The principle of the unit

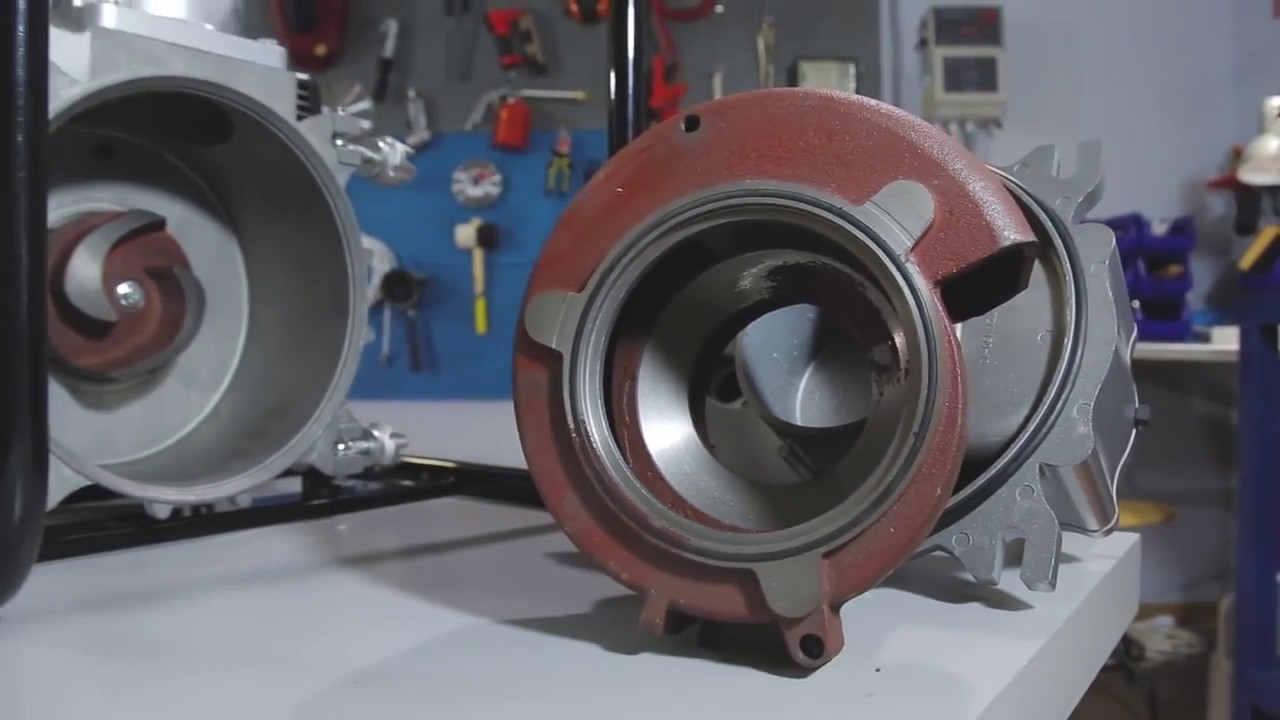

The operation of this unit is carried out in this way: the internal combustion engine drives the impeller (impeller, impeller) or the diaphragm (membrane) of the water pump. As a result, a vacuum pressure (vacuum) is formed, under the influence of which the liquid medium enters the suction sleeve and is then pushed out into the outer discharge pipe.

Due to the presence of a separate motor, the functionality of motor pumps does not depend on external energy carriers (power grid, gas pipeline). This makes it possible to use them to perform all kinds of operations: irrigation, water supply to structures, pumping water from wells, fire extinguishing and for the treatment of domestic wastewater (drain pits).

The area of operation of the electric pump is limited by the length of the supply wire, therefore, it can be fully used only within the boundaries of the suburban area.

Regardless of its low weight and size, the motor pump is endowed with high productivity. It can supply water over distances measured by more than one hundred meters.

The lineup

Let's take a closer look at the various modifications of this brand.

Fubag PG 600

A powerful specimen. Designed primarily for clean water, but also pumps water with little abrasive and suspended elements. Will be a good helper in the garden - irrigation of crops, changing the water in the pool, filling containers, drainage of an artificial reservoir.

Specifications:

- 4-stroke engine that is barely audible;

- mechanical seals specially for long-term operation;

- equipped with an auxiliary filter element for preliminary water purification;

- wear-resistant housing and impeller;

- requires the connection of 5 cm pipes;

- capacious fuel tank;

- iron frame for installation on uneven construction sites and during transport.

Fubag PTH 1000T

The pump is designed for very dirty water, with inclusions of abrasive particles up to 25 millimeters. Perfectly suited for difficult conditions, for example, for construction and installation work.

Equipped with the proven and high-tech Honda OHV engine, it guarantees high reliability and the ability to function in difficult conditions on the most challenging areas.

Peculiarities:

- reliable OHV Honda GX engine;

- the impeller and the volute are made of high-quality cast iron;

- reliable mechanical seals.

Fubag PTH 1000T ST

Powerful and reliable unit for pumping lightly contaminated water with admixtures of abrasive elements up to 8 millimeters. Excellent control over drainage of construction ditches, suitable for agricultural use.

Positive traits:

- proven and modern OHV Honda GX engines;

- impeller and pump volute made of cast iron with addition of spheroidal graphite;

- end seals made of silicon carbide;

- small mass in the synthesis with increased operational properties;

- reinforced frame structure;

- wide range of uses due to high efficiency.

PG 900 T

Pump designed for highly contaminated water. It perfectly transports water with large mechanical impurities (up to 2.5 centimeters in diameter), does not require special maintenance and is unmatched in functionality. Drainage, watering, drinking water supply, fire fighting and repair and construction works.

Pros:

- original composition of materials - cast iron, aluminum alloy and cermet in one product;

- a manual-type starter simplifies turning on the unit;

- Installed on 8cm pipes for fast water transfer;

- silent.

PG 950T

Another interesting Fubag pump for polluted water. Generates a lot of power, which is enough for high-quality execution of difficult tasks. Allows 3 cm particles in liquid. It is used in the construction industry, in the agricultural sector, in addition, in the work of housing and communal services and for fighting fires.

Specifications:

- equipped with an economical self-made motor F170 OHV;

- manual starter;

- a reliable welded frame that protects the pump and the internal combustion engine from damage and makes it possible to install the unit on a variety of planes;

- cast iron impeller, which is not subject to rust formation.

PG 1000

A productive modification used in the national economy. It does not take up much space, it is easy and simple to transport.

Peculiarities:

- 4-stroke engine, drives up to one m3 of fluid through itself in 60 seconds;

- working elements in contact with liquid made of cast iron;

- wear-resistant end coupling.

Fubag PG 1000T

Designed for operation with highly contaminated water containing abrasive particles up to 25 millimeters in size. The pump is perfect for difficult working conditions, for example, for use in construction. Due to its high head, it can be used for such types of work as transporting liquid over a long distance or height.

PG 1300T

Its working specification is highly dirty water. It has an original design in terms of materials and working mechanisms, for which spare parts can be found at any time.

Of the pros:

- cast iron body and impeller;

- branded motor from this brand;

- complete with installation kit;

- almost twice the capacity of the fuel tank.

PG 1800 T

The new leader in mud pumping - can continuously pump mud at a speed of 1,800 liters per minute. Suitable for various works on a construction site, in a village, in emergency situations.

Peculiarities:

- reliable OHV-motor Fubag;

- impeller and pump volute made of durable cast iron;

- mechanical seals made of wear-resistant materials.

For an overview of the Fubag PG900T motor pump, see below.

Specifications

Fubag motor pumps are wear-resistant. The cylinder and crankshaft are made of heat-resistant steel. The overwhelming majority of modifications are equipped with a reinforced frame that guarantees protection of working components from damage and does not allow the unit to move from vibrations that occur during engine operation. A special dipstick is provided to determine the oil level. It is attached directly to the pump body and is very difficult to lose. Replaceable filter devices preinstalled in the systems protect the unit from the ingress of dirt and solid particles. Ring repair kits, sealing glands, all this can be purchased without problems.

The most significant pump parameters are:

- throughput (measured in liters of fluid pumped over in 60 seconds);

- lifting height or pressure;

- the depth from which the pump can raise water.

In addition to them, the operating instructions cover the diameters of the holes at the inlet and outlet of the motor pump, as well as the motor power in kW.

When choosing a unit, it is necessary to know not only the suction depth of the liquid medium, but also the maximum distance to which it is capable of supplying it in a horizontal position. Here, a simple ratio comes to support the consumer. It says that 1 meter of water rise is equivalent to 10 meters of movement in a horizontal position. Knowing the area of your own site, the depth of the source and the distance to it, it is very easy to set the basic parameters of the motor pump.

Fuel consumption is another significant parameter of the adaptation. For domestic pumps with low productivity, it does not exceed two liters, and for modifications with high productivity it can reach 4-5 liters per hour.

Two types of pumps are installed on the pumps: diaphragm and centrifugal. Centrifugal pumps are capable of operating exclusively with clean or slightly contaminated water.In contrast, diaphragm pumps are designed for handling viscous and dirty liquids.