How to run in a walk-behind tractor correctly?

Running in the unit is a must. In this case, all gear pairs are rubbed in for further normal operation.

All work is performed strictly following the operating instructions. The manual contains information on the permissible loads for a specific unit model.

It is important to follow a number of rules, including:

It is necessary to run in the walk-behind tractor, observing the specified time;

If the plowing depth is specified up to 50 centimeters, then processing is performed at a depth of within 30 centimeters;

A new walk-behind tractor can be filled with oil or without

This is an important nuance.

It is important to pay attention to the selected brand of engine oil;

The brand of the motor is determined. It has directional stickers.

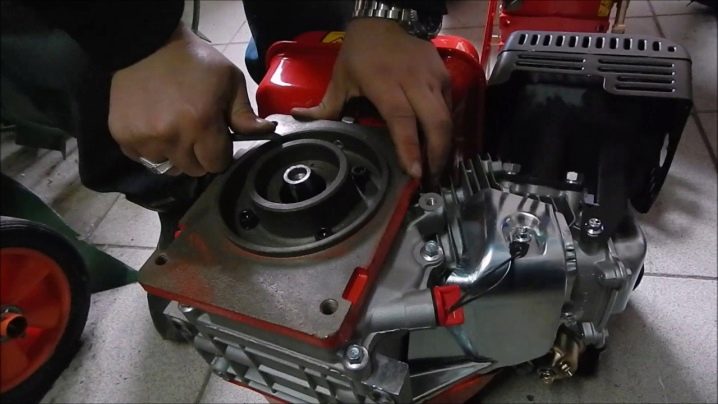

After pouring oil into the crankcase, you can start running in. If there is a problem, the oil drain bolt is unscrewed to check for the presence of lubricant.

The procedure should be carried out slowly and carefully, it is impossible to gas, so as not to provoke negative consequences.

Why is it necessary to run a walk-behind tractor at all

Without running in, the engine on the walk-behind tractor may fail. The manager selling the goods is obliged to warn the buyer about this. Not all salespeople do their job well. They do not give complete information about the rules for running in a new cultivator or give incorrect advice. Therefore, there are often bad reviews of gardening equipment.

Previously, the running-in was carried out at idle for a certain time, due to this, the moving parts rubbed in. After that, the new engine did not jam at full load. Now parts are produced with high precision, so not all models need idling during running-in.

Note! When a Honda engine runs for a long time at idle speed, fuel accumulates in the crankcase, this deteriorates the quality of the engine oil.

All operational restrictions that must be met when starting up a new walk-behind tractor are indicated by the manufacturer in the operating instructions. Their implementation extends the life of the engine, eliminates the rapid wear of rubbing surfaces, seizure, breakage, jamming.

Features of the procedure

The first step is to scrupulously check every fastener, every bolt. The tank is 100% filled with gasoline or other necessary fuel, engine oil. Be sure to take care of the preparation of the coolant in the required amount. Running-in does not only mean "grinding" the engine parts to each other, "triggering" them together. It is also required to carefully check the serviceability of the brakes and steering gears.

It is impossible to run in a walk-behind tractor normally if the steering wheel is not set according to the rules. After running-in, every detail should be inspected immediately. This takes time, so it is worth planning all the work carefully so that nothing interferes with the process. The technical inspection includes:

-

study of the condition of each oil seal and bearing;

-

rubbing them with oil;

-

immediate replacement of damaged and deformed parts;

-

checking the springs of the forks and control elements.

It is interesting: Characteristics and attachments for Oka motoblocks MB-1D1M10 and MB-1D2M16 - we learn in detail

Video: How to Run a New Motoblock Correctly

checking fork springs and controls.

What else do you need to know?

The main points that should be of interest to the farmer are the timing of dismantling and the permissible load of the walk-behind tractor. Usually the cultivator is loaded at 50% of the maximum values. That is, if it is intended for plowing a primeval tree 50 cm deep (this is possible only for the most powerful models), plowing more than 30 cm during the run is not allowed.To reduce the cost of purchasing spare parts for pass-through power supplies and find them faster, it is best to immediately select devices from well-known brands with a developed service network. The load limitation, of course, applies to the maximum load weight.

Oil testing. it is not just a visual way. It is much safer to unscrew the screw or remove the cover (depending on the model) and see if the working fluid is leaking. If it does not leak, then a full tank must be filled. After preparation, start the engine. For a while, they make it work at half load. For most modifications, this time is 8 hours.

Despite the official completion of the planter, the full cultivator can only be loaded after 20 or even 30 hours

It is important to keep this in mind. It is equally important that the most competent mileage will be successful only if the transition to smooth operation of the engine unit is smooth

The same oil level in the engine and transmission should be assessed before any start, even if you need to work for 10-15 minutes. It is also worth closely monitoring the amount of fuel in the tanks. It is unacceptable to save on the quality of fuels and lubricants. this quickly turns into even greater losses.

When the engine is running, it must first run at medium speed. Only after warming up can you start working completely. However, during normal operation after loading 100%, loading unnecessarily is undesirable. If it is possible to transport the consignment for 2 or 3 receptions, this should be done. Experienced people are also suitable for plowing, harvesting and more.

Approaching different models

You can get to the Neva and Orak in 20 hours. For an Oka walk-behind tractor with a Chinese engine, this period is 30 hours. Zirka blocks are the most capricious. they work for at least 50 hours. During this procedure, it is not recommended to immerse the plow or mill mounted on a star more than 10 cm into the ground.

It is important to remember that all lubrication units can only be lubricated with impeccably clean oil, being careful not to get dirty during refueling.

When starting a Briggs & Stretton motorized starter, you must change the engine oil every 5-8 hours. If a Honda engine is installed, prolonged downtime is unacceptable. Otherwise, the accumulation of oil in the engine crankcase will deprive the oil of its useful properties. Subaru requires:

monitor the condition of air filters;

evaluate the quality of candles and fuel lines;

Avoid heavy contamination of the cylinder ribs.

Why is it necessary to run a walk-behind tractor at all?

Such an operation will significantly increase the life of the unit, but before carrying it out, you need to carefully check the condition of all bolts

It is important that they are tightly screwed in. Then be sure to refuel the device with quality fuel, coolant and lubricant.

During the check, special attention should be paid to the performance of the steering system and braking system. The steering wheel must be placed in a neutral (classic) position

All elements are carefully inspected every 2 thousand hours of operation. Those owners who take care of their "new friend" lubricate spare parts with machine oil and if they see that, for example, bearings are completely worn out or look suspicious, they replace them with new ones. A similar situation is observed with axles and drives.

Running in a diesel walk-behind tractor (or any other) is not carried out immediately after delivery to the owner. Technique should be prepared. After all the parts are lubricated, the transmission oil must be drained, and it is in a hot state. Then the owner pours in diesel oil and very painstakingly rinses the gearbox.

It is important to use only those substances that are indicated in the instructions, otherwise problems with the operation of the device may appear.

It's interesting: Do you need rights to drive a walk-behind tractor - share our experience

Why is break-in necessary?

Engine break-in, as mentioned above, is extremely important and necessary in order to extend the service life of the equipment. This is the preparation of the machine for further work, loads. It must be carried out not only after purchasing a new unit, but also after you have carried out major repairs.

Before the main work, you need to prepare the technique. First you need to inspect each element, check all fasteners, damage or breakage. All malfunctions are eliminated immediately, otherwise unforeseen situations or even failure of the unit may occur during running-in.

Preparation process for running-in:

- check all bolts and all fasteners. They must be strong and securely screwed in;

- fill the walk-behind tractor with gasoline, and also fill it with oil;

- the brake and steering system must be checked before work, as well as several times during the running-in itself;

- the steering wheel must be in the correct position;

- check the condition of the axles, bearings, oil seals, drives;

- according to the operating manual, you must lubricate all parts with oils that require it. In this case, this stage is carried out with complete cleanliness so that dust, dirt or small particles of anything that could negatively affect the operation of the machine does not get into the oil.

Running in individual models of motoblocks

Before the first launch, study the instructions in detail. Carefully read the paragraph about running in. For motors of the same brand, the recommendations for the first start are the same.

Neva

For a complete grinding in of the transmission and all parts of the Subaru engine, the Neva walk-behind tractor is run in for 20 hours. To prevent overload, follow the recommendations:

- carry cargo, the weight of which does not exceed 150 kg;

- do not cut clay and stony soil with a cutter.

Before each start-up, the oil level is controlled with a dipstick (TEP-15), the first change is carried out after 25-50 hours of operation.

Hopper 900

With a hopper 900 motoblock, they master virgin soil, remove snow, plant and dig potatoes, transport goods. It operates in 4 speed modes, is equipped with a Chinese 4-stroke Lifan engine with a capacity of 6.5 hp, large wheels.

It takes 20 hours to run in the engine, it is performed in stages:

- after the first start-up 15 minutes idling;

- the first 7 days work at ⅓ of maximum power;

- the next 7 days are operated at ⅔ of maximum power.

After 20 hours of running-in, the walk-behind tractor is operated at full power with any attachments.

Oka

Oka with a Lifan gasoline engine has a maximum power of 6.5 hp (4.8 kW), the recommended one is 5.5 hp (4 kW), forced air cooling, TC1 ignition system. When running in the Oka walk-behind tractor, use:

- SAE-30 or SAE-10W oil;

- gasoline 92.

Note: The throttle valve must be opened ⅔ of the stroke.

The model is run in for 30 hours, simple work is performed at a minimum load. The maximum operating time with attachments on heavy (clay) soil is 2 hours. The plowing depth in one pass is no deeper than 10 cm.

Patriot

The gasoline engine of the Patriot Pobeda has a power of 7 hp, 3 speeds. It works on AI-92, AI-95 and EXPERT SAE 10W-40 engine oil. It is replaced in the engine after 100 hours. For the gearbox, Patriot HYPOID 80W85 gear oil is used, it is changed after 50 hours.

Correctly the Patriot walk-behind tractor can be run in according to the following scheme:

- start the engine;

- give to work for 30 minutes;

- gas;

- check for leaks;

- 20 hours do not operate the walk-behind tractor at full capacity.

After finishing the running-in, the used oil is drained, a new one is poured.

BRAIT

Motoblocks Bright are produced with diesel engines (BR-135DEB, BR-135DEA) and gasoline engines (BR-135G, 135GA, 135GB, 135GBE, BR-58A, BR-68, BR-70). The instructions tell you how to do the first launch:

- fill the unit with oil, fuel;

- Work for 8 hours in light mode (⅓ maximum power);

- Replace engine oil after running-in.

When the first start-up is correct, oil passes through the entire engine, lubricates the engine.

Why is running-in

The start of operation of any engine must be associated with running-in. This allows you to significantly extend the service life of any unit, including the one installed on the walk-behind tractor. At the same time, experienced craftsmen recommend running in the engine not only when buying new equipment, but also after a major overhaul.

This is very important, since only after a high-quality running-in can we expect that the equipment will work properly and without significant breakdowns for a long time.

There is a certain sequence of how to run a walk-behind tractor. First of all, you need to check the reliability of the fasteners and all the bolts. The tiller should be filled with gasoline, and only then start the engine

As with any other technique, it is important to use lubricant (machine oil) and coolant when preparing the walk-behind tractor for operation.

During running-in, not only the operation of the engine is always checked, but also the operability of the brake system, as well as the reliability of the steering. Make sure that the handlebars are in the correct position, otherwise there will be no normal break-in.

Experts recommend carrying out a technical inspection of the device immediately after running in. This will allow identifying possible problems and shortcomings, as well as eliminating them in a timely manner. After running-in, an inspection must be carried out every 2000 operating hours. Inspection of bearings and seals is mandatory. All elements should be wiped with diesel oil. Worn parts must be replaced immediately

Experts recommend paying special attention to the fork spring and control. It must be reliable enough for the equipment to work flawlessly.

The main rule for running in a motor cultivator is the correct sequence of actions. Work always begins with careful preparation. At this stage, everything should be checked, lubricated and refueled as efficiently as possible. Only then can the engine of the walk-behind tractor be started. The service life of the unit will directly depend on how well the diesel walk-behind tractor is run-in.

Running in individual models

Consider this process on walk-behind tractors of individual brands.

Oka with Lifan engine

Such a model must be run-in for 30 hours. During this time, all elements are lapped in under light operating conditions and defects are determined. A new unit with a Lifan engine during testing should operate at minimum loads.

When testing a walk-behind tractor for functional operations, the following requirements are met:

- the soil is processed to a depth of 10 cm in one pass in one direction;

- the throttle valve should be open 2/3 of its full stroke;

- on clay soil, the walk-behind tractor under load should work no more than 2 hours.

In addition, the oil level must be checked before each engine start. If there is a shortage, topping up is made to a level above the minimum mark on the dipstick.

Neva with Subaru engine

This model, like the MB-2 models with other engines, runs in for 20 hours. This time is quite enough for the parts to get used to the ideal working condition, and also to show defects in them. It is unacceptable to overload the apparatus with a large load during this period.

When running in, observe the following:

- cultivate the soil with a full set of cutters in several approaches to a depth of 10 cm in one pass;

- load the walk-behind tractor with a load of no more than 200 kg;

- before starting the engine, check the oil level and, if there is a shortage, top up above the minimum mark on the dipstick;

- refuel the unit with fuel of the required brand and proper quality.

The tension of the drive belt should also be checked regularly.We must not forget about the decoupling element of the left chassis of the walk-behind tractor.

Centaur

The unit of this brand is run in subject to clear rules. Their implementation extends the life of the walk-behind tractor as a whole.

The running-in of the new "Centaur" with air cooling is performed according to the following algorithm:

- The motor is loaded in stages: it must work at a third of its technical capabilities in the first three hours.

- After the first three hours of running-in, the oil is drained from the engine together with the transmission fluid from the transmission units.

- For the next 4 hours of testing, the engine is loaded at 2/3 of the technical capacity.

During operation, monitor the permissible loads. In the periods specified by the manufacturer, they regularly carry out maintenance and repairs.

Firework

The Salyut-100 walk-behind tractor is being run in at medium speeds. The first cultivation of the soil is carried out with 4 cutters. They are gradually buried lower with each pass. Cultivation is carried out with a coulter.

After every 30 minutes of work, take a break of 10 minutes. After the end of the first 4 hours of operation, the oil in the engine is changed. In the gear unit, the oil is changed after the walk-behind tractor has been run in.

Agate

For this model, 25 hours of running-in of parts is enough. During this period, the device must not be turned on at full load. It is also prohibited to overload it during testing with cargo.

When running in, the following standards are strictly observed:

- when testing functional modes, it is necessary to cultivate the area in 2-3 passes, deepening the cutters no more than 10 cm in one pass;

- the throttle valve opens ¾ part of its full stroke;

- idle motor operation should not exceed 10 minutes;

- check and top up the oil level in the engine.

In the further process of operation, the reliability in the operation of the listed models of walk-behind tractors is ensured by systematic maintenance and current repair work. This necessarily includes changing the oil and transmission fluid.

Beginning of work

Without running in the walk-behind tractor, it is absolutely impossible to start using it fully. Those who do otherwise are almost inevitably faced with a host of deformations and breakdowns. Also, the block may work unstable if it is not first run in. And worst of all, a premature failure of the device is likely. This is a sure road to costly repairs or even replacement of a problem device.

It is important to understand that preparation for work is no less important than the operation itself. If they try to run in a walk-behind tractor in violation of the rules, it is illiterate, then it breaks down in almost 100% of cases

Then the necessary repairs are even more expensive. It is important to take into account that if a major overhaul was carried out, the machine and its engine will have to be run in again. Without this, there is nothing to think about that the walk-behind tractor will work properly for a long time.

Why do you need a break-in at all?

Engine break-in is a very significant and serious job. It applies not only when you buy a new unit, but also after a major overhaul. This will significantly extend the service life of the machine.

Before carrying out the main process, carefully check all the bolts, which should be very tight and well tightened. The equipment itself must be filled with fuel, oil and coolant.

During the break-in process, the brake and steering system is checked

During the process, the steering wheel must be in the correct position, as this is very important. Items must be checked every two thousand hours of operation.

All spare parts are lubricated with machine oil, and if during the inspection it turns out that the bearings and oil seals are already worn out or are simply in poor condition, they must be replaced immediately. The drives and axles must also be in very good condition, otherwise they will be replaced.

Running-in is not carried out immediately. You need to prepare the device.For this, all parts are lubricated with oil, as indicated in the operating instructions. Transmission oil can only be changed after the walk-behind tractor is turned off. At what it merges hot. After that, diesel oil is poured in and the gearbox is thoroughly rinsed.

The lubricant must be used as specified in the instructions and requirements for the care of this type of equipment.

A run-in walk-behind tractor will be able to fully perform all its tasks and there will be no failures under heavy loads

It is important to do this process correctly and accurately.

General rules for running in a walk-behind tractor

Running in is a mandatory process. The further service life of the engine and other vital systems depends on it. If you immediately fill up the fuel and start work, your unit may simply burn out. During this process, all gear pairs that are in the gearbox are rubbed in.

Strictly adhere to the instructions for use. There you will find indicators of all initial loads for a particular model. For example, if a walk-behind tractor is designed to cultivate the land to a depth of 50 centimeters, then first you need to cultivate the land to a depth of only 30 centimeters and only on virgin soil. In addition, some units are sold immediately with oil filled, and some without it. You also should not forget about this and take into account during the test work.

The oil is poured into the crankcase and you can start running in. The presence of oil can be checked with a dipstick. Many manufacturers affix stickers with information about the lubricant. If this is not the case, then by the probe you will determine everything.

Even if you bought a unit with oil already in it, many experts still recommend changing it to a new one. This will make the machine easier to operate as the oil ages over time.

During the break-in, do not abruptly press the gas pedal. This will be an overload for the machine and unforeseen situations may arise, or, in other words, the machine will immediately fail. If you value your equipment and want it to last as long as possible and at the same time work at full strength, then do not be lazy to run in slowly and carefully, without overloading the equipment.

How to run in a walk-behind tractor correctly?

Today a wide variety of cultivators are presented on the market: Centaur, Neva, Shtenli, Lifan, etc., many of them are equipped with a Subaru engine, are sold with air cooling and other details. But, despite the variety of dimensions, capacities and design features, the running-in of absolutely all of these units is as follows:

- First fill up the tank. And use high-quality fuel for this. This rule, even if it is elementary, but practice shows that some novice owners, during the first run-in, simply forget about it;

- Try to always check the oil and keep it level. Top up when the need arises;

- Start the walk-behind tractor. Run at medium revs, and then change the speed and power, but not abruptly or too often. In this case, the main thing is patience, because according to the rules, the run-in should last several hours. In the process, not only the grinding of all elements of the device takes place, but also the adaptation of the operator to control the machine;

- The last step is to check the functionality. A person can perform all basic tasks, the main thing is not to go too far with speed and load. Everything must be done gradually.

It should always be remembered that walk-behind tractors are the same cars that need constant care and attention. If a person makes the weight possible for the "health" of the equipment, she will thank him for a long service life and the absence of unforeseen troubles in the form of breakdowns of parts, etc.