Peculiarities

The line of units of the Zubr trademark can be attributed to the category of powerful and multifunctional walk-behind tractors. Diesel and gasoline devices, additionally equipped with various equipment, successfully cope with tasks related to not only land cultivation, but also mowing grass, removing snow or foliage, and transporting goods. The range of products is regularly supplemented with new models of walk-behind tractors, which has a positive effect on the characteristics and parameters of the devices presented.

A feature of the Chinese Zubr motoblocks is considered to be high performance, due to the power of the diesel engine in various classes of agricultural equipment. All components and spare parts are freely available, making it easy to improve functionality or replace parts.

Among the distinctive features regarding the configuration and capabilities of Chinese units, it is worth highlighting the following points.

- All models of motoblocks, due to their characteristics and convenient control system, can be used for processing soil of varying complexity, including virgin soil. For certain tasks, it will be enough to equip the device with the most important auxiliary equipment.

- In addition to cultivating the soil, as well as mowing grass, walk-behind tractors can be used to harvest ripe crops, in particular, this applies to root crops.

- Motoblocks will be useful in the period of caring for a large area of planted crops, since they can perform soil processing on already seeded ridges.

A distinctive feature of the diesel engine range is the type of engine, due to the capabilities of which the power of the device increases, as well as its capabilities. In addition, units with a diesel engine are much easier to control, since they will be many times more powerful than gasoline cars with a similar engine power.

It should be noted that the diesel series of agricultural equipment will be more economical in terms of fuel consumption, even if we consider heavy equipment.

Agricultural machines Zubr are successfully sold not only in the Russian market, but also in Europe. All products from the Asian conveyor are assembled in accordance with international quality standards ISO 9000/2001, as evidenced by the certificates for each model.

Among the distinctive characteristics of the equipment in question, it should be noted the good quality and a wide range of components and attachments, in addition, Zubr walk-behind tractors can be operated in conjunction with home-made components that will meet the requirements of a particular owner. Due to the adapter with the steering wheel and the corresponding setting, motoblocks of a heavy category can be turned into mini-tractors. Also, diesel units assembled in Asia stand out for their quite affordable pricing policy for the Russian market.

Features of a gasoline engine on walk-behind tractors

The petrol engine on agricultural machinery is often the most problematic part. It has many features to consider when servicing and adjusting. Peculiarities:

- there are two types of gasoline engines - two-stroke and four-stroke;

- most of the parts are universal, but a number of mechanisms will require spare parts from the manufacturer;

- full installation is carried out during maintenance, which is performed at least once a year;

- most of the engines are of Asian origin, but at the same time they are of sufficient quality and easy to maintain;

- for adjustment and other processes, you will need to have the necessary tools.

In this video, you will learn how to adjust the valve in the walk-behind tractor:

In the device of walk-behind tractors, the internal equipment occupies an important place, since the performance of any work depends on it. It is recommended to service the equipment annually in special services, but additional installation will also be required after a period of inactivity or after prolonged operation.

This approach allows you to reduce wear on parts and keep your equipment in optimal condition.

Any misalignment will result in reduced power, wear on parts and permanent malfunctions. You can also find out that the procedure was carried out incorrectly by the lack of stability during operation.

For each gasoline option, the verification process is governed by a number of points, including operational data, described in the instructions, as well as brands and types of sets of parts. With different types, the level of necessary parameters may differ even with one brand of the equipment itself.

Valve adjustment has its own peculiarity

Description

Diesel motoblock Zubr HT-105 (electric starter) (6 hp) belongs to heavy agricultural equipment designed for processing all types of soils (clay, swampy, virgin, etc.). Thanks to the unit weight of 120 kg, the rotary tillers can sink into the ground to a depth of 30 cm.

In addition to plowing the land, with the participation of the Zubr HT-105 walk-behind tractor and the corresponding attachments, it is possible to carry out other agricultural work:

- landing;

- hilling;

- weed control;

- watering;

- harvesting;

- mowing;

- harvesting;

- snow removal.

As you can see, buying just one HT-105 walk-behind tractor, you get powerful functional equipment that will be used all year round. The unit is able to process small land plots of high quality, the area of which does not exceed 1 hectare.

Motoblock diesel Bison HT-105

The performance of the single-cylinder four-stroke engine installed on the HT-105 walk-behind tractor is 6 hp. Thanks to the air cooling of the motor, the duration of work with it increases significantly. The diesel engine is started using an electric starter.

The gearbox of the motorized device is equipped with three speeds:

- 2 front;

- 1 reverse.

A feature of the engine of the Zubr HT-105 model is a solid motor resource (3000 hours). In addition, an automatic decompressor valve is specially installed, thanks to which it is possible to start the engine without the participation of an electric starter. But if you decide to use the electric starter, then to start the engine, just press one button.

The wheels of the Zubr NT-105 walk-behind tractor have powerful protectors with 4 or 8 chevrons. Ground grip is enhanced and the quality of work is enhanced. The set also includes a rotary tiller.

The transmission of torque from the engine to the working bodies is carried out using a worm gear, which is the most reliable way of transmitting torque.

The engine of the Zubr NT-105 walk-behind tractor is also protected from breakdowns associated with a sudden forced stop of the unit (obstacle on the way, etc.), a special belt drive serves as protection. transmitting torque from the engine to the gearbox.

There is one more important function - the belt adjustment horizontally and vertically. Thanks to this adjustment, the operator gets additional convenience - to drive and control the walk-behind tractor walking near the unit, and not behind on the freshly plowed arable land.

Replacing drive belts in a snow blower

Snow blower drive belts are designed to transfer rotary motion from the drive shaft to the driven ones.

Therefore, if the snow blower does not move forward, or its auger does not rotate, then the belts must be checked and, if necessary, replaced.Follow these steps to install the belt on the snow blower.

- Disconnect the chute from the snow thrower.

- Remove the protective cover that covers the pulleys with belts.

- Disconnect the auger mechanism from the machine motor by unscrewing a few bolts.

- Next, you need to put a new belt on the snow blower pulley, that is, on the auger pulley. The size of the belt should be the same as that of the broken one.

- Pull the auger mechanism (you may need the help of another person) to the engine and place the belt on the drive shaft pulley so that on one side it falls under the pressure roller with the spring attached to it. The roller serves to tighten the belt.

- When you screw the auger to the motor, the auger belt replacement is complete.

Replacing the wheel drive belt is done in the same way as for the auger belt. Only after disconnecting the auger mechanism, you need to remove the cover that hides the wheel drive pulley (indicated by the arrow).

Features of the Bison technique

Since 1999, Chinese-made motoblocks have entered the Russian markets. Consumers appreciated the competitiveness of this technology in comparison with European manufacturers. She perfectly combines affordable price and high quality.

Motoblock Zubr is quite simple and convenient to use, functional and reliable. With its help, you can loosen the soil, apply fertilizers, dig up the soil, remove weeds, transport small loads, clean and remove snow.

Distinctive parameters of Zubr walk-behind tractors:

- Available spare parts. If necessary, they can be easily purchased;

- A heavy machine can handle areas up to 2 hectares. The depth of the plowed soil is up to 30 cm;

- The presence of a gear transmission and a disc clutch makes it possible to monitor the tension less often;

- Economical consumption of the fuel mixture. The walk-behind tractor can work for a long time without stopping for refueling;

- Air or water cooling. The walk-behind tractor does not overheat even in operation at very high temperature conditions;

- Electric starter or spring starter is selected depending on the wishes of the owner.

The walk-behind tractor will last much longer if it passes a preliminary run-in. The instruction manual contains recommendations for performing this process. Also, adhering to simple recommendations, you can protect yourself at work.

Adjustment of valves

In diesel motoblocks Zubr NT 105, a certain kind of malfunction occurs, which is characteristic of this particular model. In particular, we are talking about the following breakdowns:

- severe wear of the belts, as a result of which they break;

- failure of clutch pulley bearings;

- leakage of oil seals;

- incorrect positioning of pulleys caused by insufficient tension on nuts, etc.

HT 105

In addition, there are cases that it becomes necessary to adjust the valves, or rather the gap between them. Let's try to deal with this issue and describe the algorithm for correct and consistent actions:

- We need to get to the flywheel of the engine, but first we need to remove the oil sump of the air filter. There are springs on the body of this bath, which periodically fall, which causes a certain inconvenience.

- To avoid this, we will use an ordinary elastic band, which must be put on the body of the bath, and under it we have already removed all our latches. Then we freely remove the air filter bath

- We unscrew the bolts securing the flywheel housing. Remove the cover.

- Special marks are stamped on the flywheel - 0, 5, 10 and 20. At 20, fuel is injected. There is a mark on the cylinder, under which you need to bring the zero value on the flywheel. To do this, simply scroll the flywheel until these marks match.

- Remove the valve cover by unscrewing the bolts. If the lid is not easily removable, then gently knock on its body.

- To adjust the valve clearance, we need an ordinary minus screwdriver, a 10 spanner wrench and a razor blade. The thickness of such a blade is 0.1 mm, and according to the technical recommendations specified in the passport, the gap between the valves should be in the range from 0.1 to 0.15 mm.

- Using a blade, we check the clearance between the valves. If the blade does not pass, then this gap is less than the required 0.1 mm, so it needs to be adjusted.

- The adjustment is made with a screwdriver, which is inserted into the screw of the nut located on the valve. Using a spanner wrench, we slightly loosen it, and then check the gap with a blade. It is necessary to loosen the nut until the blade wobbles slightly under the valve.

- We insert the screwdriver again in this position, and then tighten the nut with a wrench. You also need to make sure that there is no shaft at the valves, so the nut must be tightened securely. The same manipulation must be done for the second valve.

- We put on all the components in the reverse order, i.e. first the valve cover, then we install the casing and the oil bath. Make sure all connections are secure.

That's the whole process of adjusting the valves, which can be completely done on your own without resorting to outside help.

Attachments

Multifunctional attachments for Bison machinery allow expanding the possibilities of agricultural technology and maximally facilitate human labor. We suggest that you familiarize yourself with the following attachments and trailed equipment.

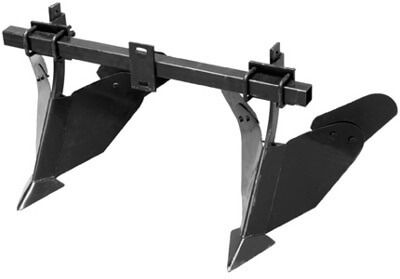

Plows the land.

Plow

Plow

Replace pneumatic wheels, loosen the soil when driving.

Lugs

Lugs

Digs up potatoes without manual labor.

Potato digger

Potato digger

Connects various equipment to the walk-behind tractor: mounted and trailed.

Universal hitch

Universal hitch

Mechanically planting potato tubers.

Potato planter

Potato planter

Consists of a wheel, a frame and a seat, is attached to the walk-behind tractor with a hitch.

Adapter

Adapter

It transports goods of various types.

Trailer

Trailer

Hilling soil, fighting weeds.

Double row hiller

Double row hiller

Allows cutters to sink deeper into the ground.

Weights

Supplied with a walk-behind tractor. Used with a trailer, mower and snow blower Bison.

Pneumatic wheels 4.00-8

Pneumatic wheels 4.00-8

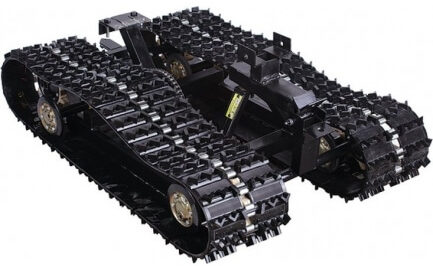

Track attachment

Allows you to increase the cross-country ability of the walk-behind tractor in the off-season, off-road and with snow.

Track attachment

Track attachment

Specifications

Bison equipment is equipped with Chinese-made gasoline or diesel engines. Compression ignition engines are heavier but have lower fuel consumption and are designed to handle increased loads for extended periods of time. Power units have a capacity of up to 12 hp. Depending on the engine power, Zubr walk-behind tractors are divided into light, medium and heavy.

The lightweight motor-cultivator Zubr GN-4 is driven by a 6 hp gasoline engine. The engine is equipped with 1 cylinder with a volume of 196 cm³ and an electronic ignition system. The power unit is started manually with a rope starter. Reversible transmission, 1 speed. The volume of the fuel tank is 6.5 liters; A92 gasoline is used as fuel. The tiller handles a strip up to 1 m wide, plowing depth up to 250 mm. The technique is suitable for processing plots of 40-60 acres.

Diesel walk-behind tractor Zubr HT-105 belongs to the middle weight category. The equipment is equipped with a multi-plate wet clutch and a worm gear reducer. The transmission has 2 forward speeds and provides a plowing depth of up to 300 mm. Reduced fuel consumption made it possible to use a tank designed for 3.5 liters of fuel. Installation of additional equipment makes it possible to use equipment for clearing the area from snow and transporting goods. The power unit can be used to drive an irrigation pump.

To medium motoblocks Zubr 8 hprefers to the Zubr JR-Q78 model equipped with a 4-stroke 1-cylinder power unit with an electric starter, duplicated by a manual starting device. The transmission has 6 forward and 2 reverse speeds. The drive shaft of the attachment is installed on the box. A dry clutch is installed between the engine and gearbox. The wheel track is adjustable in 2 positions (650 and 730 mm). The Q78 is well suited to work on 2-3 hectares.

The medium model NT-135 is equipped with a 9 hp diesel engine. with forced air cooling system. According to the operating instructions, the fuel consumption is 2.2-2.7 liters per hour. The operating consumption is slightly higher. The power unit is started by an electric starter. The transmission consists of a wet multi-plate clutch, a 2-speed gearbox and a spur gear drive.

The JR-Q79E features a 10 hp liquid-cooled diesel engine. Characteristics of the Zubr walk-behind tractor allows you to cultivate land plots with an area of 3 hectares. A belt drive is installed between the clutch and the input shaft of the gearbox. The Q79E uses a 6-speed transmission with an additional shaft to drive agricultural equipment. Shaft speed 1176 rpm. The Q79E model has a weight of 260 kg.

Heavy walk-behind tractor JR-Q12E is equipped with a power plant with a liquid cooling system. The engine with a working volume of 815 cm³ is started by an electric starter. A duplicate manual start requires a lot of physical effort. The diesel power is 12 hp. The technique allows the processing of large land plots with virgin soil. The weight of the walk-behind tractor without attachments is 280 kg.

The gearbox has 6 speeds forward and 2 - backward. To drive the wheels, a main pair with bevel gears is used. The plow included in the complete set of the walk-behind tractor allows plowing a strip 800 mm wide. Plowing depth - 180 mm. Above the engine there is a radiator for the cooling system and a fuel tank (5 liters). A headlight and 2 side lights are installed on the front.

Attachments

Today, the manufacturer offers a large assortment of auxiliary tools for joint use with walk-behind tractors of various capacities, expanding the functionality of the devices. The main components are discussed below.

Tillers

Zubr can work with two types of these tools, therefore walk-behind tractors are compatible with saber cutters or parts in the form of "crow's feet".

Mowers

The tool is very easy to install to the unit, for the device you can choose rotor elements, frontal or segment mowers. Thanks to this equipment, you can regularly mow hay and collect animal feed, as well as beautify the territory and mow lawns.

Snow blowers of various modifications

The Chinese brand proposes to use the following types of snow cleaning equipment with walk-behind tractors - a blade-blade, a set of brushes of different sizes, a screw-rotor mechanism for cleaning skids.

Plow

The most popular additional tool for walk-behind tractors, allows you to quickly and efficiently process a farm, including difficult-to-pass soil.

Soil wheels

Such an element acts as an analogue of pneumatic wheels for cars. When installing this option of attachments, you can loosen the soil.

A tool that allows you to plant and harvest root crops without the use of manual labor.

Hitch

An auxiliary element is implemented for agricultural motoblocks in order to fix various types of tools and equipment, including mounted and trailed parts.

Adapter

The mechanism consists of several elements - wheels, frame and landing block.Attaching the adapter to the walk-behind tractor is possible when using a hitch.

Trailers

Equipment required for the transportation of various goods. Before purchasing this auxiliary mechanism, you should study the instructions and parameters of compatibility with this or that model, as it may be necessary to adjust the valves.

Hillers

Useful agricultural implements, with which you can quickly huddle the soil in the beds and remove weeds over a large area of land.

An element that allows the cutters to dig as deep as possible into the ground during work.

Track attachment

This additional device is required for work in the off-season, when using the attachment, you can increase the patency of equipment on heavy ground or in winter on snow, eliminating the car getting stuck in the direction of travel

How to adjust the valves

Each model has its own characteristics for the valve regulation process. But basically there is a standard process that is not much different in the step-by-step version. Procedure:

- preparation of equipment and necessary tools;

- the casing is removed;

- after the flywheel, remove the valve cover;

- adjustable;

- installation of the cover and casing.

The list of required tools may vary, depending on the brand and features of the motor. The standard will require a set of wrenches and screwdrivers, as well as a feeler gauge or small blade.

The process itself involves setting the gaps to the optimal size. In almost any instruction manual, the value is indicated. Each option has its own mechanism with its own parameters. This must be taken into account during operation and maintenance.

Together with the engine and all mechanisms, the transmission and chassis are installed. Only a full-fledged tuning process will bring the entire set of mechanisms to an optimal state.

The setup itself includes the following steps:

- after the cover of the valve system is removed, the gap parameter is checked;

- the correct backlash should freely pass the probe under the valve;

- with the standard, the inlet type clearance is 0.15 mm, and the exhaust valve has a backlash of 0.2 mm;

- for adjustment, loosening of the fastening nuts is carried out;

- after achieving the result, the fastening nuts are tightened and the cover and casing are installed.

Do not forget to check the operation of the device after the repair

All procedures are performed strictly by a specialist or a person with sufficient experience. Different options have different indicators, but the procedure itself is standard. With any diagnosis, it is also necessary to check all systems. The further performance and efficiency of the entire device depends on this.

Various options for hand-assembled mechanisms depend only on the model range on the basis of which everything was assembled. Each type of agricultural device has its own level of parameters, which is necessary for effective work.

On a motoblock Lifan

Adjusting the valves on the Lifan walk-behind tractor has its own characteristics. There are several power options for the motor, which have their own clearance parameters. Mainly used "Lifan 6.5". The size of the gaps is set to a standard one, that is, for the inlet - 0.15, and for the outlet - 0.2. The procedure itself is also carried out in accordance with the usual procedure.

Lifan is one of the models that does not need to be warmed up before testing. The technology is warmed up after the valve adjustment, when all the systems are checked as a whole. Another important point is the ability to contact a special service, since the brand is widespread.

Almost all Lifan modifications have a similar procedure. The only exceptions are self-assembly options that are based on the model.

On the Patriot walk-behind tractor

Adjusting the valves on the Patriot walk-behind tractor has its own nuances. It should be noted that the Patriot has an identical Agro adjustment. The whole process is different from the standard plan, including for the Lifan brand.Setting:

- warming up the engine and cooling it down;

- removal of the oil bath of the air filter;

- unscrewing the casing, including all six bolts;

- dead center (0) is located opposite the cylinder mark;

- the cover on the valve system is removed;

- loosening the lock nut and checking the backlash;

- setting the desired result and tightening the nut;

- installation of the cover and casing;

- check of work.

This is interesting: adjusting the carburetor of the walk-behind tractor.

Using this system, you can vary the settings of the technique and adjust the required level of parameters.

After completing the setup, a full check of the device is required during operation.

The valves are regulated according to a standard plan that is provided for different models. Each type of engine has its own required parameters, which affects the features of the regulation. All requirements can be found in the instructions, as well as clarified in the service center, which is engaged in annual maintenance. Without a full inspection of the equipment, parts will receive additional wear and tear, and the equipment does not work efficiently.