Attachment overview

Walk-behind tractors Shtenli gained popularity due to the fact that they are able to support work with a wide range of attachments. Each owner should be familiar with the capabilities of their machine in order to use it as efficiently as possible.

Cutters

This is the basic hitch, which is at the disposal of every Stanley walk-behind tractor owner. It is used to turn over the top fertile soil layer and further increase soil fertility. During operation, the cutters are installed instead of the standard pneumatic wheels.

Plow

This attachment is used with Stenli walk-behind tractors when it is necessary to plow dense stony lands. The plow plunges into the ground and allows you to keep the walk-behind tractor in a stable position.

Mower and rake

Stanley walk-behind tractors can help in clearing weeds and unwanted vegetation from the area by connecting the rotary mower to the PTO. The mower is capable of cutting even medium-sized coarse-stemmed plants and shrubs. The advantage of rotary mowers is that when hitting a stone, the knives do not break off, but turn in the other direction, maintaining their integrity.

After mowing, many people in rural areas leave the grass to dry and then collect it as hay for the winter for livestock. A rake can be connected to Shtenli walk-behind tractors and quickly collect grass.

Potato digger and potato planter

Potatoes are in demand among the residents of our country. At the same time, planting and cleaning work takes a lot of time and requires significant physical effort. If you are the owner of a Shtenli walk-behind tractor, then this task can be performed independently by connecting the appropriate attachments.

The most common version of the potato digger is the rattling one. The potato digger picks up a layer of soil at a level of 20 cm along with the fruits, and then, with the help of a roar, breaks up large breeds of soil, leaving only root crops on the surface.

Snow blower and shovel blade

With the onset of winter, the owners of country cottages and rural residents are faced with the problem of snow removal. In our regions, heavy snowfalls are observed, and if you do not clear the adjacent territory, then over time you can simply not leave the house.

Motoblocks Shtenli together with a snow blower can help solve this problem. This attachment picks up a layer of snow and, with the help of an auger, throws it aside at a distance of 10-15 meters.

If you need to clear a small section of the road or a footpath, you can use a conventional shovel blade to do this.

Wheels, lugs and tracks

Almost the entire model range of Shtenli motoblocks belongs to heavy machines. They are equipped with high pneumatic tires measuring 6.5 × 12, which provide reliable traction when driving on any terrain.

If the adhesion to the surface is not enough and the walk-behind tractor is buried or skidding, then you can install special lugs, which are equipped with metal plates that enter the ground and stabilize the movement of the device.

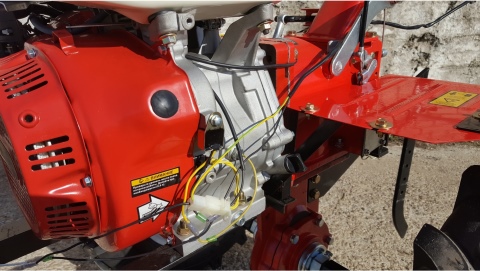

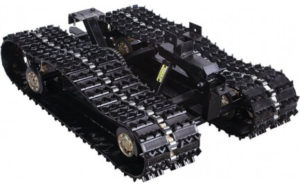

Track attachment

Track attachment

In the winter season, for driving on a Stanley walk-behind tractor, you can install a caterpillar attachment, which improves passability on loose snow and slippery ice, by increasing the area of contact with the ground.

Trailer

Heavy motoblocks Shtenli can transport loads over half a ton.To do this, it is necessary to use trailers, the configuration of which directly depends on the transported cargo:

- When transporting bulk cargo, it is better to use dump trailer options;

- If it is necessary to transport long pipes or logs of trees, it is better to use a cart on 4 wheels;

- When transporting large amounts of hay or other bulky goods, a trailer with high sides must be used.

Adapter

Motoblocks have one significant drawback, you have to move while standing behind them. Because of this, the owner becomes physically tired quickly.

To reduce the load, an adapter can be connected, which is a seat on a frame. When connected, you can control the Shtenli walk-behind tractor while sitting.

Overview of attachments for Weim walk-behind tractors

The most functional are the Weim WM 1000 walk-behind tractors, the WM 1100 series, the Weim WM 610, WM 900.With additional implements, the machines perfectly cope with a variety of agricultural works: cultivation, plowing, weeding, hilling, making beds and furrows, planting and digging up root crops, mowing grass ... Weima walk-behind tractors are used for economic purposes. Weima WM 610 successfully operates as a drive for stationary equipment.

The Weim brand manufactures its own attachments for walk-behind tractors in a wide range; aggregates with trailed implements from other manufacturers are available.

Aggregated trailed and attached implements:

Tillers - as standard, all Weima walk-behind tractors are equipped with rotary tillers. The 2 + 1 completeness allows you to cultivate with different working widths, depending on the model, from 600 mm to 1350 mm to a depth of 30 cm.

The availability of modifications with an active cutter (Weima WMX 720, WM 610, WM 1100-6) and a passive cutter allows owners to make the best choice. The cutters may differ for different machine models depending on the shaft dimensions.

Mowers - of various types, including rotary ones, are rationally installed on most Weim models, driven from the power take-off shaft.

Plow - units work perfectly with various models of plows - reversible, large, hiller.

The universal toothed harrow will perform the harrowing of the soil, if necessary, it will be loaded.

A universal rake with a working width of 2 m can be used for collecting mowed grass, cleaning the area from grass debris.

The potato planter + screen type potato digger is a great option to facilitate the laborious work of growing potatoes.

Wheels - several junior gasoline models of Weima motoblocks - WM450, WM550 are initially produced without wheels, equipped only with milling cutters, they only cultivate the land. All other models have pneumatic wheels with pronounced tread, ranging from 4.00-6, 4.00-10 and up to 5.00-12.

Lugs - used on difficult soils to increase tractive power.

Trailer + adapter - Weim walk-behind tractors are capable of transporting loads weighing up to 300 kg at a speed of 11 km / h (WM1100 series).

A shovel-blade with a working width of 1 m, installed on a walk-behind tractor, will qualitatively throw snow on the site.

Sweeping brush - with such a hitch of Weim, it will sweep the territory, clean it of debris.

Motor pump - powerful gasoline (WM1000N6 DeLuxe) and diesel versions of Weim perfectly perform water pumping.

Weighting agents - depending on the quality of the soil and the type of work performed, various weighting materials are provided.

Couplings - Weim's walk-behind tractors have a universal coupling for aggregation with various implements; in addition, couplings for special devices can be purchased.

Diesel walk-behind tractor Weim at work

About the manufacturer Profi

The homeland of the Profi brand is Germany, the SHTENLI GMBH company. The production itself is located mainly in China. All technical processes, from the selection of materials to assembly and testing, are carried out under the strict supervision of the parent organization.

Honda engine

The engine is assembled under the license of the Japanese concern Honda, in compliance with all international standards. All systems comply with CE, EU, EPA, CARB standards, have low vibration and exhaust levels, and are tested in northern climates.

When developing the design of Profi walk-behind tractors, the manufacturer took into account the peculiarities of agricultural technology in the European part of Russia, central regions, Siberia, as well as the CIS countries. The model range includes equipment for the processing of virgin, alumina, sandy and stony soils.

The universal hitch allows you to use potato diggers, potato planters, plows, cutters, harrows, tines, motor pumps, snow blowers, lawn crechers, brushes, mowers and other attachments.

What to look for when choosing a walk-behind tractor

PTO. In cultivators without a shaft, the soil is processed using milling cutters, in walk-behind tractors, active equipment is hung on a special hitch, such devices are much more versatile.

- Engine's type. For work on personal plots, you can purchase a model with an electric motor, with operation from the mains or battery. They weigh less, work quieter, do not require an oil change. Gasoline 4-stroke is more powerful, more convenient to operate, suitable for operation at low temperatures.

- Diesel engines are considered the most reliable and powerful, although they are more noisy and overall.

- Transmission. Determines the movement capabilities of the device. Most Profi models have a two-speed manual gearbox and an additional rear gearbox. A large number of gears and an automatic transmission are needed mainly for those who use a walk-behind tractor with a cart as a vehicle.

- Engine power. One of the main parameters that determines the capabilities of the equipment. Cultivators for 1-5 HP suitable for processing small areas, differ in small width and depth of plowing.

- Motoblock Profi Motors 6-15 hp allows you to cultivate several hectares, copes with heavy soils, a phased development of virgin lands is possible. 18-24 hp models in fact, they are mini tractors, with their help you can process up to 1.2 meters of land, transport up to 1-1.5 tons of cargo (we also recommend that you read the article about a Subaru engine for a walk-behind tractor).

- Cooling system. In simple models, the engine is cooled using fins on the body; these are slow-speed and not too powerful options.

- The more efficient ones have forced air fans.

- Almost all Profi models are equipped with liquid radiator cooling systems.

- Equipment weight. Depends on the thickness of the metal used, the material of the wheels, the type of engine and gearbox.

- Heavier motoblocks allow you to plow deeper, more stable on the road (especially when used with a cart), but the lungs do not burrow into the ground, it is more convenient during transportation.

- To increase the weight of the walk-behind tractor, you can purchase special removable weighting materials or use home-made devices made of steel or cast iron.

- Headlights. Allow you to work at night.

- Possibility of installing active or passive equipment. If the walk-behind tractor is equipped with a power take-off shaft (PTO), then attachments with moving parts can be connected to it. The PTO system can be spline or pulley-belt.

- In simple models and cultivators, it is possible to work only with rigidly fixed elements.

Attachment overview

Now motoblocks have already become an integral part of the life of rural residents. They allow you to automate a large amount of work thanks to additional attachments. Each owner should be familiar with the assortment and possibilities of hinges.

Motoblock Profi 1030

Motoblock Profi 1030

Cutters

This is a standard attachment that comes with most Profi walk-behind tractors.

Cutters allow you to turn and mix the topsoil, thereby increasing soil fertility.

Cutters

Cutters

This attachment is installed to replace the standard pneumatic tires on the wheel axle.

Plow

This attachment is designed for the cultivation of virgin lands, when the cutters cannot provide normal cultivation of the soil.

Plow manufacturers offer different options for their attachments. The most popular is the reversible plow, which allows you to turn the soil several times on the share, break up blocks and only then throw the soil to the side.

Mower and rake

Motoblocks Profi are capable of cleaning the area from weeds and small shrubs.

The most popular option is the rotary version of the mower, which cuts the grass using rotating knives. A feature of rotary mowers is the ability to process any type of soil at different slopes.

If you need to work on densely overgrown areas, you can use a segment mower, which during operation moves the blades alternately towards each other.

After the vegetation is cut, it dries up and can be collected with the help of the Pro walk-behind tractor and a rake.

Potato digger and potato planter

Potatoes are in demand throughout our country, but the work associated with them requires a lot of physical and time costs.

The potato planter is a 30 liter tank into which potatoes are poured. From there it is fed by means of a conveyor belt. A plow is installed in front, which makes a ditch, and at the back, a hiller buries a trench.

The potato digger picks up a layer of soil 20 cm deep, and then, with the help of a roar, breaks up the clods of rock, and leaves the potatoes on the surface, which just remains to be collected.

Snow blower and shovel blade

When the winter period of the year comes, heavy snowfalls are observed in our country. Motoblocks Profi are distinguished by an improved starting system and allow the motor to be driven even at negative temperatures.

The snow plow picks up the snow with a 1 m wide bucket and then throws it to the side with the help of a rotor.

If it is necessary to clear a small area adjacent to the house, then you can use a conventional blade-shovel.

Wheels, lugs and tracks

Motoblocks Profi belong to the heavy class, which is able to carry out almost any type of work. However, under increased loads, the device may slip or burrow into the ground. To prevent this, lugs can be installed instead of standard tires.

In the winter season, to improve cross-country ability, you can install a tracked module, which increases the weight of the walk-behind tractor and the area of contact with the surface. Caterpillars are most often used when driving a walk-behind tractor over long distances in winter.

Trailer

Motoblocks Profi have excellent traction characteristics and can carry loads weighing over half a ton. There are several types of trailers, and you need to choose the right one from the transported cargo:

- The most popular is the universal dump trailer version, which allows unloading by simple lifting from the front;

- If it is necessary to transfer hay or other bulky cargo, then it is recommended to use a cart with high sides;

- When transporting long log cabins or pipes, you should choose a trailer with 4 wheels.

Trailer

Trailer

Adapter

To reduce the physical stress on the owner of the Profi walk-behind tractor and make the work more comfortable, an adapter can be connected to it. This is a special attachment with a seat, thanks to which you can control the device while sitting.

Adapter

Adapter

If you have a trailer, you can use it as an adapter when driving over distances.

Trailers and flotation improvement

Despite the fact that wide wheels are installed on the walk-behind tractor, and it itself has an impressive weight, this is not always enough for reliable grip. In order to eliminate slipping, they are used. Their diameter is 30-60 cm, and the weight of one pair is in the range of 40-70 kg.Ground hooks are installed in cases where plowing is carried out on loose or wet soil.

Some owners of a walk-behind tractor weld a frame to its frame, in which containers with water or sandbags are placed. In winter, the wheels are replaced with modular tracks, which turn the walk-behind tractor into a full-fledged snowmobile.

Improving the usability of the unit and expanding its functionality is achieved by using the following hook-on devices:

- Adapter. It is used for trips over various distances when the road is in poor condition. The adapter relieves the stress on the legs of the worker when processing large areas.

- Cargo trailers. Used during planting and harvesting operations. In the local area, the use of trailers is necessary for the transportation of heavy things, garbage disposal, and moving bulk cargo. By design, trailers are divided into single-axle and two-axle.

- Combined carts. They have 2 seats, a chassis and a small body. The drawbar of the bogies is adapted for attaching attachments. You can use the carts for picnic, fishing trips or shopping at the village store.

- Sled. They are used in winter to transport people and various goods. According to the design, the sleds are subdivided according to the methods of sliding. You can buy a sleigh with a flat bottom or runners.

With good adhesion to the ground and in a low gear, the walk-behind tractor can tow trailers weighing up to 1000 kg. Such opportunities are used during rescue operations. Stenli units successfully pull out cars stuck in mud and snow, evacuate faulty equipment, motorcycles and snowmobiles. On a good flat road, walk-behind tractors with a trailer can accelerate to 18 km / h.

Instructions for use of the "Titan" walk-behind tractor

The user manual will help the new owner of the "Titan" walk-behind tractor to get acquainted with the units, learn how to work on it and much more. The instructions describe the following sections in detail:

- The device of the "Titan" walk-behind tractor, its assembly.

- Technical characteristics of the Titan walk-behind tractor of the selected modification.

- Safety requirements.

- Powerplant first start-up guide, running-in.

- Maintenance stages.

- Typical malfunctions of the "Titan" walk-behind tractor.

Let's take a quick look at some of the sections.

Run-in of the "Titan" walk-behind tractor

The procedure is designed to prepare a motorized device for the stresses that arise during various agrotechnical works. The break-in period begins immediately after the first start of the power plant.

Run-in lasts up to 8 hours, during this time, under conditions of low loads (gentle mode), the moving parts of the engine, gearbox and gearbox are rubbed in. During the running-in period, the "Titan" walk-behind tractor must not be loaded, the power must not exceed ¾ of the engine power. During this period, it is necessary to check how the mechanisms work, how the speeds are switched, etc.

Maintenance of the "Titan" walk-behind tractor

This section consists of several steps:

- Oil changes:

- for transmission, 80W-90 GL-5 oils are used, which are changed every 100 hours of operation;

- the engine should be filled with engine oils 10W-30, which are changed every 25 hours of operation.

- Daily care “before” and “after” use:

- before starting work, check the oil and fuel level, fastening bolts, tire pressure;

- at the end of field work, the walk-behind tractor is cleaned of all types of contamination and lubricated.

- Preservation of the "Titan" walk-behind tractor for long-term storage:

- draining fuel and oils from the walk-behind tractor system;

- cleaning from contamination;

- lubrication of all parts and assemblies.

- Scheduled technical inspections.

Typical malfunctions of the "Titan" walk-behind tractor

Motoblocks "Titan", like all existing equipment, periodically fail. The cause of breakdowns can be:

- poor build quality;

- improper care of the walk-behind tractor;

- wrong working principle;

- non-observance of the rules of the instruction;

- mechanical damage arising from contact with foreign objects, etc.

Let's consider some malfunctions and their causes, this information is more fully provided in the operation manual:

- The power plant does not start for the following reasons:

- the quality of the fuel does not correspond to the norm;

- there is no fuel in the tank;

- poor quality of lubricants;

- the oil in the system runs out;

- filters are dirty and require replacement and cleaning;

- the ignition system for gasoline models requires attention (check the performance of the spark plugs, carburetor, condition of the high-voltage wire, magneto, ignition setting, etc.);

- the diesel fuel supply system is out of order, check the injection pump, hoses);

- there is no compression in the engine head.

- Strong vibration of the "Titan" walk-behind tractor during operation:

- the mounting bolts are loose;

- the attachment is not correctly connected to the walk-behind tractor.