How to choose?

For belt sanders

When choosing sandpaper, there are some key aspects to consider.

- The size. Without knowing him, making a choice is pointless. The width of the consumable must match the sole. In extreme cases, it can be narrower. For individual modifications, it will not be easy to choose equipment: not every outlet has sandpaper, for example, with dimensions of 100 × 620 (100 × 610 is a much more "popular" option) or 30x533. Therefore, you need to take care of this even when buying a grinder.

- Abrasive grain size. It is marked with a number. The larger it is, the softer the sandpaper. It is not hard to understand that the hard consumable is intended for layer removal, not for polishing. Ideally, you should have several belts with different sizes of abrasive, as the sanding procedure is usually carried out in several steps: first, roughing, and then final (with a material with a small grain size).

The seam. Not only the service life of the sandpaper depends on it, but also the quality of grinding. The joint must be strong, otherwise it may turn out that the sandpaper will not wear out yet, but will already lose its functionality due to the breakage. It is also necessary to check the uniformity of the seam. If it is higher than the web, then the unit will vibrate during operation. And that's not the worst part. Regret awaits you when, having processed the plane with low-quality material, you will feel with your hand the countless grooves that have arisen after the jolts. Especially inexpensive consumables sin with this, therefore it is also necessary to observe savings wisely

It is important to look at the quality of the joint: there should be no protrusion. You just need to run your finger along the back, putting the sandpaper on a flat surface, then everything will be clear.

Separately, it should be said about the appearance of the edges of the consumable

Good quality equipment has smooth edges, without hanging threads.

- Centering. Before work, a knowledgeable user “drives” the grinder without load, finds out if there are any flaws, cancels them, and only then starts the process.

- Rigidity. Exemplary sandpaper must be resilient and strong. Samples with a hard canvas are prone to deformations, which are not the best reflected on the resource of the consumable, which can leave a mark on the quality of work. The markings on the sandpaper and on the product box must match, otherwise you may end up with low-quality equipment.

- Storage. Ideal conditions: temperature 18 ° C and humidity level 50-60%. Abrasives in this matter are quite finicky, in a few months they can become unusable.

For flat (vibration) grinders

Let's talk about consumables for flat grinders. As equipment for surface grinding units, sheets with an abrasive coating, in other words, sandpaper, are used. Compacted paper is often used as the base, and aluminum oxide or corundum is used as an abrasive material. The sheets have holes for dust removal. Their number and location may vary.

Therefore, it is important to use exactly the equipment, the holes of which coincide with the holes on the base of the sander.

At times, a stearic coating is used to eliminate the adhesion of sandpaper to the plane and smooth the processing when working with soft wood. Consumables on the sole are fixed either with clamps or by means of adhesive tape. Velcro is a lint-like fabric and is a collection of many hooks. This is a simple and quick way to change the equipment, it may only be difficult to find samples of the appropriate size.

For units with ordinary clamps, it is easier to choose a consumable. There are ready-made sheets in the trade. You can also buy ordinary cuts of abrasive material and make a sandpaper on your own. First you need to cut a sheet of a suitable size. Then perforation should be made either through a home-made device, for example, with a hollow tube of the required diameter with a sharpened end, or through a factory hole punch, which you can buy additionally. There are also grinders on the market that have a replaceable grinding plate. Due to this, the sandpaper can be fixed in different ways.

Summarizing the above, we can conclude that sandpaper is an ideal material for sanding work. However, in order for the surface treatment to be of high quality, it is worth choosing the most suitable consumables for each specific case.

For information on how to choose sanding paper for a sander, see the next video.

How to use a sander for wood and other materials

The operation of the grinder is generally described in detail in the product data sheet. Each instrument has its own nuances, therefore, in each particular case, it is necessary to carefully study the instruction manual

General precautions are as follows:

-

When using the grinder, you must use sound-absorbing headphones to prevent injury to the eardrum.

-

You can only use a tool that is known to be in good working order. It is unacceptable to start work with the machine with signs of mechanical damage, a broken or frayed power cord.

-

If you are handling metal parts that cause sparks, keep the area close to the work site free of flammable or combustible materials.

-

Eye protection is required from dust or sawdust. Building glasses made of safety glass will help with this.

-

Replacing or cleaning the dust container should only be carried out with the tool turned off, after the engine has come to a complete stop.

-

It is necessary to protect the mucous membrane of the respiratory organs from dust. For this purpose, it is imperative to use a respirator during work.

-

Construction gloves will help protect your hands from possible injury.

When choosing a grinder, you should take into account the degree of stress to which it will be subjected. If the time of using the instrument does not exceed 2-3 hours a day, you can purchase inexpensive hobbyist models. If the operation is supposed to be 4 or more hours a day, the best option would be to purchase a professional unit designed for long-term use.

Pads and sponges

The shoe is an extremely useful tool for manual grinding, its presence and correct application will speed up the process. The shoe is usually a regular wooden block wrapped in sandpaper. Its abrasive side should be on the outside, and the non-abrasive side should be attached to the block with a large stapler or PVA glue. In some hardware stores, ready-made pads with sandpaper are sold, that is, you can not do it yourself, but just buy it.

Foamed polyurethane sponges are also used for sanding wood. They are more convenient to use than emery, since you can rinse them after working under water. Abrasive sponges and wipes are great for finely hand sanding wood, allowing you to process even the smallest parts. They can also be used for sanding primed or varnished wood.

What kind of skin is used for grinders

Sandpaper is one of the oldest human tools. The first mention of it dates back to the 13th century in handwritten parchments in China. An unknown author described in detail the recipe for making NB from shark skin and crushed shells using natural glue.

Since then, "sandpaper" has undergone many modifications, but the basic principle has remained unshakable. An abrasive grain powder is attached to a paper, fabric or other flexible base, which is used to process a particular material. The production of this product has acquired a global scale, and therefore a certain system of certification and labeling has emerged. Various hard materials are used to create an abrasive layer: electrocorundum, silicon carbide, garnet, as well as fine diamond chips.

A variety of types and forms of sandpaper

A variety of types and forms of sandpaper

The main characteristic of the sanding paper is the grain size, which characterizes the productive qualities of the SB.

The grain size can range from 2.5–5 microns to 1 mm, and is indicated by a number on the marking in tens of microns (corresponds to the minimum grain size). The letter "H" is placed after the number. The smallest sandpaper is designated by the letter "M", it is also called "zero".

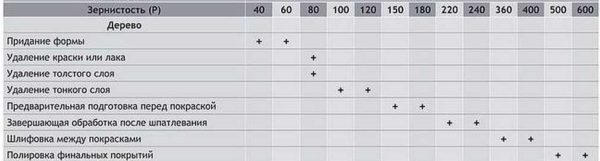

Using the table, you can select the grain size required for processing a particular material.

NB designation table, designation, grain size

| Appointment | Marking according to GOST 3647-80 | ISO-6344 marking | Grain size, μm |

|---|---|---|---|

| Coarse-grained | |||

| Very rough work | 80-N | P22 | 800–1000 |

| 63-N | P24 | 630–800 | |

| 50-N | P36 | 500–630 | |

| Rough work | |||

| 40-N | P40 | 400–500 | |

| 32-H | P46 | 315–400 | |

| 25-N | P60 | 250–315 | |

| Primary grinding | 20-N | P80 | 200–250 |

| 16-H | P90 | 160–200 | |

| 12-H | P100 | 125–160 | |

| 10-H | P120 | 100–125 | |

| Final sanding of soft wood, old paint for painting | 8-H | P150 | 80–100 |

| 6-H | P180 (P 220) | 63–80 | |

| Fine-grained | |||

| Final sanding of hardwoods, sanding between coats | 5-H, M63 | P240 | 50–63 |

| 4-H, M50 | P280 | 40–50 | |

| Polishing final coats, sanding between coats, wet sanding | M40 \ H-3 | P400 | 28–40 |

| M28 \ H-2 | P600 | 20–28 | |

| Grinding of metal, plastics, ceramics, wet grinding | M20 \ N-1 | P1000 | 14–20 |

| Even finer grinding, polishing | M14 | P1200 | 10–14 |

| M10 / N-0 | P1500 | 7–10 | |

| M7 \ H-01 | P2000 | 5–7 | |

| M5 \ H-00 | P2500 | 3–5 |

Marking of sandpaper in Russia is carried out in accordance with GOST R 52381-2005.

What should be the grit of sandpaper for work

As you can imagine, different abrasives are used for different processing of materials. Now we are not talking about the form of release, but about the size of the grain, the method of its application. The type of abrasive and the method of application are of secondary importance. They more affect the durability of the material. But as usual, better means more. Here everyone chooses for himself. But the grain size is better to select for specific tasks.

Sandpaper for sanding wood for painting: choice of grain size

What sandpaper to grind wood

To prevent the skin from clogging, the grain must be applied at intervals. This is an open type of application. In this case, you do not have to often "knock out" or change it. Base type - paper or fabric. Paper is cheaper, fabric is more expensive. If you have a sander, see the recommendations for it. For processing by hand, you can attach a piece to a special holder or nail it to a block.

How to choose sandpaper grit for woodworking

Recommendations for the choice of grain size are given in the table. For primary processing, sandpaper from P40 to P80 is used. This is shaping, removing a thick layer. We use the same materials to remove varnish and paint from wood. To prepare the tree for painting, you need P100 to P240. For sanding after applying the first coat of varnish, take P360 or P400. And finishing to smoothness - actually polishing and varnishing - these are already very small P500 and higher. In general, polishing is a separate topic, and there you need to grind step by step and apply paint or varnish. And each time the grain is taken more and more subtle. And they finish polishing with a generally soft polishing (felt) material.

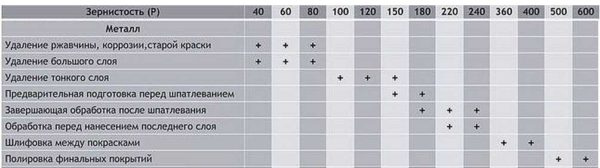

What kind of emery to process metal

For metal processing, you will have to take tougher abrasive materials, which means more expensive ones. Ordinary corundum will cope with aluminum and its alloys. They also process cast iron, bronze and black steel. For brass, you need at least zirconium, but titanium or alloyed alumina is better. Better yet, ceramic

Also note - the application method must be closed.

For grinding and polishing metal, a different type of skin is needed, and we select the grain size for the type of work

The principle of selecting the grain size is the same: for coarse processing, the increased "roughness" of coarse grains, the finer the processing, the finer the abrasive. To remove rust and level the main roughness, take the coarsest sandpaper. The thinner the layer, the smaller the grain size. So everything is logical here

Note, however, that there are two or three grit sizes for each job. This does not mean that you need to take any of the indicated

This means that each size must be processed to get a good result. Although, if the appearance is not so important to you, then you can use one of the recommended sizes.

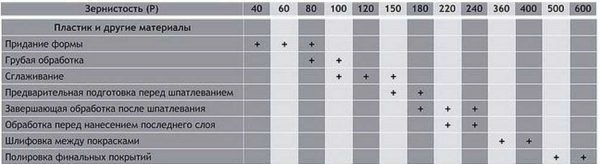

Sandpaper for plastic, stone, ceramics and glass

As for the type of abrasive and its application, the recommendations are the same: stronger, more dense arrangement. But sanding is recommended with water supply, so a waterproof modification of the emery is required.

Sandpaper for plastic: choice of grit

For finishing plastic and glass, even the smallest grit sandpaper - the same zero or P800 - will be too coarse. It will leave visible scratches. These materials are brought to smoothness using GOI paste and even thinner grinding compositions. But this is a separate story and its own technologies.