Adjustment of the unit valves.

Without correct adjustment of the valves and other important components of the engine of the mechanism, normal operation is impossible.To carry out adjustment work, such tools are required as:

- a set of various wrenches;

- a set of different screwdrivers;

- special shaped probe and other tools that may be needed in the process.

The concept of valve adjustment means the establishment of the most optimal clearance between the valve and the cylinder wall. The size of the gap, as a rule, is indicated in the instructions attached to the unit.

It may differ in different designs of the walk-behind tractor engine. The sequence of work of the valve adjustment process is as follows:

- the engine of the unit is freed from the casing;

- the valve cover is dismantled;

- the valves are being adjusted;

- the valve cover is replaced;

- the power plant is covered with a casing.

The procedure for performing work on adjusting the valves may differ slightly, depending on the brand and engine power of the unit. The size of the gap must be checked with a feeler gauge.

In the intake valves of the power plant, the clearance should be -0.15 mm, for exhaust valves, it should be 0.2 mm. With a properly adjusted gap, a special dipstick should fit freely under the valve itself.

For adjustment, it is necessary to slightly loosen the nuts, then insert the dipstick. At the end of the adjustment process, the nuts must be tightened. It does not hurt to carefully check the gap again, and then close the valve with a cap. The final action is the engine is covered with a casing.

After correct valve adjustment, the operation of the power plant will be much more efficient, and its operating period will also increase.

This article describes the adjustment of the walk-behind tractor, namely its main parts: the carburetor, valves and the fuel system. The process is not easy, so we have included some photos and videos as well.

Adjusting the fuel system of the walk-behind tractor

If the fuel is not supplied to the cylinder, then, first of all, it is necessary to check if there is enough fuel in the tank. You also need to check whether it goes to the carburetor. For this, a hose is removed from the inlet connection of the device. If we are talking about a K45 carburetor, press on its quench so that the fuel starts to pour out through the drain hole.

If fuel does not enter the carburetor, then you need to unscrew fuel tap, completely disassemble it and remove accumulations of dirt from the mechanical filter. To achieve maximum cleanliness, all components must be treated with gasoline. The fuel cock is assembled and returned to its original location.

If fuel enters the carburetor, but is not supplied to the cylinders, it is necessary to check the correct operation of the fuel valve, as well as the presence of dirt on the jets.

To deal with the carburetor of a gasoline walk-behind tractor of the KMB-5 type, you need to remove it from the engine and pour out the fuel from the float chamber. Through the fitting (see figure), with the help of which the gasoline is supplied, it is necessary to supply the air mixture, having previously installed the carburetor in the operating position. The passage of air should go unhindered, and when the carburetor is turned over, it should completely stop. These features indicate the full performance of the part.

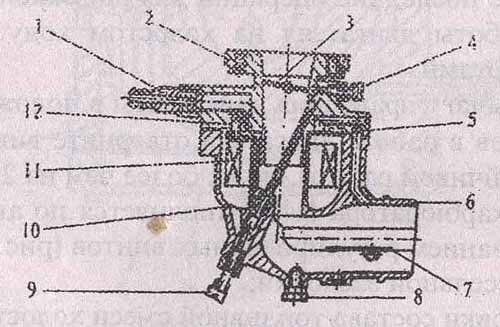

Rice. 2. Carburetor KMB-5

Details in the figure: 1 - fuel supply connection; 2 - upper body; 3 - throttle valve; 4 - idle needle; 5 - jet; 6 - lower body; 7 - air damper; 8 - screw fixing the tie; 9 - maximum gas needle; 10 - spraying element; 11 - float; 12 - fuel supply valve.

The fuel level inside the float chamber can be adjusted using the float tab. Ideally, it should range from 3 to 3.5 centimeters.

To purge the jets, it is necessary to unscrew the screws responsible for full and low throttle. Cleaning of the carburetor parts begins by unscrewing the screws that hold the upper housing. The lower body is removed, the fuel supply valve is flushed with gasoline, and the dirt from the nozzles is blown out by a pump. It is necessary to check if the float is intact. It is absolutely impossible to use rags in the cleaning process.

After completing the cleaning, the housings are connected. It is necessary to check that the spray tube is clearly inserted into the hole located on the upper body. Open the throttle valve and check how well the assembly is done. The screws that secure the upper case are tightly tightened. After the assembly process is completely completed, the carburetor should be adjusted. This will significantly improve the performance of the walk-behind tractor with attachments, since for correct operation, ideal adjustment of all its parts is required.

If the carburetor DM 1.08.100 is installed on the engine of the walk-behind tractor, then the procedure for adjusting it will be as follows:

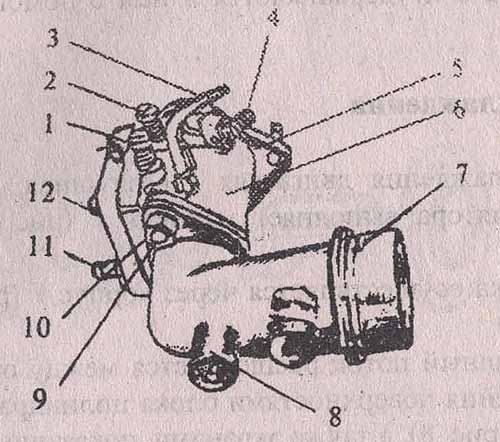

- Screw in screw 10 (Fig. 3) at idle until it stops and unscrew it half a turn.

- Then you need to tighten the full throttle screw 9 and unscrew it completely by 2 turns.

- Unscrew the screw 4 (Fig. 4) of the minimum engine speed right up to the stop of the lever against the bore of the carburetor body and turn it in 2 turns.

- Start the engine of the walk-behind tractor, then adjust stable operation at maximum speed after warming up with screw 9.

Do not allow the engine control lever to be turned off, move it to the minimum throttle (rpm) position and by unscrewing screw 10 set stable idle rpm.

Rice. 3. Carburetor DM 1.08.100

Rice. 4. Carburetor DM outside

That's basically it. The main points of adjusting the main parts of the walk-behind tractor are considered. Adjust your walk-behind tractor with pleasure!

Model Honda 160

The features of the Honda 160 walk-behind tractor include:

- The ability to change the track width, which is achieved by rearranging the rubber wheels.

- Large ground clearance, which allows the cultivator to move over the plowed land.

- The unit is equipped with a four-stroke single-cylinder engine for a Honda walk-behind tractor.

- Honda engine power - 5.5 hp.

- The torque is 3.6 thousand km.

- The transmission has 1 forward and 1 reverse speed.

- The volume of the fuel tank is 3.6 liters.

You can increase the performance of the model if you put the hitch on the wheels, so that the unit turns into a mini-tractor.

Maintenance tips for motoblocks with a Honda engine

One of the main manipulations in the case of maintenance of motoblocks is to adjust the valves. The reliability of the engine and the entire walk-behind tractor directly depends on this manipulation. In particular, it is necessary to carry out this procedure if the walk-behind tractor is jerky, makes noise and gives out periodic malfunctions.

Setting the valves is the setting of the required clearance parameters. The norms for setting the gaps are often spelled out in the technical documentation of the device. All models have their own acceptable values in terms of clearances.

Acceptable valve clearances for a conventional device are as follows:

- in the case of the inlet valve - 0, 10 - 0, 15 mm;

- for the weekend - 0, 15 - 0, 20.

To adjust and dismantle them, you will need tools such as:

- set of wrenches;

- flat screwdriver;

- styli for 0.10 / 0.15 / 0.20 mm.

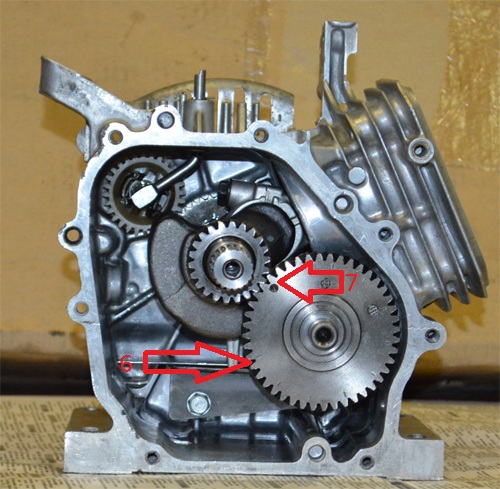

For an optimal valve setting, the following manipulations should be performed:

- make sure the engine is not hot;

- detach the oil bath reservoir from the air filter and the filter element;

- loosen and disconnect with a wrench 4 bolts located in a circle on the protective casing;

- disconnect the starter and flywheel guard;

- at the end of the flywheel it is necessary to bring it to a stable position of the "dead center", the mark located on the edge of the cylinder blowing must coincide with the zero mark of the flywheel;

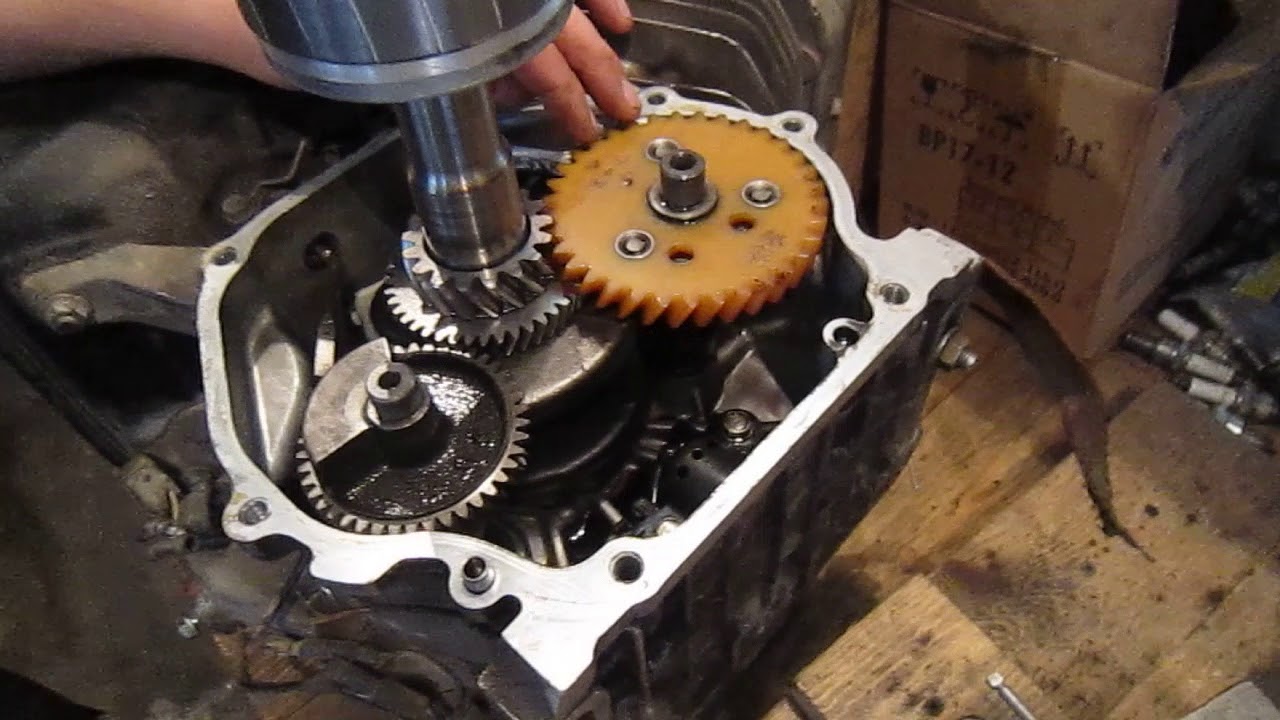

- detach the cover with a paronite gasket by unscrewing the 3 fixing bolts in advance;

- check the width of the gaps: the inlet valve is located next to the filter, and the outlet valve is located next to the muffler;

- to measure the interval, it is necessary to insert a dipstick between the valve and the rocker arm;

- if the distance does not correspond to the permissible, then adjust the elements using a spanner wrench and a screwdriver;

- clean all connectors of the device with a piece of cloth;

- collect the engine back;

- make sure the walk-behind tractor is working.

If there is a leak of engine oil from the gearbox of the walk-behind tractor, this indicates that it is necessary to replace the oil seal.

This can be done as follows:

- disconnect the cutters from the shaft, clean them from traces of dirt and oil;

- loosen and disconnect the bolts fixing the cover that protects the gearbox, if things are so that the cover adheres very well to the housing, knock on it with a hammer;

- remove the unusable oil seal, clean the place under it;

- squeeze out the sealant on the edge of the new gland, place the part in place, tighten the cover tightly.

An overview of a walk-behind tractor with a Honda engine is waiting for you in the next video.

Description

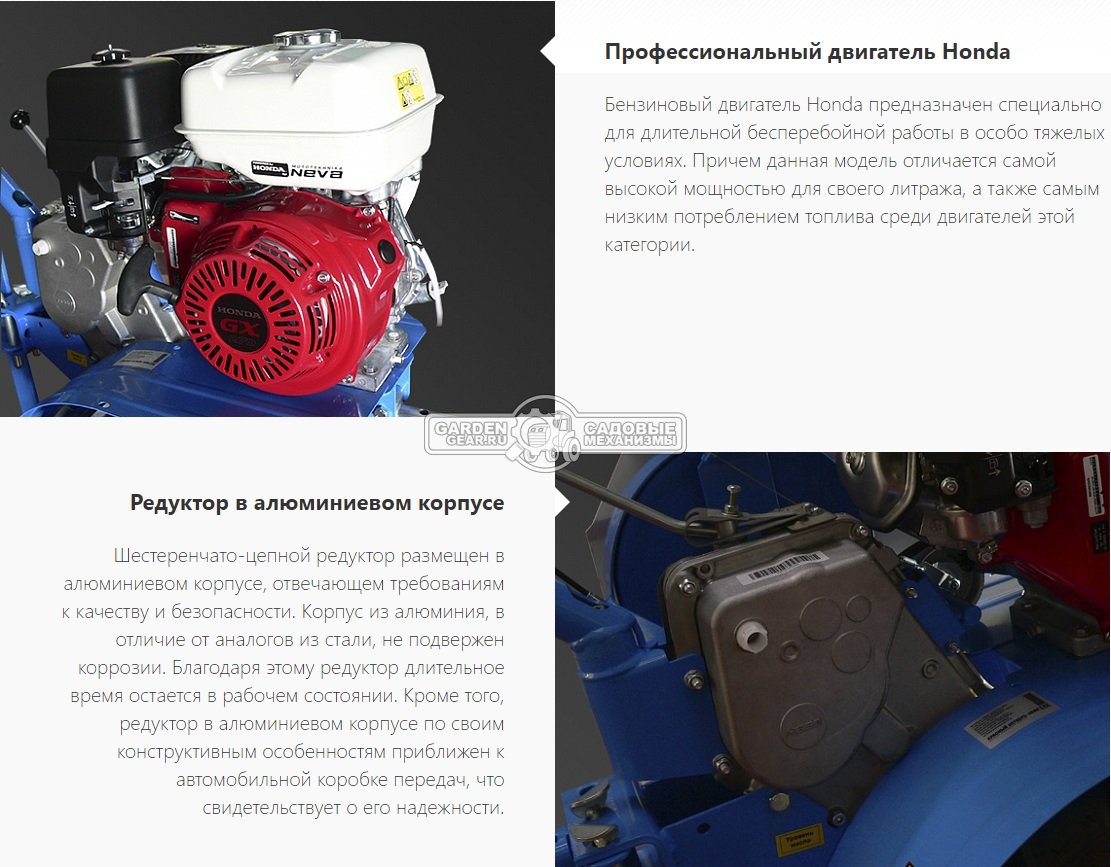

All engines have forced air cooling and contactless magneto ignition.

Generator with Honda GX-200 engine

All single-cylinder engines, except for the GX-100 and GXR-120, have the same design, differing only in the sizes of units and parts. The base model is the GX-200. Engines have a highly tilted left (when viewed from the recoil starter side) cylinder, lower camshaft, valve in the cylinder head, splash lubrication system, flywheel fan, single chamber horizontal flow carburetor and swing air damper. The GX-100 and GXR-120 engines feature a vertical cylinder arrangement and an overhead camshaft.

The single-cylinder models GX-25 and GX-35 belong to the Mini-4 series, which are among the lightest, smallest and quietest on the market. A special feature of the iGX series engines is the built-in electronic control unit ECU with the STR self-adjusting regulator system.

Two-cylinder V-shaped engines.

Benefits and features

The advantages of professional Honda GX engines include:

- Strength: Professional configuration for demanding professional use.

- Power: Maximum power to weight ratio. Today's Honda GX models are 6% more powerful than previous generations.

- Long service life: all components are designed for long term use.

- Smooth and quiet operation: The tilted cylinder arrangement and the optimization of the rebalance ratio reduce vibration to a minimum, while operating quietly due to the superior muffler design. Precise mechanical overdrive regulator maintains the correct speed change. The noise level is reduced to 5 decibels.

- Reliability: Proven design, proven through years of use in the toughest conditions. Each engine has a cast iron cylinder bushing, ball bearing crankshaft, chrome-plated top piston ring, and replaceable valve guides to provide extended service life.

- Easy Reliable Starting: The OHV engine is equipped with maintenance-free electronic ignition and automatic cylinder decompression for easy and reliable starting.

- Lifespan: Maximum peak in life for professional use.

- Economical: lowest fuel consumption in its category. The top valve design allows for up to 30% less gasoline than comparable LOVE engines and 12% less than the older GX models.

- Low Oil Level Sensor: The Oil Alert system will automatically shut off the engine if the oil level becomes too low.

- Horizontal shaft.

- Sustainable: Fully redesigned for worldwide use, including the EU, and meets the EURO2 emission standard and EPA / CARB regulations.

Chinese clones

Unitedpower GG6200 generator with UP-188 engine, which is a Chinese clone of the Honda GX-390 engine

The engine of the Chinese company Lifan is structurally and dimensionally similar to the Honda GX-390, but has a larger working volume - 419 cm3

Due to the fact that Honda GX engines have a sufficiently technological design and a high margin of safety, they have been massively cloned by Chinese factories since the early 1990s. As of 2013, clones of Honda GX engines are produced by more than 500 factories in China, and production volumes are dozens of times higher than the output of the original engines. By the beginning of the 2010s, the quality of these products had increased significantly, and the price was significantly lower than that of the original. Thanks to this, they have gained great popularity among manufacturers of inexpensive motorized equipment. However, due to illegal copying, the access of engine clones to the US market and a number of European countries is closed.

A number of Chinese companies have made changes in the design of the original Honda GX engines, in particular, they mastered the production of engines of other working volumes (in particular, 65, 94 and 419 cm³), added electric generators to the engine design to power the on-board network of cars (in particular, Lifan engines can generator with power up to 200 W). Chinese engines have a cast iron cylinder liner (original engines have a wear-resistant cylinder bore coating). Many years of operating experience have shown that, although such a design is “outdated and low-tech,” it provides the engines with high reliability, especially when operating in harsh conditions. In addition, a number of Chinese manufacturers use a different model designation system: the letters UP (universal petrolium - universal petrol) and three numbers, the first of which indicates the number of cylinders, and the last two - the cylinder diameter in millimeters. For example, the GX-200 is sold under the designation UP-168 (1 cylinder, 68 mm), and the GX-390 under the designation UP-188 (1 cylinder, 88 mm).

Since about 2013, Chinese manufacturers have started to make significant changes in the design of engines in order to reduce costs and at the same time improve performance. As a result, Chinese engines began to lose compatibility in terms of parts both with the original Honda GX engines and with each other. A number of companies, for example, Lifan, create power units for motor vehicles based on the design of Honda GX engines.

Thanks to the Chinese clones, the engines of the Honda GX family as of 2013 are the most massive in the world and have become the de facto standard in the design of gas generators and walk-behind tractors. The most popular models among the Chinese clones are the GX-200 (UP-168) and GX-390 (UP-188).

general information

The new GX270 features variable ignition timing (digital CDI), higher compression ratio, improved carburetor performance, and a lighter piston. The result is increased power and torque levels with improved fuel efficiency and reduced noise and vibration levels.

The dimensions and appearance have remained virtually unchanged to guarantee 100% interchangeability with older GX270 engines. For the same reason, the name of the engine remains the same, but all new models are numbered "2" in the series (T2 or UT2), and older versions are numbered "1" (GX270 K1 / T1 / UT1).

In 2014, Honda introduced a "high slope" version of the GX. The GX270, GX340 and GX390 are now available for multipurpose use, including providing power for walk-behind tractors.

Honda GX-270 CDI engines have new features:

- A special one-way valve built into the cylinder head improves oil return flow and guarantees optimal lubrication in inclined conditions.

- Bracket-protected diaphragm fuel pump and adapted fuel line routing ensure optimum fuel consumption.

- Fuel level indicator and carburetor with internal air vent prevent overfilling and ensure safe operation in all conditions.

Honda GX270 CDI engines produce 8.5 hp. (actual - 8.4HP) at 3600 rpm. and a torque of 19.1 Nm at 2500 rpm.

Efficient gas mileage

The CDI digital ignition system with variable distribution and high compression ratio, combined with the precision shaft design from the Honda GX270, ensures precise valve timing and optimal valve closure for increased gasoline efficiency.

Full package

Honda GX-270 ball bearing crankshaft, cast iron cylinder liner, helical tooth gearboxes, improved piston design with two compression rings and one oil ring, heavy balance shaft and high-precision structural components ensure greater stability and lower vibration no matter which unit is used. Simple throttle control, large fuel tank with car cap, double oil drain and fill, easily accessible spark plug and high power starter are all advanced features of the updated Honda GX-270 CDI. And for those who need more functions, additional options are available: an electric starter, a spark arrestor, as well as a charging coil for charging the battery and a lamp coil for powering without using a battery with multiple output options.

Model Honda F810

This type of equipment from a Japanese brand is made to perform several tasks at the same time. Motoblock Honda F810 has the following advantages. An interesting layout is available: the motor has a transverse arrangement, like the belt clutch. This made it possible to reduce the size of the machine, making it more compact.

The 810 model is used to work in fields where it is necessary to cultivate, create beds, huddle, plow, dig and plant root crops, remove and throw snow, create harrows, and transport goods.

A wide range of attachments. For example, you can purchase various types of plows, a rotary soil cutter, a set of cutters that are installed in place of wheels, a potato digger, special wheels:

- with lugs;

- rubber;

- on rubber with pneumatic tires.

To remove snow, you will need a snow blade and a snow blower attachment.

Machine Specifications:

- The weight of the cultivator is 113 kg.

- Engine displacement - 3.9 liters.

- Honda engine model GX-240.

- Chain transmission.

- The transmission has 2 reverse and 6 forward gears.

- Engine power - 6 kW.

- The handle is adjustable in height and reach.

Engine classification

All Briggs & Stratton models can be divided into the following types.

- Consumer: Classic, Sprint, Quattro

- Enhanced: Quantum, Intek, Intek I / C

- Semi-professional: Intek I / C, Intek PRO

- Professional: Intek PRO, Vanguard, Power Build, Professional

Series I / C

The abbreviation "I / C" in Briggs & Stratton engines stands for "Cast Iron" or "Industrial Commercial". As the name suggests, they use a cast iron liner, which significantly increases the life of the piston group. Power from 3.5 to 11 horsepower.

Briggs & Stratton engines of this series are four-stroke and are used on cultivators, tillers, wood chippers, high pressure washers, water pumps and portable generators. They are a prototype for Russian engines of the Kadvi plant of the DM series.

Vanguard Series

Every Vanguard engine starts quickly, runs for a long time, and is very efficient. These motors increase the capabilities and functionality of the equipment in the most difficult working conditions.

Commercial Power is an important segment of the Briggs & Stratton Engine Power Products group. People need commercial equipment equipped with durable, high-performance ICEs that never fail. Briggs & Stratton Commercial Power manufactures premium Vanguard 4-stroke gasoline engines designed for power equipment. Regardless of your commercial application, Briggs & Stratton has powerful and reliable engines that start quickly and last for a long time.

Intek Series, Intek I / C, Intek Pro

Intek series of semi-professional motors used for both domestic and small industrial purposes. Designed on the basis of previous series motors with the difference that the valves are not on the side, but on the top (OHV). Weight is 14-23.5 kg, power is from 5.5 to 10 hp.

American Briggs & Stratton Intek Pro series engines are professional and highly reliable. They are used on devices that operate continuously or for a long time: mini-power plants, generators, motor pumps, construction equipment, etc. The power of the motors of this series is 6.5-10 hp.

Classic, Sprint, Quattro series

These are single-cylinder engines with a vertical shaft weighing up to 10 kg and a power of 3.5-4 hp. They are characterized by low weight and reliability. They are mainly installed on lawn mowers.

The design of these series engines is quite simple: an aluminum body, a cast iron cylinder liner, side valves (SV), a foam air filter, simple bearings. Despite this, the motors are reliable and suitable for most consumers who rarely use their household appliances.

Quantum Series

These are 5.5-6 hp engines. They are similar to the motors of the previous series, but differ in increased power, reduced noise level and a reinforced gas distribution mechanism. An additional difference is the air filter - it is a replaceable foam cartridge.