Varieties

By combining the above factors, manufacturers have developed and are currently producing standard products with different blades, handle and tooth shapes. To understand how to choose a hacksaw for wood, you first need to familiarize yourself with the existing types of saws.

Type 1: Classic

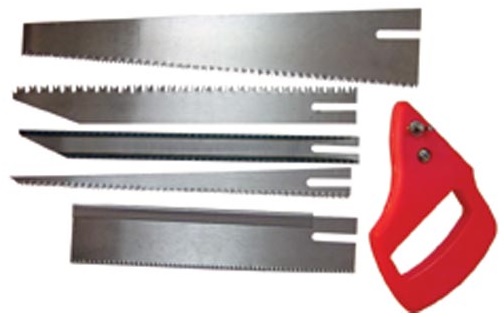

The main type of saw that almost every man has, even those far from construction and carpentry. This hacksaw can have a blade of any length with a different number of teeth, often the tool is equipped with interchangeable blades that come with the purchase.

Type 2: Narrow

Its other name is circular hacksaw. It takes the name from the main application - lines of various shapes are cut out for it, moreover, it does it neatly and clearly. It is also used to cut through round, square holes. The saw blade is narrow, the teeth are frequent, can be located both on one working plane, and on both.

When working with a saw, you should be careful: if the movement is uncertain, the blade will turn in the other direction, therefore, the choice of a hacksaw for wood with a narrow blade should be stopped on a product made of high-quality hard steel that will not bend during the sawing process.

Type 3: Backed

A hacksaw with a backing is equipped with a stiffening rib (the same backing), which does not allow the blade to bend during operation. Thus, the tool is not able to make a cut lower than the width of the saw blade.

Obushkovaya the hacksaw is always equipped comfortable handle at an angle of 45 to the blade for easy execution of work.

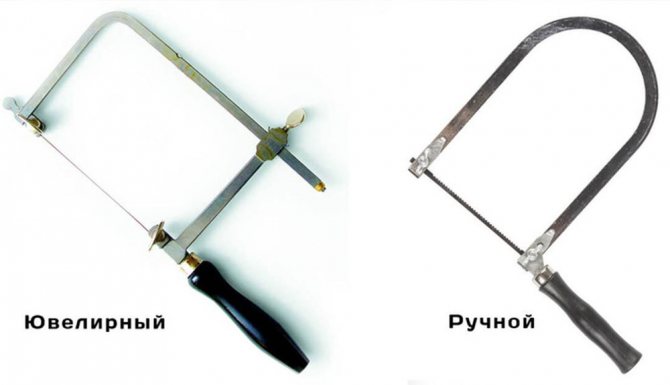

Type 4: Bow

For plumbing, an archery saw is indispensable: it serves to cut rough parts of the trunk, knots, to cut figures from plywood and other wood materials, to cut wood along and across the fibers. The use of a bow saw is so widespread that it alone can replace a small woodworking machine.

The wide range of work carried out slightly obscures the main disadvantages:

- Bulky. A bow saw is a complex structure, its bearing part is made in the form of a large curved arc, to which a blade with teeth narrow as a thread is attached.

- Fragility. It is necessary to work with the tool extremely carefully: the blade during operation can fly off the mounts and break, its frequent replacement is required.

Type 5: Reward

The award saw takes a lot of effort to master. It is a tool that resembles a plane. It is equipped with two handles. Its main application is cutting grooves and spikes, the depth of holes and depressions can be of different sizes, moreover, on rocks of any hardness.

Type 6: Folding tool

A mechanical hacksaw that you can take with you on a hike or on vacation. It is compact, lightweight, and completely safe when folded. The folding hacksaw has fine teeth and a short, pointed blade.

Types of hand saws for wood

A small, narrow saw is a structure that consists of a straight-line flat blade and a handle. She performs delicate work: through cuts, cut out curved parts.

This type of tool is designed for sawing wooden blanks, the thickness of which does not exceed 8-10 cm, sawing small branches and small works in the garden

In the manufacture of narrow models, manufacturers install blades with triangular double-sided teeth, or with parallel sharpening. The disadvantage of the tool is that when pressed during operation, the blade can deviate from a given direction.

A standard hand saw can be equipped with any type of teeth and is often equipped with replaceable blades of various types and designs.

To be able to saw off workpieces at a certain angle using a standard hand saw, you have to purchase special miter boxes

But despite the declared versatility of their use, it is not advisable to use saws of this type in the manufacture of furniture.

Both narrow and conventional saw blades tend to bend as the material becomes stiffer.In these cases, it is effective to use canvases equipped with a backing, which acts as a kind of stiffening rib.

Hand saws equipped with a backing are designed to create shallow cuts in a wooden surface of any thickness

The backing prevents the saw from making a cut deeper than the width of the blade, as it prevents the blade from going further into the tree.

Bow-type saws are more bulky devices that act as an analogue of a jigsaw.

The main purpose of this type of saw is to create an accurate cut when working with surfaces located at any angle.

Due to the solidity of the design and the threaded connections of the handles, bow-type saws are able to easily overcome knots, performing cutting along radii and curved patterns.

Depending on the purpose and design of the saw, there may be:

- swinging - for longitudinal cutting;

- transverse - for sawing blanks across the wood fiber;

- circular - for cutting holes, making rounding and curly sawing;

- thorns - for cutting connecting spikes, as well as cutting out simple geometric shapes on the workpiece.

Only with an onion-type hacksaw can you cut the material up and down, sawing blanks with complex lines and performing the work alone without involving an assistant.

Views

Hacksaws are very diverse: for plywood, logs, for plastic, for laminate, for concrete, for foam blocks, for gypsum, as well as locksmith and carpentry, pneumatic, folding and many others.

There are two basic types of hand saws: for wood and also for metal. Devices suitable for processing wood have rather large teeth and can even be used for sawing aerated concrete and gypsum plasterboard sheets.

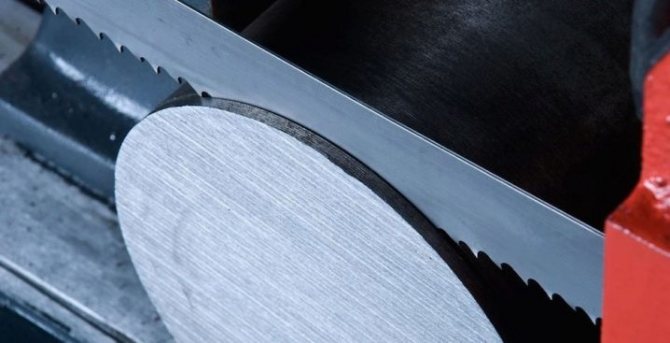

Metal tools can cut almost all types of materials, including wood, expanded polystyrene, as well as polystyrene and aerated concrete. They have rather small incisors, and the cutting site comes out quite neat, small chips are formed during work.

There are several types of hacksaws for wood material: classic, circular, and also thorn.

Classic

The classic hacksaw is also called standard, wide. It is a traditional sawing tool and is used for longitudinal as well as cross cuts. With the help of a classic hacksaw, you can cut down tree branches or shorten boards. Such saws are used in joinery and carpentry, it provides a fairly quick and easy cutting, and the cut itself turns out to be deep and very rough, while large chips are formed.

Circumferential

The circular saw is considered a specialized tool, due to the small width of the blade, it allows you to cut curved parts. The main task of such a device is reduced to the possibility of cutting sheet material, when it is necessary to work along clearly defined contours.

A narrow web is considered more maneuverable.

Circular saws are quite light and compact, often the cutters are located on both sides and can vary in size. Thus, it is possible to cut with different degrees of purity. If you buy a model with fine teeth, then the cut will turn out to be smooth and even.

Thorn

A spiked hacksaw is often called a butt saw or a hacksaw. This is a rather peculiar tool, the basic task of which is to remove all protruding grooves or spikes. Such saws are traditionally used by fitters and carpenters to form a perfectly smooth cut.

The finger saw blade is rather thin, so the sawing channel comes out rather narrow.

To prevent the canvas from beginning to bend, a small back is attached to the side opposite to the teeth (it is necessary to give sufficient rigidity).

The incisors of the tool are made in the form of an isosceles triangle.

Suitable only for cross-cutting, with the thickness of the functional part not exceeding 1.5 mm.

For metal

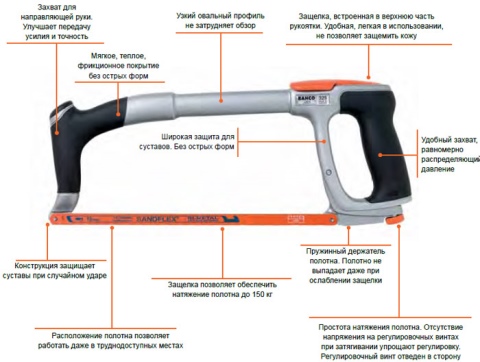

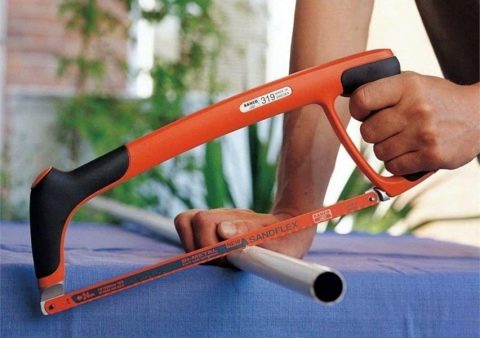

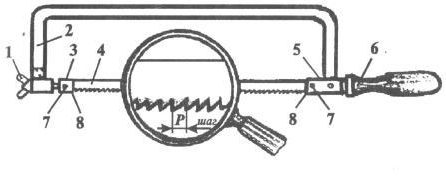

We should also dwell on a hacksaw for metal. It has its own design, which includes a cutting blade and a frame for high-quality grip.

The blades are usually replaceable, the teeth are small, and are specially hardened.

The blade is made from high speed steel alloy. Dimensions do not exceed 40 cm in length, the cutting depth is limited by the parameters of the frame.

The disadvantage of such heads is rapid wear, and users also note that there are frequent cases of breakage of individual teeth.

Peculiarities

There are various options for a hand hacksaw, but the main (or most common) ones are full frame, which use 12 "or 10" blades.

Regardless of the type of hacksaw, it is important to ensure that you are purchasing a high quality tool made from a special alloy steel

In more modern models, the blade can be adjusted in length, which allows you to remove branches of various thicknesses. The cutting element is placed in the posts that are on the frame. Many people do not understand that you can install it in different positions for your own needs. The blade simply moves left and right or up and down.

Among the huge range of products offered, all models differ in the shape of the handle, dimensions, dimensions of teeth and other parameters. The buyer should take into account his own needs when choosing the material of the canvas and its dimensions.

If you intend to saw boards and remove small branches, then you should pay attention to the tool, at which the width of the metal cutting part ranges from 28 to 30 centimeters. For construction purposes, a canvas from 45 to 50 cm is used, but you can find more on the market - it all depends on what kind of work you plan to do

The efficiency of the tool depends on the proportions, so the thickness of the wooden blank should be half that of the hacksaw. In this case, more sweeping movements are obtained, therefore, it is possible to complete the task faster. Large teeth must fully enter the material - this is the only way the sawdust will be removed.

The convenience of the user during work will depend on how much the manufacturer has thought about the handle. This structural element is attached to the back of the blade, sometimes you can find a pistol-type handle on sale. The handle is created from two materials: wood and plastic. In more expensive versions, it can be rubberized, which significantly improves the interaction of the hand with the surface.

Another feature that can distinguish wood hacksaws from each other is the firmness and size of the cutting teeth. If you look closely, the pointed elements never stand one behind the other, since in this case the tool will immediately get stuck in the material. To simplify the task, the teeth are given a different shape, which is also used for different cutting options:

- longitudinal;

- transverse.

The rip-toothed tool is used to cut along the grain of the wood. The main distinguishing feature is that each pointed element is rather large and sharpened at right angles. The tool cuts wood like a chisel.

To saw across, take a different unit, in which each tooth is sharpened at an angle. There are also Japanese teeth, which are narrow and very long, and there is a double bevel cutting edge at the top of the blade. You can find on the market and a universal tool that can be used in both cases. Its teeth are sharpened symmetrically.

What does it consist of?

The tool in question has a very simple and straightforward design. If we talk about hand-held models, then they look like a bracket, between the ends of which a stretched canvas is fixed.

Usually, the tool also includes a frame and a hacksaw.Each of the constituent parts has its own subtleties and characteristics, and each of them is irreplaceable.

For example, a frame secures the saw blade. It can be created from various materials, depending on what you have to work with. For example, if we are talking about sawing some hard products, then it is better to use an option made of composites of a very strong type. Also, the frame structure will be in direct dependence on the conditions of use.

For example, if you have to regularly deal with cutting iron in hard-to-reach places, then it is better to buy a model that will have a blade tilt regulator for cutting or a not very large frame.

A hacksaw device will be incomplete without a blade. It is a thin strip made of steel. Despite this, it is the most fragile part of this device. For this reason, you should be very careful and attentive while working. Otherwise, the canvas will simply break. This part has special wedge-shaped teeth.

When choosing a saw, you should pay attention to whether the teeth of the panel have been hardened. The fact is that this procedure can significantly increase the time of using the tool and its performance characteristics.

If it is required to cut hard metal products, then blades with not too large teeth are used, and soft options are processed with large incisors. It is better to purchase bimetallic or hardened solutions. They should be placed in a canvas frame so that the teeth are in the opposite direction from the handle.

How to identify a quality tool

In order to understand how high-quality the device is in front of you, you need to take into account the following parameters:

Working blade length. Will depend on the size of the workpiece. The average length of the working part is from 300 to 700 millimeters.

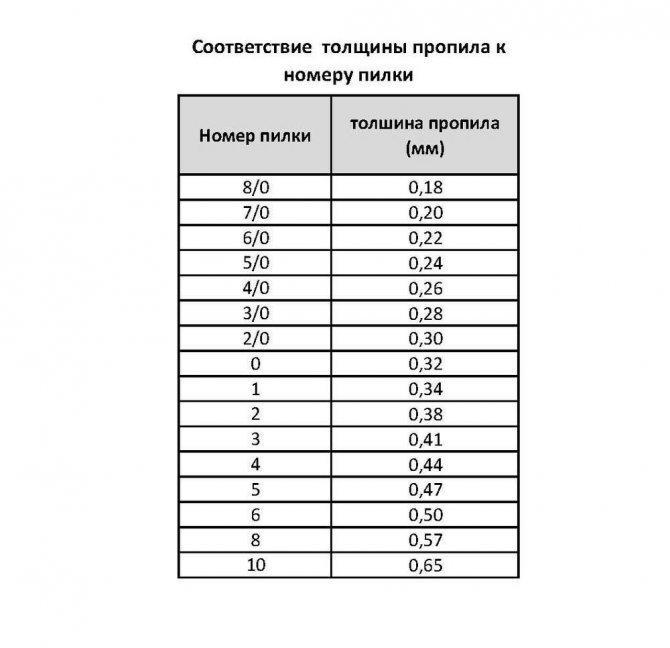

The step of the teeth. This parameter controls how hard or thick the material needs to be cut. For example, a pitch of 3.5 millimeters is used to saw soft wood materials. A step of 5 millimeters is used for working with harder types of wood.

When choosing a hacksaw blade, be sure to consider the quality of the coating. In case of poor-quality coating, the enamel may crack in the process.

Exploitation

Now let's talk about how to properly use a hacksaw for metal. To work with her, you do not need to have any special knowledge. The essence of the work will be similar to its wood counterpart. The main thing here is to change the blade in time, choosing its specific type and pitch of teeth. Cutting thin sheet metal properly with such a tool will not be very easy.

First you need to figure out how to fix the canvas. If the panel is one-sided, then the teeth should be directed from the handle forward and downward. To install it, you need to loosen the tension screw, dismantle the old canvas from the pins, put a new one and tighten it so that it literally rang from the click like a guitar string. It should also not be fixed too much, so that the canvas simply does not break. The best position can be found exclusively by experience, since everything will be individual for each hacksaw model.

Before the direct start of work, you should grasp the handle with your hand, and sometimes grasp the vertical edge, which is located opposite to the handle. Now you need to put the tool bar on the cutting line. Moreover, this must be done strictly in the direction of the cut line. The angle of inclination should not be too large. The canvas should almost be on the part, at an angle of 30 to 45 degrees, so that noise and vibration are minimal. And the cutting line will be as flat as possible.

Cut across metal at right angles only in emergency situations. The evenness of the cutting line will depend on the smallest angle of inclination.

It is better to do the first movements with not too much effort, so that the canvas enters the metal and does not slip from the line to the sides. It is necessary to carry out movements of the translational type and press the tool as tightly as possible to the material with which the work is being carried out. And when returning to its original state, the pressure can be relieved. As soon as the canvas, as it were, clings to the metal, you can begin to work with it to the fullest.

The range of motion should be maximum, up to the edges of the canvas. The hacksaw arc should not hit the workpiece. Also, you should not cut in one place, otherwise the canvas will very quickly be erased in some area and become unusable. The arc should be kept straight and not allowed to deviate to the sides.

The direction of cutting must be exactly the same as the surface of the hacksaw arc. Also, do not forget that sharp jerks can cause the blade to break.

Types of hacksaws for wood

- ordinary;

- narrow;

- onion;

- with a butt.

The cheapest wood saw is a narrow hand saw. This tool is suitable for sawing branches in the garden and small work with blanks. As a rule, either double-sided triangular teeth or parallel sharpening are used.

You need to understand that you can work with this hacksaw only with workpieces no more than 7-12 cm thick. A very short blade does not make it possible to create a lever, respectively, cutting thick parts is sick to require a large load.

Conventional saws can be of any kind of teeth. The choice will depend only on the tasks for which you plan to purchase the tool

You only need to pay attention to the fact that it is undesirable to work with these saws during the production of furniture. Or you need to buy special large miter boxes so that you can cut at a certain angle

Butt saws are used as an auxiliary tool. Their main task is small cuts into parts.

Bow hacksaws are an analogue of an electric jigsaw. They make it possible to make the most accurate cut and work with different workpieces at different angles. Exists:

- transverse;

- sweeping;

- spike;

- external.

Sweeping hacksaws make it possible to perform longitudinal cutting. Today there are canvases 40-80 cm long. Longer workpieces can only be cut with a power tool.

Cross hacksaws are used to cut workpieces across the grain. They can make a cut, and at right angles, and at any other. And ideally straight edges come out on the section of the cut.

Circular hacksaws

Spiked hacksaws make it possible to perform simple geometric shapes on the workpiece.

The difference between bow saws is that the fastening mechanism is purchased once, and they do not spend money directly on the saws, buying new blades.

Wood saw manufacturers

Professional saws are of good quality and meet the specified characteristics. By purchasing tools from trusted manufacturers, you can be sure that this product will serve you reliably and for a long time. Among the proven manufacturers, it is necessary to highlight:

- Stanley;

- Bahco;

- Sandvik;

- Gross.

Bahco

Sandvik saws can also be found on the market. This company is part of Bahco, because the quality of the goods meets the general requirements of the company.

Stanley

Gross

There are also domestic manufacturers offering high-quality and relatively inexpensive saws. Among which:

- Piranha;

- Bison.

Saws Bison

- can not be used to work with hard wood;

- continuous work time no more than 10 minutes (then a pause of 15 minutes);

- do not leave outside (it will rust quickly, even with low humidity).

Regardless, the characteristics of the hacksaw are suitable for cutting trees.

Saws Piranha

About safety and comfort

The most comfortable is the two-piece handle

A set of interchangeable blades is far from superfluous for working with workpieces of various sizes and performing different types of cuts.Saws are often equipped with accessories with different cutting edges and different shapes - for cutting branches, making transverse and straight cuts, etc. and damage to the surface of the canvas.