Considerations when choosing a circular saw guide

The use of a guide bar for a circular saw requires taking into account the following features:

- parameters of processed wood blanks;

- saw technical capabilities;

- the frequency of using this additional tool.

When choosing a guide rail design, you should evaluate the frequency of use of this unit, that is, how often you are going to use it.

One of the important features when choosing a guide is to evaluate the technical characteristics of the saw used.

In this case, special attention should be paid to the following parameters:

- permissible cutting length;

- power of the tool used;

- the width of the resulting groove;

- features of the saws used (disc diameter, tooth size, and so on);

- permitted direction of sawing (longitudinal, transverse, arbitrary);

- the ability to cut dense products (hard wood, laminate, laminated veneer lumber);

- the procedure for using the existing system for ensuring safe operation for a specific type of circular saw.

Making a guide bar for a circular saw will add a set of accessories. The device will allow for high-quality processing of wooden products. The combined use of a circular saw and a guide bar results in a smooth, high-quality edge ready for further processing.

Circular saw guide making process

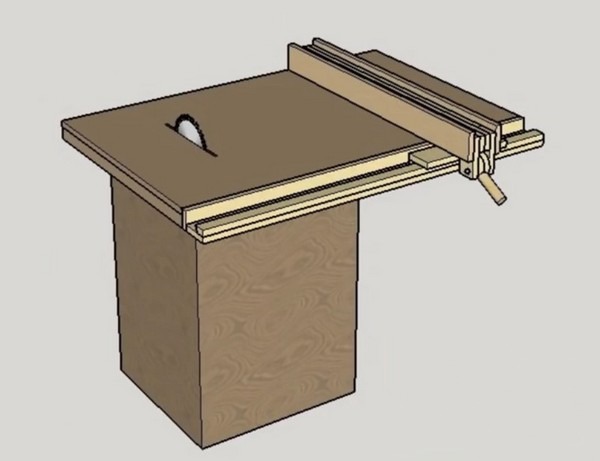

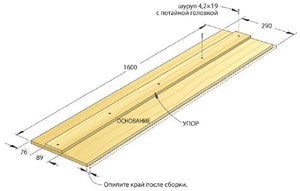

As for the size of the proposed design of the guide, it is selected individually for the depth of cut of the existing saw, as well as those workpieces that will be processed in the future.

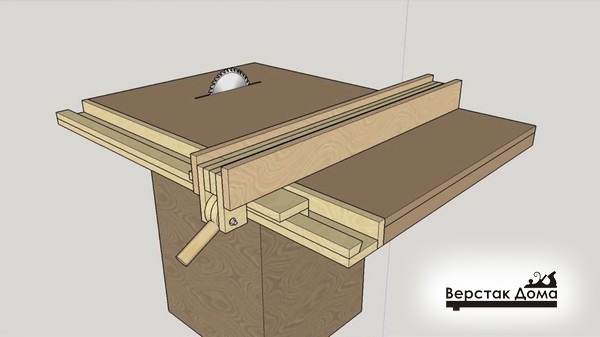

A plywood sheet is used for the manufacture of countertops. Its length can be anything. The width can be made 35 cm, which will be convenient for the vast majority of circulars. Having stepped back 10 cm from the long edge of the plywood, you need to apply the markings to install the profile with the T-slot. It is desirable that the profile is shorter than the actual length of the table top, which will make it easier to store the machine in the future. The profile must be seated in the groove. It is most convenient to choose it with a manual router by setting a parallel stop. When working with plywood, it is better to go deeper gradually, making a sample in several passes.

To remove defects on the surface of the countertop, you need to grind the plywood.

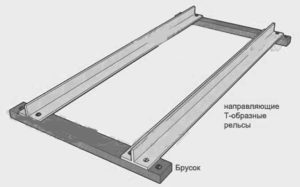

The T-slot profile is pressed flush into the resulting slot. It is fixed with self-tapping screws along the entire length.

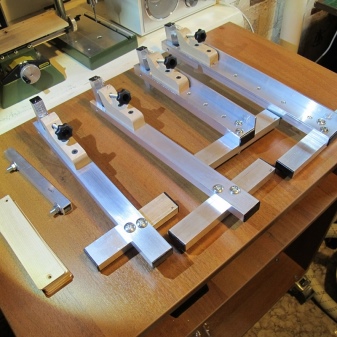

For a direct guide for the power tool itself, you can find a corner, but often it has the same sides, which is not very convenient. It is much better to buy a channel and cut it lengthwise, getting 2 excellent corners with a low side.

Now you need to make stops for the guide. For this one should take 2 boards with a section of 30 mm, the length corresponding to the width of the plywood tabletop. In this case, their length is 35 cm. As for the width of the boards, it should be equal to the actual cutting depth of the circular plus 8 mm. Aligning the boards with each other and placing them on the edge, you need to mark 7 cm from the edge. The length corresponding to the width of the saw sole is measured from this line. The second mark should be set slightly wider, taking into account the wall thickness of the corner and a gap of 1 mm.

Having clamped the boards in a vice, you need to saw down everything along the drawn lines with a hacksaw to a depth of 1 cm, and then select a groove.

Now you need to attach the boards to the countertop.To do this, they are first glued, after which they reach out with screws.

Note that the second board is fixed at the end of the T-slot profile, not the plywood. Before gluing, you need to envy the T-bolt profile. On the racks obtained from the boards, you need to fix the corners from the channel directly into the groove, thereby adding rigidity

To make the structure collapsible, it is better not to screw the screws into the wood, but to install the furniture dowel and then use the screw

On the racks obtained from the boards, you need to fix the corners from the channel directly into the groove, thereby adding rigidity. To make the structure collapsible, it is better not to screw the screws into the wood, but to install the furniture dowel and then use the screw.

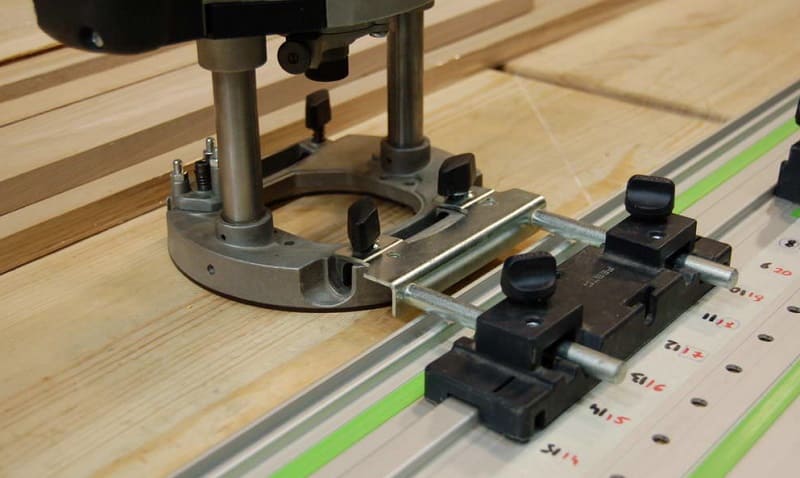

You can also move the guide rail so that it can be used for the router. You will need to make a couple more holes and install furniture dowels.

Let's paint the resulting fixture.

For the convenience of further storage of the machine in a suspended state, a through hole can be cut on the plywood protruding beyond the working part of the tabletop.

Now you need to put the circular on the runners. It should be turned on and driven from one edge of the tabletop to the other. The slightly protruding disc will make itself a groove of about 2 mm, due to the fact that the grooves of the posts were deepened not by 8 mm, but by 1 cm.

So that when the saw moves, it does not skew and does not slow down, you can attach a furniture corner to its sole by slightly grinding it. This may not be necessary, a lot depends on the type of sole.

Using an already almost ready-made machine, you can make guides for fixing workpieces at an angle. First of all, stops at 45 and 30 degrees are useful. To do this, taking 2 slats, you need to drill into them hole for sliding T-bolt.

Having fastened one workpiece at an angle of 45 degrees and pressing the manual adjustment nut, you need to cut off the protruding end with a saw. The resulting segment should be glued to the bottom of the back of the plank, creating an additional stop. It will rest against the side end of the table top, so in the future it will be possible to fix the guide without a protractor. In the same way, you can prepare special guides for other corners.

On the bolt protruding from the T-shaped guide profile, you can fix the presser foot, guides and other joinery, expanding the capabilities of the resulting machine. The production cost of such equipment is low, while its functionality is sufficient for processing medium-sized workpieces or precise fast trimming of sawn timber.

Clear saw operation:

Working with a router:

Other types

If the plywood rail for some reason does not meet your requirements, you can make the guide more complex. Below are a few more examples of guides for manual circulars that anyone can make with their own hands.

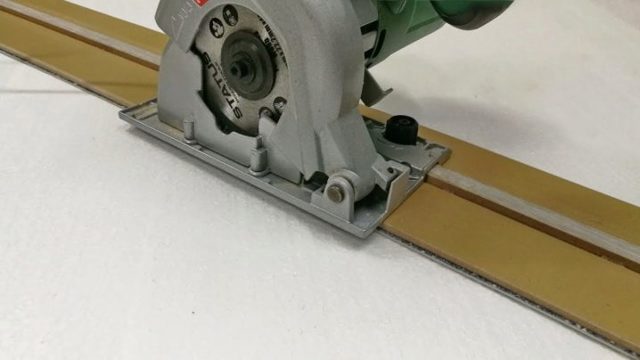

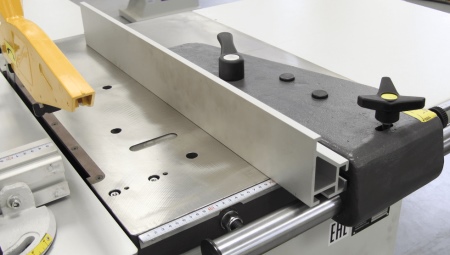

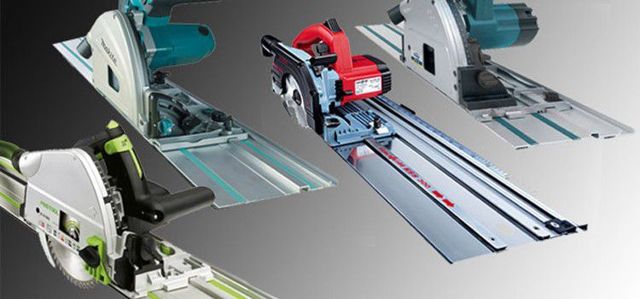

Aluminum profile rail

Such a bus differs from a simple plywood bus in that a U-shaped aluminum profile is installed in the guide gap. Its advantage is that the rigidity of aluminum slightly increases the cutting accuracy.

For better glide of the saw on the rail, instead of a thick plywood, you can attach a pair of fluoroplastic or other material with a low friction coefficient of a suitable height to the guide groove of the sole as stoppers.

Building rule ruler

There are long aluminum rules that are used by finishers to line the walls. For making a guide ruler with your own hands, rules are suitable, the design of which provides for a trough for free movement of the handles.

The main advantage of such a ruler is the absence of elements protruding above the surface of the workbench. To do this, you need to take two collapsible clamps and slightly modernize them.

The handles are removed from the rule, and their upper parts are removed from the clamps, which are replaced with polypropylene or fluoroplastic inserts. The profile of these inserts must be T-shaped so that they can be installed with the wide part in the groove of the rule and held there.

The result is a ruler that attaches to the workbench only with the bottom. This will allow you to move the saw freely in the work area without getting caught.

However, such a tool cannot be called a full-fledged bus. This is exactly the ruler that needs to be adjusted before each cut.

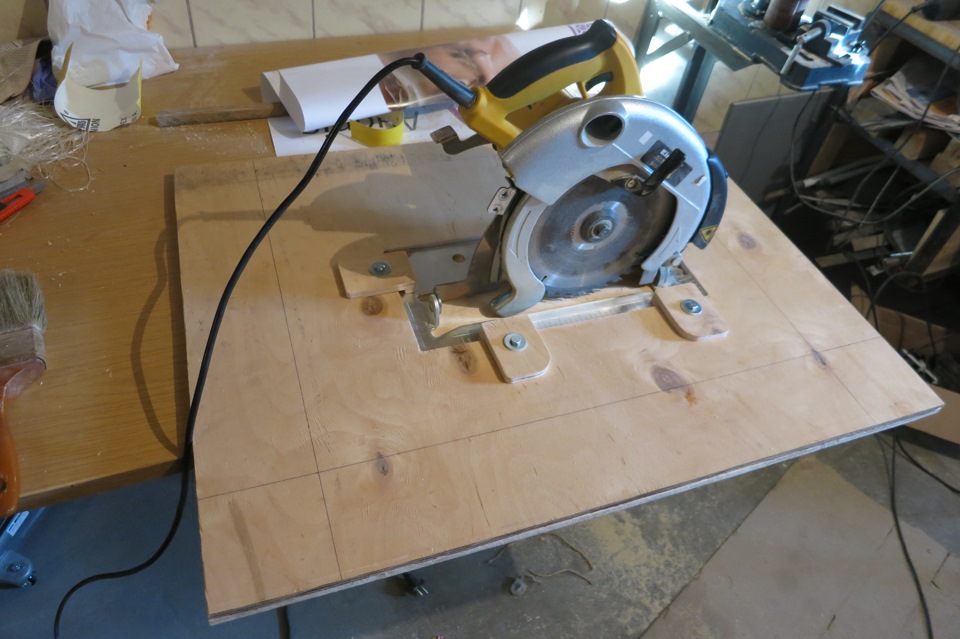

Rail miter box

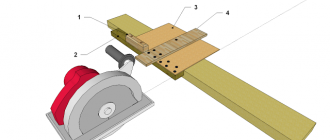

This device is more often used for cross-cutting (trimming) material.

This device is more often used for cross-cutting (trimming) material.

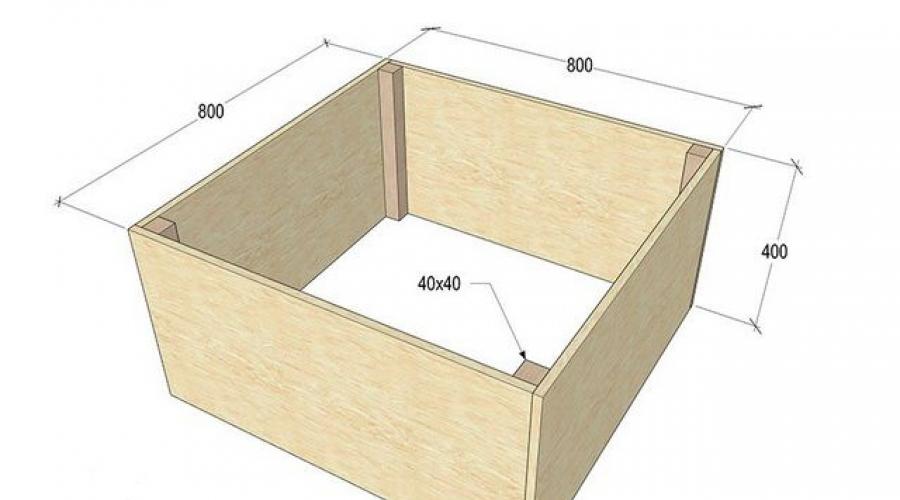

It usually consists of from two parallel metal corners, the ends of which are rigidly fixed to a plywood or metal base.

The saw platform moves freely along the corners, like on rails.

The corners are fastened with bolts or studs, which are also used to adjust the height of the "rails" relative to the base. The height should be such that the cut material passes freely under the corners.

To make the movement of the saw smoother, the corners on the inside can be glued with a material with a high slip coefficient. For an even smoother ride, you can mount the saw sole on a platform with metal wheels.

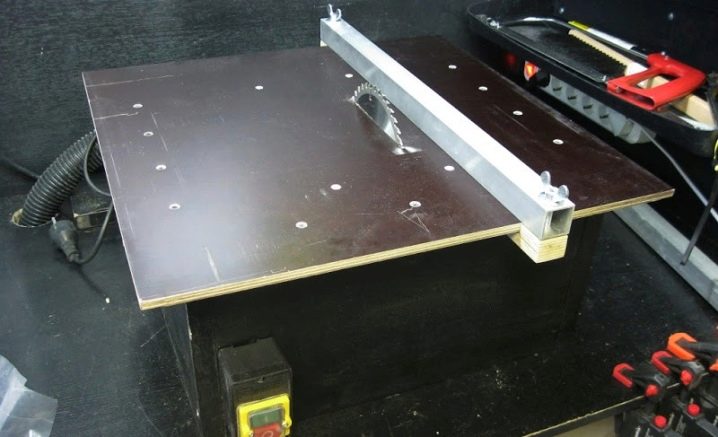

Outrigger carriage on bearings

The outrigger circular saw is more like a stationary panel saw. This design is highly stable and therefore provides high cutting accuracy.

The outrigger carriage is made of a metal I-beam, which is firmly attached to the workbench with its bottom plane. The carriage itself moves along the upper plane - a platform, the lower edges of which are bent inside the I-beam and are equipped with bearings that allow it to slide freely. The same bearings, tightly pressed against the I-beam axis, exclude the side play of the carriage.

Parallel to the carriage, the saw sole is attached to the outrigger guide. The guide can be made from two parallel corners or pipes - thus, by moving the saw blade, you can adjust the size of the cut of the material.

This design is good in that the saw support platform is adjacent to the workpiece, which means that the cutting depth does not decrease.

Additional functions

Riving knife

The riving knife prevents the disc from biting during operation, it prevents the material from squeezing the disc after cutting.

For safe and efficient operation, there are models that support connecting the vacuum cleaner to the saw blade structure. The main purpose is to clean the workplace. The sawdust is blown away, thereby clearing the cutting site, as well as the air in the room from wood dust and shavings.

Often, manufacturers do not complete their models with adapters for vacuum cleaners, so in this case you will have to additionally buy an adapter.

Dust collector

The presence of a dust collector allows you to "accumulate" the formed sawdust in a special container, thus maintaining cleanliness in a closed room.

Laser pointer

A special laser pointer is usually built into the saw blade body. Makes it easier to use and improves cutting accuracy.

Backlight

The presence of backlight makes it possible to use the saw in dimly lit rooms.

The presence of rubber pads on the handle reduces the strain on the hands and eliminates the risk of the device slipping out.

For your safety, manufacturers come up with various additional functions. For example, start blocking is most common. To start the saw, you must press two buttons at the same time.

Varieties

The range of circular tools produced by Interskol is impressive.It presents many models of power tools, including DP 235 m 2000m, DP 165 1200, DP 210 1900, DP 190 1600, DP 225. Moreover, to choose the optimal solution, it is necessary to rely solely on the individual needs of a particular buyer.

The range of circular tools produced by Interskol is impressive.It presents many models of power tools, including DP 235 m 2000m, DP 165 1200, DP 210 1900, DP 190 1600, DP 225. Moreover, to choose the optimal solution, it is necessary to rely solely on the individual needs of a particular buyer.

All the variety of sawing tools offered on the market today can be presented in the form of two large groups:

- Manual. From the name it is clear that their work is done manually. Among the advantages of these devices, it should be noted high mobility, ease of use due to well-thought-out ergonomics and design.

- Stationary. The main differences between these models are associated with their design: these models have a guide rail, as well as measuring rulers, marked on the desktop. The main advantage of such devices is that they can be used to provide a higher accuracy of cutting materials.

There is also another classification of Interskol saws, where the main sign of separation is their scope. Depending on the purpose of use, two groups of power tools can be distinguished:

- Amateur. With a sufficiently low drive power, these models attract consumers with a reliable mechanism. The design of these saws is represented by a functional guide rail, an anchor, an elaborate work table and other elements that are typical for amateur saws. All this makes these saws a reliable tool for active use in the domestic environment. Although they have less power than models belonging to the second group, amateur saws from Interskol are very durable and rarely fail.

- Professional. The distinguishing features of these devices include the presence of a more powerful engine, an improved guide rail, an anchor, and a wide working table. Saws belonging to this group of power tools are focused mainly on industrial use. For household needs, circular machines would be a more suitable option.