How to choose?

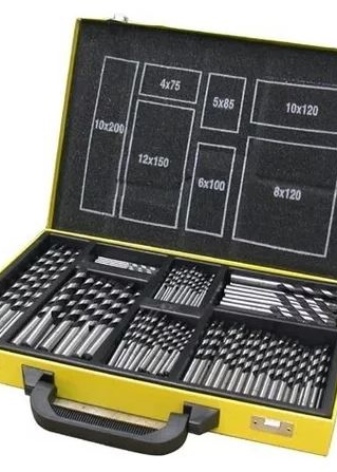

The choice of a Forstner cutter depends on the tasks to be performed with its help. In carpentry or in manufacturing, this is a frequently used tool, where different drill diameters are used, so for such intensive use it is advisable to have a complete set of the required dimensions in stock. As for domestic use, the drill is purchased for a specific task, then it is rarely used. In this case, there is no need to buy a set of expensive tools, since the costs may not be recouped.

To purchase a quality Forstner drill, you need to pay attention to several main features:

- the original model of the drill has small round holes in the center of the working part;

- the cutting blades of the cutter interrupt the annular rim only at two points opposite to each other;

- the blades of the original drill can only be sharpened by hand.

The original models of Forstner's drill are made only by the only American company in the world, Connecticut Valley Manufacturing. Here, each part of the tool structure is milled separately from a steel billet, and the alloy contains an admixture of carbon, while other manufacturers make each part of the drill by casting with the subsequent assembly of finished parts. A real Forstner cutter has a thicker cutting part than its counterparts, so such a tool is less susceptible to overheating and rotates faster, making it possible to work at high speeds of the power tool, while maintaining the quality of hole processing at the highest level.

In the process of choosing a Forstner cutter, it is necessary to pay attention to the appearance of the condition of the cutting edges. It often happens that manufacturers pack their products in opaque packaging

In such cases, it is impossible to consider and evaluate the details of the tool, so you run the risk of purchasing a low-quality product, which, when opening the package, may appear with burrs, chips or deformation.

Principle of operation

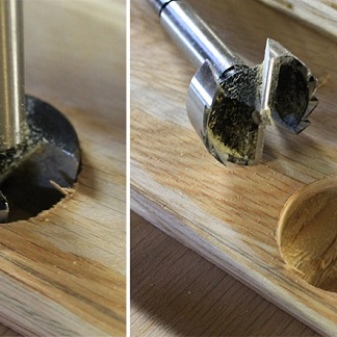

Although today the forstner drill for wood is strikingly different from the invention of Benjamin Forstner 145 years ago, its principle of operation has remained unchanged. The wood is still cut with the external cutting surface, and with the help of the cutters inside this rim, the wood is removed and "thrown" out.

All original Forstner drills have a center point, although the tip is the cutting edge that surrounds the point. For the correct use of the drill, you need to make a marking with a marker, touch the marking point with the central edge and press it into the material until the circular cutting plane touches the surface of the product (and it should lie flat on the surface). After that, you need to start drilling at low speeds (800 - 1800 rpm).

It is worth mentioning the general principles of using a Forstner drill:

- The larger the hole you need to make, the slower you need to cut it. Otherwise, the cutting edges will simply overheat, and may also disrupt the drill.

- In order not to accidentally make the hole deeper than necessary, take a special forstner drill with a limiter for work. Such a stop itself will stop drilling in time.

- In case you need to make a hole in a thin sheet of wood, where there is a risk of accidentally piercing it through and through, you can use two Forstner drills: one regular and the second with a ground off central point. It's simple - we start drilling with an ordinary forstner drill, and then we use a tool with a sharpened point, with which we finish the work.

How to sharpen?

In the process of work, any, even the highest quality, drill becomes dull. Original products can be sharpened by hand, and non-original counterparts can be sharpened on a grinder. When sharpening a Forstner cutter, specialists are guided by certain rules:

- the cutting part of the annular rim is not manually sharpened - this is done only on sharpening equipment;

- it is necessary to grind the cutters minimally so as not to change the geometry and proportions of their working surfaces;

- internal incisors are sharpened with a file or a grindstone.

In the next video, you will find a review and testing of Forstner's Protool ZOBO drills.

As a conclusion

Despite the simplicity of their design, drills belonging to the category of pen drills allow you to create holes of various depths and diameters in the tree. A feather drill is also successfully used for metal work. Naturally, for efficient processing of productsmanufactured from different materials, it is necessary to select the right tool.

The advantages of using drills of this type also lie in the fact that even a person who does not have high qualifications is able to qualitatively sharpen and restore their cutting part, which cannot be said about drills of any other category.

Varieties

For high-quality drilling in wood, you need to choose the right drill. Currently, the user can choose from several types of products.

Crowned. The main purpose of this type of drill is the process of cutting through holes that can provide an optimal seating area for the socket. Attachments that have a diameter of up to 65 millimeters are usually equipped with a shank with a diameter of 19 mm. For large specimens, the fasteners have a diameter of 32 mm. The number of toothed segments of the ring is influenced by the size of the bit for the tool, usually it is 2-16 teeth. The drill has found its use in the formation of clean cuts, which are characterized by the smoothness of the inner part of the grooves. At the end of the workflow, the user does not have to make improvements or remove burrs.

Assortment overview

Currently, the company "Enkor" produces a variety of models of construction drills.

Step models

Such products represent a part with a small cone-shaped tip. Moreover, its surface consists of several metal steps of different diameters, but the same thickness (as a rule, there are only 13 such elements on one drill). The end of the nozzle is pointed. This drill can be used to create depressions of different diameters without repositioning the cutting element. Each step of the tool has a special marking.

Drills for metal

The range of products most often includes drills with a spiral design of the working part. They are manufactured from high-speed, high-performance steel base. Drills for metal from this manufacturer, as a rule, have 2 spiral grooves, designed for timely self-removal of chips, and 2 cutting edges. Most metal models come with a thin cylinder shank.

Forstner drill

Such drills have the appearance of a metal structure, in the central part of which there is a point. A sharpened blade is placed perpendicular to it. It is a zigzag cutter. The Forstner drill is often used for woodworking. In the process of work, the product first strongly cuts into the wooden surface, outlining the direction, then there are circular grooves - they do not allow the nozzle to change its position. Only then does the cutter begin to make a depression in the surface. Their shank type is usually cylindrical.

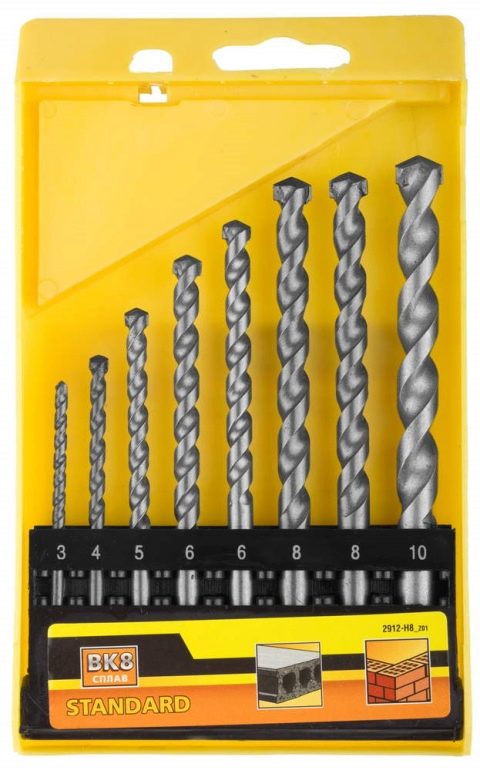

On concrete

Thin drills designed for for processing concrete structures, often have a small diameter. Their working area is made in a spiral shape. These varieties are best used for drills that have an impact function. Conventional tools will not be able to work hard concrete. Unlike standard models for wood or metal, these parts have small solders made of carbide materials, they are located on the end stop. These additional elements are needed in order to punch concrete surfaces, while at the same time significantly increasing the life of the cutting part.

Drills with countersink

Such models are often sold in whole sets. They are used when processing wooden objects. Countersinks are in the form of small attachments, consisting of many small thin blades. Such an element allows, if necessary, to create conical and cylindrical recesses. Countersink drills slightly increase the diameter of the holes already made in the material. At the same time, they significantly improve the surface quality without forming even small irregularities and scratches.

Feathers

These samples are thin milling cutters equipped with two cutting edges and a centering tip. Pen products for drilling, as a rule, are produced with a hex shank, which provides the most reliable fixation in the drill chuck. In the process of work, the chips will need to be removed periodically on their own. These drills are capable of making indentations up to 110 millimeters long. The diameter of the holes can be from 6 to 40 millimeters. These varieties have a significant drawback: they are prone to jamming at high speeds, so work with such a tool should be carried out as carefully as possible and constantly checked.