Seeder

There are several basic elements in any planter:

- Tools for burying the planted elements, leveling the soil.

- Openers. Most often they are of the disk type. Designed to cut layers of soil in order to embed crops to the desired depth.

- Seed or root feeding device. First, there is a uniform selection, then the material enters the seed tube.

- Containers in which the planting material is placed.

- Frame with fasteners for hitching with mini tractors.

There is a basic solution that suits those new to the industry. Assumes the execution of work with the following move:

- Disc blanks are taken first. They are fixed on the main working axis, evenly. 3 pieces will be enough for a start.

- Any of the discs is supplied with a rim, which is drilled with an electric drill 12 times. This is how the owners receive blanks for placing the seeds inside. Chipboard, plywood - acceptable materials for the box.

- Part of the structure on top accommodates granaries. This is the name of the bunker, inside which planting materials are poured.

- Seeding devices are manufactured separately. It is permissible to use wooden shafts supported by two bearings.

- Any wheels can be used.

- The supporting frame is U-shaped as standard. Strip iron will be the best option.

- The hopper is secured with bolted ties.

The second manufacturing option is in many ways similar to the one described above. The main difference is the drilling of additional holes inside the hubs. The coulter is made of sheet steel. Brackets are used for fastening.

Exploitation

Before starting work, the equipment must be set up and checked. The first step is to check the presence of all parts, as well as their condition, after which it is assessed whether the bolted connections are well tensioned

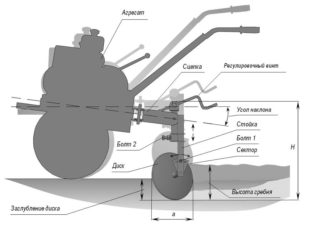

It is immediately important to pay attention to the adjustment of the position of the hiller. If it is necessary to increase the height of the ridge, then the discs come closer together, their angle of installation increases, as well as their depth. Lowering the height of the ridge is carried out when moving apart the discs, as well as reducing the specified parameters

Lowering the height of the ridge is carried out by moving the discs apart, as well as decreasing the specified parameters.

To change the space between the discs, you will have to slightly unscrew the nuts on the brackets, change the position, and then tighten them again. To adjust the installation angle, loosen the bolts. Next, the hillers line up in the desired position, the bolts are tightened again. V the case when a change in the depth of penetration is required, again it will be necessary to unscrew the bolts, correct the situation, that is, raise or lower the hiller itself, and then fix everything back. It is not customary to place the hillers on the front hitch of a mini-tractor, so they are fixed at the rear using a double hitch.

When everything is checked and adjusted, the work of the hiller should be checked in an empty area, if something is wrong, re-adjust

During the test run, it is important to note both the functioning of the individual parts and the entire mechanism. Having started the operation of the hiller, sharp turns at the end of each bed should be avoided

It is necessary to turn smoothly in the first gear of the mini-tractor. If it is nevertheless necessary to make a sharp turn, then at this moment the hitch with the hiller should be raised.

When a mini-tractor needs to be taken to a storage location or to a new cultivated area, this has to be done exclusively in the transport position. In the event that the vehicle, together with the hiller, must be transported over a long distance along unsatisfactory routes, then this must be done with the help of vehicles, partially disassembling the agricultural equipment and fixing its position.In general, the operation of the hiller for a mini-tractor should be carried out in accordance with the instructions attached to the attachment, in compliance with safety requirements.

After work, the hillers must be cleaned of plant residues, soil and dirt. You should immediately inspect the equipment and assess if everything is normal. If necessary, the fasteners are immediately tightened. It is necessary to store the hiller for a long time in a dry room with the necessary protection from the resulting moisture. Before moving the device there, it should be cleaned, wiped dry and smeared with a thin layer of special grease.

In a protected room, the equipment is fixed in a stable position, after which, if necessary, it is tinted with paints and varnishes. The drums with bearings are washed separately, dried and treated with a suitable product.

Different models of hillers

The hiller is the second most important tool after the plow and winch. With its help, you can first cut the furrows for planting, and then fill them with planting material.

Carrying out the hiller along the aisles of evenly planted rows of potatoes, you can observe how the wings of the tool quickly pour soil into the holes with tubers

On sale you can find several options for the models of this tool.

Option # 1 - lister hiller

This is the simplest type of tool and has a fixed working width. The design consists of two connected and slightly spread fixed wings. Since the tool wings are stationary, the furrow width cannot be adjusted by adjusting the hiller to the row spacing. Therefore, when working with such a tool, the aisles are adapted to the capabilities of the hiller, and not vice versa. Traditionally, manufacturers produce products with a working width of 25-30 cm, which is also far from the most convenient option, because the technology of growing potatoes provides for a row spacing of 50-60 cm.

Such tools are designed to work with motor cultivators, the power of which does not exceed 3.5 HP, and the total weight of the unit is 25-30 kg

A feature of the design of lister hillers is also the presence of thin racks that prevent overloading of the cultivator when the hiller is buried in layers of dense soil.

Some models of lister hillers have a streamlined shape, which is more preferable, since when working with such a tool, the soil turns out and dries out less.

Option # 2 - products with variable working width

Such tools are more convenient to use, since they are equipped with an adjusting mechanism with which you can change the position of the wings. This allows the tool to be adapted to different row spacings.

Such hillers are designed to work with more powerful walk-behind tractors with an engine of 4.0 hp. and more, the weight of which exceeds 30 kg

A significant drawback of such structures is their high energy consumption. The reason for this is that in the process of operation, the wings of the tool move the soil to the side, part of which, after passing through it, nevertheless crumbles back into the furrow. As a result, the back and arms get tired faster, and some of the engine power is wasted on useless work. But despite this, they are one of the most popular models among most gardeners.

Option # 3 - disc models

Disk hillers cost an order of magnitude more expensive than their traditional counterparts, but the efficiency of working with such tools is many times greater

The main advantages of disc hillers are:

- A successful combination of the walk-behind tractor with the tool itself. Using a disc hiller, when the speed of the cultivator decreases, its power increases. This not only increases the efficiency of cultivation, but also has a positive effect on the operation of the unit itself.

- Ease of use.To work with such a tool, you need to make a minimum of effort: it pushes itself forward without requiring additional pushing from behind.

- Versatility of application. With this tool, hilling can be done both after planting the tubers, and during the period of active growth of the aboveground part of the crops.

Choosing among the variety of assortments, it is advisable to give preference to models made of alloy steel, equipped with rolling bearings (and not sleeve bushings), with a large diameter and thickness of discs.

Option # 4 - propeller-type hillers

The principle of operation of the tool lies in the work of special propellers, under the action of which the soil is first crushed and weeds are combed out, and after that the beds are spud with loose soil

Such hillers are intended for equipping walk-behind tractors and motor-cultivators, which have two forward gears. This is necessary so that in the second gear with an increase in power up to 180 rpm, using the tool, you can not only loosen, but also transfer the soil into the beds from the row spacing.

Recent Entries

The time has come to carry out the first feeding of tulips 5 flowers that provoke a headache: you should not plant them in large quantities 5 flowers, similar to chamomile, which bloom all summer

Sprayer and manure spreader

The cost of such products will depend on how the owners approach the manufacture. To assemble with your own hands from scrap materials you will need:

- A pump with a voltage of 12 V.

- Pipes.

- Square metal profiles.

- Tank, plastic or stainless steel. The minimum required capacity is 200 liters.

The spray pipes are attached to the structure after the frame is welded. The sprayer is connected to the mini tractor hitch. Better to make the spray boom moveable. To do this, the automobile structure is connected to a jack, it will work from a hydraulic system.

Homemade sprayer on a mini tractor on video:

The manure spreaders are supplied with wheels. Their tread must be strong enough to avoid slipping. The belt conveyor is responsible for the supply of fertilizers, the drive from the trailer wheels sets this part in motion. Adjustments and shutdowns are often done manually.

How to choose?

The choice of a hiller depends on its purpose. For example, a three-row option is unlikely to suit the owner of six acres, but in a farm it will become an indispensable assistant in the cultivation of root crops or berry crops. When choosing a product, you should focus on completeness. For example, disc types of hillers on a frame are often sold without a hitch. If you overlook the complete set, you will have to postpone work in order to buy or make a hitch yourself.

It is clear that for a domestic cultivator and for MTZ it is effective to use different models of hillers.

Multifunctional Polish models have taken root on the Russian fields. They are suitable for large areas with a slight slope. For subsidiary farms, it is worth acquiring a universal mechanism that is compatible in parameters with an existing or planned walk-behind tractor or a walk-behind tractor.

For gardeners working on large potato plots, an active two-row type of hiller is suitable. The rotating blades will cope with three tasks at once: they loosen the ground in the aisles, chop down weeds, and form mounds over the lashes.

Views

There are several varieties of tractor hillers on the modern market.

Lister equipment for a mini-tractor is considered the simplest model. Work with the ground is carried out thanks to the presence of a pair of connected and slightly spread wings. Thin strut prevents overloading when the moving device is immersed in the soil

It is important to mention that the lister hiller does not have the ability to adjust the grip, that is, the row spacing must correspond to the equipment, and not the canopy to adjust to the existing beds. The grip width of the device is always fixed and ranges from twenty-five to thirty centimeters

This gap is sometimes not enough for processing large areas, which, of course, is a drawback of this variety.

A model with a variable working width is considered more convenient for operation, which indicates the possibility of adjusting the processed space.

- The disc hiller is considered a versatile device, very convenient to use. Such equipment allows you to cultivate the land not only during planting, but also when the potatoes are actively developing. Models made of alloy steel and equipped with special rolling bearings instead of sliding bushings are considered the most reliable. The large diameter and thickness of the discs are also important.

- The next type of hillers is called propeller-type devices. As you might guess from the name, hilling of the soil in this case occurs with the help of propellers. These parts rotate, crush clods of earth, and then transport them from the space between the rows to the beds themselves. As a rule, propeller-type hillers are mounted on moving vehicles with two forward gears. Such a condition is necessary so that in the second gear, the power of which reaches 180 rpm, in addition to loosening, the earth is also thrown over.

It is worth mentioning that many craftsmen make such attachments on their own from improvised means, since the Internet contains a large number of suitable drawings and instructions. The role of discs is usually played by lids from old pots without enamel coating. The diameter of the circles in these cases varies from forty to fifty centimeters, and the edges of the covers must be sharpened and, if necessary, slightly bent. A contour is assembled from pipes and bushings, on which the discs are then fixed. The frame itself also has to be supplied with wheels for movement.

Feasibility of the procedure

Disc hillers are used for a very important agricultural technique - hilling. Carrying out this event is a mandatory procedure when growing potatoes.

It performs a number of important tasks:

- elimination of weeds, which is quite problematic to perform manually with a hoe;

- hilling protects tubers from direct sunlight, which, when potatoes are close to the surface of the earth, can slow down their development, and sometimes even lead to drying out;

- correct and timely hilling leads to an improvement in soil air exchange and normalizes the evaporation of moisture from the earth's surface.

If there are several rows of potatoes in a summer cottage, there is, of course, no need to purchase a hiller, but if rather large areas are occupied with potatoes, then mechanization of this process cannot be dispensed with.

how to plant potatoes under a hiller? | Topic author: Anatoly

Vitaly So they plant it with a motor-cultivator, but it is also possible with a manual hiller. You make the rows of Roman with the hiller, put the potatoes, and then go through the hiller again between the rows and fill in the potatoes. It is very convenient if the width of the hiller can be adjusted - make the grooves narrow and fill them wide.

Ruslan Plant just under the straw, without digging or hilling, but after sprouting, constantly put a bush of weeded grass on the floor

Valentin is not entirely clear what a hiller is

Nikita for a hiller, there is no other way.

Igor Make the furrows a hiller, lay out the potatoes and ash, and then put the shovel in your hands and close the furrows.

The principle of work of hillers

The hiller allows you to dig a furrow of the required depth with a dump of black soil on both sides.

In terms of its importance in the processing of potato plantations, the hiller takes second place after the plow. The design of its working body allows you to dig a furrow of the required depth with a dump of black soil on both sides of it

When planting, the groove needs to be made larger, since the potatoes need a thick layer of soil on top. Then the tubers are evenly laid and the row is filled up. During hilling, it is not necessary to provide a large penetration, which significantly reduces the load on the engine of the walk-behind tractor.

Weed control will take place both between the rows and along the potatoes themselves. The working bodies of the hiller, cutting off the soil in the inter-row space, will simultaneously weed it, and the earth, which the dump-wings feed on the row, will completely fill up agricultural crops and weeds. If for potatoes this is only good, then for unwanted plants it is guaranteed destruction.

Important points in work

There are other types of devices, among which the rotary hiller, two-row hiller, etc. should be distinguished. Despite the fact that a double hiller allows you to process a large area, many prefer ordinary single-row ones, since only they can work with light walk-behind tractors. The single-row hiller, although it allows you to huddle only one bed per pass, has the advantage - you can fine-tune the device.

Also, in theory, it is quite simple to huddle potatoes: you should sprinkle the base of the bush with soft and loose earth. This allows you to create favorable conditions for the development of root crops, improves aeration, and weeds are destroyed. In the process of hilling, the earth moves from the intervals between the beds to the bases of the bushes. Many do not know when to hilling and how to properly use hillers with walk-behind tractors.

More experienced people recommend hilling about 4 times per season. This is due to the fact that the tuber of a potato (or other root crop) is capable of development only at a depth of 15-20 cm. At the same time, the hilling process allows the potato to develop in different directions. Thus, the hilling process creates additional opportunities for the development of root crops, increasing the yield and quality of the fruit. At the same time, it is most effective to huddle wet soil - after rain, dew, etc.

It is strictly forbidden to huddle with dry soil - this can lead to the death of the plant.

The first hilling is done almost immediately after the potatoes emerge.

Before starting work, you must be extremely careful about setting up the unit: it is important to set the distance between the discs or knives so as not to damage the plants, but at the same time so that the seedlings are not completely covered with earth. The height of the slide should cover the base of the stem to the leaves, which allows you not to destroy the plant and allow it to develop

The next hilling is done when the tops reach a height of 30 cm.

At the beginning of work, incorrect installation of the hiller's plows is often revealed. It either buries deeply in the ground, or, conversely, goes practically along the surface. The solution to this problem is simple - it should be adjusted more precisely.

Hillers on a mini tractor are installed in the same way as installation on a walk-behind tractor. However, it should be remembered that to work with these blocks, the width of the bed should not exceed the distance between the wheels of the tractor or walk-behind tractor.

One more detail - for some models of hillers it is impossible to adjust the angle of attack, on which the efficiency of work depends. Therefore, you should be extremely careful about connecting a walk-behind tractor or tractor with a hilling device and carefully adjust the distance between the discs or knives.

Important tips and tricks

When starting the manufacture of attachments and other equipment intended for land cultivation, it is necessary to take into account some of the features of the production of products. If you assembled and run a cultivator or hiller with your own hands, it will be impossible for you to guess how it will behave on the ground during work.

Especially if a tractor equipped with a homemade product has to work on different soils. Thus, a homemade cultivator for the T 25 may be too light, since it was assembled according to the scheme for the T 16, which has a lower engine power.

The same applies to such equipment as a home-made cultivator on the T 40 - although this tractor has a lot of power, it will not be advisable to put large equipment on it.

In this case, he will be able to process a larger area, in a short time, with the same robotic performance.

Why hilling is needed

Some gardeners get by with growing potatoes and without hilling the beds. However, in order to grow a really good harvest of large root crops, hilling is necessary.

This procedure provides the plant roots with better air access, and it also helps to retain moisture. In addition, hilling causes the plant to develop stolons (side shoots), resulting in more tubers.

On the video - why hilling is needed:

Of course, you can huddle potato beds with a hand tool, however, this method is only suitable if the beds are small. For large areas, it is necessary to use a hiller, which significantly speeds up and simplifies the work process

It is also worth paying attention to why a potato digger is needed for the Neva walk-behind tractor, and what is its price

How to make a hiller for a mini tractor with your own hands?

It is quite simple to make a hiller for a minitratkor with your own hands. The choice of design will depend on working conditions and your preferences. Having mastered the manufacture of this equipment, you can safely make your own rotary tiller for a mini tractor.

Most often, homemade hillers for a mini tractor are lister and disc.

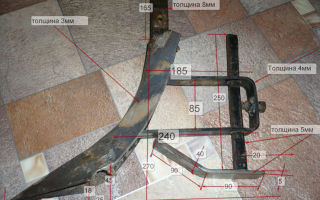

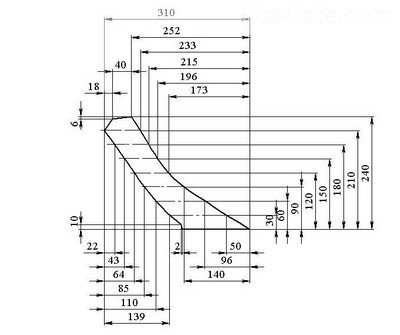

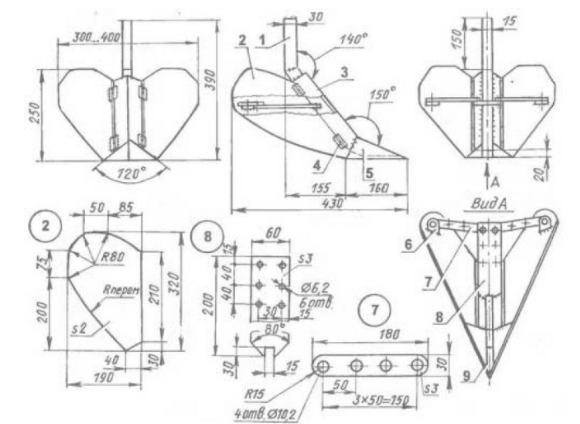

Drawings and dimensions of lister equipment are shown in the diagrams below:

The manufacturing procedure is as follows:

- a tube of a smaller diameter is inserted into the pipe intended for the rack, the height of the device is adjusted;

- in order to find the optimal angle of inclination during processing, use the tarlep to adjust the angle of inclination between the rod and the stand;

- the stand itself is made of a pipe approximately 1 m long, bent at an angle of 15 degrees;

- hiller rods are made in the form of U-shaped forks, about 50 cm wide and about 20 long. The front link handles are made a little longer. They are inserted into a vertical rack;

- the hiller itself is made from 2 metal plates with a thickness of about 2 mm. Having bent them in the necessary way, we weld the device to the rack;

- a ploughshare is welded to the wings, made of steel of a slightly thicker thickness and sharpened for better cutting of the ground.

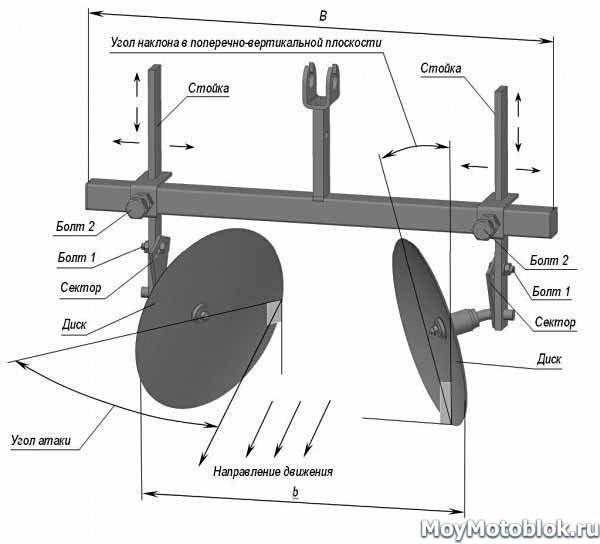

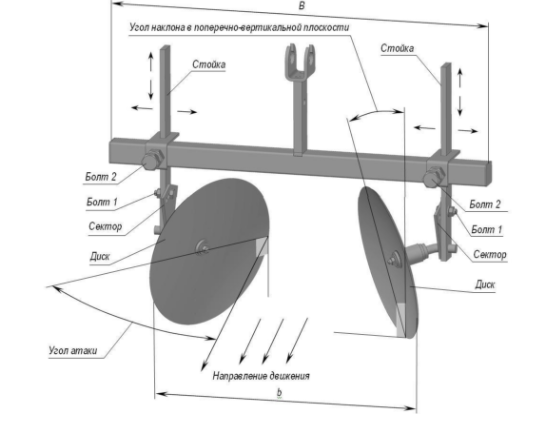

The manufacture of a disc hiller for potatoes on a mini tractor is carried out according to the following algorithm:

- Identical, symmetrical hemispherical discs are cooked from metal sheets 1.5-2 mm thick.

- The discs are attached to the rack using bolts or welding at the required distance and at the desired angle.

- The discs are connected by adjustable adapters. The rotation of the discs around its axis is regulated by tarleps.

- The hiller is connected to the minitractor by a T-shaped leash with a coupling device.

Alternatively, we suggest that you familiarize yourself with a video that shows the manufacture and operation of a manual lister hiller:

With your own hands

The most important starting material for construction is old pot lids.Here it is necessary to take into account the fact that the specified raw materials must be made of metal and not have an enamel coating.

The optimum diameter of the lids is 40-50 centimeters. This is quite enough, since potatoes do not immerse their roots very deeply - by 15-20 centimeters.

The next step is to sharpen the edges of the covers. These actions are best performed using a special unit. It is worth clarifying that these elements will serve as discs for a homemade hiller for a mini tractor. (See photo).

An important point in the production of these elements is the shape of the caps. If they are straight, bend their edges slightly. This can be done with a hammer.

In order for the unit for your minitractor to be as convenient as possible, you should design a special trolley. It is she who optimizes the process of moving the blades of the cutter, which loosens the soil.

In order to accomplish this task, pipes and bushings are used. Further, the unit on the mini-tractor is equipped with wheels that are attached to the frame of the structure.

For the convenience of constructing the unit, you can pre-sketch the corresponding drawings, which will clearly show through all the details of the project. Such drawings can be made by anyone who is at least a little familiar with the specified process.

It is worth noting that a homemade unit does not have to be built in accordance with any aesthetic norms. The most important thing is that your cultivator-hiller for a mini tractor functions smoothly and performs its direct duties as efficiently as possible. Then the potatoes in your garden will feel comfortable enough, which will allow you to harvest a rich harvest.

Exploitation

You bought a hiller for a mini tractor or created it with your own hands, you need to know how to correctly, which means it is safe to operate this device. First of all, it must be said that the hiller is capable of performing several agricultural operations:

- hilling.

- loosening the soil.

- cultivation.

- cutting of furrows.

An important advantage of the unit is that its owner has the ability to independently regulate the work of the hiller, depending on the conditions and specifics of the process. In addition, the weight of the equipment is quite small, which makes it easy to install or change special feet on it. (See photos).

Another important advantage of this device is its ease of use. To use a hiller, a mini tractor is not required to have a high power rating, since the specified equipment belongs to the traction class.

This is how we gradually got to the basic rules of working with a potato hiller.

- Before the unit is started, it is necessary to carefully inspect it for the reliability of fastening all working elements.

- There are a number of manipulations that should be carried out exclusively with the minitractor turned off. These are the following actions:

adjustment of parts of the mechanism;

- installation of certain structural elements;

- cleaning of specific parts from dirt and plant parts;

- repair and preventive manipulations;

- It is allowed to turn on the PTO shaft only at minimum speed.

- During the movement of the hiller, there should be no people in the area of its action.

Upon completion of the working process, it is necessary to thoroughly clean the unit from soil and plant residues. Make sure your equipment is absolutely clean and dry before you retire it. Ignoring this rule will lead to undesirable consequences that may interfere with the further operation of the device.

In the case when it is planned to store the hiller for a long time, excluding the use of a device, all its working surfaces must be treated with solid oil.If it is necessary to involve the device in agricultural activities, the specified grease must be removed.

This video provides information on how to build the described device at home, spending a minimum of time and money.

Making a disc hiller

In this type of agricultural equipment, the main working bodies are discs. Their use is much more productive, since the required accuracy and shape of the beds are achieved. The configuration of the product is such that the risk of damage to the tubers and stems of the plant is almost completely eliminated.

If it is not possible to purchase industrially manufactured discs, then you can make them yourself. For this, sheet steel 2 mm thick or wide iron lids from pots are used.

If there is a mismatch in shape, then the hiller will come off the row and cut the stems of the plants.

A disc hiller is made in the following sequence:

- Work items are being made. Depending on the power of the mini-tractor and the type of soil, the hillers are designed single-row or multi-row. The discs are made in pairs. Their edges are folded in different directions. For this, a heavy hammer and anvil are used. Bushings or powerful rolling bearings are inserted into the center of the circles.

- The hiller frame is being assembled. Better to do this by welding. It is recommended to strengthen vertical and horizontal parts with steel ties from pipes or corners. In order to be able to adjust the grip angle, screw lanyards are attached to the frame.

- The discs are mounted on the axle. Tuning and adjustment of each fragment is carried out. If a multi-row device is being manufactured, holes are drilled in the bracket for attaching disk modules.

- The quality and correct assembly of the product is checked. After that, it is fixed on the mini-tractor bracket and tested in the field. If flaws and shortcomings are identified, then they are eliminated in the workshop.

Upon completion of mechanical work and debugging, the hiller is given a presentation. It is completely cleaned of dirt, dust and rust. Moving parts are lubricated, and the rest of the surfaces are painted with acrylic paint.

Rotary mower for mini tractor

Before starting work, it is important to take care of the materials and tools in advance. It is permissible to use everything that is at hand, therefore problems should not appear

Suitable:

It is permissible to use everything that is at hand, so problems should not appear. Suitable:

- any kind of metal barrels;

- spare parts from equipment that is out of order;

- old frames.

To collect this part, a minimum knowledge of technology, skills in handling welding machines will be enough.

Any type of rotary mower contains blades mounted on discs with a cover for additional protection. The movement of the mechanism begins at the expense of the shaft, which takes power.

The order of work will be as follows:

40cm metal corners are used in frame design. When connecting, the use of conventional welding machines is permissible. Cutting elements can be assembled on the basis of knives from old tractor mowers. But without a minimum of 30mm clipping, the technique won't have enough traction.

Two circles of 390 mm diameter are cut out of sheet metal having a total thickness of up to 4 mm.

They are assembling knives in circles

It is important that they remain free to rotate after completion of work. Vegetation is then cut off only due to the action of centrifugal forces

The lower discs of 450 mm diameter are taken from old cultivators. This is usually the bottom part.

Special shafts - the place of attachment of discs with knives. The element can be supported on a 30 cm diameter metal pipe. Additional bearings are indispensable. Installation of one is performed on the pipe, the second is connected to a welded pulley.

Knife discs are mounted on an axial shaft.The pulleys and pipe are then welded together. The homemade mower is almost ready.

At the top, at the final stage, a protective casing is mounted. 1150 mm - working width for rotary mowers.

The lower discs can be mounted directly to the frame, which simplifies the design.

Making a homemade rotary mower in the video: