Operating rules

Competent use of any device is the key to its durability and maintaining a high level of technical performance. Naturally, the tracked walk-behind tractor is no exception, so the owners of such equipment must take into account some important points.

- The optimal speed is in the range of 18-20 km / h.

- Take into account the load capacity of the platform. According to the current statistics, 200 kg models are in the greatest demand.

- The maximum allowable snow depth, limited by the location of the power plant, is also an important indicator. Modern modifications of the modules allow tracked walk-behind tractors to move in snow up to 50 cm deep.

- The maximum depth of liquid mud is 45-50 cm. As in the previous case, the determining factor is the engine height.

To maximize the life of the track assembly and the walk-behind tractor as a whole will allow compliance with several simple rules for operating equipment. Before and after each trip, it is strongly recommended that you:

carry out a thorough inspection of track chains and other elements of the module;

control the degree of tension;

check the quality of fastening of all parts;

pay great attention to the condition of the tracks.

Features and device

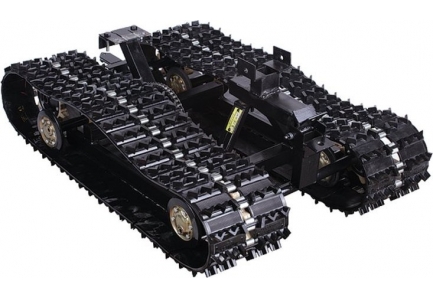

Tracks for a walk-behind tractor greatly simplify both the transportation of cargo and the movement of the device itself. Due to the fact that the caterpillar mechanism covers a fairly large surface, the walk-behind tractor moves much more evenly, exerts less pressure on the surface and does not get stuck on difficult soils. The tiller on tracks is able to work even in bad weather, and in good weather it becomes even more maneuverable.

The maintenance and use of the tracked module does not cause any particular difficulties for the owners, and it is not difficult to do it yourself. It should be borne in mind that when the walk-behind tractor is equipped with a tracked module, its speed decreases. However, the device's ability to navigate difficult terrain, transport cargo and even clear snow from the area is increasing.

Motoblocks with tracked modules otherwise completely coincide with conventional walk-behind tractors. The engine must be four-stroke with the ability to lock the axles so that the device can turn without making a whole circle. There is also a requirement for water cooling to cope with high loads that cause the motor to overheat. This type is more effective than air. The clutch system, gearbox and gearbox for tracked mechanisms are presented in the traditional version. The walk-behind tractor is controlled on tracks with a handle.

When creating tracks on your own, it is important to understand that if you design them too high, the center of gravity of the walk-behind tractor will change, and it will begin to experience difficulties turning, and even tilt to one side or another. To prevent such a situation, the second driven axle will have to be made longer by a couple of centimeters.

Also, with the help of the bushing, it will be possible to expand the wheelbase that already exists on the walk-behind tractor.

Other equipment equipped with tracks instead of wheels

If you look at it, then you can put any equipment on the tracks, regardless of its purpose. And if earlier only garage craftsmen, of whom there are a great many in Russia, were engaged in such "experiments", today you can see a similar factory-made technique.

Caterpillars are equipped not only with snowmobiles and swamp vehicles, but also with mini-tractors, which were not originally intended for these purposes. But of particular interest is the production cars delivered on the tracked course.

Crawler vehicle: buy or do it yourself

If we talk from the point of view of economy, then the independent production of tracks for a car is more acceptable. However, in this case, you should be prepared for the fact that you will have to often be repaired in the field. But there are also pluses - several breakdowns, and the garage master knows all the weak points, after which he strengthens them.

The factory version is more expensive. But here you can rely on the tests carried out. Although, as practice shows, such track blocks break at the most inopportune moment. We invite you to watch a video in which the "Niva" is installed on the tracks (though not with your own hands, but in the factory).

DIY snowmobile tracks

A priori, the snowmobile must be equipped with tracks - without this, it will not be able to move. However, the problem is that they can fail.

In this case, there are 3 options for the development of events.

- If you have the time and desire, it is quite possible to use a conveyor belt as a homemade caterpillar for a snowmobile. The main thing is to firmly sew the ends and reinforce the sides so as not to stay in some kind of snowdrift away from people when the connections are broken. In a winter forest, repairing a snowmobile track with your own hands, although possible, is problematic.

- Turn to the craftsmen, whom you can always find in garage cooperatives.

- Purchase new tracks from a specialist store. This option is good, but it can make a dent in the family budget.

These tracked snowmobiles are assembled by craftsmen.

These tracked snowmobiles are assembled by craftsmen.

Homemade mini-tractor on tracks: what to do with your own hands

The best mini-tractor is the modernization of the walk-behind tractor. If the owner does not want to put it on the caterpillar track on his own, or there is simply no time for this, it is quite possible to purchase the necessary components.

And after the tracks for the Neva walk-behind tractor or any other have been purchased, you can attach various attachments to it (plow, hiller, flat cutters). Prices for small tracks for walk-behind tractors are not too high, unlike long elements used in larger vehicles.

We offer you to see in the video review how the walk-behind tractor looks and works on tracks.

Homemade tracked all-terrain vehicle: do-it-yourself swamp vehicle

All-terrain vehicles-swamp vehicles are a different story altogether. For many hunters and fishermen, making an all-terrain vehicle from a walk-behind tractor ("Neva" or any other) remains the only way out today. Not everyone can afford the purchase of such equipment. In addition, a homemade unit is easier to repair on the road if you assembled it yourself by a screw.

We bring to your attention several photo examples of interesting homemade products from motoblocks and chainsaws, set on a caterpillar track.

Well, now - a bonus: several photos showing the height of the imagination of our craftsmen and examples of its implementation.

Well, now - a bonus: several photos showing the height of the imagination of our craftsmen and examples of its implementation.

1 out of 6

Advantages and features of a homemade snowmobile

The vehicle has a mechanical drive and a tracked walk-behind tractor, when driving on which, you will not get stuck in snowdrifts.

The steering comes from the skis, and the steering system is in front, so you can easily control it.

The price when buying a particular vehicle is important. Therefore, if you count, the cost of making a snowmobile yourself will be five times lower than buying it from the manufacturer. And it will come out even cheaper due to the available walk-behind tractor and other parts.

Reliability - where a person does not pass and a car does not pass, the snowmobile will overcome all obstacles with ease.

If the snowmobile is made by hand, then the designer approaches the choice of parts very carefully. By doing everything yourself, you are responsible for the quality of your design.

In addition, by paying great attention to the components of the mechanism, you make the snowmobile all-round.

How to make a caterpillar on a walk-behind tractor with your own hands

If you wish, you can independently modify your walk-behind tractor, turning it into a tracked all-terrain vehicle or a snowmobile. The main rule is to take into account what kind of work the tracks are intended for in order to choose the right material, because they must be not only durable, but also extremely light.

Having the materials at hand, having correctly calculated the length of the caterpillar, you can make it yourself using simple improvised means.

First of all, you need to equip your walk-behind tractor with an additional pair of wheels. For each side pair, the caterpillar track will be worn.

The length of each of the two goslings will be equal to the circumference of one wheel and the distance between the axles of each pair of wheels, multiplied by two.

The material for homemade products can be:

- conventional conveyor belt and bush-roller chain;

- car tires;

- belts and chains.

So, let's consider several options for making a goose yourself, depending on the material used.

From the conveyor belt

This method is the simplest, since it does not require a large number of special tools and auxiliary materials.

- When choosing a belt for a caterpillar, give preference to a strip with a thickness of at least 7 mm, because it has a fairly large load. Hitching with moving parts will be provided by a sleeve-roller chain.

- To give the tape strength and increase its operational life, it is recommended to sew along the edges of the tape with frequent stitches with a pitch of about 10 mm.

- It is also necessary to sew the tape along the ends in order to connect it into a ring of the required diameter, or use, for greater reliability, hinges resembling a piano canopy.

- Make sure that the additional wheelset that you install on the walk-behind tractor frame is the same diameter as the main wheels on the walk-behind tractor.

From the tire

It is enough just to make a durable reliable goose for a walk-behind tractor from a tire. The process of manufacturing from a car tire does not take too long, since it does not need to be stitched and lugs built up - the tire itself is a closed structure with a tread for traction.

The manufacturing process is divided into several stages:

- With a very sharp knife dipped in soapy water to enhance the cutting ability on rubber, cut a tape for the goose of the required width.

- The sides of the tire are cut off with a jigsaw with a fine-toothed file.

- The hard parts on the inside of the tire are also cut off with a knife or jigsaw.

However, here, too, there are several points that you should pay attention to:

- The tread pattern should be clearly expressed, since its reliefs are a kind of lugs that increase the adhesion of the moving mechanism to the surface.

- The length of such a track is limited by the diameter of the tire, therefore, before attaching an additional pair of wheels, this should be taken into account.

Of belts and chains

In order to make a tracked all-terrain vehicle from a walk-behind tractor, you can use ordinary belts with a wedge-shaped profile. The connection of the belts to each other is carried out by grousers attached to them on rivets or screws. This gives us a belt track.

To make a goose from chains (chain tracks), you need to take two pieces of the same chain of the desired length.

- The end links of both segments are expanded in order to connect them into two closed rings.

- The unclenched links are clamped again, and then welded for strength.

- Sections are cut from steel of the required thickness, which will serve as lugs.

- The lugs are bolted from both ends to the links of both closed chains, thus forming a relief track for the walk-behind tractor.

Additional Tips

Before you make a tracked drive for a walk-behind tractor, you need to make drawings, determine the dimensions. They do this so that in the case of a very high self-made caterpillar for a walk-behind tractor, it will be necessary to change the center of gravity of the walk-behind tractor. This will inevitably provoke problems when turning, as the technique will fall to the side. To avoid this, the second driven axle must be made longer.

On a note! You can increase the wheelbase of the motoblock unit. To do this, purchase a sleeve. It is placed on the main shaft.

In addition to the rules regarding the power of the engine, they also look at the cooling system:

- Air cooling is ineffective with significant overloads, which will damage the engine.

- It is correct to use water cooling, which has proven to be stable.

Attached attachments to the walk-behind tractor can seriously improve the data on the patency of equipment. Therefore, it is possible to diversify the range of operations carried out that a home-made apparatus can handle. To put it another way, the created base in some situations outperforms standard wheels. However, the alteration of motoblock equipment may not suit the owners of these technical devices. It is about the special requirements for the engine.

The motor fits with good traction. Homemade production is suitable for execution in a garage. That is why the garage-built unit is an excellent replacement for the tracked monoblock units on the market.

Algorithm for the execution of parts

There are several proven ways to make a caterpillar with your own hands. They have proven to be the most reliable.

Application of the conveyor belt

It is considered one of the simplest methods. In addition to the conveyor belt, a sleeve roller chain is required. The simplicity in this case lies in the fact that manufacturing does not require a large amount of auxiliary materials and tools. To extend the life of the conveyor belt in the device, you need to circle it around the edges with fishing line

In this case, it is important to ensure a step of 10 mm. To connect the tapes, in this case, a ring is necessary, you need to sew it along the ends or use hinges

Particular attention is paid to the thickness of the conveyor belt. The level of load on the unit directly depends on this.

Optimal will be the selection of a tape with a thickness of at least 7 mm. Among other things, you will have to take care of an additional wheel on each side.

You can remove it from the old car, but it is important that its diameter coincides with the same parameter for the wheel on the walk-behind tractor

Car tire use

For a walk-behind tractor, caterpillars are often taken from car tires. Craftsmen claim that the design has high reliability when the specified element is included in it. In order for the resulting walk-behind tractor to be practical, it is imperative to take care of the quality of car tires. They must have the correct tread pattern. In this regard, tires from large cars and tractors are preferable. The tread pattern is of key importance as it acts as a lug.

The manufacturing process can be roughly divided into several stages. Here they are:

- After finding suitable tires, a track for tracks is cut out of them. This is a laborious job that will take a long time.

- Use a well-sharpened knife for cutting. Better to take the one that shoemakers use. From time to time, it must be moistened in a soapy solution. This will make the rubber easier to cut.

- Both sidewalls are cut from the tires. To simplify the process, you can use a jigsaw with fine teeth for this.Remove excess fragments inside the tire, if necessary. If the track is too hard inside, this manipulation can be repeated.

The advantage of this method is that there is no need for a ring connection. The tire already has a closed structure.

Thanks to this, it is possible to improve the indicators of the reliability of the tracks, which is especially important in conditions of heavy loads. Yet such tracks are of a rather limited length.

It corresponds to a similar parameter for a car tire.

Of chains and belts

Track ATVs are often manufactured using conventional V-belts. They are connected between themselves by means of lugs. The belts are attached with screws or rivets.

An additional way is to use chains of the same size. This material is often found in large quantities in the garage of summer residents. The manufacturing process boils down to the following points:

- Take 2 chains of the same size. The last links are broken, after which they are combined into a closed ring. The links are pinched and welded.

- With lugs, they connect the chains to each other and provide reliable fastening. These fixtures can be made from plain steel plates of suitable thickness. They are connected by means of bolts.

If you don't want to make tracks yourself, you can take such products from old technology. For example, a walk-behind tractor on Buran tracks demonstrates good efficiency. It makes sense to use just the old parts, since the new Buranov tracks are quite expensive.

The principle of movement of tracked vehicles

For a tracked vehicle of any purpose, be it a tank or a snowmobile, the forward motion is provided by a tracked propulsion unit (DG).

It uses two motivating factors:

- torque Mk transmitted from the engine / power drive to the drive wheels;

- traction of tracks with the ground.

The caterpillar or caterpillar chain of the main engine is called a link structure, which is a solid continuous belt or chain.

The principle of the caterpillar track is illustrated by the kinematic diagram of the operation of the main engine, located below. The following positions are indicated on the diagram:

- pos. 1 - caterpillar;

- pos. 2 - supporting rollers, which prevent the sagging of the track belt;

- pos. 3 - drive sprocket (drive wheel), which converts the torque from the engine into the traction force required for the machine to move forward;

- pos. 4 - support rollers providing full contact of the track bed with the surface of the ground support;

- pos. 5 - shock absorbers;

- pos. 6 - a steering wheel, which serves to direct the forward motion of the machine, and transfers part of its weight to the ground.

The crawler movement is carried out as follows:

- The driving sprocket (pos. 3) is supplied with torque MK.

- The spinning sprocket rewinds the continuous belt / track chain (key 2).

- The caterpillar (pos. 2) is in close adhesion to the support surface (ground, loose soil, etc.). It is affected by:

- force Rz - reaction of the support surface, which the caterpillar transfers to the vehicle frame;

- weight load G;

- tangential reaction of the ground support Pk.

The rewound belt / track chain is continuously laid in the direction of the vehicle's forward motion on the ground surface of the track rollers, creating a path for the machine wheels with lower resistance to movement than on soft ground.

The specific pressure on the support (ground) along the length of the track is uneven - increased in the area of the driving sprockets, decreased in the front part in the area of the guide wheel (pos. 6). The maximum ground pressure from the main engine is in the area of the track rollers (pos. 4).

Caterpillar made of car tires

Homemade caterpillar made from car tires is the most common way to make attachments yourself. To do this, select tires, preferably from large trucks, taking into account also the shape and pattern of the tread. This will help to avoid interaction with mud, sand and snow in further operation.

For a tracked walk-behind tractor, you need to cut the tire so that the running belt itself remains, that is, get rid of the sides. To do this, you need a well-sharpened knife (mainly a boot knife is used).

Such work, of course, will take a lot of time and patience, since the process is quite painstaking. To make things easier for yourself, periodically lubricate the surface of the knife with soapy water. Next, you should process the wrong side of the tire by cutting off excess layers. In addition, you can design your own track grousers.

The advantage of this type of homemade track attachments is that the tire itself is initially a closed loop. This reduces the likelihood of rupture or damage during operation. The disadvantage is that the fixed width of the tire allows it to cover a fairly small ground surface. But it doesn't matter - the tires can be doubled or tripled at the discretion of the owner.

What can be made of?

When choosing a material for tracks, it is important to consider that it should not be excessively heavy. Since the walk-behind tractor itself does not have a powerful engine, it simply cannot cope with weighty material and, most likely, will break

The caterpillar mechanism, as a rule, is made of motorcycle tires, chains, pipes, belts, or a conveyor belt in combination with a bushing-roller chain.

Most craftsmen create tracks from tires - these parts are easily converted to the desired design. It is necessary to choose tires for large trucks, taking into account the existing tread pattern and shape, because the correct pattern will improve grip. It is better if these are spare parts that previously belonged to tractors or other large-sized models.

A properly selected tread will be in good contact with wet ground, ice-covered and snow-covered surfaces. In addition to materials for the tracks, to design a full-fledged device, you will need a walk-behind tractor with a gearbox, as well as a pair of additional wheels. If necessary, an additional cart is attached to the walk-behind tractor and, if desired, even on skids to transport goods through deep snow.

Homemade track links

You can also make your own homemade goose tracks from any suitable material. The main thing that needs to be taken into account is what kind of load you are going to give to your walk-behind tractor.

From plastic pipes

You can use pieces of plastic pipe as tracks on a goose for a snowmobile. To do this, cut the plastic water pipe # 40 into lengths equal to the width of the caterpillar. Use a circular saw to cut each piece lengthwise into two equal halves, or use a circular saw for wood.

The resulting tracks must be attached at regular intervals to the conveyor belt with furniture bolts No. 6 with large hemispherical caps.

From wooden blocks

Sometimes, if the load on the goose is not very large, you can use birch blocks as tracks. They are not particularly durable for heavy loads, but they are light, affordable, and a track with such tracks can be repaired at any convenient place.

Iron tracks

The most reliable are metal tracks made of high quality iron. For this purpose, metal pipes or profilecut into pieces of the desired length. A profile metal pipe is cut according to the same principle as a plastic one and is attached to a conveyor belt with bolts.

However, metal tracks, despite their noticeable strength, also have their drawbacks: they are heavy compared to plastic and wooden ones, and can bend during use. To straighten the track, you need to remove it from the goose, and this is a laborious operation.

When choosing the material from which the track links will be made for your mini-all-terrain vehicle, you should evaluate the degree of load and operating conditions. To overcome the snowy expanses on a homemade snowmobile, light plastic or wooden tracks are perfect, and for using a walk-behind tractor as a mini-tractor, it is still better to make a caterpillar with metal lugs.

Let's sum up

Despite the fact that some people prefer to purchase ready-made tracks or even units equipped with them, the manufacture of such elements in Russia will never cease to exist. After all, Mother Russia was famous for "Lefties" in all centuries. And the need to save money will only spur this trend, which is very encouraging.

The main thing here is to approach work with all responsibility and with the thought that it cannot be quit halfway. And then such work will be within the power of even a novice garage master.

And the beetle on the tracks looks good.

And the beetle on the tracks looks good.

There you can also express your opinion about what you have read, leave a review or share your personal experience in assembling a goose

Also, please do not forget to rate today's article - this is very important to us. And finally - another short video that you will definitely like

Previous Gardening TechniqueHow to properly wind the line around the trimmer: step-by-step guide and video instructions