What elements include the device of hydraulic jacks

Jack characteristics table.

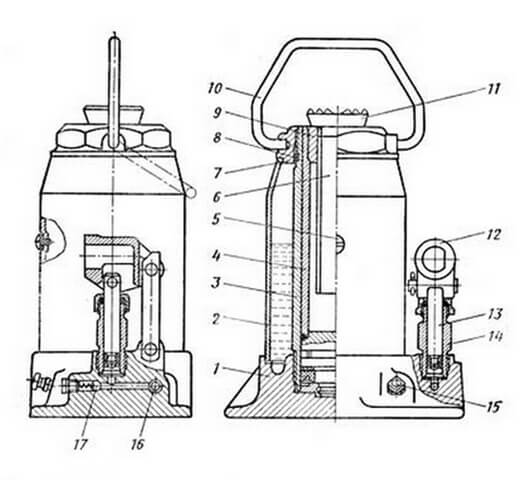

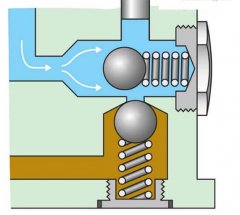

The lever of the device drives the pump, which pumps hydraulic fluid into the cylinder through a special valve. A hydraulic or working fluid is oil that is squeezed out in a cylinder. The jack is lowered back when the valve located on the pump is open to allow hydraulic fluid to flow into the pump.

Hydraulic jacks are easy to use. They should be located on level ground under the vehicle. After closing the valve of the device, its lever is pressed until the vehicle is lifted to the required height from the surface.

To lower the vehicle back to the ground when the wheel has already been replaced, the valve opens smoothly counterclockwise. When the device is in its original position, the valve is closed back by turning it in the opposite direction.

How to properly pump a jack

The operating principle of the screw jack.

The jack, like any mechanism, requires periodic inspection and maintenance. Liquid can be added to the cylinder, since the use of the device is associated with the leakage of oil through the seals, as well as the oil seals. When using a jack to repair a car, a safety stand is used. By adjusting the device with it, you can prevent the car from falling to the ground if the jack is faulty.

Storing the device in places where there is high humidity will lead to rust on the cylinder. For the same reason, the slave cylinder can become unusable. However, the disadvantage of a hydraulic jack is its slow operating speed and low lifting height. Some models have a fairly large dead weight, so it is not very convenient to transport it in the trunk.

How to add oil?

The hydraulic fluid is filled in through the filler neck located on the side of the housing. It is also a level. There is no load on the plug, there is no pressure inside the body. Then it is necessary to bleed the hydraulic jack. This is a simple but responsible procedure.

After priming, raise the stem to its maximum height (no load). Then the jack is placed horizontally with the filler plug facing up. The plug is loosened and the rod is pushed vigorously into the cylinder. Most of the air will be squeezed out into the liquid container.

Then the plug is tightly closed, and several (up to 20) full cycles of lifting to the maximum height with a load of 30-50 kg and lowering of the stem are performed. After that, a control lift should be performed under an increased (100-500 kg) load. If the jack “does not hold” the load, repeat the pumping process.

What kind of oil to fill? The one that is indicated in the product passport or in the instructions. If the documents are lost - find information on the manufacturer's website. Experienced masters advise using the so-called. spindle. This is only true for older models.

Still have questions? Watch the video about the repair of a 12-ton bottle-type hydraulic jack.

Without a jack, a car enthusiast, without exaggeration, remains "like no hands." And it is needed not only to change a wheel on the road. A good jack is indispensable for some types of repair work - especially in a regular garage that is not equipped with a lift. For example, when assembling the suspension after repair, when it is necessary to make the final tightening of the levers.There is absolutely no need to lower the car on the wheels, so that the silent blocks take a "working" position - just jack up the lever to give it the desired position. A sliding hydraulic jack is especially convenient - thanks to its design, it can be installed under a part located low - so that no other jack can get under it. But, like any other mechanism, the jack can fail. Repair of a rolling jack is available to anyone who repairs a car on their own.

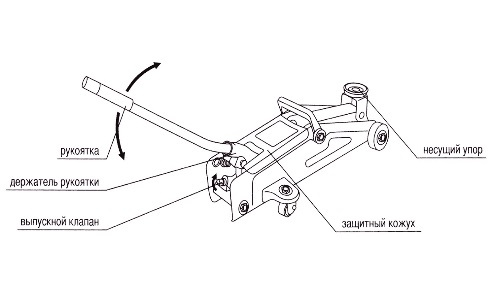

Let's just talk about what you need to pay attention to first when repairing a rolling jack with your own hands. First of all, consider its device.

The main causes of hydraulic jack malfunctions and how to fix them

Jack repair scheme.

One of the most common causes of jack breakage is oil leakage. As a result, air enters the working chamber, as a result, the lifting mechanism does not work at full strength or stops functioning.

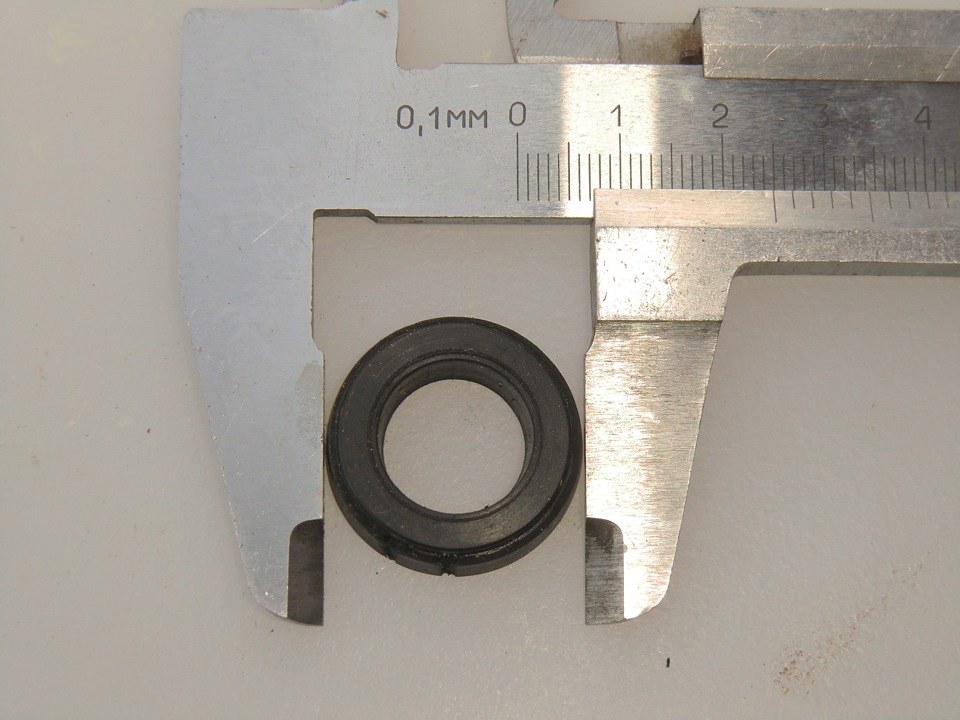

This problem can be avoided by periodically performing maintenance on the hydraulic jack, which consists in controlling the amount of fluid, and, if necessary, topping it up into the working cylinder. A decrease in the amount of oil in the system can be the result of natural operating loss, as well as due to damaged or faulty oil seals and seals. In this case, the usual liquid topping up will not solve the problem; it will be necessary to replace the failed seals and oil seals.

Due to the lack of working fluid in the system, air takes its place - this can be guessed by the decreased efficiency of the jack. You can get rid of this problem by pumping. To do this, open the oil tank cap and bypass valve and bleed the hydraulic pump. If the malfunction is in this, then provided that this work is done correctly, the jack will again be in working order. But if this does not help, then either the cause of the malfunctions is different, or more serious repairs will be required. Sometimes this problem can be solved by unscrewing the shut-off needle two turns, at the same time raising the piston to the top point, and then releasing it so that it reaches the bottom. This action must be repeated 2-4 times.

If corrosion is found and parts are damaged, they are replaced.

Often, the hydraulic jack may malfunction due to corrosion, which can attack the extendable pistons (rods or plungers) and the interior of the housing. But to find out the reason, you need to disassemble the device. To do this, you can contact a service workshop or carry out the work yourself. You will need a set of keys, a repair kit, a container for draining the old oil and a canister with a new one for filling into the system after repair.

A bent rod also often causes the jack to fail, in this case, if provided for by the design features of the model, it can be replaced with a new one, and often this means that the jack cannot be repaired even in a service workshop.

You can remove dirt by washing it with kerosene. The bypass valve can also be the culprit quite often. It may have some deformation, or dirt has gotten into it, which causes the ball to not sit tightly in the seat and, therefore, fluid flows out. This problem is solved mainly radically - by replacing the bypass valve.

Instructions for correct pumping of the jack device

Scheme of filling the hydraulic jack with oil.

Among the advantages of jacks, a rigid structure is distinguished, as well as the height of lifting the load from the ground, the highest lifting capacity with a smooth ride, and the minimum pickup height. All these advantages result in high efficiency.

The reasons for equipment failure can be any. For example, long-term operation of the device can cause the accumulation of air in the form of bubbles.This reduces the efficiency of using the jack, that is, its efficiency drops sharply. This is due to the ingress of air into the hydraulic mechanism due to a lack of hydraulic fluid.

Bleeding and jack troubleshooting

Bringing the device to its original state will allow performing the following actions:

- Pumping should be started if the bypass valve with the oil tank plug is open.

- The pump of the device is pumped a certain number of times, which will displace all the accumulated air from the working cavity into a special container for liquid.

- Close the oil tank opening and bypass valve.

Otherwise, the above actions, according to the instructions, are repeated.

How to properly pump a jack using a different algorithm

Corroded parts are recommended to be replaced.

Since the above method of pumping the jack is not the only one, you can perform the following steps in stages:

- When the load is slowly lifted by the jack or its complete malfunction, the presence of air in the cavity of the device is determined.

- The locking needle should not be unscrewed by 1.5-2 turns, and the jack plunger is lifted by the screw to the upper point, which is extreme, and then it is lowered again to return to the bottom position.

The last operation is repeated 2-3 times. To avoid this problem, you should periodically check the fluid level in the jack. If it is not enough, then be sure to add oil.

The pumping of the jack is repeated after the ingress of contaminants into the working cavity. To remove contamination, the head of the case is unscrewed, then kerosene is poured into its base. Next, the jack is pumped, after unloading the shut-off needle. After completing the operation, the kerosene is removed, and the working cavity is filled with clean hydraulic fluid.

In general, the algorithm looks like this:

- Oil is poured, then the box is closed.

- The piston should be bled by raising it to failure.

- The plug is unscrewed and pressed on the piston, releasing air from the cylinder.

- Add oil by closing the plug, etc.

This is done until all the air has escaped and the hydraulic oil is released in accordance with the pumping of the brakes.

Main characteristics

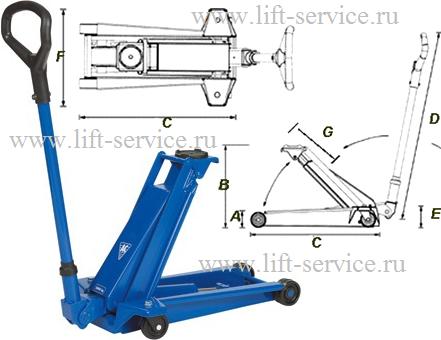

Carrying capacity. Carrying capacity starts from 2t and above. A simple passenger car for everyday needs will have enough carrying capacity of 2 tons. Such a tool does not take up much space, it can be stored in the garage and taken with you on a trip. If you have an SUV, a lifting capacity of 3t or more is recommended. In any case, it is better to know the weight of the car in advance, and be guided by its value in choosing.

Maximum lift height. It is different for each model

Owners of SUVs need to pay maximum attention to the parameter. It makes no sense to pay for a tool that lifts the car by 2 cm

The maximum lift height for SUVs starts at 450 mm.

Minimum height. The parameter determines the ability to roll the device under the car. A rolling jack with a minimum height greater than the ground clearance of your car is not your assistant. Be sure to measure the ground clearance (clearance) before choosing.

Ease of use. Rubber pad on the bearing stop.

Mechanism drive type. Cardan and toothed. Recommended cardan type, it has proven its reliability and is also more repairable.

Repair of a rolling jack

You will need:

- wrench;

- container for draining oil;

- kerosene;

- butter.

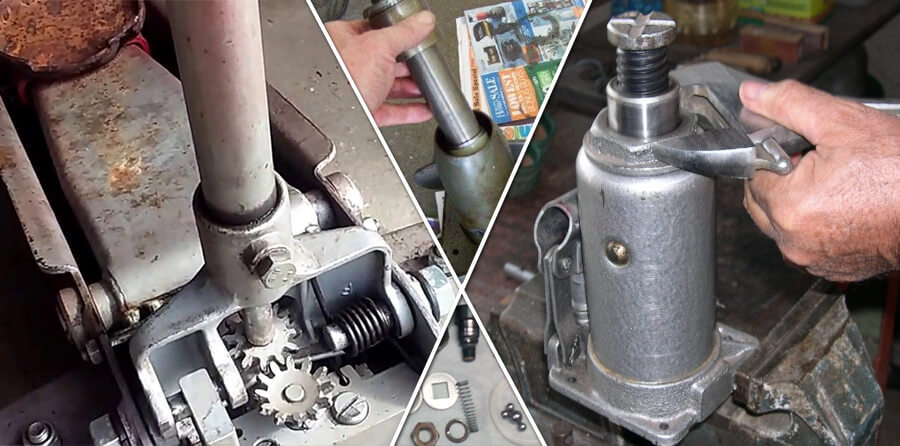

During the operation of the jack, its breakage may occur. The malfunctions of this device include oil leakage, jamming when lifting to a height, or, conversely, its refusal to descend. In any case, it should be repaired.

If the cause of the breakdown is oil leakage, then first you need to disassemble the device. Then the pistons are removed from it and checked for corrosion. After that, all dirt and the resulting corrosion are carefully removed. Next, the stock is checked. In the event that it is bent and deformed, the repair of the jack can be considered impractical.

The principle of operation of a hydraulic rolling jack.

When repairing a valve that allows oil to pass through, you need to unscrew it and check if dirt has got inside and if it has been deformed. In the event that it has undergone mechanical deformation, the valve should be replaced. If it gets dirty, then the working fluid will flow due to the fact that the ball has ceased to sit tightly in the seat. Therefore, first, the old working fluid (oil) is drained into the prepared container, while pumping the system with the lever, raising and lowering it.

Then all parts are thoroughly washed from the trapped dirt, as well as from the remnants of old oil. In this case, it is imperative to replace all the cuffs, as well as the gaskets. If the dirt gets directly into the working cavity, then to remove it, you will need to unscrew the head of the case.

After that, kerosene is poured into its base and executed. In this case, the shut-off needle must be unscrewed. At the end, the kerosene is removed, and a clean working fluid is poured into the working cavity.

Repair in this case is carried out as follows. First you need to open the plug at the oil tank and the bypass valve. Then, at a fast pace, the pump of the hydraulic press is pumped several times in order for the air from the working cavity to move into the container in which the oil is located. The oil tank opening and the bypass valve are then closed. If the whole process is done correctly, the jack will start working normally. With the remaining air in it, all actions are repeated again.

If this device does not work or raises the load very slowly, then air can be removed from the working cavity in another way. For this, the shut-off needle is turned one and a half or two turns. Then, with the help of a hand, the plunger is lifted by the screw, reaching the extreme upper point.