Electric shears for metal "Makita"

Makita Corporation is a well-known Japanese company that manufactures petrol and power tools. The corporation presented more than 1,000 product names to the world market. Of these, there are more than 350 types of power tools that are highly durable. The Makita brand is considered the best in the manufacture of electric metal shears.

Main types:

- leafy;

- cutting;

- slotted.

The power tool is designed for cutting various metal products. The design has a built-in thickness gauge that adjusts the cutting depth.

Experts worldwide confirm that every element in Makita products is made of durable material. The models provide a high level of security.

The power of the power tool varies from 260 W to 660 W and operates from a 220 V network. Scissors can weigh from 1.5 kg to 16 kg. And the cutting element is capable of 1300–4600 strokes / min, cutting metal from 3.5 to 4 mm. There is almost no vibration from the punches, so the cut is very accurate.

The electric shears have additional functions that protect the consumer and prevent the tool from being switched on unintentionally. In addition, there is a retainer that maintains continuous, long-term operation, and gives the consumer time to rest.

Electric scissors from Makita are in demand among professionals. On average, their price is 20 thousand rubles.

Electric metal shears should be part of every master's toolbox. They perform one task - they cut metal. When buying, the characteristic features and personal desires of the consumer are taken into account.

How to choose?

Precision, efficiency, safety and ease of use are the most important qualities when choosing tools for cutting sheet metal.

Professional workers sometimes use battery-powered scissors. However, the price of such models is quite high. In addition, if the volume of work is not too large, then it makes no sense to use this type of scissors.

When choosing, they are more often guided by the parameters of the materials being processed and based on this, they make a choice between single and double-lever scissors.

- Single-arm scissors are more difficult to use and require more experience. But they increase the tactile sensations when working with the material, therefore, with sufficient experience, they allow you to make a more accurate cut.

- Two-arm scissors cut material more easily. However, it is recommended to use them primarily where accuracy is not important. Paradoxically, people who have a lot of solid metal material for hand cutting are more likely to choose more complex tools. But at the same time, they are better at processing metal with single-lever scissors.

When looking for hand scissors, you need to pay attention to the handle, which will provide a safe and comfortable grip of the tool. If you need scissors with increased strength and durability, you must also pay great attention to the blades.

If you need scissors with increased strength and durability, you must also pay great attention to the blades.

It is necessary to check the technical parameters of specific models, as well as the characteristics of the processed material.

- The hardness of the blades. HSS carbide blades have a hardness of 65 HRC. It is currently the hardest material used in the production of steel shears.At the same time, the lion's share of products is made with softer blades from special (61 HRC), alloy (59 HRC) or tool steel (56 HRC). At first glance, the differences between them are imperceptible, but after about a dozen cuts you can clearly feel them (even if all the tools are made according to GOST).

- Increasing the hardness of the coating. In addition to the induction hardening process, the hardness of the blades is affected by coating them with various substances. Today, professional titanium nitride (TiN) coated steel shears are very popular. They cut strong and hard metal sheets well and are used where standard solutions are not applicable.

- Edge. There are two options to choose from in this question, the edge is either smooth or jagged. In the first case, the cutting line is straight, but the operation itself is rather complicated and more time-consuming. In the second case, the cut plates will not interfere with the progress of the work, but the edge will be uneven.

- Scissors lips. They can be profiled in such a way that the cut piece bends and does not interfere with the further process, or so that the separated part is blocked on one of the jaws (in blind scissors). In theory, the first option is more convenient, but sometimes folding will damage the part, so it is undesirable.

- Brand. Although Stanley or Makita scissors are more often chosen than others, they do not differ in quality from most other products.

Care and storage

Let's take a look at a few rules on how to properly store and care for your scissors.

- The scissors should be cleaned periodically. This is especially true for professional tools, for example, manicure or hairdressing salons - particles of nails and hair remain on them. You can wipe them with a wet cloth or wash them with hot water, and then be sure to dry them using a hair dryer. If this is not done, rust will form on the instrument over time.

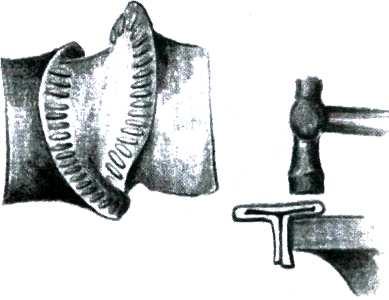

- Once a month, the middle zone, where the screw is located, and in which the blades are connected, must be lubricated with a special oil. This should be done by spreading the blades and rings to the sides. This procedure is mandatory for hairdressing scissors.

- When the screw is loosened and the blade connection is loosened, it is necessary to tighten it with a screwdriver.

- You need to store the scissors in a closed state with the blades connected, it is advisable to put them in a case.

- Do not let the scissors become dull. To prevent this, or if the blades have already become poorly cut, it is necessary to sharpen them. Try to carry out this procedure regularly, do it yourself at home or in the workshop.

Many centuries have passed since the first scissors appeared. During this time, the world has changed dramatically - today we live in the era of high information technologies. But in the 21st century, scissors have not lost their relevance and, having traveled a long way of development, continue to improve and penetrate into new areas of human existence.

You can learn how to sharpen scissors correctly by watching the video below.

Features of choice

The width of the teeth is an important characteristic to look out for. The wider the teeth, the more volume of hair removed

Therefore, a hairdresser should have in his arsenal several options for scissors for all occasions.

Sizes and shapes. Thinning tools are available in sizes 5.5 and 6 inches. 5 "is rare. In 90% of cases, their shape is straight. In order for a haircut to bring a minimum of inconvenience, it is necessary to find a model that will fit nicely in the hand of the hairdresser. And when buying, you should try on two or three pairs of scissors that look identical. After all, the best hairdressing scissors are made by hand, so there are no two absolutely identical pairs.

The author of the article

The author of the article

Vasilisa PetrovaMinor of our team and ideological inspirer

Articles written

39

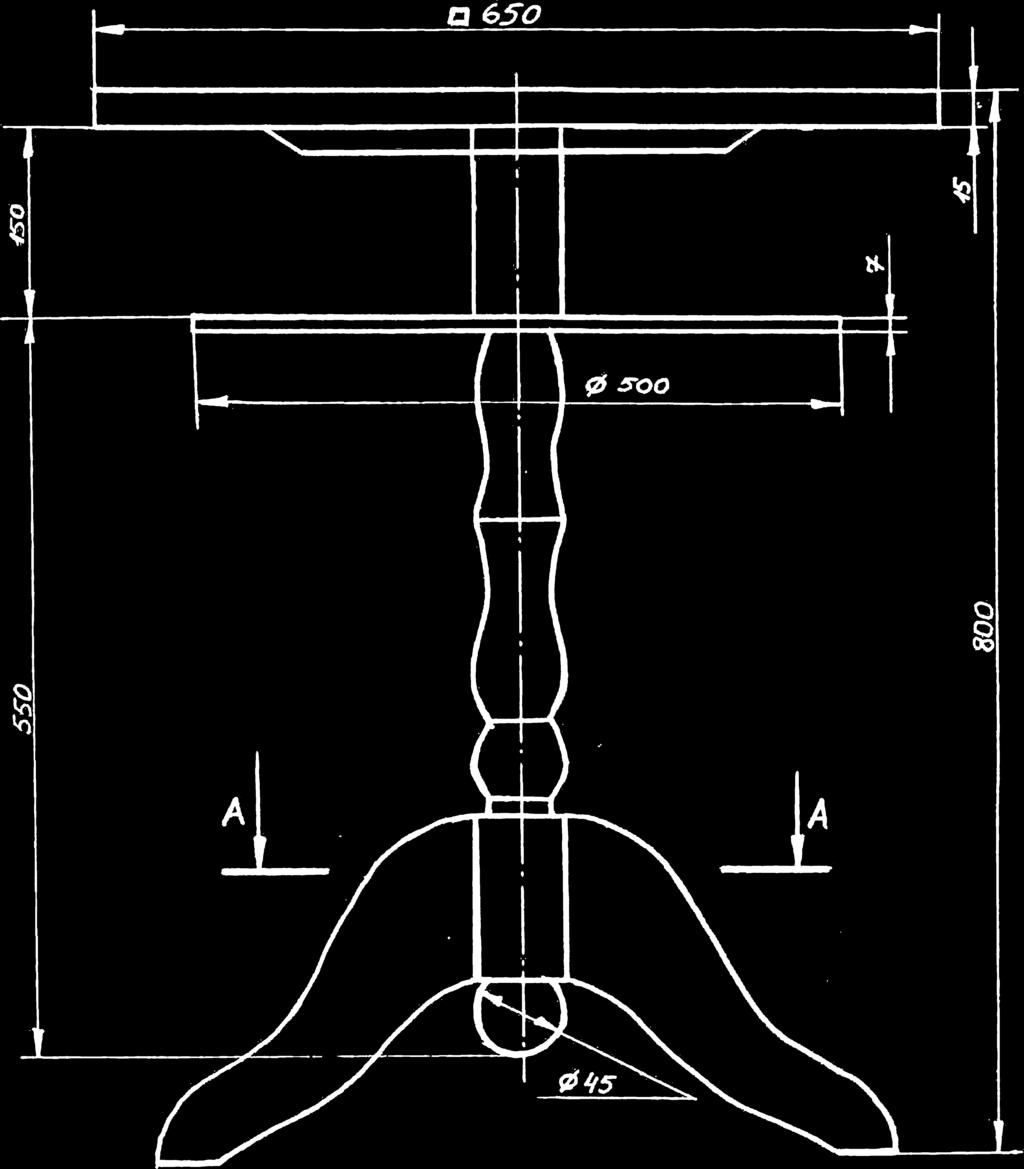

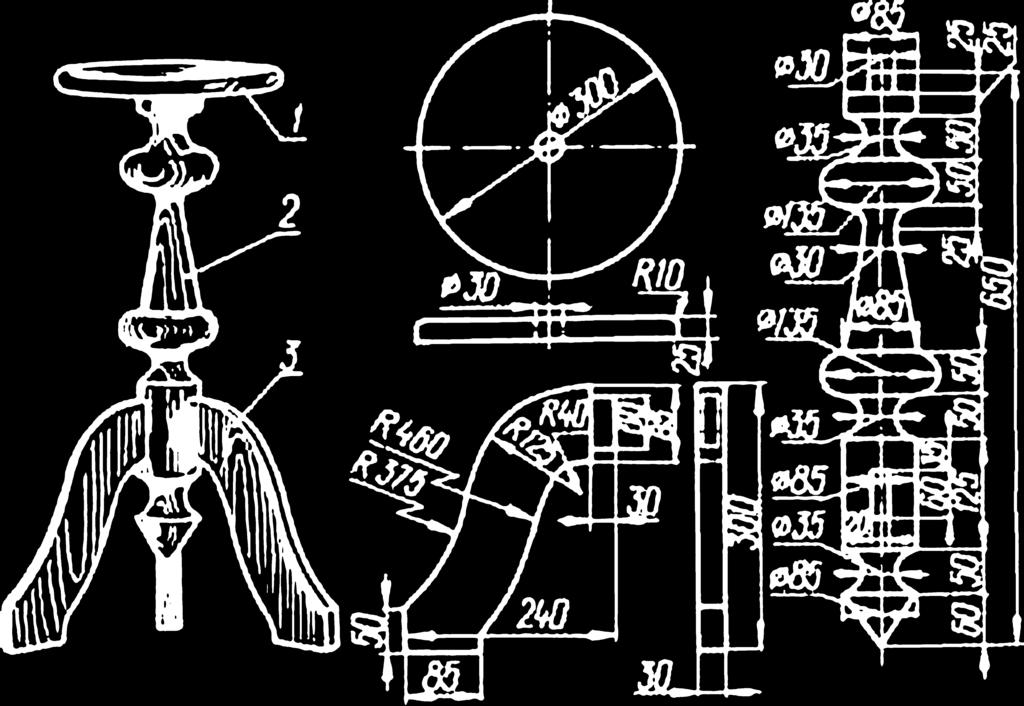

Varieties of electric shears for metal, tool characteristics

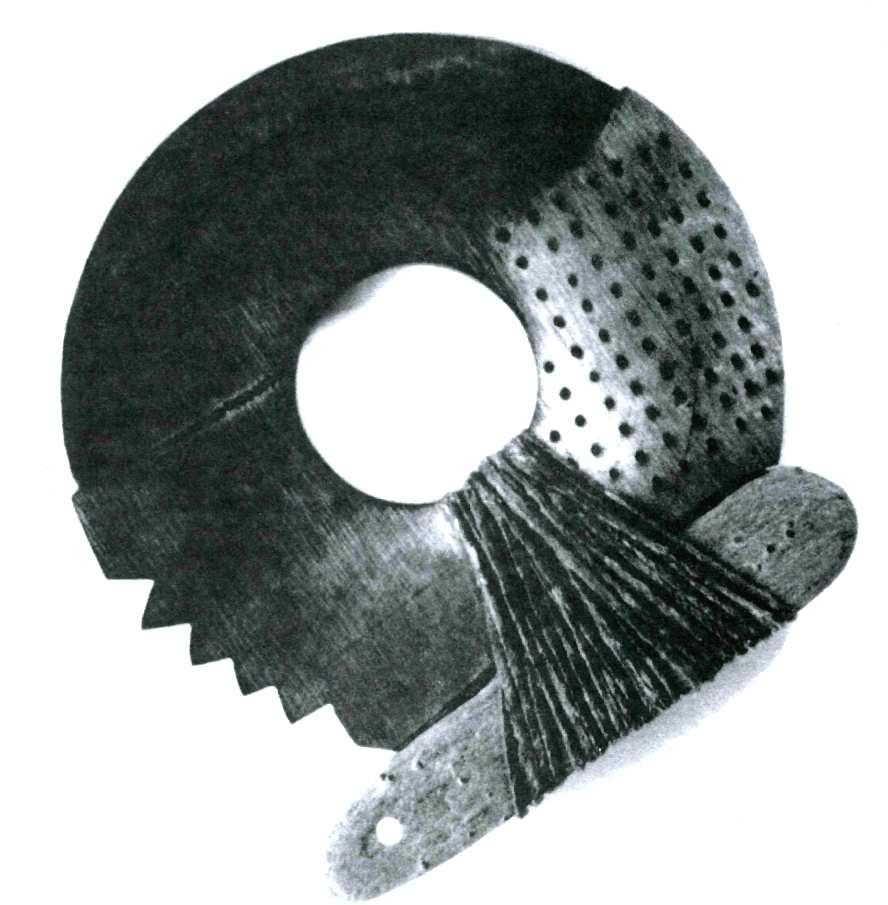

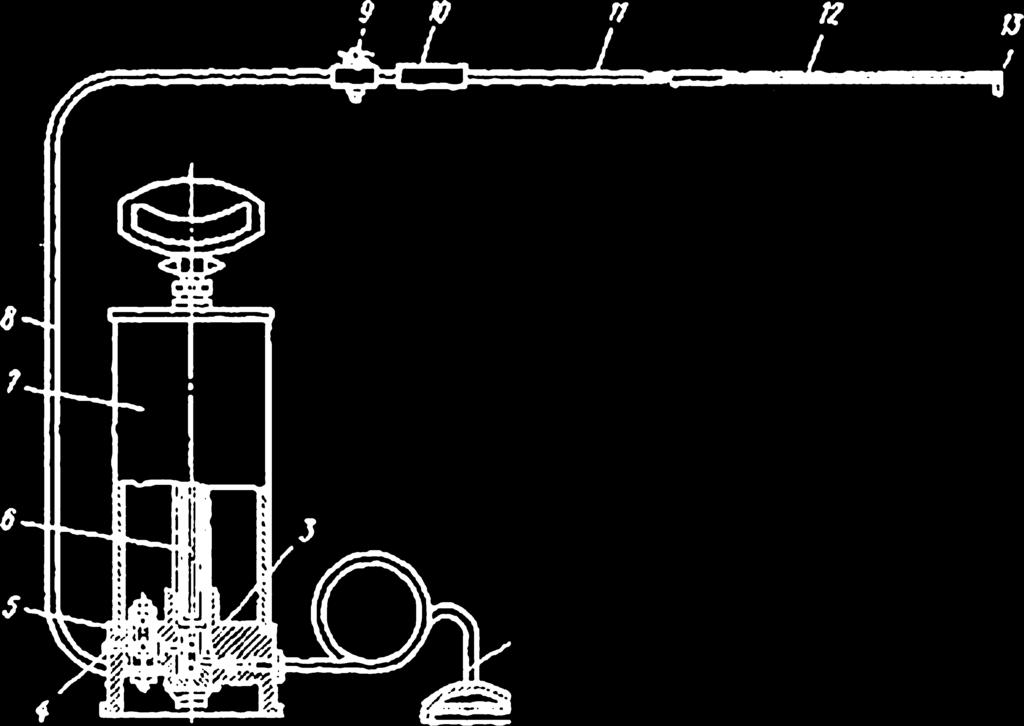

Electric shears for metal by the method of deformation of the processed material are sheet, slotted and punching. The first type of tool, in terms of its principle of operation, is most similar to a manual device. The static knife is securely attached to a rigid support element, which has a horseshoe design. The movable blade works in a vertical plane by means of a reciprocating motion.

Electric sheet metal shears can process sheet metal of different thickness. The device is pre-configured by reinstalling the support platform, thereby adjusting the gap between the lower and upper knives.

Sheet metal tools are characterized by high speed and productivity of work, precision of a straight cut. It is capable of cutting wire or fold material. During the processing of the material, no waste is generated in the form of small and long spiral shavings. Due to the fact that the knives have a square shape with cutting edges along the edges, when one of them is blunt, you can change the position of the blade by placing it with the sharp side.

Of the shortcomings, it should be noted that the workpiece can only be processed from its edge. Scissors are bulky, do not differ in maneuverability, which is necessary for curvilinear cuts and profile blanks. The price of sheet-type metal scissors starts from 6 thousand rubles.

Electric shears for metal are sheet, slotted and notched

Characteristic differences of slotted metal shears

The slotted design is equipped with two knives. One of them is fixed and fixed from above. It is made in a U-shaped design, equipped with two cutting edges. The lower blade of the tool carries out reciprocating movements in the vertical plane with the entry into the slot of the fixed knife of the electric scissors.

The tool can be adapted to different sheet metal thicknesses thanks to the option to adjust the gap between the knives. When cutting a metal workpiece, thin spiral chips are formed that come out upward and to the side. Periodically, it must be cut with wire cutters.

Slotted scissors for metal can cut the workpiece in any part of it, thus eliminating deformation of the sheet, and the cut is smooth and clean. The tool can be used to make holes, which is very important when deciding how to enlarge a hole in metal without a drill. Thanks to the narrow nose, the device is convenient to work in hard-to-reach places. The scissors work well with the folds of the steel sheet.

Slotted metal shears are used for cutting metal with a thickness of no more than 2 mm

Special Features of Metal Nibbling Shears

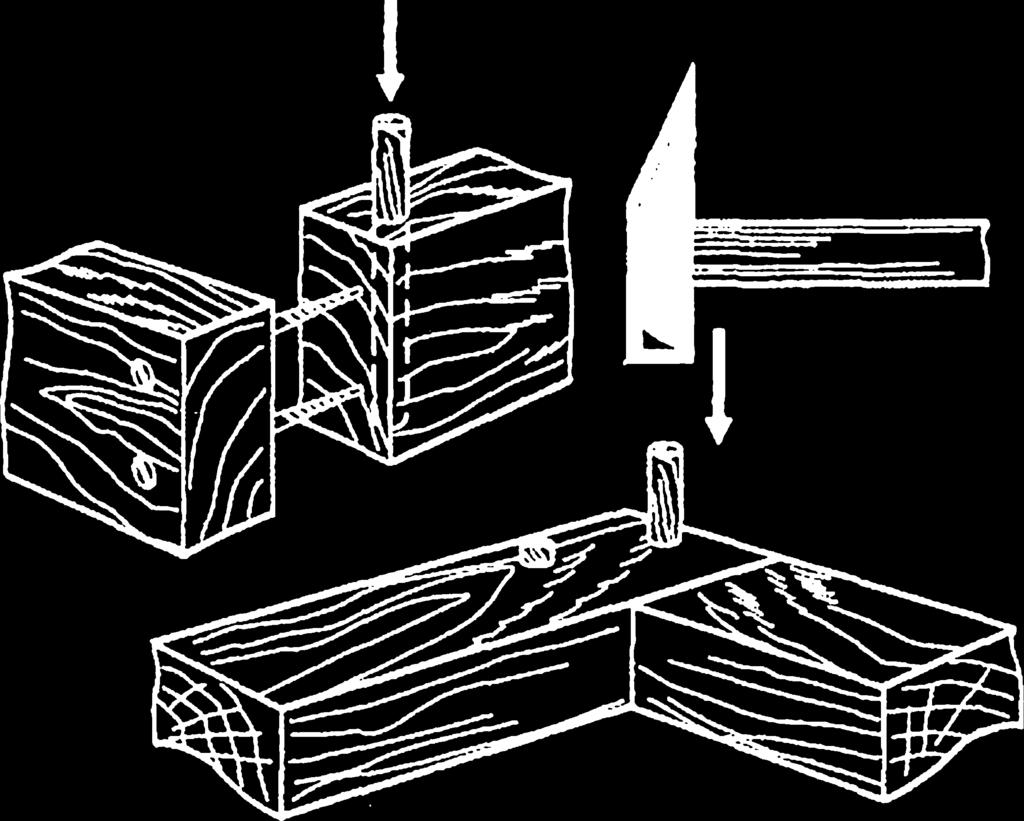

The electric metal punching machine is a compact punching press that can be manually moved along the blade in a predetermined cutting direction.

The design consists of a die and a punch. The first element has a round or square shape, it is fixed on the matrix holder. The punch acts as a punch. It is a movable element of the structure. The punch is fixed in the slider, making reciprocating movements transmitted by the crank mechanism.

Electric cut-through shears for metal of a square shape are designed for processing sheet material with a thickness of more than 3 mm, and round ones can cut metal up to 3 mm thick. During the cutting process, the punch will make holes in the sheet, which form a continuous track. Its width is equal to the diameter of the punching element. The die and punch are equipped with a stepless 360-degree rotation option, which makes it easy to make curved cuts. To reach hard-to-reach areas, the die is fixed at 90 ° angular spacing.

Nibblers for metal ensure a clean cut and do not deform the workpiece

Metal cutting shears are characterized by versatility, good maneuverability, minimum turning radius, extended functionality, good visibility of the working area. The tool is capable of making curved cuts, a variety of holes and pattern cuts. He can start work not only from the edge, but also from the central part of the workpiece. The tool provides a clean cut without deforming the workpiece. Thanks to the high power of the device, the shears can cut thick workpieces.

Among the shortcomings of the tool, one can single out its ability to strictly maintain a given straight line. He has a hard time coping with thickness differences on the workpiece. In the process of work, a large amount of metal waste is formed in the form of sharp sickle-shaped shavings.

Real facts from the history of scissors

To date, experts have not yet come to a consensus regarding the country, which is in fact the birthplace of scissors. Some are sure that they appeared in China, while others, that in one of the Mediterranean countries.

Starting from about the 4th century BC, they were distributed in a huge number of countries - from Egypt to England. This device was used for a wide variety of purposes - animal husbandry, medicine, sewing and sewing of things, and even manicure and hairdressing services.

Time passed, and the device of scissors was constantly improved. So, in the 8th century AD, an artisan in the Middle East had the idea to bend the handles of scissors with rings, and, most importantly, connect the blades with a rivet. Unfortunately, history has not preserved the name of this innovator. There is a theory that the Archimedes lever pushed him into such changes.

Like most other tools and gadgets, scissors have gone through a number of transformations. Over time, they began to be made in different ways, from different materials, they began to differ from each other in shape and finish. For 3.5 thousand years of their existence, they have managed to go a difficult path to real jewelry and technological masterpieces.

During this period, many other tools were invented, designed to cut, cut or pierce something, but none of them can compare with scissors in simplicity and efficiency.

For almost two centuries, spring and lever scissors existed in parallel and to some extent competed with each other. Evidence of this fact has been found in miniatures and paintings that date back to the 9th century.

Evolution of appearance and purpose

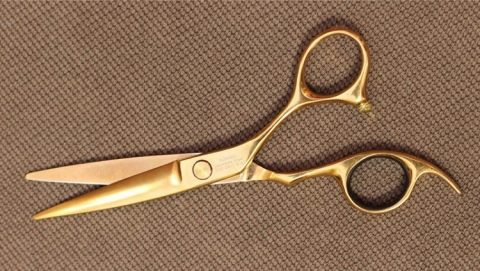

Over time, scissors began to be made from different materials - iron, silver, steel. Then the most expensive began to be covered with gold and decorated. Sometimes the craftsmen were so keen on decorating the instrument that it became impossible to use it for its intended purpose. Some resembled a bizarre bird, whose beak cut paper, others had curved vines instead of standard round finger rings, others were very similar to dragons from oriental tales, etc. Many of these instruments, made from precious metals (silver and gold), became real luxury goods.

In parallel with this, scissors began to be invented for specific purposes and specialties. Some were used in medicine, others in barbershops, and still others for cattle breeding. In France, there were special devices that were used to butcher poultry. In Germany, there are tools that are used to cut metal in cases of traffic accidents - they can cut a door that cannot be opened or the car body cannot be opened.

Lawn scissors were invented in England.

In Russia, scissors appeared in the 10th century; they were found in the village of Gnezdovo (12 km from Smolensk).

In ancient times in Russia, artisans were engaged in the production of scissors, mainly in the provinces where knives were made. Only the blades were hardened.An important point in the process was the processing of two blades at the same time, so that they were exactly the same. The rings were only tempered on elite tools to facilitate the polishing process.

Progress did not stand still, and over time they began to make ceramic scissors, which were much stronger and stronger than steel ones, had a longer service life and cut an order of magnitude thinner.

But this turned out to be not enough, and tools were invented that in their appearance are absolutely not similar to their "original version", but more like a knife for a meat grinder - such a knife easily cuts rubber, linoleum, plastic or thick leather, at a speed of about 20 m / s.

Another modern substitute for steel scissors is laser. They are able to cut the material according to the pattern that is set by the program, and immediately process the edges to avoid sprinkling. The operating speed of such a device is about 1 m / s.

Electric shears: types

These tools are classified by type of food and by purpose. Electric scissors can be divided into 2 main categories according to the type of power used: mains and battery. Mains receive electricity from the mains through a cord, rechargeable batteries have a reserve of energy and are more mobile, but need to be recharged.

By appointment, electric scissors are divided into:

- leafy;

- slotted;

- cutting.

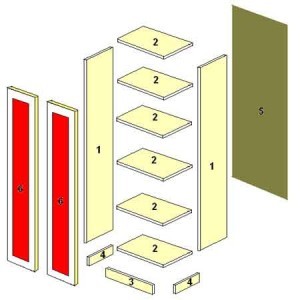

Sheet metal cut metal up to 3-5 mm thick. Structurally, they resemble ordinary ones, in which one blade moves, and the other does not. You can start cutting with this tool only from the edge of the sheet.

Slotted blades are structurally different in the shape of the blades: the upper one has a U-shape with two cutting edges and does not move during operation, the lower one performs reciprocating movements.

The advantages of the device are that its cutting part is narrow and allows cutting even in hard-to-reach places, and cutting can be started from any point on the sheet. The disadvantages are that this is one of the weakest scissors with a maximum workpiece thickness of up to 2 mm and a small turning radius.

Cutting (temporal) scissors are designed to work with any kind of profile - straight, tubular or corrugated. The working body consists of two parts: a punch and a matrix. In fact, this is a miniature punching press that is manually moved along the desired contour. This is a mobile, powerful and high-performance device, the main disadvantage of which is the excessive consumption of metal due to the wide cut.

Separately, it is worth talking about press scissors. These are the heavyweights of all the aforementioned tools. They are used for cutting sheet metal into dimensional workpieces, cutting section and profile steel, cutting grooves and holes, etc.

This type of shear is classified as hand tools, hydraulic tools and container tools. Their working part is similar to a guillotine, but reinforced with a press. This equipment is widely used in industry and metal processing. More compact models of shears are widely used in locksmiths and small production.

Scissors evolution

Thanks to the rich imagination of the craftsmen and the constantly growing demand, the shape of the blades and handles has been constantly improved. The scissors were made in the shape of an exotic bird, whose sharply sharpened beak cut the matter. The rings for the fingers were entwined with vines, roses, lilies. The scissors were made in the shape of a dragon, decorated with ornate painting. The passion for beautiful things led to the fact that too abundant jewelry prevented the normal use of the object.

Over time, both craftsmen and customers began to pay more attention to the convenience and quality of products. Customers required the blades to fit snugly and precisely together. Gradually, the models acquired smooth contours, and the blades were decorated with only neat engraving and delicate inlays. In the history of scissors, a new round was outlined: they became more and more beautiful, comfortable and accurate.Retaining the basic design, they were decorated with fine carvings, slightly changed their shape in order to make life more aesthetically pleasing.

In the Middle Ages, in the circle of aristocrats, scissors were used to demonstrate a man's interest in a beautiful lady. In the 14th century, it was considered good form to present a pair of elegant gold scissors in a leather case to your object of adoration. Then the British created a device for mowing lawns, the French learned how to use a tool to cut clothes, the Germans created industrial copies.

In addition to traditional hand samples, there are electric scissors today. In appearance, they resemble a drill with a special attachment and allow you to cut rubber and plastic at a speed of up to 20 meters per minute. In addition, the inventors came up with a whole machine based on ordinary scissors, designed to cut textiles. This high-tech device is able to reproduce patterns on a monitor, transfer them to fabric and cut out on its own. The cutting speed is over a meter per second.

Ancient greek legend

The history of the appearance of scissors in Ancient Greece is associated with an interesting legend.

At a time when people and gods existed hand in hand, when nymphs splashed in the ponds, and unicorns and other bizarre creatures ran through the green, lush thickets, there lived a shepherd named Fersit. Once he saw on the top of a very high mountain the shine of an object unknown to him. When he went up there to see what kind of golden shine it was, he saw a herd of unusual rams - their fur sparkled in the sun, as if it were made of pure gold. Fersit was amazed at what he saw, and he wanted to take one of the wonderful animals to show people. But he did not succeed - even the youngest animals were so strong and stubborn that the shepherd could not budge them.

When the man returned home, he told the inhabitants of his tribe about what he had seen, but he was laughed at, since the story seemed to them an absolute fiction. Fersit was very upset by this, and he decided to prove to his fellow tribesmen that he was not a liar. He connected the two knives with a flexible and rigid staple and, returning to the top of the mountain, sheared a whole bag of wool from the golden lambs.

Types of modern scissors

Modern scissors can be divided into the following categories:

Household. These are universal scissors familiar to everyone. They can have a completely different shape, size, shape of sharpening and material of manufacture.

When buying, special attention should be paid to the metal from which the tool is made - stainless steel products will last longer.

Kitchen. In turn, they are divided into: universal (ordinary scissors that are used in the kitchen), multifunctional (have wide handles and various additions, for example, for cracking nuts, opening bottles, etc.) and specialized (tools with a special device designed for cutting poultry and meat or for cutting greens).

Hairdressers

There are: straight (for haircuts and thinning);

thinning;

flag;

hot (similar to utility scissors, but the blades are heated to a certain temperature).

Manicure. Used for hygienic, edging and cuticle removal.

For cutting and sewing. Different tools are used for different processes: for cutting, for cutting threads, for embroidery, zigzag, for processing silk, with rounded ends, folding scissors.

For cutting metal. There are a lot of varieties of such scissors, but they can be classified according to several characteristics: by the type of cutting: knife and punching;

for mechanization: electric and manual.

Electrical. Such scissors are battery and mains: sheet (for metal with a thickness of 3-5 mm);

slotted (for materials with a maximum thickness of 2 mm);

cutting (work with any kind of profile).

Press scissors.Used to work with sheet metal: manual;

hydraulic;

container.

Roman history of the invention of scissors

It was only in the 8th century AD that a craftsman from a Middle Eastern country figured out how to cross two knives, fasten them with a nail in the middle, and bend the handles. What craft this invention was intended for is unknown, but since then, significant changes have begun in the history of scissors. Craftsmen experimented with shape and size, decorated products with forging and painting, put autographs and seals on their crafts.

In Europe, scissors appeared two centuries later. Around the same period, around the 10th century AD, this useful item reached Russia. The first Russian scissors were discovered by archaeologists in the Gnezdovsky burial mounds near Smolensk.

The modern look was given to the device by the genius inventor and artist Leonardo da Vinci. His manuscripts contain a drawing of the tool that most accurately reproduces the appearance of the scissors as we know them today. After that, the device became widespread; hairdressers, tailors, and doctors began to use it.

Device and characteristics

Let's take a closer look at how exactly scissors function in our time.

Material

The backbone of modern scissors is made of steel. It has all the necessary characteristics for an object whose purpose is to cut: steel products are strong, hard and wear-resistant, capable of withstanding high thermal and mechanical loads. For the production of scissors, high-carbon, chromium-nickel, chromium vanadium compounds are used. The denser the substance the scissors have to work with, the stronger the material for their manufacture. Handle covers are made of plastic, silicone and rubber.

The form

The shape of the scissors is also determined by the specific task that they will perform. Blades can be straight or curved, with sharp or rounded ends, short or long, with a flat or serrated cutting surface, and they can also be equipped with additional cuts and grooves for various purposes. As for the shape of the handle, it is most often either 2 rings or simple straight handles. Power tools have a special design, different from other types. We'll talk about them below.

Dimensions (edit)

Scissors come in different sizes. Probably the smallest representatives of the genus are manicure products, their length is very small - about 10 cm. This is due to the fact that the task of such scissors is to carefully cut the nails, the size of which is also small. The medium-sized scissors (about 50 cm) include kitchen, stationery and tailor scissors. And, finally, the largest dimensions are garden shears and tools that are designed for cutting metal (their length is about 1 meter, they weigh significantly more than the rest).

Use tailor's scissors for fabric only

And the last piece of advice. Never use a tailor's scissors to cut materials other than fabric. Even paper should not be cut with sewing scissors. Stationery scissors are intended for paper.

Especially take care of scissors from household members. Children are very fond of cutting out all sorts of crafts from cardboard, and sometimes grandmother has nothing to cut the fins of the fish with.

If you follow these rules, then the scissors will serve for more than one year, without requiring repair and for many years they will not need to be sharpened.

If you often have to cut zippers or metallic threads, get separate scissors for this purpose.

How to sharpen scissors at home

Sharpening of scissors, especially used by hairdressers and tailors, should be done on a special machine and always by an experienced craftsman. But often there is a need to urgently sharpen scissors at home, without wasting time on going to the workshop. Can I sharpen the scissors myself?

Fabric cutting knife

What is the difference between a round knife for cutting fabric and tailor's scissors. How to use OLFA circular knives, sharpen the blade, etc.

How to choose zigzig scissors

If the purpose of tailor's scissors is clear, then what are curly zigzag scissors for, especially if there is an overlock and do you need to buy them at all? It is to these questions that the atelier technologist will try to answer.

Fur technology

You cannot cut fur with scissors. Only a special knife can cut a fur skin and only along the flesh, that is, on the back of the hairline. The skin is laid on a wooden or plastic surface and, without pressing strongly against the board, cut with a movement towards oneself, along a previously marked line. A shoe or clerical knife should be very sharp.

Recommendations for working with leather

Why can't you cut leather with tailor's scissors? It is possible, but nevertheless, it is more convenient to cut the skin with a knife, since the edge is formed perfectly even, which is very important when sewing leather products. Plus, the skin will quickly dull the blades of the scissors.

It is better to cut the leather on a large wooden surface, so that it is not a pity to damage it with a knife blade. It is best to mark the lines on the skin with a helium, silvery pencil.

Tailor mannequins

The use of a mannequin in a tailor's work is imperative, as is the availability of good quality tailor's scissors. Mannequins can be roughly divided into two groups: industry standard mannequins used for professional tailoring and extendable mannequins designed for hobbyists.

Tailor's pins

Not only tailor's scissors, a good sewing machine and other sewing tools are essential for a good tailor's work. Small sewing supplies such as tailor's pins will make your job a lot easier, especially if you have several different types of pins in stock.

Sewing machine repair:

- Sewing machine Podolsk

- Sewing machine seagull

- 1022 class sewing machine

- Overlock class 51

- Repair, setting up overlocks

- Sewing machine problems

- How the sewing shuttle works

- Why does the stitch loop

- Sewing machine lubrication

Sewing machines:

- Brother sewing machine

- Covering sewing machine

- Embroidery Machine

- Sewing machine classes

- Janome sewing machines

- Podolskaya 2M PMZ

- Instruction Podolsk 142

- Sewing machine manufacturers

Knitting machines:

- The basics of knitting fabric

- Knitting machine repair

- Knitting machine Severyanka

- Double Knitting Machine

- Knitting machine Neva-5

- Toyota KS-858

- How to knit the first row on the machine

- We knit by car - the first steps

- Yarn for machine knitting

Helpful hints:

- How to choose a sewing machine

- Sewing threads, which is better?

- What can be sewn from the old

- How to choose an iron

- Household iron with steam generator

- What to make out of an old fur coat

We sew ourselves:

- How to sew chair covers

- We sew the sofa cover ourselves

- Replacing the zipper in the jacket

- How to hem jeans

- How to sew a bedspread

- We sew bed linen

- Pattern and tailoring of skirts along the side

- How to sew fur mittens

- Fitted sheet

- How to make jeans shorts

home

Instructions

Sewing accessories

Useful Tips

Sewing Dictionary

map of site

Contacts