Woodcarver's arsenal of tools

The main tool that allows you to perform wood cutting, as mentioned above, is a burr. The implementation of such a procedure, during which a layer of the processed material of various depths is removed, is ensured by rotating the cutter, as well as its translational movement along the required trajectory. Accordingly, equipment is also required with which the tool used will be rotated. Such equipment, indispensable for an engraver and any woodcarver, is a drill, often called a dremel.

Dremel launches electric engravers for the domestic and professional grade

The word "dremel" comes from the name of the German company Dremel, which produces a wide range of electrical equipment, in which drills and specialized engravers take an important place. The drill kit from Dremel and others already includes everything you need to set up the tool and get started.

It is also possible to cut wood using cutters using a conventional electric drill or screwdriver, if you equip them with a flexible shaft and a special nozzle on it, into which the burr is installed. Such a simple device is also suitable for an engraver working with products made of metal and other materials.

Flexible shaft for drill

The quality and attractiveness of the work performed when cutting wood directly depends on the characteristics of the equipment used. Even the experience and knowledge of the person performing such work cannot positively affect the characteristics of the finished product in the absence of the appropriate equipment and wood burrs.

Varieties of attachments for a grinder for wood processing

Rough wood stripping

Disc planer

This attachment almost completely replaces this hand tool.

An irreplaceable thing if, for example, it is required to rough out a log - when erecting a log house, preparing fence supports, and so on.

Application features:

- In this case, the protective cover can be removed. Such a packing is one-piece and does not break. But protection from flying chips (glasses, tight clothing, gloves) is required.

- It is allowed to work only with a "grinder" in which a second handle is provided (or installed). The angle grinder must be held when roughing the wood with two hands.

Rough disc

The main purpose of such nozzles is to remove bark from wood, hew the workpiece. If the "grinder" is in skillful hands, then with such a device it is possible to make a sample of the material. For example, if you need to cut a bowl. If a log house is being erected, then an angle grinder with such a nozzle perfectly replaces a carpenter's ax.

In some cases, sawing can be done with a roughing disc. True, the cut will be wide, and there will be a lot of waste (shavings, sawdust).

Milling

Disks

These attachments are available in various designs. The main difference between the devices is in the size of the abrasive grains.

In terms of their specific application, they are not much different from rasps. The only difference is the speed of the technological operation. With certain skills, it is advisable to use such attachments for finishing wood.

Cutters

They are, and especially for wood. The assortment is significant, since nozzles of this type differ in configuration, arrangement and size of teeth.

Purpose of cutters:

- Sampling of grooves.

- Pre-alignment of edges.

- Bowl carving.

- Sawing (for small sections of wood).

Application specifics:

- When processing wood with such attachments, it is forbidden to dismantle the protective cover.

- Each product has instructions. It clearly indicates what types of work this nozzle is intended for, the recommended speed of the "grinder" and so on.

Wood sanding

If we decipher the abbreviation LBM, then it is clear that finishing is the main purpose of the "grinder".

Cord brushes

They are used mainly for primary (coarse) sanding of wood, when it is required to smooth out the unevenness of the sample.

End disks

The names speak for themselves. The end parts of wooden blanks (cuts) are processed with such nozzles. Especially effective when you have to deal with miter cuts.

Petal nozzles

The most used grinders for grinders.

Such nozzles are used sequentially, so you will need several of them to process wood. Grinding begins with a disc with a "coarse" abrasive, and gradually the grain size must be reduced. Consequently, the devices in the process of working on the "grinder" are periodically changed.

Grinding wheels

The most versatile attachment to the "grinder". It alone is enough for varying degrees of grinding. The nozzle itself is a metal base on which circles with one or another grain size are attached. They can be easily changed either as they wear out, or in case of moving to another area of work. Therefore, only circles are consumable. The nozzle itself is used indefinitely.

Application specifics:

- Sanding wood.

- Parquet scraping.

- Processing of edges and ends.

- Cleaning wood before painting.

Wood polishing

For these purposes, brushes, discs and circles are used. Their "working elements" can be made of sponge, felt, fine-grained "sandpaper" and a number of other materials.

The article provides examples of only the basic types of grinder attachments. There are quite a lot of products of this class, so it is not difficult to choose the best option for processing any wood. The author hopes that the information provided will help the reader with this.

On a note!

Wood processing means its cutting (sawing). Sometimes, in the manufacture of piece parts, you have to deal with their adjustment at the installation site even before starting to grind the sample. Some "craftsmen" (and there are a lot of them among friends and on the Internet) are advised to use circular saw blades for such operations. It is strictly prohibited! Here are just the main reasons why this should not be done.

- "Bulgarian" is a high-speed machine. And although the metal from which the cutting discs are made is durable, it does not withstand for a long time in this mode. More precisely, cutting edges (teeth), which are fixed by soldering. During intensive work, they fall off and fly to the sides, and with great speed. The consequences are easy to predict.

- Not all discs in size (first of all, the outer diameter) are suitable for installation on angle grinders. This means that you will have to dismantle the protective casing. The same thing - you can forget about the safety of the employee.

- The structure of the wood (even hard wood) is rather loose. Therefore, there is a high probability that the saw blade may jam due to constant vibration. How the "Bulgarian" will behave in such a situation, given its power and speed, no one will undertake to predict. But the fact that she will easily get out of her hands is unambiguous.

- Constant changes in the mode (for the same reason - the viscosity of lumber) lead to systematic overheating of the angle grinder engine. With this use, the "grinder" will not last long.

That is why wood processing with its help is carried out only superficially - rough cleaning, grinding, brushing. And for cutting, you should use sawing tools and mechanisms (hacksaw, circular saw, electric / jigsaw, and so on).

Choosing wood cutters for a drill

When choosing nozzles, their parameters are important. Nozzles are not only of different types, but also differ in the types of materials that are planned to be processed with them. A number of the main criteria for choosing milling nozzles include:

- Product size, which depends on the technological task at hand

- The shape of the cutting knives on which the final result depends

- Sharpening angle

- Production material that affects not only the capabilities of the nozzles, but also their service life

- Purpose. The attachments can be used for processing not only wood materials, but also for metals, plastics and various types of natural stone.

Wood processing with a milling cutter on a drill

When choosing a product, you need to pay attention to the manufacturer, but if you plan to use the considered attachments on drills, then it is advisable to buy cutters from inexpensive products

Diamond burs for engraving work

The most popular types of working attachments used to complete engraving machines are diamond burs for the engraver. The basis of such a tool is made of tool steel, and diamond powder is applied only to their working part. The mechanical characteristics of diamond powder make it possible to successfully use the attachment for processing such hard materials as steel, ceramics, glass, artificial and natural stones.

Expensive dental diamond burs have a long service life

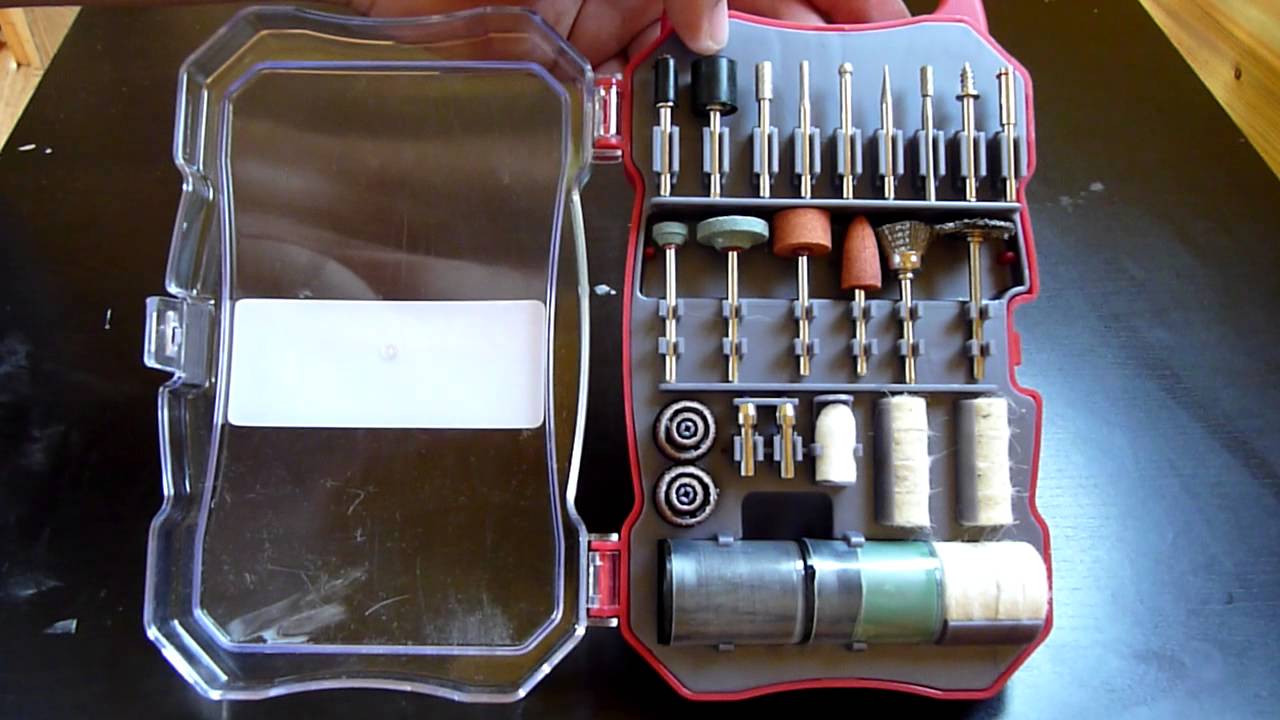

Diamond burs (or cutters) are mainly used for finishing shaped holes. As a rule, diamond consumables for an engraver are sold in whole sets of 10–20 tools of various shapes and sizes. When working with them, you should strictly follow the rules of their operation so as not to damage the diamond dusting. The standard shank diameter of diamond engraving bits is 3 mm.

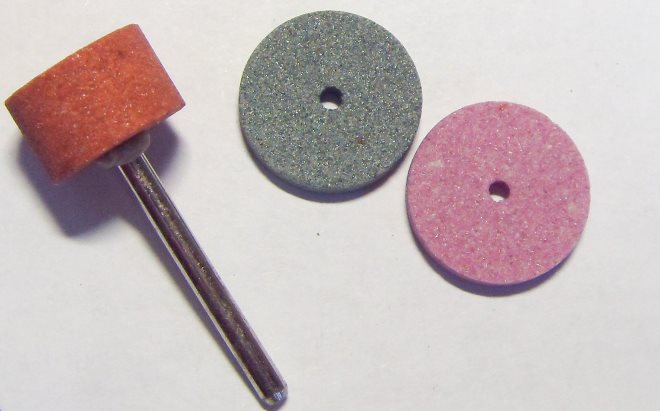

Abrasive tools

The most budgetary option for use in a set with a drill or engraver are nozzles, the working part of which is made of rubber and abrasive material. Their shank diameter is 2.3 mm, and they are mainly used for metalwork, including stainless steel. Abrasive tools are usually sold in sets of 6 and come in a variety of blade configurations.

Abrasive cutters (aluminum oxide) for processing steel and non-ferrous metals

Individual manufacturers (in particular, the company "Fit") produce abrasive engraving tips in various colors, which allows the user to easily determine the category of the tool. So, abrasive cutters are red, intended for work for metal, are made of aluminum oxide, and green ones, made of silicon carbide, are used for processing stone, glass and ceramics. For the convenience of performing various technological operations, diamond cutters are made with a different shape of the working part, but their shanks always have the same diameter.

With the help of abrasive nozzles for the engraver, such operations as boring holes, surface grinding, etc. are performed. These nozzles are optimal for use at home, for a professional their capabilities will not be enough.

Nozzles can be in the form of removable working heads, fixed on the corresponding shank

Classification of wood processing nozzles

Approximate prices, in relation to the Moscow region, in Russian rubles

By execution

Depending on the configuration, the attachments are used not only for surface treatment of wood.With their help, you can grind (polish) holes (as a replacement for a grinder). It is not difficult to make devices cylindrical (thin) or conical.

Plate nozzles

Available in several modifications. The difference is in the form of abrasive material. If wood sanding is required, then this is rubber (the preferred option) or plastic. For polishing, it is advisable to purchase attachments, on the working part of which fine-grained sandpaper is fixed. They can achieve better (finer) wood processing.

Recommendation - efficient processing of wood with a plate-type drill attachment is complicated by the fact that it is difficult to keep the drill in a strictly vertical position. To achieve a good result, it is advisable to fix the tool, and move the workpiece relative to the working part. The machine for attaching the drill is easy to assemble by yourself.

Price - from 162

On sale there are nozzles in which the angle of the abrasive attachment pin is provided. But they are quite expensive, and not every store can buy them. Therefore, a machine with the ability to change the position of the drill is a more acceptable solution.

Drum attachments

Mainly used for machining the end pieces of wood blanks and holes. They have a cylindrical shape and differ in the method of attaching the emery tape - using a bolt or special inflatable blocks. Some types of baits of this type are also used in everyday life for plucking (at low speed) birds when it comes to a large amount of work.

Price - from 178

Cup attachments

The assortment is significant. Differences in size and abrasive material. It can be both metal "villi" (hard wire), and dense fabric, leather, felt and even foam rubber. The choice of fixture is determined by the desired degree of wood processing. If it is required to achieve a sharper selection of the texture of the material, then the sampling of wood pulp is made with just such nozzles.

Price - from 189

A variety of devices in this group are disc nozzles. What is the difference is clear from the picture (the villi are located diametrically).

Price - from 398

Fan attachments can also be attributed to this type of attachments. They are also called petal.

The main purpose is wood polishing at the final stage of processing.

Price - from 65

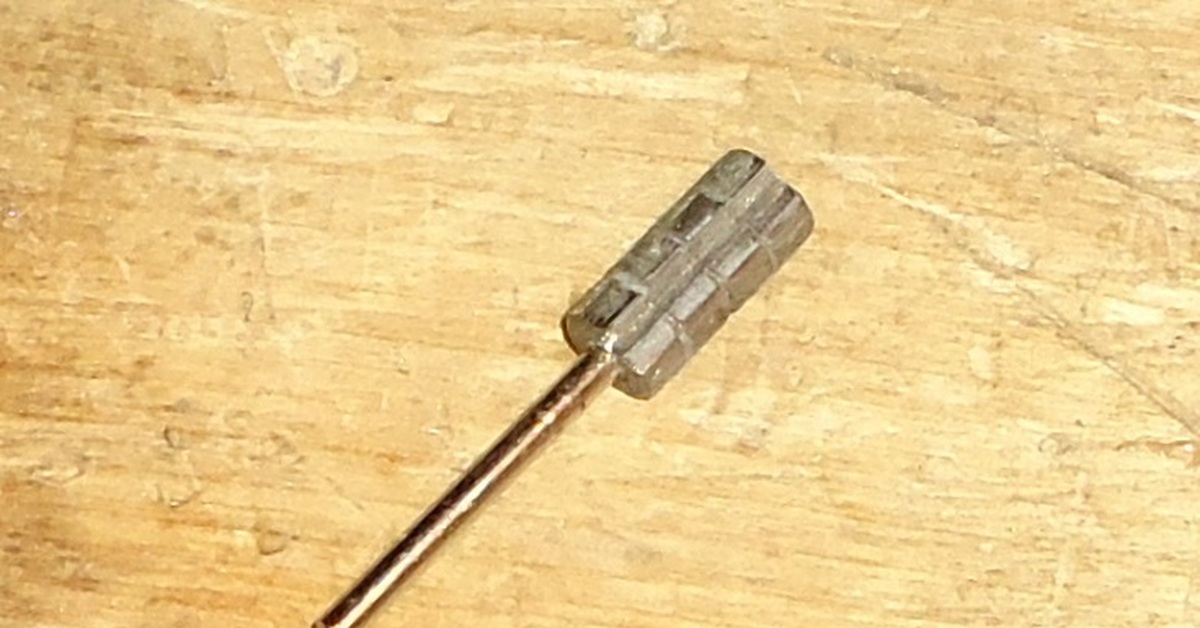

Homemade attachments for engraving machines and drills

For simple engraving work in a home workshop, a cutter, a cutting disc, grinding and polishing cones can be made with your own hands. As a simple cutter for equipping an engraver or a drill, you can use a grooved wheel from a conventional lighter or a dowel, on the head of which working teeth are cut. A working attachment for grinding or polishing is also quite simple: for this you can use a wooden drum with a shank, on the side surface of which sandpaper is glued.

Many homemade engraving attachments (if they are used to do not too difficult work) perform well, while the cost of their manufacture is minimal.

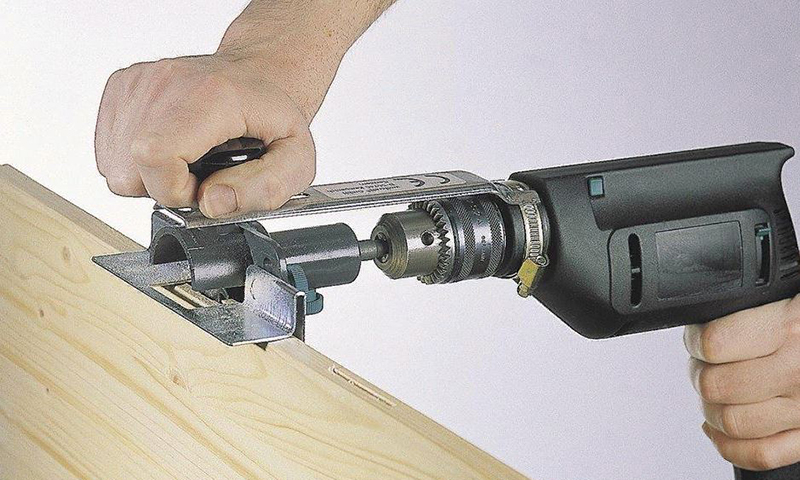

For curved cutting

There is an interesting device that allows you to turn a drill into a jigsaw. The device is fixed in the chuck and makes it possible to cut wood-based sheet material, plastic and even thin sheet metal. The cutting tool is a movable file.

This device is a useful thing in the household, but the attachment has a rather high price. If you often need to make curved cuts, you should consider buying an inexpensive jigsaw.

There are other similar devices. Drill bits for drilling round holes in wood are very popular.They help overcome the drill size limitation found on most models and drill any hole diameter.

Drill bits - accessories

We have already written how an electric drill can be turned into a lathe and drilling machine (insert links), and also adapted it to work as a circular saw.

We present to you several tools to further expand its capabilities.

1. Drilling and milling attachment for an electric drill.

This device allows you to obtain high-precision holes of large diameters in various, incl. round, workpieces, perform some milling work, which is ensured by high accuracy of mutual positioning of the cutting tool and workpiece.

2. Universal sharpener.

This device, like no other, justifies its considerable cost by its high versatility. With its use, sharpening all the cutting tools available in your household: from knives and axes to drills and cutting edges of any tool, will turn into a simple undertaking.

3. Holder with a clamp.

Such a universal holder allows you to fix your electric drill in any convenient place and use it with various tools and as a sharpening machine, and grinding and polishing, and milling, and even a mini-turner. The main thing is that you have both hands free.