What attachments for a walk-behind tractor can be made by hand?

It all depends on the qualifications of the home craftsman and the set of tools that he has. We advise beginners to start their experiments with the simplest designs - a fan potato digger or a hiller.

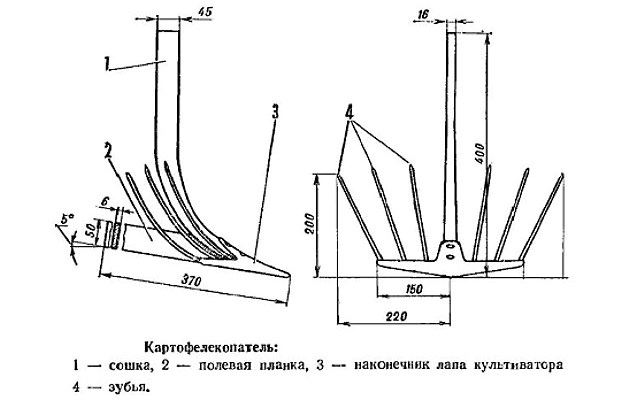

The design of the device for digging potatoes is shown in the sketch. It consists of a wide bent plate (paw) welded to the vertical bipod and the field bar. The teeth from the reinforcement are attached to the rear edges of the paw by welding.

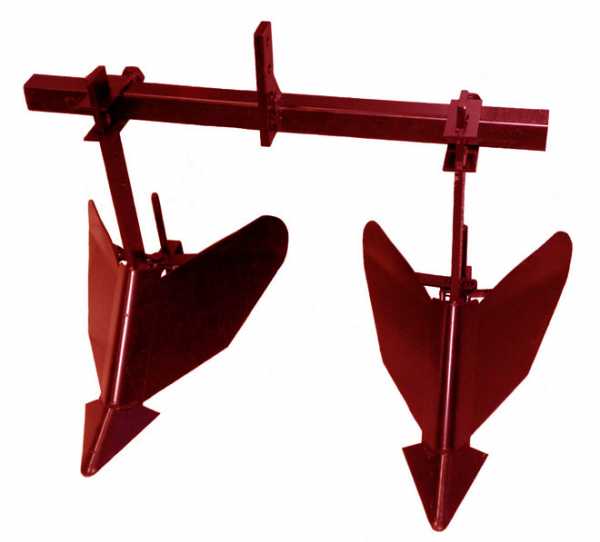

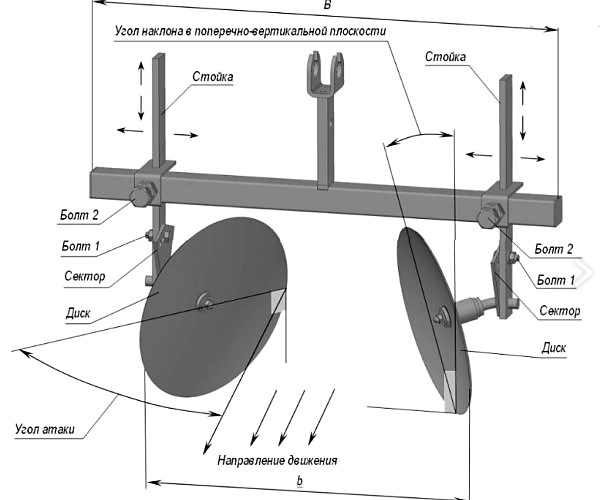

It is easier to make a disk model from hillers. Its main elements are discs that can be cut from the ends of old gas cylinders. They have the right shape, diameter and metal thickness.

Quite a lot of design solutions have been invented for the device itself, you can be convinced of this by watching videos of self-made people, as well as various assembly diagrams.

In addition to discs, you will need:

- two posts made of steel strip;

- two rolling bearings;

- bolts for attaching the struts to the frame and adjusting the pivot sectors;

- crossbeam from a profile pipe;

- T-shaped leash.

The main condition for the high-quality operation of such a mechanism is the accuracy of the manufacture of all parts and the symmetry of the installation of the disks. Otherwise, it will be taken away from the furrow while driving.

Manufacturing of other suspended structures

The walk-behind tractor can be equipped with a variety of useful devices - a plow, a rake, all kinds of shovels, mowers, skis, brushes. Desire, clear schemes and description of work will help to repeat store counterparts of hinged elements and even improve them, since they will correspond to individual requirements and conditions.

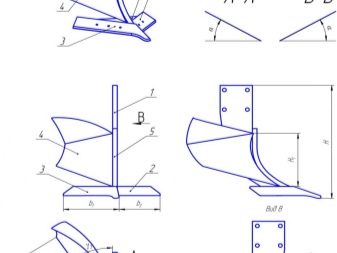

So, to cultivate the land, a plow is needed that can overcome virgin soil overgrown with grass, wet or stale soil. For its manufacture, a steel plate with a thickness of about 5 mm is required. Using the rollers, the plate is bent into a cylinder. The edges are sharpened with a grinder.

By the same principle, it is easy to make a furrow-forming attachment. It is good if there are racks from the cultivator. They can be attached to a corner or made two racks from scrap materials. For this, plates are cut from a metal sheet with a thickness of 1.5-2 mm. The size of the plates should correspond to the depth and width of the furrow. They are fastened with bolts to the struts of the structure. You can use such a nozzle for instillation. One has only to give the plates the required shape. They should be in the form of a disc or circle, located at a certain angle. From above, such plates are located closer than below. Due to this, the discs, while rotating, open the cavities outward.

The attachment to the cranberry walk-behind tractor contains a self-propelled crawler platform. The intake is fixed on the swing frame of the platform. It is made in the form of a box with bent parallel teeth. Moving, the device with the help of the fan pulls the berries into the box. The fan is powered by the engine. Screw-shaped spirals are installed in the box.

Plucked cranberries are heavier than garbage, so they fall to the bottom of the container. Leaves, small specks that fall along with the cranberries, are removed through the hole along with the air flow from the fan.

A brush for a walk-behind tractor is used to clean the area not only from leaves, but also from shallow snow. Simplicity, efficiency and versatility of use are the obvious advantages of this hinged element. A brush shaft is vertically attached to the walk-behind tractor.A ring and discs with brushes are alternately put on it. The diameter of the rings is 350 mm. The width of the grip of such a brush is usually made no more than one meter. So the walk-behind tractor remains maneuverable and covers a fairly large surface area for cleaning.

The length of the bristles is 40-50 cm, otherwise it will soon begin to wrinkle and wrinkle. It will not be possible to restore the properties of the bristles, just attach new discs. The speed of the walk-behind tractor with a hinged brush fluctuates in the range of 2-5 km / h, depending on the engine power of the unit.

How to make a plow for a walk-behind tractor with your own hands, see the next video.

Everyone knows the saying that the king is played by the retinue. Without the accompaniment of a crowd of nobles, advisers and formidable guards, any monarch will seem to you an ordinary person. In the same way, without the addition of attachments, the most expensive walk-behind tractor is a useless piece of metal.

We will talk about the types of hitch for this type of equipment and their capabilities in this article.

How much oil to pour into the gearbox of the walk-behind tractor

When operating the walk-behind tractor, it is necessary to maintain a constant oil level in the gearbox. If this simple rule is not followed, the remaining lubricant can boil and jam parts. Only high quality oil is poured. Even with constant maintenance of the level, breakdowns occur. When using a chain drive, the chain breaks or stretches. If traces of oil appear on the outside, this is a sign of oil seal leakage. Worn out parts require replacement with similar ones. It is better to purchase them from a reputable manufacturer.

The gearbox ensures uninterrupted operation of the walk-behind tractor, extends its service life and increases the efficiency of the unit. In this case, a good helper is the lubrication of its parts. For lubrication, gear oil is poured. Its possible brand is ZIC 10W40, Super T-3. The oil level is determined in this way:

- you need to take a wire about 70 cm long instead of a probe and bend it into an arc;

- insert into the filling hole until it stops;

- pull out the homemade dipstick back;

- the wire should be oiled to a length of about 30 cm.

This level is considered to be the norm. If there is little oil, you need to add it to the norm. In the purchased gearbox, the level must be indicated in the instructions. The Chinese walk-behind tractor can be sold without oil.

How to make a hand spacing cultivator

To tackle narrow spaces between rows, the cultivator must first be compact. A hand-held device called the Hedgehog is well suited for such work. Having all the necessary parts, it is easy to make it yourself. To assemble the "Hedgehog" you will need: a U-shaped bracket with holes, a shaft, a handle and wheels with metal spikes.

- To make the walk-behind tractor easy to move around the site, you need good wheels. To do this, take medium-sized steel pancakes and weld metal spikes to them. Spikes are easy to make, you need to sharpen the cone-shaped reinforcement.

- Ready-made cutters are put on the axle.

- The axis is inserted into the bracket and fixed on both sides.

- The fastener is welded to the end of the staple and the handle is inserted.

The equipment is assembled and ready for cultivation and weeding between rows.

From trimmer

A do-it-yourself cultivator made from a trimmer will help to process a small area quickly and easily. You can assemble it from improvised materials: a working gasoline trimmer, grinder or welding, garden forks, steel pipes.

- For the manufacture of cutters, teeth from the pitchfork are used, which are bent into the desired shape. Usually, the soil is loosened to a depth of 10 to 15 cm, so the length of the tines should be no more than 15 cm.

- Next, we do the working part. The forks are flattened to a width of about 1 cm.

- The cutters are sharpened with emery and fixed on a round penny.

- A penny with a diameter of 10 cm should be perfectly flat. The cutters in the amount of three pieces are evenly spaced on a penny.If you put more than three pieces, the device will be very overloaded.

- The final part is connecting the base to the cutters and a trimmer. It is good if the shaft end is threaded. Then the trimmer is simply screwed onto it.

The technique is designed for loosening the soil at a shallow depth.

How to make a flat cutter with your own hands?

A practical addition to the walk-behind tractor is a flat cutter. This is an indispensable assistant who creates beds, weeds and spuds plantings, levels, falls asleep, loosens the ground. The possibilities of such a nozzle are almost endless.

A flat cutter will again help to form grooves for planting and fill in the seeds. This is the function of the burier.

You can use the Fokin flat cutter as a hitch for a walk-behind tractor. He has the necessary holes for hanging on the structure. If a flat cutter of a different size is required, then you can make it yourself. Drawings and a small metal workpiece will help with this.

The metal must be of sufficient thickness and strength so that in the future it can function as a blade. The sheet is heated with a blowtorch and bent according to the pattern. When the plane cutter is in shape, it is cooled with water. In order for this workpiece to become an attachment, it is necessary to make holes for fasteners and sharpen the workpiece with a grinder.

How to choose?

The choice of attachments to some extent depends on the power of the motor-block motor. This technique is of three classes: light (household), medium (semi-professional) and heavy (professional). Shaft with power take-off promisingly increases the capabilities of equipment, with its help attachments are equipped.

Hinged attachments for various types of economic activities often cost more than the walk-behind tractor itself. To make a choice, you should think about which jobs are the most time consuming. For them, you can choose more complex equipment. Simplified nozzles are quite affordable to make yourself.

Sometimes for soil cultivation, they do not know which is better to choose - milling cutters or a plow. To choose, you should study the features of the soil of your site. To plow a field with soft soil, milling cutters are used, and a plow is used to work on hard soil.

Choosing a small walk-behind tractor for a summer residence, many turn to the Czech-made model "MF-70". It can be used for mowing grass in the area, removing snow, delivering small loads. Due to its compactness and maneuverability, "MF-70" is used for work in hard-to-reach places. To help gardeners and truck farmers, a new model of the StavMash BM-15 walk-behind tractor has been developed. This technique has already proven itself quite well, with the help of attachments, any work on the garden plot is performed.

The Brado BD-1600 walk-behind tractor is purchased for work on small farms. It is equipped with the most powerful four-stroke gasoline engine. The equipment weighs 120 kg, is capable of plowing depth up to 30 cm. Self-propelled walk-behind tractor SW 360 (SunGarden MF 360 S) is designed for professional use. There is a large selection of equipment for the technique, the replacement of which takes place without the use of tools.

A walk-behind tractor with attachments will facilitate the work of a summer resident with a small land plot and a farmer with a medium-sized field. The amount of work performed directly depends on the engine power and the specifics of the attachments.

Next, see the video review of attachments for the walk-behind tractor.

DIY trencher from a walk-behind tractor

The owner of a small land plot in the course of construction work, the development of the local area has to solve the problems of laying water supply, sewer, cable networks. The trencher will significantly reduce the time for carrying out such work, save you from manual labor with a pickaxe and a shovel, but:

- It is not always possible to rent heavy construction equipment - a private construction site is generally limited in size, part of the work has already been completed, which limits the maneuvers of the tractor and excavator.

- The mini grooves offered on the market are too expensive and not very functional; any owner will hardly consider purchasing them for their own needs an effective investment of money.

Having experience in working with metal, welding and cutting equipment, you can build a homemade trencher based on a walk-behind tractor in a home workshop.

Technical and operational parameters of the project

| Parameter indicator | unit of measurement | The quantity |

| General diagram of the product | mounted on a single-axle walk-behind tractor 8-13 liters. with. with power take-off | |

| Power point | Hydraulic type - pump NSh-10 on the shaft of the walk-behind tractor, motor of the cutter GMSh-32 | |

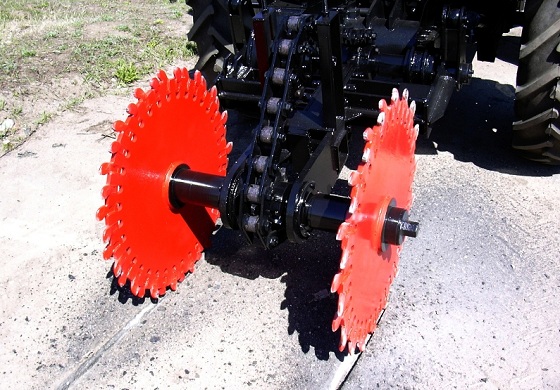

| Cutting discs | Road milling machines | |

| Digging depth | m | up to 0.35 |

| Trench width | m | 0,10 – 0,15 |

| Performance | m / h | up to 25 |

| Weight limit | Kg | 80 |

The structural diagram of the device is based on the solutions adopted by the manufacturers of the ETs-1800 road milling machine.

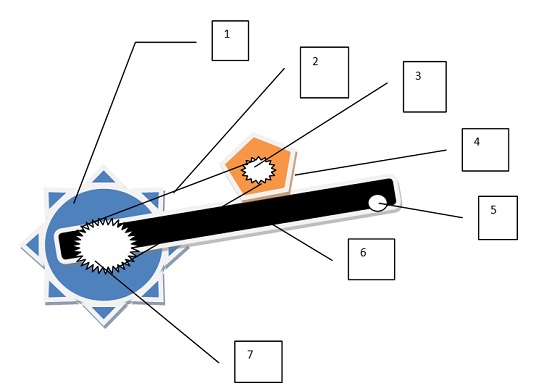

Cold milling machine EC 1800

Hinged executive body: 1 - cutting disc; 2, 3, 7 - chain transmission: 4 - hydraulic motor; 5 - the shaft of the hinged device; 6 - bar discs.

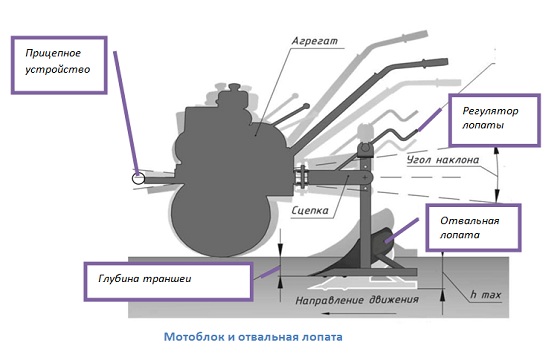

Motoblock and moldboard shovel

Varieties of garden branch crusher

There are several classifications of branch shredders for a walk-behind tractor, differing

- by the type of power plant;

- by motor performance;

- by the number and quality of cutting knives;

- according to the principle of operation of the unit;

- by appointment;

- with or without additional functions.

Let's analyze each option in more detail.

Engine types and their performance

For the full operation of a garden chopper for a walk-behind tractor, motorized devices with the following power plants can be used:

- gasoline type;

- electrical.

Gasoline engines are more efficient and do not require a power source. Electric models are more unpretentious in maintenance and do not require special care, they are quiet, but they will not work without being connected to the mains or to the battery.

The number of cutting edges, their features

Cutting mechanisms are of the following types:

- circular saws fixed on the shaft in the amount of 15-30 pieces;

- a jointer knife with grooves, in an amount from 2 to 6 pieces;

- synchronously rotating shafts with knives.

Knives can be of two types:

- with one blade;

- with two blades.

The second option allows, in case of bluntness of one cutting edge, to turn the knife over and continue working with the second cutting edge. The knives are easy to replace and sharpen.

The simplest attachments for a motor cultivator

The simplest attachments for a walk-behind tractor are plows, hillers, cutters, etc. Most of the designs are single-row. Heavier types of motoblocks are also produced, including multi-row ones.

Attachments allow you to diversify the capabilities of the walk-behind tractor

Attachments allow you to diversify the capabilities of the walk-behind tractor

The equipment produced for the walk-behind tractor allows you to increase the wheelbase and increase the stability of the couplings, which make it possible to install a plow or a knife hiller. The use of a harrow or a small rake, which are mounted on the "Oka", "Luch" or "Neva" walk-behind tractor, allows you to work with cut crops and their residues in the ground. Obligatory devices are lugs installed on motor cultivators. With the help of them, you can perform complex types of work: plowing or milling the soil.

Among the new models used for motoblocks are potato planters, seeders, equipment for snow removal, and harvesting. Mechanization allows crops to be carried out at the right time. For example, attachments for motor cultivators allow you to sow small seeds and crops.

With the help of KS-1 potato planters weighing more than 40 kg, about 100-120 kg of potato crops can be planted in 1–1.5 hours.Seed material is loaded into the hopper, and then it is fed using the chain drive of the planter. Before using attachments for walk-behind tractors, it is required to carry out cultivation and cutting of furrows in the ground in advance.

On the walk-behind tractor, you can install equipment that allows you to dig and collect potatoes. The tubers can be dug out of the ground with a plow. It is best to use more versatile types of attachments and equipment to them, allowing you to harvest partially.

How does a walk-behind tractor with attachments work?

The documentation for the attachment contains recommendations for choosing the operating modes of the used walk-behind tractor. Typically these are tractive effort and operating speed.

The methods of mounting and the necessary adjustments are indicated. For self-made devices, the selection of parameters is carried out during operation.

Consider a few general guidelines:

- the tractive effort of the machine can be increased by installing factory or home-made lugs instead of pneumatic tires. It is allowed to install weighting agents on the walk-behind tractor that are included in the list of additional equipment;

- the working speed of the machine in most agricultural operations is achieved in the lowest gear and should not exceed 4 km / h;

- it is more convenient to operate the unit, not following it on foot, but driving the machine from the seat of the adapter trailer.

TELL YOUR FRIENDS

Additional units

If necessary, other equipment can be attached to the Neva MB-2 walk-behind tractor.

- The rotary brush is a hinged nozzle, thanks to which you can quickly sweep dirt from the road, as well as remove freshly fallen snow from sidewalks and lawns.

- Blade blade - attachment only for heavy implements. It is used for the transportation of bulk materials (crushed stone, sand, gravel) in large volumes.

- An earthen drill is necessary for drilling holes up to 200 cm deep for various supports for plants and landscape compositions.

- Branch shredder - intended for clearing the area after cutting trees and shrubs. By the way, the waste obtained in this way can be used as compost or for mulch.

- The wood splitter is a convenient attachment for the owners of the Russian bathhouse on the site. The device allows you to chop wood for the stove or fireplace quite quickly and without any effort.

- Fodder cutter - used for the preparation of feed for cattle and other farm animals, allows you to achieve grinding of grain crops, root crops, tops, straw and grass.

- Hay tedder - makes hay making work easier. Optimal for a small country house or farm.

- Motor pump - used for efficient pumping of water from tanks, reservoirs and basements.

For the arrangement of trench burials, you can use a special trencher, it is commonly purchased by owners of their own land plots, as well as by utility workers for arranging foundations, conducting underground pipes, cables and power grids, as well as for drainage and arranging foundations.

Among the owners of country houses, such attachments as a sled with runners and a baler are in demand.

These units are widely used due to their high functionality. In addition to the main work, with the help of a digger, you can loosen the soil, cut out pieces of earth when removing the old yard cover on the local area.

See the next video about the Neva walk-behind tractor and its attachments.