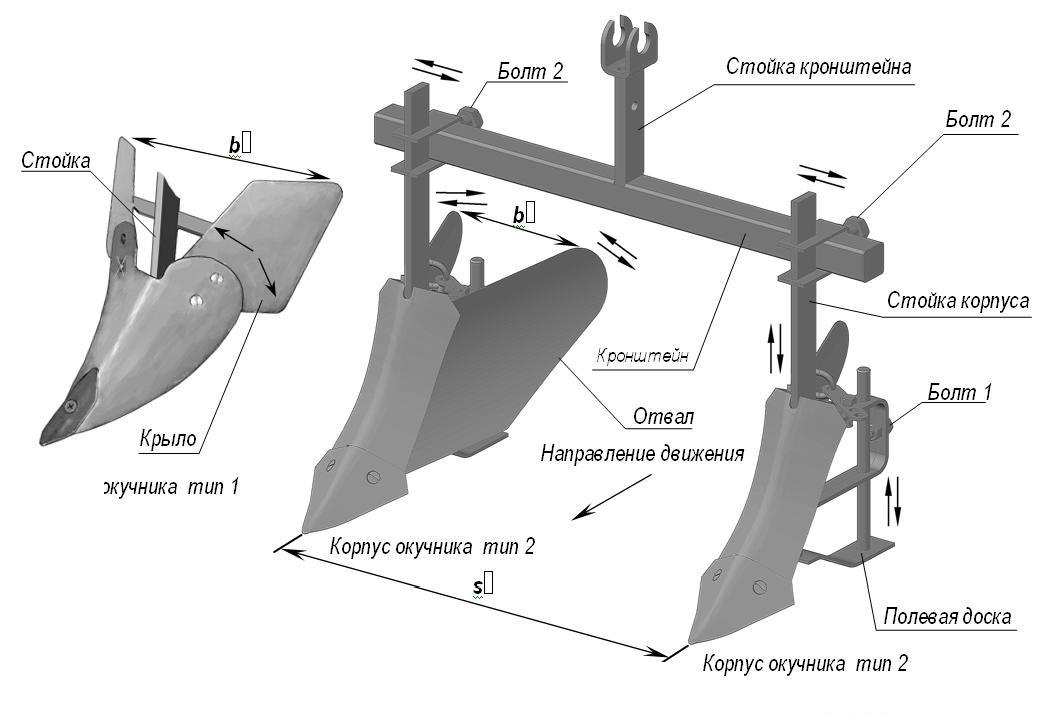

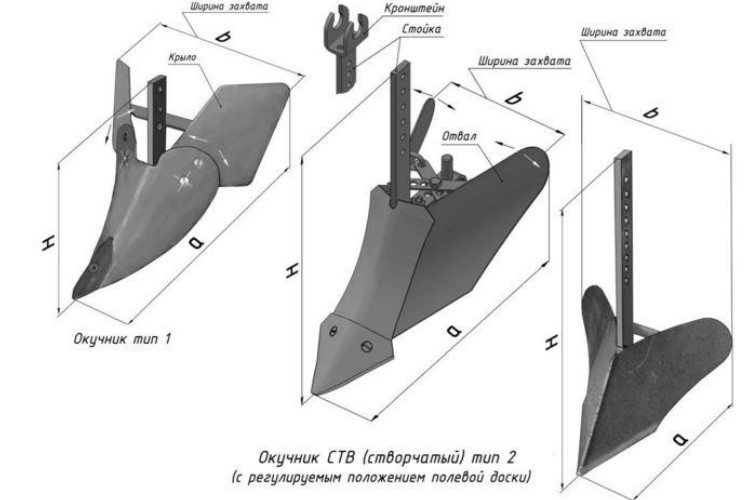

Lister hiller

This type has become widespread among farmers. Its external resemblance to a butterfly is given to it by wide dumps. The latter are made from steel sheet. They are located on either side of the axis. During operation, the equipment lifts the soil with a cutter, and the plows distribute the soil from the center to the edges, forming a ridge. The tip of the device is lowered below the soil level to a predetermined depth. The latter is set using a retractable leg located at the rear of the mechanism.

In the factory design, the camber width has a fixed value (on average 25-30 cm). The limitation of the working distance makes it difficult to huddle crops with a row spacing of 40 cm or more.A movable structure is used to change the dimensions. The variable width attachment has an adjustment mechanism that expands or compresses the blades. This allows the tool to be adjusted to the desired row spacing. However, a large processing area leads to an increase in power consumption.

For your information! With an increase in the working width, a weak implement in one pass will not be able to form a ridge of the required height. Several treatments will be required for one bed.

Disc hiller

Universal disc weeding machine for cultivating the topsoil. Working body - concave discs made of sheet steel. They enter the ground at a given distance, loosen it and form a ridge. For effective use, it is necessary to install discs at an angle in the vertical plane, as well as relative to the direction of travel. Positive sides:

- Adjusting the processing width. The distance between the two discs mounted on the frame is set depending on the size of the row.

- Combination with all types of walk-behind tractors. Tillage will be performed even by low-power units, and the fastening design allows you to install the equipment on any of them.

Manual hiller: how to do it yourself at home A potato hiller is an indispensable thing in the household. Technological progress has long stepped far forward, appeared ...

Propeller hiller

It is an active type of tillage tool, the principle of which is the rotation of curved blades. It is used only on equipment equipped with a power take-off shaft. The latter drives the rotor disc. Rotation of the latter during tillage allows to obtain good productivity and quality of ridge formation. In one revolution, the disc loosens the soil, cleans it of weeds, throws it into the beds, and at maximum speed throws the soil to another place. However, the complexity of manufacturing does not allow making such equipment without the use of metalworking machines.

Watch the video: Disc tiller for walk-behind tractor

To make a potato tiller, you need to follow these steps:

- First, the two discs are fixed at the desired angle by welding or pins (bolts). The deflection of the discs should be outward. With this mounting option, the gap between the discs is not adjustable.

- To make discs with adjustable spacing, holes are drilled on the support beam to optimize the work to be done to secure the tension chains from the outer edges of the discs.

- Further, either handles for human control or holders for agricultural machinery are designed. For manual control, it is better to make control for two at once.

If the hiller is assembled to be operated by one person, then it becomes heavier from above and a skimmer wedge is installed on it, in order to steer when pulling. Various mounts, cam mechanism, brackets, and other parts are useful for work.

The above drawings and models of the potato hiller are conditional, because every craftsman will assemble the structure in a way appropriate to his needs and convenience. When working with a manual potato tiller, you need to get used to it, calculate the pressure force in order to turn out a layer of soil of the required height. It should also be noted that hilling is best done after precipitation. Such a tiller can also be used for digging furrows for planting potatoes.

Useful video: How to make a manual disc hiller

Any farmer who has the necessary tools and a little free time can make a manual disk hiller for potatoes with his own hands. A simple technique made from scrap materials will make it easier to grow vegetables in the country and will help to harvest a good harvest with minimal costs.

How to install and use a hiller

When installing the hiller on the walk-behind tractor, it is important to orient it correctly - parallel to the line of the ridges

Before starting work, the tool must be installed in the hitch of the walk-behind tractor and secured with bolts or pins. To make installation quicker, it is convenient to use hollow axles with cotter pins.

You can adjust the angle, for example, of the disc type of the tool, by tilting the frame in relation to the walk-behind tractor. This partly affects the depth of the furrows. The hiller is adjusted by moving the sole in the vertical plane using the fixing holes made in the rack. And by moving the brackets, you can control the width of the passage.

It will not be superfluous to check the tightness of the bolt connections before work. To do this, it is necessary to carry out a trial processing of an area where there are no plants. In the process, you need to carefully monitor how the individual nodes work. If errors are found, loose connections must be tightened or the tip set up again.

If the walk-behind tractor is used for the first time, it is very important to carefully study the instructions for use and special recommendations for the safety of operating the equipment.

In particular, during the processing of ridges, the following rules must be observed:

- move the equipment over long distances only disassembled;

- do not make sharp turns;

- move in transport position.