Safety recommendations

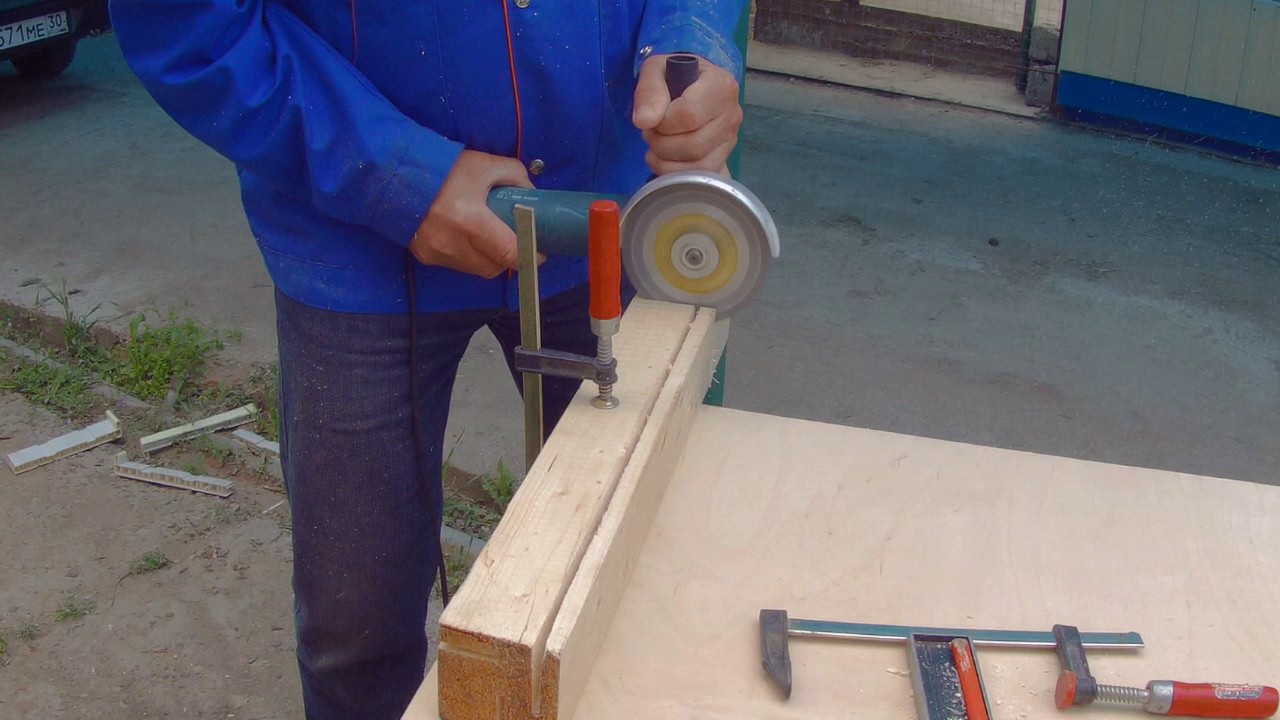

It is necessary to follow the rule: the larger the rasp disc, the lower the speed. In addition, manufacturers protect the user as much as possible by releasing discs with high (sometimes double) strength. But if the disk is used more than necessary, all these measures become meaningless.

Important tips on what to do:

- work with a protective cover;

- protect the face and head;

- check lumber for nails and screws;

- hold the device firmly by hand;

- use an additional handle (many hold the device with one hand);

- do not allow the tool to heat up, avoiding the risk of smoke.

Originally posted 2018-03-28 15:09:01.

Shape and number of segments

The number and shape of the segments differ based on the conditions and the required quality of work. They are also positioned differently, which is reflected on the working properties of the nozzles.

Double segment

Diamond cups with double-row segments eliminate large defects on concrete. They easily cope with large beads, protruding seams. They can reduce the thickness of the screed. The surface after processing is rough, finishing grinding is carried out with another nozzle.

Boomerang

The shape of the segments resembles the weapons of the Australian aborigines, which is why the cups are so named. These are diamonds of the finest fraction, which determines the purpose of the attachments - finishing grinding. Thanks to her, the screed acquires a mirror-like flatness. Light weight, balance allow using "Boomerang" with a "grinder". The rig is stable and soft in operation.

Square

The square cutters of increased thickness are located at a distance from each other. This allows you to remove the protrusions on the concrete, level the surface. The weight of the disc is large, which helps in the work. Powerful segments shear off unnecessary elements. Coarse processing is used to prepare for subsequent operations. After it, a rough surface with good adhesion remains, which requires coating with different compositions.

Turbo and Typhoon

Typhoon is used for roughing and grinding ultra-dense and hard materials. The high wear resistance of the segments increases the service life. "Turbo" is used for high quality grinding. Attachments of this type are used for processing chamfers, edges, bends, engraving work.

The cutters of both attachments are perpendicular to the rotation. The slots between them are of the minimum size, which makes the working surface almost solid.

Classification

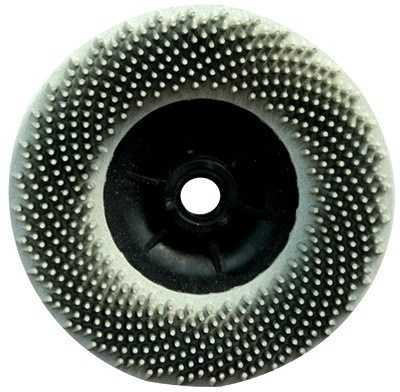

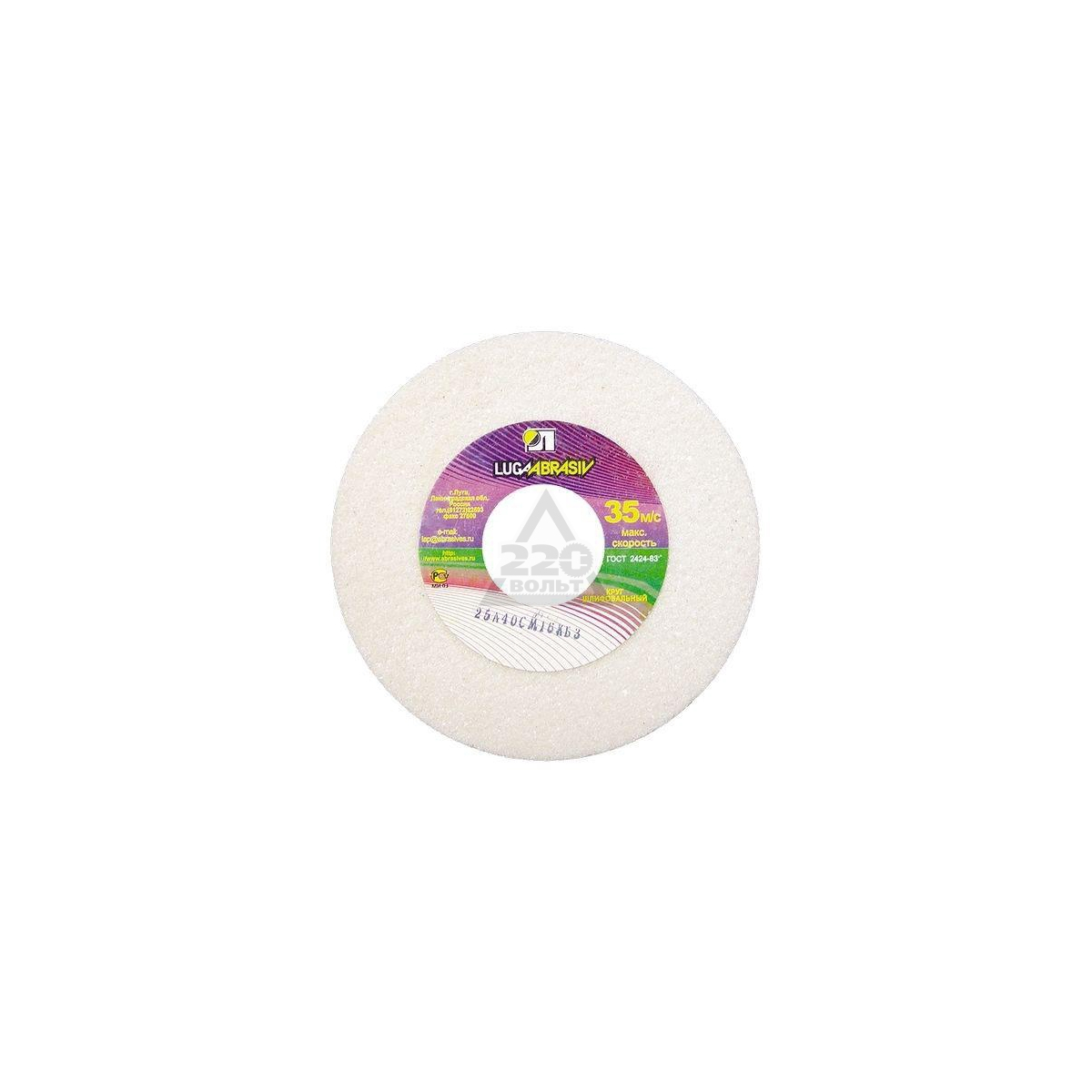

Lobe nozzles are excellent for cleaning iron from paint or rust, grinding seams, welding and removing scoring when metal processing by cutting or stamping. They are also used in the preparation of wood for applying paint or varnish. The principle of operation of different discs is the same - removal of the top cover of the material by means of an abrasive applied to the base. Manufacturers produce a wide variety of abrasive discs exclusively for surface polishing and face grinding, and modifications are also available to clean internal, hidden voids. The petal disc has excellent plasticity.

Scope of application

The high reliability and durability of the diamond cup set it apart from other tools for processing hard materials. With the help of a nozzle, concrete, brickwork, stone slab, porcelain stoneware, paving slabs are peeled and polished. Diamond discs are widely used for polishing natural stone - marble or granite.Operations performed with discs include rough, profiled and finishing grinding operations. Diamond cups are used for the following purposes:

- removal of screed sagging;

- roughing irregularities;

- alignment of seams;

- grinding of joints;

- cleaning surfaces;

- removal of the old or protruding layer;

- finishing polishing.

When installing nozzles on a grinder, a dust extractor is usually used or the surface to be treated is moistened with water (wet grinding). This will help reduce dust and make cleaning easier.

are widely used in dismantling works. They effectively remove layers of old glue, hard-to-remove coatings (epoxy, plaster, gypsum) and have a long service life. Grinding with a diamond cup saves time: it not only removes unnecessary layers, but also immediately smoothes the surface.