Design features of a hacksaw for metal

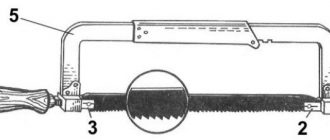

The widespread use is largely determined by the device of the hacksaw for metal. It is presented in a C-shape, between the two edges of which there is a special canvas. When considering what the tool consists of, note the following:

Lever. Today, the handle of a hacksaw for metal in most cases is made of two different components, which ensure a long service life. The shape should be comfortable enough, and the element itself should be placed at the top of the structure or on the side. The top location in most cases is used when it is necessary to process hard-to-reach places.

Frame. It is designed to take the load, as well as damping vibration at the time of operation. Today, various materials are used in the manufacture of such tool elements. In order to carry out the processing of hard-to-reach places, the structure often has an element due to which the tilt of the web is adjusted. The frame is made in one piece or sliding, the second version of the design allows you to install the product with different lengths.

The canvas is represented by a hard alloy tape. This element is considered the thinnest and most fragile, represented by a combination of small teeth located relative to each other at a certain distance and angle. At the time of work, you should be careful, as even minor mistakes can lead to damage

When choosing, attention is paid to the fact that the surface must be hardened, since otherwise the required level of wear resistance cannot be ensured. To increase productivity, a blade with a rare tooth is selected, to increase the quality of a cut with a frequent

Recently, bimetallic blade has become widespread.

The design features of the hacksaw for metal determine the very widespread use of the tool. The main part determines the duration of use and other points, the cutting speed and cutting quality depends on the installed blade.

Donut

Flare. Donut. Donut. Burgundy Burgundy ° Ð ”и. Lol l l l l l l l l l l l l l l + l ± n.

ÐÐ »ÐμкÑÑонно-л ÑÑÐμвР° Ñ ÑвР° ÑкР° пÑимÐμнÑÐμÑÑÑ Ð¿Ð¾ Ñой пÑиÑинÐμ, ÑÑо поР· воР»ÑÐμÑ Ð¼Ð³Ð½Ð¾Ð²Ðμнно нР° гÑÐμÑÑ Ð¼ÐμÑÐ ° л Ð »Ð² оÑÐμÐ½Ñ Bumpy bump. Good morning Bush.

Bump, bump, bump. Burgundy, bark, bark, bark ¿ÐºÐ¾ÑÑÑÑ Ð¾Ð ± ÑÑнÑÑ Ð½Ð¾Ð¶Ð¾Ð²Ð¾ÑнÑÑ Ð¿Ð¾Ð »Ð¾ÑÐμн Ð'л Ñ ÑÐ ° Ð ± Ð¾Ñ Ð¿Ð¾ мÐμÑÐ ° Ð »Ð» Ñ.Burgundy and burgundy Bump, bump, bump, bump, bump Bumpy flare. Donut 7-15 donut 7-15 donut ± оР»ÑÑом кол иÑÐμÑÑвÐμ Ð'Ð »Ñ пÑоиР· воÐ'ÑÑвР° Ð ± ÑÑÑÑоÑÐμжÑÑÐμй ÑÑÐ ° л и. Lateral bowls Hearty, hearty, hearty, hearty, hearty, hearty, hearty, hearty ÑÐ · Ñ Ð ± имÐμÑÐ ° Ð »Ð» иÑÐμÑÐºÐ¸Ñ Ð¿Ð¾Ð »Ð¾ÑÐμн Ð · Ð ° ÑÑÐμÑ ÑовÐμÑÑÐμнÑÑвовР° Ð½Ð¸Ñ ÑÐμÑнол огии ÑÐ »ÐμкÑÑонно-л ÑÑÐμвой ÑвР° Ñки Rose, Rose, Rose, Rose, Rose. And a few minutes later L ± lol l l l l.

Jigsaw

Circular and chain saws cannot replace a device that uses a narrow blade that moves up and down at a high frequency.

Thanks to this arrangement of the working body, the jigsaw allows you to quickly and accurately cut curved flat parts. Plywood, ceramics and plastic, OSB and soft metal - all this can be cut with a good jigsaw with a quality file.

Jigsaw

For each material, manufacturers make special saws that differ both in the inclination of the teeth and in their frequency.

For example, wood is better cut by a file with a large tooth. With sheet metal, a blade with a fine serrated notch will confidently cope. We will not give special recommendations on the choice of saws for a jigsaw, since the manufacturer indicates the recommended type of material on each of them.

The main technical parameters of the jigsaw are engine power, saw stroke frequency and maximum cutting depth (indicated for different materials).

For household models, these parameters are within the following limits:

- Power from 400 to 900 watts.;

- Stroke frequency (with the possibility of smooth adjustment from 0 to 3000 rpm);

- Cutting depth (wood - 45-80 mm, steel from 4 to 20 mm).

A useful option for the jigsaw is a laser pointer. It helps to clearly see the direction of the cut when the marking line is hidden under a layer of sawdust

When choosing an electric jigsaw, pay special attention to the attachment in which the file is attached. It should provide the most reliable clamp

Otherwise, the file will regularly pop out of its weak "embrace".

Types of hacksaw blades

A hacksaw blade is considered the main part of a hand tool. The performance of the tool and the accuracy of the cut depend on its type.

Cloth for metal

It contains a large number of fine teeth... Cutting metal with large teeth will not work.

The length of the blades is 150–300 mm. The canvas can be made from different materials:

- carbon steel;

- cobalt steel;

- carbon and high speed steel.

Tungsten filament

Strings are made from tungsten carbide. Their length is 30 cm. They are suitable for fastening in the framework of standard hacksaws. The diameter of the string is 2.7 mm. With it, you can make precise cuts. The string is suitable for straight and curved cuts, cutting circles.

Diamond string

The basis of such a string is alloy steel, on which diamond spraying is applied. Coating thickness - 2 mm. The string is fixed in the clamps with rings.

A quality diamond wire should cut a variety of materials quickly.During work, its surfaces and work area must be moistened with water to avoid overheating.

Diamond string (Photo: Instagram / abraziv_ykt)

Ð Ð ° Ð · воÐ'кР° Ð · ÑÐ ± ÑÐμв

Bumpy bumpy bump Midnight sun L '' ± ±. Burgundy L · nl ± ".

Burgundy "bark" Rose and Rose. ÐÑи ÑÑом вÑпоР»Ð½ÑÑÑÑ Ð¾ÑгиР± кÑÐ ° Ñ Ð¿Ð¾Ð» оÑнР° вÑÑоÑой 2 - 3 мм вмÐμÑÑÐμ Ñ Ð · ÑÐ ± ÑÑми попÐμÑÐμмÐμнно в оР± Ðμ ÑÑоÑÐ¾Ð½Ñ Ð½Ð ° 0,25 - 0.6 pp. Bumpy bump.

Burgundy "bauble" bauble L Donut. Burgundy 2-3 flats - 3 flats »ÐµÐ²Ð¾. Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose GREAT - LITTLE, LITTLE LITTLE, LOOK. Heart, heart, heart, heart, heart, heart, heart

ШР° г Ð Ð ± Ð °

Burgundy DOWN, DOWN, DOWN 18, 24 DAY, 32 DAY. Red line 7, 10 line 13 line, line

Bang bang bang bang bang bang bang bang bang bang »Ð ° ÑÐ ° Ñпил ивР° Ðμмой Ð · Ð ° гоÑовки. Burgundy lily 2 - lilac 2 - lilac 2 - lily Good morning Good luck and good luck. Heart and soul ¸Ñе

| Lolly | ¾ | ||

| LOOK 5 LOOK | LOOK 2-5 LOOK | Locally 2 locally | |

| ± | |||

| Close | 18 | 18-24 | 24-32 |

| Lkl ± lmu | 18 | 18-24 | 24-32 |

| Light | 18 | 24-32 | 32 |

| Ð ¢ вÐμÑÐ'Ð ° Ñ ÑÐμÐ · инР° | 18 | 18 | 24 |

| PICTURE | 18 | 18-24 | 24-32 |

| Flat | 18 | 24-32 | 32 |

| Ð ¢ вÐμÑÐ'Ð ° Ñ Ð¿Ð »Ð ° ÑÑмР° ÑÑÐ ° | 18 | 18-24 | 24-32 |

| Igloopl1 | 18 | 18-24 | 24-32 |

| ÐÑгкР° Ñ ÑÑÐ ° Ð »Ñ | 18 | 24 | 32 |

| Flip-flop | |||

| Velvet | 18 | 24 | 32 |

| Bunker | 24 | 24 | 32 |

| Flare | |||

| Velvet | 18 | 24 | 32 |

| вÑÑокоР»ÐμгиÑовР° ннР° Ñ | 24 | 24 | 32 |

| Goodbye | 24 | 24 | 32 |

| ÐÐμÑжР° вÐμÑÑÐ ° Ñ ÑÑÐ ° Ð »Ñ | 18 | 24 | 32 |

Types of hacksaw blades and their design

Do not forget that the production of a working hacksaw blade is carried out in accordance with the established standards in GOST 53411-2009. The specified information in this regulatory and technical documentation defines the allocation of two main groups: for machine and manual cutting. It should be borne in mind that a hacksaw blade for metal is purchased extremely rarely, since such equipment is used extremely rarely. For a hand hacksaw, the following versions are produced:

- Single hacksaw blade for metal with a distance of 250 mm between fasteners. In this case, the total length is 265 mm. This version is suitable for a tool that is used when there is no need for high productivity.

- Single versions with a distance of 300 mm between two fasteners. The total length is 315 mm.

- For greater productivity, a double hacksaw blade is installed. The length of this version is the same as the previous one.

The value and pitch of the location is regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main operational characteristics largely depend. The most widespread are the following alloys:

- X6VF.

- B2F.

- High speed alloys, for example, P5M5 and P12.

A hacksaw blade with tungsten carbide spraying has recently been quite common, since it is characterized by increased wear resistance. It should be borne in mind that the spraying can have a wide variety of colors, there are blue versions on sale, ordinary dark gray steel.

The considered tungsten hacksaw blade is characterized by the fact that with a high hardness of the working surface, the structure is characterized by high sensitivity to bending load. That is why, if the metal is carelessly cut, such a product will not be able to serve for a long time.

Manufacturers can achieve a high strength index through heat treatment. In this case, it is worth considering the following:

- The main part of the product is characterized by a hardness of the surface layer of about 44-46 HRC.

- Depending on the type of material used in manufacturing, the hardness of the tooth varies in the HRC range from 64 to 67. This indicator is characteristic of alloyed alloys. High speed steel is characterized by having an HRC hardness in the range of 73-78 units.

Do not forget that significant differences in hardness cause the product to be sensitive to bending. The tool is designed for various loads, it should not exceed 60 kg with a pitch of 1.4 mm, as well as 10 kg with a pitch of less than 1.4 mm.

A fairly large number of varieties of such a product determines that there are no serious problems with the selection of a suitable version.

It all started with a simple hacksaw

It is this saw that is the ancestor of the family of hand tools designed for woodworking. As soon as the first ingot of iron was smelted, a man had the idea of forging a tool for cultivating the land from it.

It can be assumed that the ax became the second after the hoe. The third was probably a saw with a handle, known to us today as a hacksaw. Over the centuries that have passed since its invention, she has acquired numerous "brothers and sisters", performing dozens of different jobs.

The accepted classification divides this type of hand saw into two groups:

- Hacksaws for wood;

- Hacksaws for metal.

Depending on the direction of cutting, hand saws for wood are divided into three categories:

- For rip sawing cutting;

- For cross-cutting;

- Universal (longitudinal-transverse).

The difference between them lies in the shape of the cutting teeth: they are inclined forward on the rip saw, and straight on the cross-cut saw.

The universal hacksaw tooth is also tilted forward, but has a special sharpening. It allows you to cut along and across the grain.

By design, hand saws are divided into several types:

- Classic hacksaws (transverse or longitudinal cutting);

- Circular saws (for cutting holes);

- Spike saws (for cutting connecting spikes).

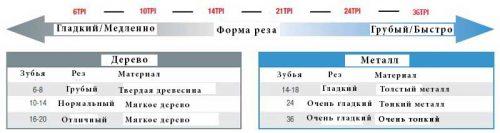

When choosing a hand hacksaw, not only the shape, but the size of the teeth plays an important role.

There are three types of incisors:

- Fine tooth - 2.0-2.5 mm (for high-precision sawing and cutting of small items);

- Medium tooth - 3.0-3.5 mm (for medium-sized parts);

- Coarse tooth - 4.0-6.0 mm (for coarse cutting of beams and logs).

The international classification divides hacksaws not by the height of the teeth, but by their number per 1 inch of the cutting blade.This standard has taken root in our country, so do not be surprised if you see the letters PPI or TPI on the instrument label. The number behind them is the number of teeth per inch of length. The larger it is, the smaller the tooth (eg PPI 8 or TPI 14).

Today on the market you can see a modernized type of hacksaws. They can be easily distinguished by the gaps cut in the canvas. As a result, the teeth are arranged in groups of 6-7 pieces.

This tool is designed for cutting raw wood. The gaps between the teeth are needed so that wet chips do not clog the cut and are easily removed during work.

In addition to the usual hand hacksaws, users are now offered an electrified version of the tool. The powerful electric chopper can easily handle a large amount of sawn timber cutting without too fatiguing the owner.

Its versatility is achieved by being equipped with saws with different lengths and widths of the blade and the size of the teeth. This allows you to successfully work not only in wood, but also in plastic and metal. Another name for this tool is a reciprocating saw.

Reciprocating electric hoe

The main parameter characterizing the capabilities of electric hackers is power. It ranges from 400 to 1600 watts. The cutting depth directly depends on it, which ranges from 90 mm for household models, up to 200 mm for professional models.

Hand tools for metal processing are not so diverse. There is only one type of hand saw that can cut this material. Its working body is a wide or narrow blade with fine hardened teeth. It is inserted into the bow holder and tightened with a screw.

Types of hacksaw blades

According to GOST hacksaw blades, there are two types of blades: for manual cutting and machine cutting.

Manual cutting blades have three main parameters:

- The distances in single models between the fasteners are 250 +/- 2 millimeters. The canvas is 265 mm long.

- The gap in single models between the mountings is about 300 millimeters. The blade is 315 mm long.

- Double. The distance between the fasteners is 300 millimeters. The canvas is 315 millimeters long.

The thickness of the hacksaw blade (in a single version) does not exceed 0.63 millimeters, in a double one - 0.80 millimeters. The height of models with a single row of teeth is 12.5 millimeters, in models with a double row it is 20 millimeters.

The requirements of GOST regulate the pitch of the teeth, distance, quantity.

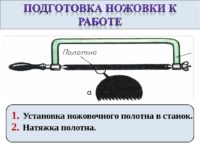

Methods for installing the canvas

- threaded clamp;

- lever mechanism.

In the first case, the web is stretched between the mounting holes and fixed with a wing nut. In the second, the actions are performed in the same way, only the file is put on and removed by means of a special lever, usually located at the edge farthest from the handle.

The blade is installed in such a way that the teeth tilt to the side opposite to the handle. When using a hacksaw, the metal layer will be cut off when moving "away from you". The opposite direction - "towards yourself" - is an idle run, in which the workpiece is not cut. Therefore, efforts during the reverse movement are in vain. In addition, it is so easy to dull the blade teeth.

With electric hacksaws, the working body is attached differently. For example, the following is the process of replacing the blade for a reciprocating saw Makita JR 3070 CT... This requires:

- turn the holder head counterclockwise at a small angle so that the internal slot allows you to remove the product;

- remove the canvas;

- place the end of the new file into the slot of the holder until it clicks.

By the way, the canvases are also divided by the type of the shank (the area that connects to the holder). There are shanks with one stop, two-jaw, universal 1/4, clamping 1/2 and special for Makita saws, which have two holes at the end.

The principle of attaching hacksaw blades to saber saws is the same for all devices; the manufacturers have thought about the design, made the insertion of the cutting element convenient and made the work of the user easier.

How to properly work with hacksaws?

Deal with the canvas before starting work. Place the new blade in place of the old blade by releasing the tension, teeth first away from the handle. After these steps, tighten the blade well.

Cutting metal correctly with a hacksaw also comes through trial and error. Grasp the handle with your working hand and hold the vertical edge with the other

It is important to make a small slanted angle when working, from 30 to 45 degrees, for the most even cut line. It is possible to work with an angle of 90 degrees, but in exceptional cases and when necessary.

You need to start with the least effort for more contact with the material. When moving the tool forward, try to increase the pushing force and, if the blade fits well into the metal, you can increase the pace of work.

Use the canvas to its fullest, let the whole part take part in the robot, and not just a certain area. This will help avoid rapid blade wear.

Do not forget about smooth movements to avoid breakage at unnecessary moments. This little instruction on how to cut metal correctly will help you get to mastery faster and make fewer mistakes.

Product classification

Hacksaw blades are a narrow strip, at the ends of which there are two holes for attaching to the tool. There are three main criteria for their classification:

- purpose (for hand / electric hacksaws);

- material of manufacture;

- parameters of the teeth.

The division into groups according to the first sign occurs as with hacksaws - they distinguish canvases for hand (mechanical) and electrical (sometimes called machine) tools. The sizes of the work items vary. So, for hand-held canvases are used with a length of 250-300 mm, a width of 12-25 mm, a thickness of 0.63-1.25 mm. An example is a domestic-made canvas made of X6VF steel with parameters 1.25x12x300, which will cost the buyer 30 rubles apiece.

Parameters of files for power tools vary from 150 mm in length to 55 mm in width, from 1.25 to 2.5 mm in thickness. An example is a blade for a HAMMER RS BL 001 reciprocating saw, the parameters of which are 150x19x1.25 mm, and the cost is 100 rubles per piece.

Another difference between saws for hand and saber saws is the number of holes for fasteners. The former have two, the latter have one.

Electric hawk cloth

- carbon (the least durable, suitable for non-ferrous or soft metal; marked as HCS); for example, Bosch HCS TF 350 M 408 mm GFZ for 1400 rubles;

- high-speed (have the most wear-resistant teeth, but are fragile and high price; HSS marking); Gross HSS 18TPI 300 mm - 160 rubles per pair;

- bimetallic blades (an innovation on the market, displacing analogs; the base is carbon steel, on top of which a high-speed strip is welded, serving as the basis for the teeth; denoted by BIM); Gross Variozahn 300 mm BIM from 300 rubles per pair.

There are also blades made of alloy steel (designation HM), but more often they are used for cutting brick, concrete or stone.

The size of the teeth for metal hacksaws is 2-2.5 mm. This parameter is considered "small", since there are products with a larger tooth (for example, for wood saws it is 4-6 mm).

International standardization provides for a different principle of dividing canvases. So, the number of teeth per 1 inch of the file is taken into account. This number is shown in the marking before the letters PPI (points per inch - "point per inch") or TPI (formula "PPI - 1"). The higher the number, the finer the tooth is represented on this blade.

When choosing products for a hacksaw, the user does not have to guess for a long time - most of the well-known saws have a pitch of 18 or 24. This is how branded products for construction are indicated (for example, Standart 24 TPI 300 mm, Kraft-Flex 18 TPI from the manufacturer Kraftool).

The main classification of hacksaw blades for metal is compiled on the basis of the above criteria

It is important to know that the presence of set teeth is welcome if the user expects comfortable work without pauses and tool breakages. Now about how to correctly install a hacksaw blade in a hand or power tool

Criterias of choice

There is no one-size-fits-all product that can satisfy all customer needs

Therefore, when buying, you will have to pay attention to a number of points.For example, the width must be selected based on the type of work

It varies in the range of 14-80 mm. The standard is considered to be 31-41 mm models. In order not to get confused, you can refer to the instructions for the existing machine. As a rule, it always indicates the main characteristics of the desired canvas. By following the specific parameters, you can purchase the right option, thanks to which the machine will work with high productivity.

Tooth type

The teeth of the cutting band have a special arrangement. It is not straight, but deviated to the sides from the plane of the main belt. The type of such an arrangement is called a wiring, which can be different. Today it is divided into three types: straight, wavy and alternating.

The alternate deflection of the teeth to the right and left sides allows for a wider cut. This prevents the tape from getting caught in the workpiece being processed. More often today they buy canvases in which the layout is as follows:

- right, straight, left;

- right, left in turn;

- wave with a change in the angle of inclination of the tooth.

Blades of the first type are used in work with packages of solid blanks, pipes and profiles. The second option is considered universal, however, as practice shows, it shows itself better when working with soft metals. The third type of wiring is used when working with thin-walled pipes and small-sized workpieces.

The form

The shape of the teeth of the band blades also varies. The developed standard solutions allow you to choose an option, taking into account the needs of the buyer.

- The NORMAL serrated edge is positioned upward in relation to the blade. This form does not have a chamfer; it is used when cutting high-carbon steel parts.

- The HOOK has a 10 degree front tilt. Solid rods of different sections made of alloy steel can be cut with such teeth. Also, this blade can cut thick-walled workpieces.

- The RP version is characterized by a 16-degree incline of the cutting edge. Blades with this form of teeth are bought for working with non-ferrous alloys. You can also use such a tape for cutting difficult-to-cut grades.

- The MASTER form is considered universal and the most common. Its slope of the chamfer can be 10 and 15 degrees, there is also a grinding of the longitudinal edge, which allows you to reduce the roughness of the machined edge.

Step

Blades for metal band saws can also differ in the number of teeth. The choice of the pitch directly affects the quality of the cut. With a constant pitch, the number of teeth can range from 2 to 32 per inch. In this case, the greater their number, the smaller should be the cutting thickness of the workpiece. In analogs with a variable pitch, the number of teeth varies in the range from 2 to 14 per 1 inch. The choice of the correct tooth pitch is selected taking into account the thickness of the walls of the pipes and profiles, with which you will have to work in the future.

Cutting speed

The cutting mode will depend on different parameters. One of them is the processed material. You will have to take into account the steel group and alloy, as well as the size of the part itself and the tooth pitch. Here you will have to choose a specific brand, since this factor also determines the quality and efficiency of the canvas.

The rotation speed of the belts is not the same, sellers will indicate this when buying

It is also important to decide on the feed rate of the band, since ideally each saw tooth should cut a chip of a specific thickness. Each machine has its own set speed, and therefore you will have to select the desired value based on this

Of course, you can go experimentally, buy a tape and look at its efficiency already on shavings. However, it is better to initially select the desired option, because the quality of the work performed directly depends on this. In addition, it is important to understand that the performance of the web and its resource are not endless.

Belt speed and feed are considered key criteria.Based on them, they select the modifications of the canvases, the pitch of the teeth, and the setting.