Selection recommendations

In order to decide which motor pump to choose (domestic, imported, "alteration" from a pneumatic pump), you first need to determine for yourself several factors of choice.

- Terms of use. It is worth deciding what type of work will be carried out, since the type of pump (general or special purpose) depends on this. The first variety is suitable for everyday life, and the second is highly specialized.

- The type of liquid transported. Varieties of pumps according to the type of liquids are described above.

- Outlet hose diameter. Determine it by the diameter of the cut of the outlet. The larger the diameter, the more efficient the pump.

- Lift height of the liquid. Indicates the amount of pressure generated by the pump. Described in the instructions.

- The presence of filters that protect the pump from mechanical impurities in the liquid. The presence or absence of filters can affect the cost of the unit.

- Pump performance. The amount of water pumped by the pump over a period of time is an important indicator for selection.

- Fuel type (in our case, diesel).

- Fuel consumption (specified in the instructions).

Some people say that piston pumps made from pneumatic pumps or pieces of plastic pipes can be equipped with an engine to transport water. But it is worth considering that the service life of such a pump will be extremely short, and the efficiency of work due to insufficient fit of the components will be at a low level.

Application area

The main task, which is almost always successfully solved by a motor pump for dirty water, is to pump various kinds of liquids interspersed with fractions of various sizes. The degree of pollution must necessarily correspond to the design of the device for its successful operation. A motor pump is used for dirty water in many areas, in particular, in construction, the oil industry, in everyday life, housing and communal services, etc.

Pumping of water and liquid can be carried out from any object, from wells to drainage of reservoirs. The simple principle of use and efficiency make it possible to use such a device as a motor pump for dirty water, in case of floods, for pumping water from basements and civil structures for various purposes.

How to use it correctly?

In order to start working with a motor pump, you need to follow a few simple rules.

- Unpack the device, check the complete set, the numbers of the warranty card and the engine. This is best done when purchasing.

- Check the insides of the pipes for foreign objects.

- Mount the parts of the path by connecting the filter to the suction, and the pressure and suction hoses to the nozzles.

- Carry out a visual inspection to ensure that the pressure and suction hoses are securely fastened.

- After that, the engine is prepared for start-up, following the sections of the factory "Operating Instructions" (refueling with fuel, oil, and the like).

- The device is placed near the place where the liquid is transported, the suction hose is lowered into the reservoir / reservoir (vertically).

- Clean water is poured into the pump body through a watering can to fill the pump. Water is poured until air ceases to come out of the case. The pressure hose is installed 10 cm above the unit body. Screw on the plug tightly.

See the features of the motor pump below.

Popular manufacturers

At the moment, there are several popular manufacturers of motor pumps on the market. Let's take a look at some of them.

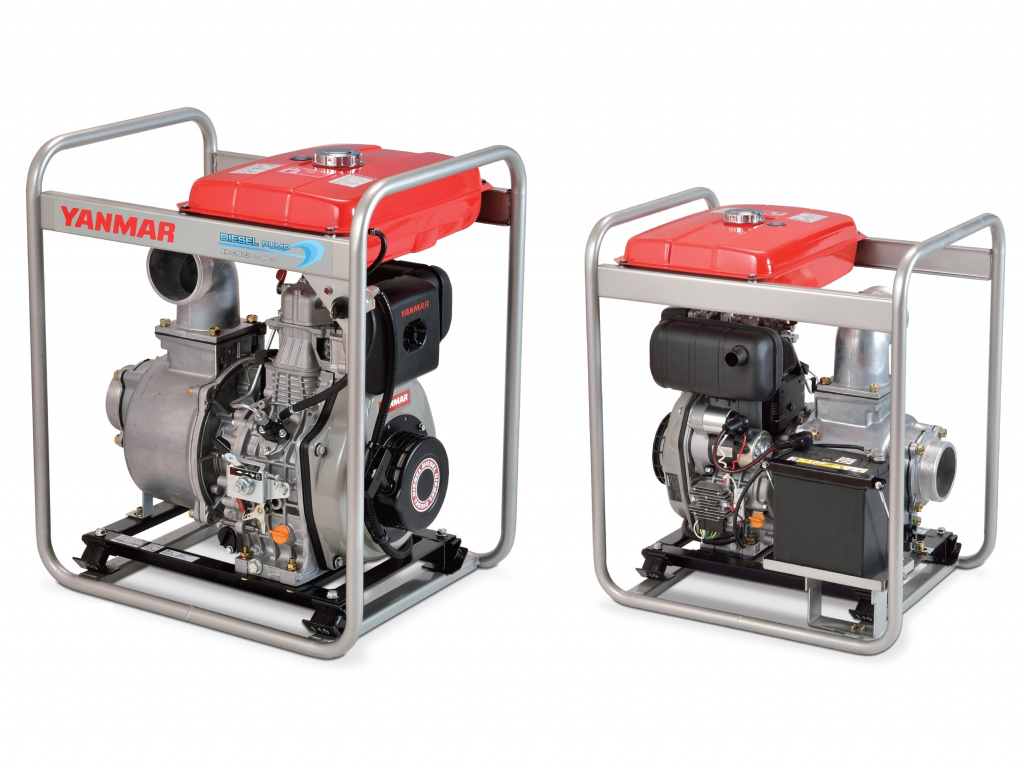

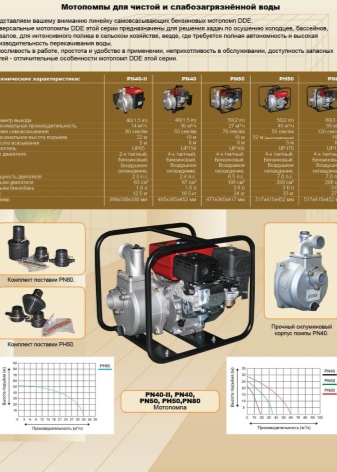

Yanmar is one such manufacturer. Some models of motor pumps of this company are made on the basis of diesel engines and diaphragm pumps for various degrees of water pollution with an impurity content from 5 to 31 mm. They have low fuel consumption, spacious tanks, low noise and vibration levels, and are easy to start in all weather conditions. We can cite as an example several units from the model series, in which centrifugal or diaphragm pumps are installed.

- Yanmar YDP20TN / Yanmar YDP30N / Yanmar YDP40STN / Yanmar YDP40TN - These models are equipped with four-stroke diesel engines, with outlets ranging from 50 to 100 mm in diameter. The presented units boast a lifting height of highly polluted, clean or slightly polluted water to a height of up to 7 meters (0.7 kgf / cm2). They are capable of transporting liquid in volumes from 33 to 105 thousand liters / hour and have a relatively low weight from 56 to 109 kg.

- The Yanmar YDP20DN is a diaphragm model for heavily contaminated water. Equipped with outlet pipes with a diameter of 50 mm. The weight of the installation is 53 kg, the volume of the pumped liquid is 11400 l / h with the possibility of lifting this liquid by 7 meters.

The market is now dominated by narrowly focused Russian-made motor pumps, for example, "Geyser" and "Vepr".

Geyser motor pumps are used to extinguish fires using clean or slightly contaminated water with possible inclusions up to 3 mm. These units stand out from the competitors due to the high pressure of the supplied water - up to 190 meters (19 kgf / cm2) - and low prices. This is achieved by installing domestic components on the unit - VAZ engines, which were installed on the 2108 model, and pumping parts of domestic manufacturers.

The lineup includes many models of both stationary and mobile devices based on ZIL, UAZ and MZSA trailers. For example, the MP-20/100 and MP-40/100 models. "Geyser" MP-20/100 and "Geyser" MP-40/100 due to trailers have a mass of 215 and 950 kg, respectively, the diameters of pressure pipes are 100 and 125 mm, the same height of water rise to a level of up to 7 meters, but the volume of transported liquid differs by almost two times 72 thousand and 144 thousand l / h.

Vepr models are mainly used on ships for pumping water with impurities up to 6 mm in diameter. The lineup has a large number of models, we will single out from them, for example, MP-1800 BF and MP-2200 BHM. These devices can pump out water from a depth of up to 8 meters, are equipped with outlet pipes with a diameter of 100 mm, due to which the volume of liquid reflux is 108 and 132 thousand l / h, respectively, and the weight is 46 and 60 kg.

Elitech models are designed primarily for domestic use for pumping only clean or slightly contaminated water, as well as an option for extinguishing small fires with impurities up to 15 mm, silt and stones. Motor pumps are easy to use and do not require any special skills to operate them. The lineup has several devices, for example, Elitech MB 1000 D 80 and Elitech MB 1600 D 100. These units are equipped with outlet nozzles with diameters of 75/100 mm, capable of raising water to a height of 8 meters and transporting up to 60 and 96 thousand l / h respectively. The weight of the devices is 30 and 47 kg.

Principle of operation

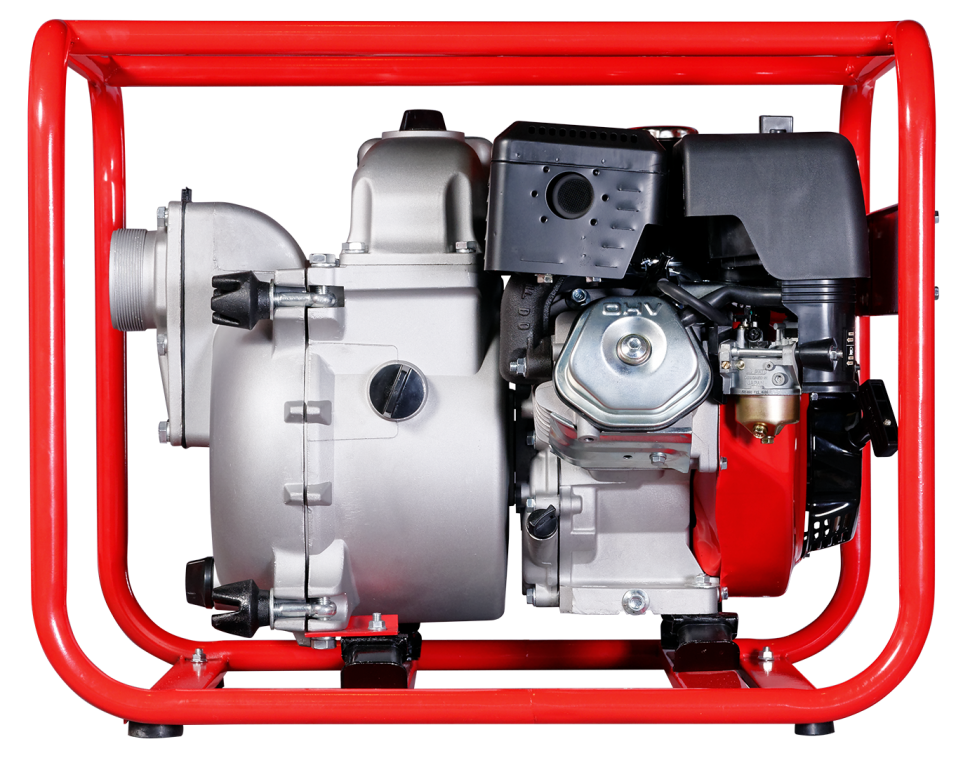

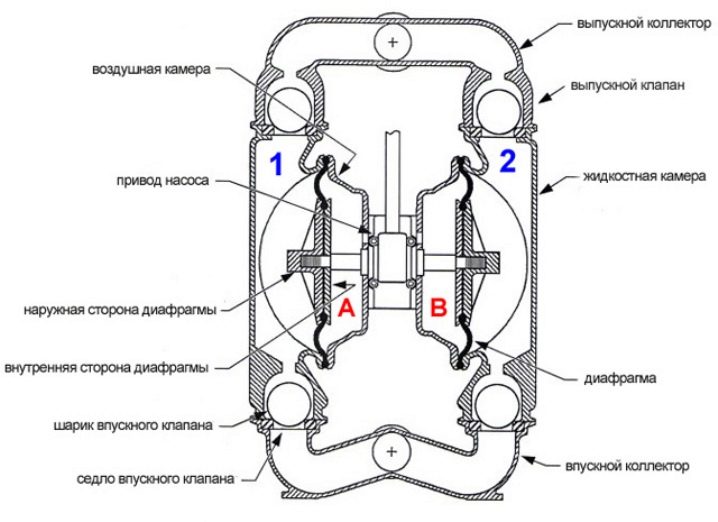

The main element of any water motor pump is a pump that transports water at high speed. Basically, two types of pumps are used - centrifugal and diaphragm. To ensure that there is sufficient pressure in the diaphragm pump, a well-coordinated pair of diaphragms is used that alternately expel the water. Their principle of operation is similar to that of a piston in a cylinder. Due to the alternate squeezing of the working fluid into the pipe, the diaphragms maintain a continuous high-pressure flow.

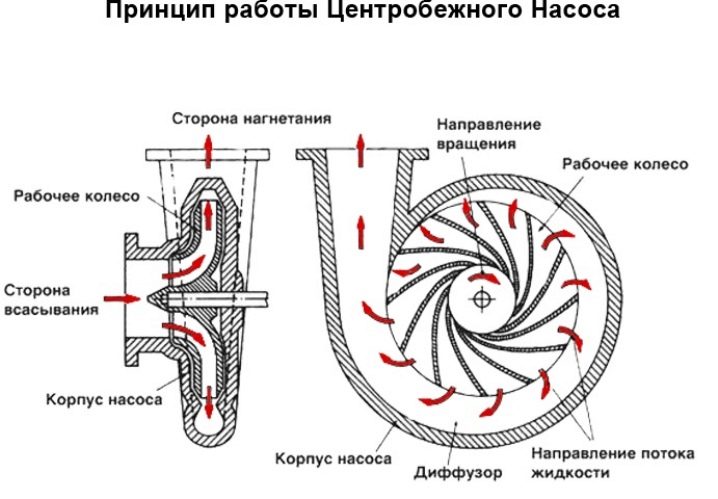

The most widely used device is with a centrifugal pump. The motor rotates the pump impeller through a belt drive or direct connection. At high impeller speeds, the centrifugal pump, due to its design, generates a region of low pressure on the inlet hose, as a result of which liquid is sucked. Due to centripetal forces, the impeller generates a high pressure area at the outlet.As a result, a stream of water is formed, which creates the required operating pressure in the outlet hose.

The prevailing part of the pumps is equipped with check valves. Gasoline motor pumps are supplied with meshes with cells of various sizes. The mesh size varies depending on the possible degree of contamination of the pumped water. That is, the grids act as filters. Cases of pumps and motors are mainly made of steel to insure pump working parts against damage. To increase maintainability, most of the pumps have collapsible casings.

Device and principle of operation

Equipment diagram and device

A distinctive feature of this technique is the presence of an internal combustion engine running on gasoline or diesel fuel, while the classic version of the pump is equipped with an electric motor. A motor pump for pumping dirty liquid and water consists of two main units: the directly pumping part of the mechanism, which is exactly the pump itself, and the drive mechanism is an internal combustion engine.

The pump is made in the form of a die-cast casing equipped with a cover. Both elements are securely tightened with screws. For tightness, there is a sealing gasket at the joint.

A motor pump for pumping dirty water provides for the possibility of draining water from the pump through a special pipe and plug. In the upper part there is an element for connecting a pressure hose. The impeller wheel is directly connected to the motor shaft. All connections are fitted with gaskets.

The motor pump for pumping dirty liquid and water functions according to the following principle: due to the connection between the impeller and the engine, a centrifugal force arises, under the influence of which the process of pumping liquid occurs. An impeller with an impeller throws water out of the housing further towards an element called a branch pipe. The motor pump for differently contaminated water also functions on the basis of the principle of vacuum in the system, which allows you to act on the valve and take water through the pipe.

Selection of equipment by power

To transfer fluid further along the chain, connecting elements are used - hoses. Clamps are usually used to secure them to the body. Depending on which version of the pump is being operated, the response time of the device may vary, which is largely determined by the height at which the pumping is carried out. A motor pump for slightly contaminated water often has structural differences from models designed to work with dirty liquid: a two-stroke engine is provided for them.

Peculiarities

The motor pump can be used for various purposes.

- Filling or draining swimming pools.

- Watering private or agricultural areas.

- Pumping water from common sources.

- Pumping various liquid chemical, acidic and other agricultural substances.

- Removing water from various pits and trenches.

- Pumping water from flooded areas of houses (garages, basements and similar structures).

- In case of various emergencies (floods or fires).

- When creating artificial reservoirs.

The main characteristics of a motor pump are:

- the amount of liquid transported (l / min);

- working depth of liquid suction;

- diameter of hoses;

- dimensions and weight of the device;

- fluid head pressure on the outlet hose;

- pump type;

- type of fuel for the engine;

- the degree of contamination (particle size) of the pumped liquid.

There are some individual options:

- engine characteristics;

- the amount of noise;

- way of starting the engine;

- the cost of the device.