DIY constructive mechanism

To personally make a homemade differential for a mechanism such as a walk-behind tractor, you should pay special attention to work. In this case, it is required to consider in detail the entire algorithm of actions for the manufacture of such parts:

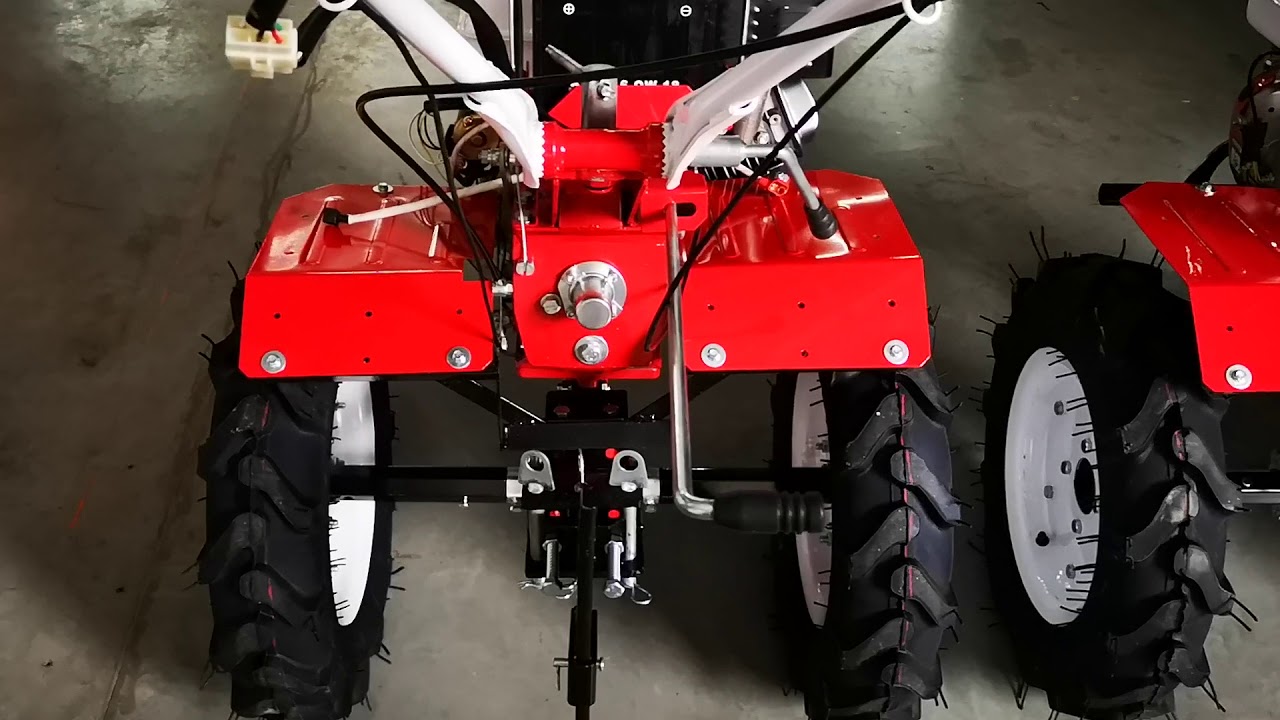

First of all, it is required to take into account the design features of the equipment used (special equipment).

It is also important to choose the optimal installation option that suits the design features of the technical device.

You need to download and print a diagram with exact dimensions or make it yourself.

Further, all the elements for the manufacture of such a mechanism are selected separately (hubs, for walk-behind tractors, gears, a camshaft and other components).

Next, you also need to choose the option for manufacturing such a device as a differential for special equipment.

Study in detail all the materials regarding how such a mechanism is performed in practice with your own hands.

After studying the theory and preparing the necessary components, you also need to select the tools.

During the assembly process, it is also recommended to use the appropriate video instructions that are available on the Internet.

All prepared elements must be pre-adjusted to a single size that is used on the walk-behind tractor.

Subsequently, according to the instructions, all structural components are collected together.

At the end, the part is checked for operability, and only after that it is installed on the axis of the special equipment.

This design should be done strictly according to the instructions.

This design should be done strictly according to the instructions.

In the manufacture of such a mechanism, it is required to ensure that the free travel of this part does not exceed 240 degrees. During manufacturing, it is required to adjust the parts in such a way that free play is provided, which will not be impeded by anything.

If the differential for the walk-behind tractor is made on your own, you must strictly observe all dimensions, and also avoid gaps, otherwise this type of equipment will last a short time

It is also important when creating a structure to also use only high-quality materials that were used to create factory components.

Additionally, it should be noted that there is no need to purchase all the parts for the device, since spare parts previously installed on the walk-behind tractor can be used for this element. In other words, you can remove the working mechanism from the technical device for domestication, and then modernize it so that it meets all the requirements of the owner of special equipment.

This is interesting: adjusting the carburetor of the walk-behind tractor.

Creeper

The grip of the wheels of the soil cultivating machine with the soil can be increased by using lugs or a creeper for the walk-behind tractor. The creeper is one of the attachments. It makes it possible to reduce the speed of the agricultural unit and increase the tractive effort together with the torque. An analogue of the gearbox works with the help of a chain and sprockets on the shafts. If desired, this device can be made by hand. Details are used from other techniques.

Each considered converter is endowed with its own shortcomings. To reduce their number to a minimum, you should try to make the device yourself. A homemade item can become better quality and easier to use than a purchased copy.

Blade for walk-behind tractor

The dump is a necessary device that is needed at any time of the year. The front knife is used to clean snow, plan the area, dig holes and move bulk materials. Such equipment for the Neva walk-behind tractor is of good quality, but not everyone can afford it. Do-it-yourself dumps require minimal financial investment. By installing the front knife on the Neva walk-behind tractor, you can solve many household tasks. With levers and hydraulics, a homemade shovel can also be used as a loader.

To make a blade, you will need the following tools:

- roulette;

- welding machine;

- electric drill;

- Bulgarian;

- spanners;

- acrylic paint;

- barrel 200 l;

- reinforced rubber;

- sheet steel 5 mm;

- profile pipe 40x20 mm;

- paint and brush;

- bolts and ties.

Before making a dump, it is necessary to calculate the correspondence of the power of the walk-behind tractor to the dimensions of the bucket. Excessive loading leads to rapid wear of parts and mechanisms of the unit. Depending on the weight and power of the machine, shovels are made 60-100 cm wide and 20-30 cm high.

Do-it-yourself snow removal homemade products for the walk-behind tractor are made in the following sequence:

- Marking the barrel, sawing it into 3 identical parts vertically. Cutting 1 piece into strips 5 cm wide.

- Bonding 2 blanks with bitumen and rivets. Aligning the edges of the product. Bucket reinforcement with transverse struts.

- Securing strips of sheet metal along the edges of the shovel. This is done using welding or bolts.

- Drilling bolt holes. Rubber strip attached to the bottom of the bucket.

- Shovel hitch making. It is done by attaching a piece of pipe and a semicircle of sheet metal to the blade by welding. Holes are made on the sector to adjust the angle of attack. A self-made snow removal device is attached to the motoblock bracket with an adapter from a profile pipe.

The finished product needs to be cleaned and painted. All bolted connections must be lubricated regularly to prevent corrosion.

Differential for a walk-behind tractor - how it works and what it is capable of

Diary entry created by user CaimanTeh, 02/26/15 .480,

To demonstrate the differentials, Denis turned the walk-behind tractor back and forth. The demo was short, but this option interested the participants in the topic Motor-cultivators Pubert & Caiman

The topic seems to have quickly figured out what kind of additional differentials for the walk-behind tractor are, but since the question arose, I decided to make a small photo report. After filming, the demonstration walk-behind tractor with a differential was filled with gasoline and oil, so it was driven to the service room. It is cramped there, there are a lot of other equipment around, so it was not possible to twist it. From Caiman Vario I got only a photograph.

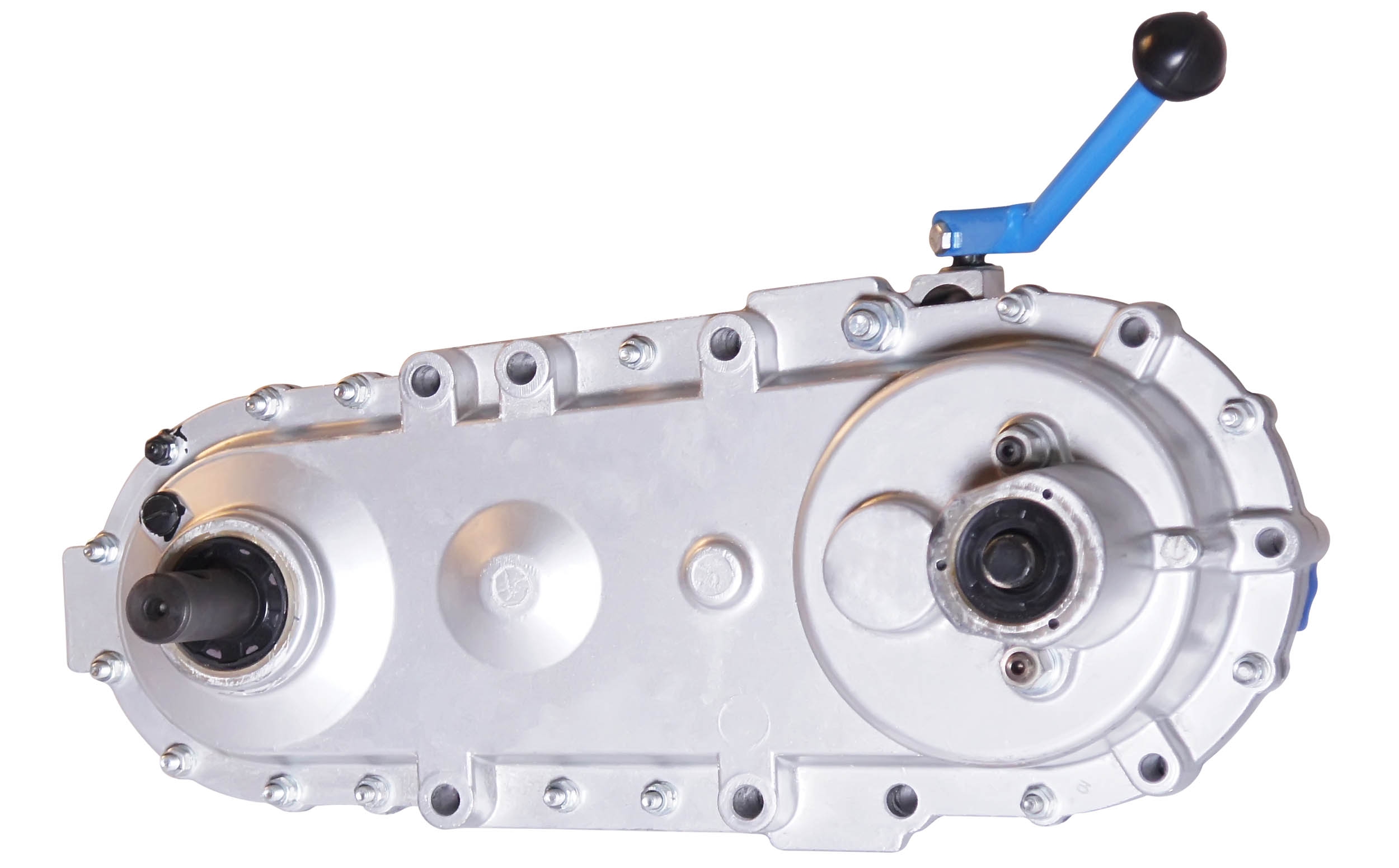

Differential for Caiman Vario walk-behind tractor

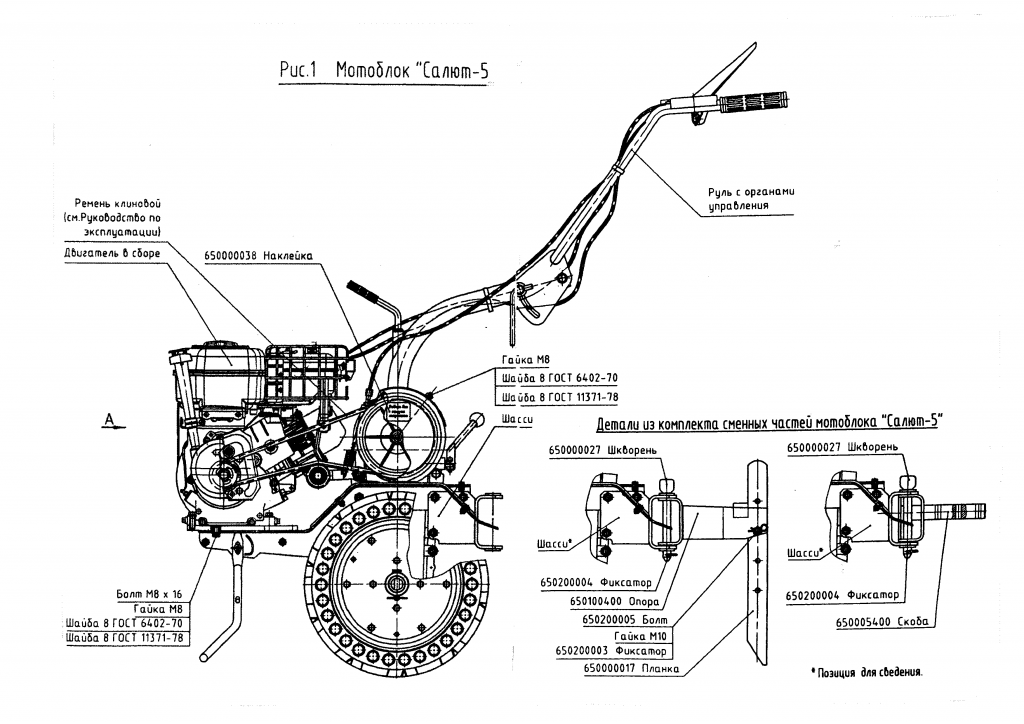

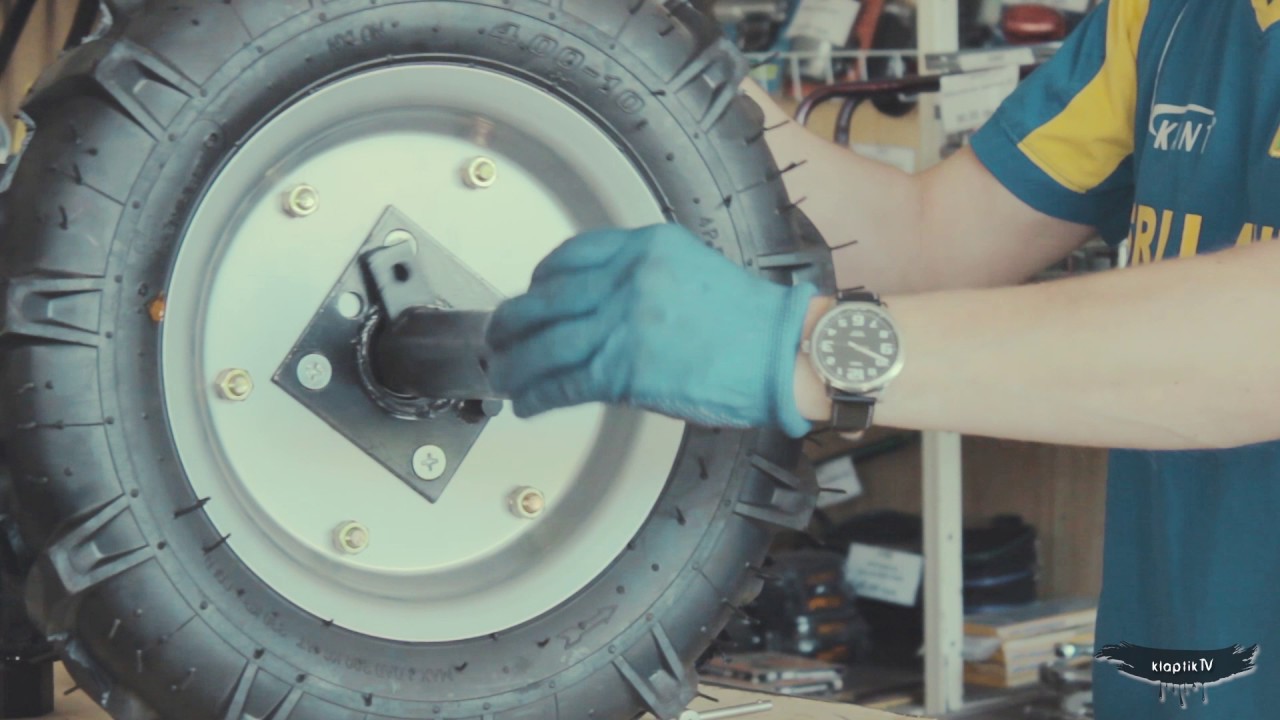

So, these are the differentials, or rather the semi-differentials installed together with the standard rubber wheels in size 4.00-8. (The set of two semi-differentials is called "Differentials with extensions for the VARIO / Q Junuor / Q Max walk-behind tractor" and has the code R0101.)

How is it done

The design of such differentials for walk-behind tractors (and motor-cultivators, by the way, too) is extremely simple:

- the wheel hub is not fixed to the axle

- there are projections on the axle and hub (indicated by green arrows) that prevent the wheel from turning a full revolution

How it works

During normal movement of the walk-behind tractor, the protrusion on the axle rests against the protrusion on the hub and transfers the rotation to the wheel. In this case, both wheels will rotate at the same time.

But if you push the walk-behind tractor forward, the differential hubs will work like overrunning clutches, and the protrusions on the wheels will "run away" from the protrusions on the axle. They will not be able to run far - having made an almost full turn, the protrusion on the hub will burrow into the protrusion on the axle, but this will be enough to make the maneuver.

After completing the turn, a walk-behind tractor with a differential will be able to drive only at the expense of one wheel until the protrusion on the axis of the second wheel "catches up" with the protrusion on the hub. It is also possible to slip with one wheel until the “unlocked” wheel comes into working condition.

Why do we need differentials for a walk-behind tractor

In simple terms, the walk-behind tractor needs differentials to turn at the end of the furrow. This is how the same Caiman Vario unfolds on lugs and without differentials.

To turn the walk-behind tractor and return to the cultivated area, the lugs have to be dragged along the ground. And here it all depends on the weight of the walk-behind tractor (or motor-cultivator) and the strength of the operator.

At the end there will be a video showing how differentials make this task easier.

Differentials on the Pubert Quatro Junior walk-behind tractor

Above was a picture with a differential hub that is different from that installed on the Caiman Vario - in the showroom there was another walk-behind tractor with a similar design of differentials.

Differentials on the Pubert Quatro Junior walk-behind tractor

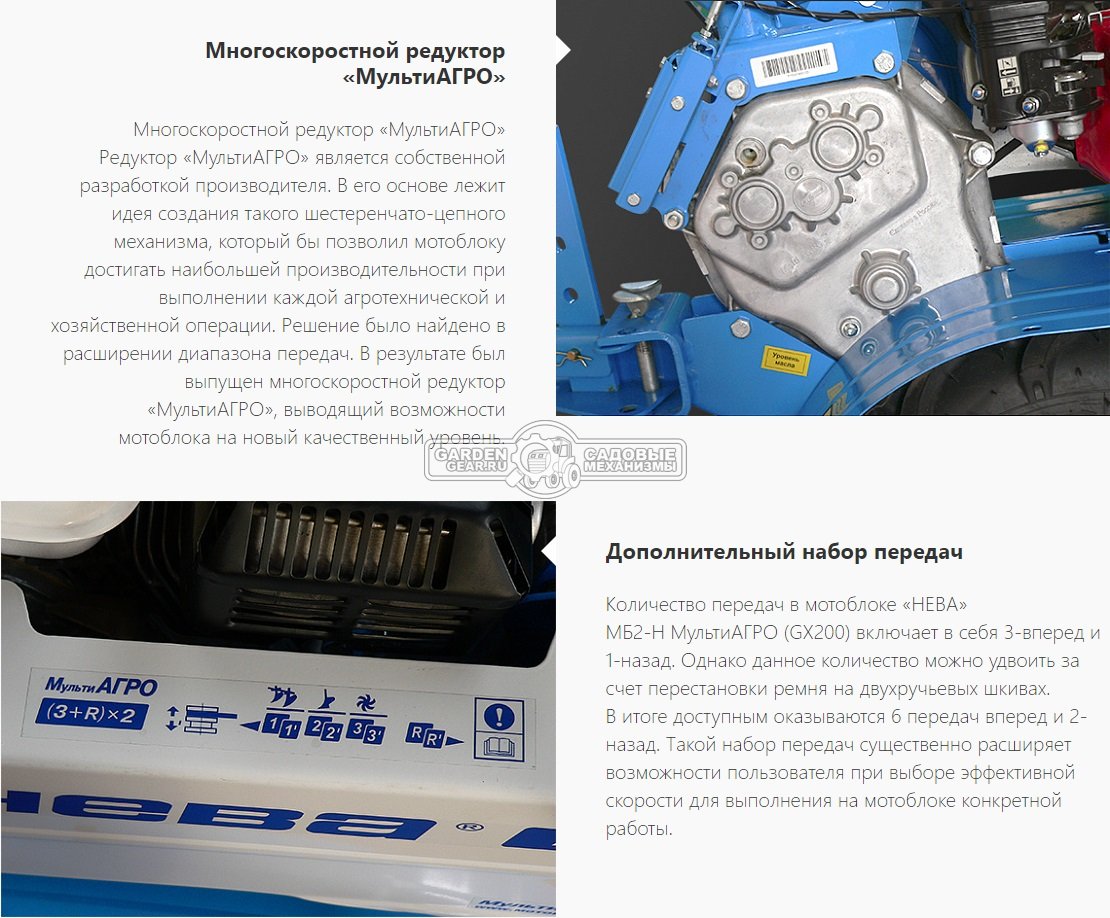

Unlike previous domestic differentials suitable for several models, these are part of the native French "Plowing Kit" (code 8000010205) for the Quatro Junior and QJ V2 models (Caiman, Pubert and MasterYard, including models with a diesel engine), which includes includes:

- differentials

- wheels 5.00-10

- weighting agents

- reversible plow

Quatro Junior with such a kit has a wide track and a weight of over 100 kg. In order to deploy it with locked wheels, you need to be either very strong or very stubborn. In any case, such a turn at the end of each furrow will take a lot of time and effort.

Being from motoblocks, approximately in the same weight category, I decided to wrestle with him. To do this, I rolled it out to an open area in the showroom.

Testing the capabilities of differentials on a walk-behind tractor

How to choose a walk-behind tractor?

Before purchasing the unit, you must focus on the complex of operations that the walk-behind tractor will have to perform. You should not buy the most expensive modifications of units that have a full set of functions in their arsenal. Not every model will be able to cope with the task at hand.

For example, in large areas with a dense soil composition, the best option would be to buy a heavy unit, while in a small dacha a light-class walk-behind tractor will be enough.

And also, when choosing, it is necessary to decide on the type of fuel on which the agricultural machine will work. Units with a gasoline engine are quieter, lightweight and easy to maintain. Diesel walk-behind tractors are noisier, but they take up with their high power. The downside of a diesel engine is its high price.

It should be borne in mind that additional attachments can often be provided by another manufacturer. In this case, an adapter is required to connect the implement to the purchased walk-behind tractor. This can lead to unit malfunction or work problems.

On the market today, the range of motoblocks is quite diverse. Models of such companies as Husqvarna, Profi, Hyundai are in great demand. In our country and neighboring countries such machines as "Belarus", "Neva", "Salyut-100" are presented. Of course, one should not discount the Chinese firms Forte and Wiema, because their products are also quite in demand.

If we compare foreign models with domestic counterparts, we can see that their cost is not always justified by the reliability and ease of use. In addition, imported models will require expensive consumables and experienced technicians to carry out maintenance. Both are very difficult to find.

Domestic firms are focused on ease of use, low cost. The decisive factor is the ability to repair the walk-behind tractor on your own.

Best Small Class Model

A light walk-behind tractor is a wonderful unit that will come to the aid of a summer resident or a merchant who owns a small plot. The versatility of the device is an absolute plus here, because with its help it will then be possible to perform many different operations.

Mobile K MKM-3 PRO MBK0018441 6.5 hp

Specifications:

Specifications:

- class: light;

- maximum processing width 105 cm;

- speeds: 2 forward, 1 back;

- engine: Loncin G200FA;

- reducer type: gear-chain;

- type of wheels: cast rubber;

- weight: 69 kg.

Despite the rather modest dimensions and weight, this device, manufactured in the city of Gagarin, is distinguished by considerable power, as well as a processing width of more than a meter.

With its help, you can not only weed the inter-row, plow the land, but also dig up potatoes, pump water or mow the grass.

There is also a possibility to attach a trailer. Cast wheels - on the one hand, it is less practical and adds weight, on the other hand, it allows you not to fiddle with tire pressure and selection of inner tubes. The gear-chain mechanism cannot be called cheap, but it is still cheaper than the gear mechanism. The reliability of the unit is characterized as high.

| pros | Minuses |

| Possibility of completing with different engines | Cast wheels |

| Versatility of use | High price |

| Reliable work |

Review

| Artyom Sokolovsky, 64 years old, Samara region: |

| I bought such a device for the farm. The plot is small, so I was initially looking for a light walk-behind tractor. This one is simply excellent: unlike Chinese cars, this is a full-fledged walk-behind tractor: a huge number of attachments can be connected to it, and, of course, I made a trailer. True, the price is considerable, but it justifies itself. |

Power distribution mechanisms

Cultivation and other work that is carried out using a walk-behind tractor should involve the movement of the unit in a straight line. The work of the machine is carried out due to the action of a rigid drive on 2 wheels, which simplifies the use of a walk-behind tractor. Frequent turns of the walk-behind tractor require significant efforts, since the wheel will brake with lugs. At the same time, it is very difficult to tilt the unit in the presence of a wide track of the walk-behind tractor and its sufficiently large weight.

A simpler and more constructive way to solve the problem that arises due to the rigid connection of the wheels involves the use of overrunning clutches. They allow the wheel to rotate at a faster rate than the axle driving it.

The use of overrunning clutches is also typical for the power drive of machines with connected axles. When turning, the wheel tends to rotate faster than the front shaft. As a result, this leads to the disconnection of the freewheel on the wheel running along the outer radius. On the one hand, entry into a turn should be facilitated, but the torque should be communicated to the wheel to a greater extent.

The solution to the problem is associated with the use of a classic gear differential, which distributes power in an inverse proportion to the resistance to rotation of the wheels. Under production conditions, the solution to this problem involves forced full or partial blocking off-road, otherwise the entire power of the unit is redistributed to the skidding wheel.

Why a differential for a walk-behind tractor

A walk-behind tractor with a differential often becomes the subject of hunting for a modern summer resident. Differentials are also called locking swivel extensions, which are necessary to reduce the turning radius, this allows you to increase the wheelbase, or rather, the width of the track and wheels. Thus, the walk-behind tractor becomes more maneuverable, overturning when cornering is excluded.

The differential is able to block one wheel, as a result, it is possible to achieve independent movement of the wheels, guaranteeing easy turning.A walk-behind tractor with a differential can be deployed without the use of physical effort, and this ability will not be affected by the presence or absence of attachments. If we rearrange the fixing bolt from the groove of the bushing to the cylindrical hole, then the differential can be used as a simple extension, which is necessary to increase the wheelbase.

Differentials are mounted on the equipment output shafts and are suitable for units with round output shafts with a diameter of 30 mm. Now that it has become clear what a walk-behind tractor with a differential is, you can consider some of the most popular models, their features and characteristics will be discussed below. After reading the reviews, you can make your choice.

Types

A walk-behind tractor is a kind of mini-tractor, sharpened for a variety of agricultural operations on relatively small areas of soil.

Its purpose is to perform arable work on small and medium-sized land plots, cultivate the land using a harrow, cultivator, cutter. Also, motoblock devices can handle planting of potatoes and beets, mow grass, transport goods (when using a trailer).

There are gasoline and diesel varieties of motoblock devices. For the most part, diesel units are more powerful than their gasoline counterparts. In the price category, gasoline-powered devices win - they are cheaper. But the choice largely depends on the size of the land plot and the frequency of use of this technique, because diesel is more affordable than gasoline.

Motoblock devices are available in two- and four-wheel configurations. Not all devices have a reverse-reverse function.

This is interesting: Multifunctional homemade products from a walk-behind tractor engine