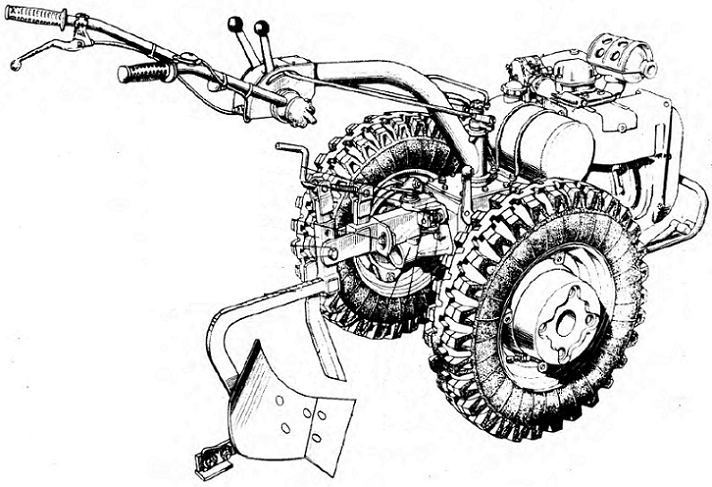

Setting up the MTZ walk-behind tractor

If you want to get maximum efficiency when working with an MTZ walk-behind tractor, then you need to configure it before starting work. It is most advisable to carry out the adjustment after idle time or long-term storage. Despite the fact that new walk-behind tractors are set up directly at the factory, after purchase, it is necessary to additionally inspect and check all systems and, in particular, the operation of the engine.

Motoblock MTZ-12

Motoblock MTZ-12

Motor tuning sequence:

- Adjust the fuel fluid as the control screws can move.

- Check the distance between the valves and make the recommended one. This allows you to control the amount of fuel fluid entering the carburetor.

- Using idle speed, adjust the carburetor. Then at minimum and maximum throttle.

- Set the pneumatic tires to the same atmospheric pressure. The recommended indicator is 2 atmospheres. If this is not done, then the unit will have an uneven run, it will be difficult to control and turn to the side.

The device of the MTZ walk-behind tractor

Motor-cultivators of this model began to be produced back in Soviet times, their main advantage is ease of operation and repair. Any summer resident is capable of dealing with such a device.

Engine

The first models of this brand were equipped with domestic UD-25 and UD-15 motors. However, over time, the device was improved and already for modern models of MTZ 05 motoblocks, Japanese Honda engines were produced. Their main difference from Soviet models is that the device is more reliable and has an increased service life.

The cost of such a unit has also changed over time, walk-behind tractors with Japanese engines were quite expensive, so it was decided to change the manufacturer, and now this equipment is equipped with a Chinese-made Lifan engine. The device is inferior in quality to Honda, but it has an affordable price.

Running in

If you have purchased a new unit, the first operating step is running it in. Such a procedure is carried out so that the new parts of the unit are adjusted to each other's work and begin to act in concert.

The running-in procedure must be carried out for at least 10 hours. To carry out the operation, the walk-behind tractor should work for the specified time with the engine on and light loads.

Do not forget about running in a new engine

Do not forget about running in a new engine

Clutch adjustment

Clutch is one of the most important components of an engine. Therefore, each owner of the MTZ 05 walk-behind tractor needs to know how to adjust the clutch correctly. There are two reasons why it can fail:

- If the cultivator is trying to crush with the lever fully depressed. In this case, the walk-behind tractor will lead to the side. The problem can be solved by tightening the adjusting screw.

- If, when the clutch is lowered, the walk-behind tractor does not deliver the required power. In this case, the screw, on the contrary, must be loosened.

Transmission

Many owners of walk-behind tractors complain about the characteristic sound that comes from the gearbox when the unit is operating. This is a clear sign of a problem with the transmission. The most popular reason is poor quality oil or insufficient quantity. For motor-cultivators of this company, it is better to use imported fluids, because only in this way you will protect yourself from problems with the gearbox.

If there is simply not enough oil, then it should be topped up. In order to avoid the latter case, it is necessary to regularly check the level of this fluid before starting the operation of the unit.

If there is a sufficient amount of oil and the noise continues, then the gears are the problem. The only way to solve the problem is to replace the part.

If the noise appeared due to problems with the transmission of the gearbox itself - switching them or jamming, then there may be several reasons, and in this case the repair cannot be postponed. The first step is to adjust the clutch. If everything is fine with the clutch, but the problem remains, then, perhaps, the gearbox parts are worn out, then they should be replaced.

Special features of the device

walk-behind tractor "Ray"

Motoblock MB 5040 "Luch", of course, is very far from ideal. Although, all modifications of this walk-behind tractor are far from it. Many details require modifications, such as a muffler, which its owners change over time to a quieter one - the noise during operation really interferes with the order.

Motoblock MB 5040 "Luch",

Some small, but very important parts are made of not the strongest materials - duralumin cranks can quickly fail and interrupt field work, which is completely dependent on the walk-behind tractor. But there are no less positive moments in the work of this technique.

Its low cost, thanks to which "Luch" and similar motoblocks Cayman, Texas, Foreman, Viking, Forza, Sadko outperform more expensive modern technology, immediately attracts attention. Made in accordance with GOST, these walk-behind tractors are as strong as steel, because, oddly enough, they are made of steel and are strong enough and of high quality - a small and not the most powerful MB 1, if necessary, can cope with a load weighing up to 900 kilograms

Made in accordance with GOST, these walk-behind tractors are as strong as steel, because, oddly enough, they are made of steel and are strong enough and of high quality - a small and not the most powerful MB 1, if necessary, can cope with a load weighing up to 900 kilograms.

For more information about the MB 1 walk-behind tractor, see the video:

The same applies to the cultivation of the land - no matter how "heavy" it is, he will cope with the task, although it will take time. But, getting to work, the Soviet walk-behind tractor requires adjustment and minimal maintenance, especially after a long period of inactivity. However, like any technique.

Features of using the Belarus MTZ-05 walk-behind tractor

Before starting operation, it is necessary to run in the engine so that the parts are worn in and the lubricant penetrates into all the necessary places. Motoblock MTZ-05 must be kept clean and regularly maintained. Lubrication of the walk-behind tractor is carried out according to the table given in the instructions.

You can read in detail the instructions for operating and repairing the engine here.

Engine

In the Belarus MTZ-05 walk-behind tractor, small-displacement engines UD-15, UD-25 and their modifications can be installed. Motors of this type are designed on the basis of the Zaporozhets MEMZ-966 model. UD-15 is a single-cylinder engine, and UD-25 is produced with two cylinders. Depending on the engine configuration produced, UD-15G, UD-25G, UD-25S may have different names.

On the walk-behind tractor, you can install Japanese Honda and Lifan engines, as well as Chinese Lianlong engines, which are excellent in terms of technical characteristics. The difference is characterized by the build quality and the number of hours that each motor has to run. The indicators from the Honda manufacturer are especially distinguished.

Gasoline with any octane number is suitable as a fuel, as long as it is clean and free of impurities. An SAE 30 seasonal oil is suitable as a lubricant. Alternatively, 5w30 or 10w30 are available. In winter, it is advisable to use a special synthetic oil of the 0w40 brand.

Adjustment of valves

It is also necessary to check the clearance between the valves regularly, so after a certain period the clearance may increase, and this leads to uneven operation of the engine and the occurrence of insufficient power. The optimal gap is considered to be from 0.1 to 0.15 mm.

In order to make the adjustment, you must adhere to the following steps:

- Disassemble the casing and remove the oil bath;

- Using a screwdriver, loosen the nut, then insert the blade and tighten;

- Focusing on the blade, slowly tighten the nut;

- Thus, the adjustment is made until the free movement of the valve is eliminated. Check the density;

- Put back the oil sump and cover.

Adjusting the valve clearance on the MTZ walk-behind tractor

Adjusting the valve clearance on the MTZ walk-behind tractor

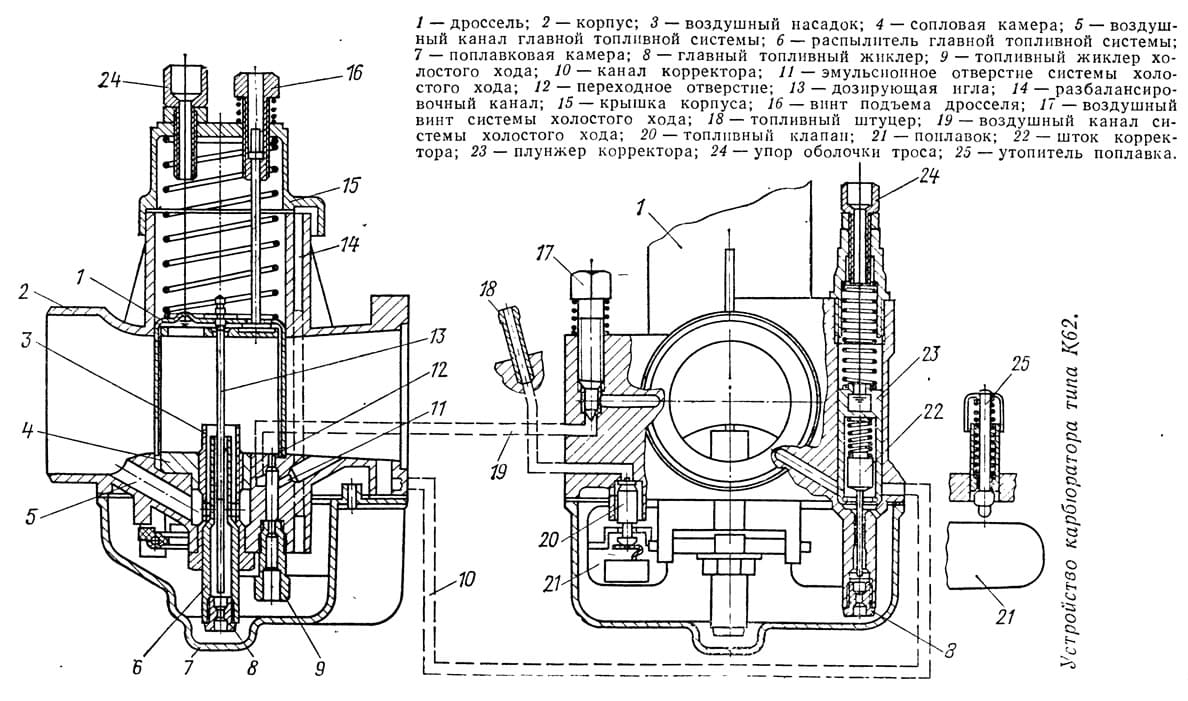

Carburetor adjustment

If the walk-behind tractor does not support the gained speed, then this indicates the need to perform control manipulations. Usually, adjustments are made before work at the beginning of the season. After a long downtime, the equipment needs careful maintenance, as well as after the unit has been used at maximum power for a long time. Pre-heat the engine and start adjusting the carburetor:

- Screw in the throttle and maximum throttle screws completely and then loosen one and a half turns.

- Start the engine and leave for 10 minutes.

- Set the power plant control lever to the minimum division. Make sure that the engine does not stall.

- At idle, adjust the operation with the throttle screw.

- Check the tightening of the screw, where, with excessive force, the mixture is enriched, and when loosening, the amount of air increases.

The idle screw allows you to adjust the maximum idle speed. Adjust the same at low speeds. The use of various options allows you to determine the angle at which the damper is closed.

Move the lever to the "gas" position. Observe the engine operation, if it is also unstable, then adjust the screw to the ideal state

But it is important to know that more revolutions should not exceed 2.5

Clutch

Particular attention is paid to the clutch, as it plays an important role in the operation of the engine. Setting up requires attention and patience

There are such malfunctions that require repair:

- The lever is fully squeezed out, and the walk-behind tractor makes attempts to make a movement. Try tightening the adjustment screw.

- If the lever is lowered and the walk-behind tractor slips, then adjust the degree of tightening of the adjusting screw.

Gearbox device

In order to avoid damage to the gearbox, it is necessary to monitor the quality of the oil being poured and replace it regularly. This is done in order to prevent gearbox jamming, which can occur due to poor quality lubricant. It is best to fill with gear lubricants.

Before each use of the walk-behind tractor, be sure to check the oil level. As a rule, a dipstick is used to measure the level, which is lowered dry into the tank. And after extraction, a decision is made on the need to top up.

Carburetor adjustment. | Topic author: Mitsue

In order to save the engine during the running-in period, the Chinese are reinsured.

Mikhail (Delman) how can a common man in the street make a jet with a lower flow rate?

Using (Ramakrisna) Mikhail, solder the old nozzle with tin and drill a smaller hole, or choose a suitable nozzle, which is more correct

Denis (Vishala) Article awesome))))

Denis (Vishala) Kostya, Bend or solder the valve foot.

Mikhail (Delman) Another observation: the main jet from the VAZ carburetor is ideal for KDshek carburetors. Tomorrow I'll go and ask about the sizes. I have a millimeter in diameter. Vprinsepe and it can be adjusted if the native is lost

Farid (Ratnamala) How many turns should the mixture adjustment screw be turned out before the first start?

Denis (Vishala) Farid, this is an idle screw.The mixture in this carburetor is adjusted by the position of the needle and the selection of the jet.

Farid (Ratnamala) Denis, I see, thanks!

Sergey (Volkert) how to understand 80 cube I bought or 50.

Alexey (Eckehard) Unscrew the candle from the cylinder, insert a straw into the hole and lower the piston to the lowest position. now take a 20 cc syringe and pour gasoline into the cylinder. You will be able to count the skok poured)) 49 or more is not 80 for sure, but about that)))

Denis (Vishala) Sergey, can I have a photo?

Denis (Vishala) Andriy, very good.

Marat (Aingeal) Alexey, I am plagued by vague doubts if I lower the piston to the lower position and pour gasoline into the cylinder with a syringe, whether gasoline will flow through the exhaust or intake ports of the cylinder into the exhaust pipe and into the engine. Picture 3 shows that the channels are open at the bottom of the piston

Alexey (Eckehard) Marat, Logically !! I didn't think about that))) So the windows can be drowned out, for example with plasticine. I need to conduct such a test at my place. The season will end then and I'll see.

Marat (Aingeal) Alexey, I think it's easier to find out the diameter and stroke of the piston after which I think it will be possible to calculate the volume of the cylinder.

Vladimir (Achelous) Sergey, Sorry for breaking in without asking, accidentally hitting a link. On the F80, the studs for attaching the cylinder are M8, on the 50-ke - M6.

Vladimir (Achelous) Alexey, Alexey, so you will fill in 200 cubes. Everything will flow through the windows into the crankcase, and then into the muffler!

Vladimir (Achelous) To optimize the KD carburetor, the first step is to lower the fuel level in the carburetor. To do this, it is enough to disassemble it, unscrew the inlet fitting, remove the gasket from under it, and carefully assemble it back. Without the gasket, the level will drop to (-10) - (-11) mm .. Solder the nozzle with acid with solder, and blow into it while the solder is melted. Excess solder will fly out, a hole will remain, which must be calibrated with a conventional sewing needle with a diameter of 0.65-0.67 mm, pushing it to the middle and pulling it back. Carefully remove excess solder from the widened part of the hole with a drill (MANUALLY!) So as not to damage the jet itself, i.e. calibrated part. The throughput of such a jet will be 72-76 ml / min. Full turns will appear.

Device

The Mole walk-behind tractor is a fairly typical design without the use of frills. This model of the walk-behind tractor began to be produced in 1983 in Moscow, but then the production of this unit expanded, so they began to be produced also in Omsk.

They were equipped with factory engines, the power of which did not exceed 2.6 hp. It is attached, like the gearbox, to the frame with ordinary bolts. The declared power was not always enough, so many owners of Krotov adapted to some alterations, changing the factory engine to more powerful models.

In general, the device of the Mole walk-behind tractor looks like this:

- Frame structure on which the combustion engine and gearbox are located.

- The control levers, on which the clutch are located, as well as the engine speed regulator.

- A wheelbase that allows the unit to move freely from place to place. During operation, these transport wheels are retracted.

- Rotary tillers that fit onto the gearbox output shafts.

For more details about the Mole walk-behind tractor, see the video:

As we can see, the design is very simple, which allows you to independently carry out repair work. And you may have to do this, because the factory engine does not always work in a stable mode.

The principle of operation of the Mole walk-behind tractor is as follows. The torque is transmitted to the gearbox, and then to its two outgoing shafts through the V-belt. When the clutch is pressed, the belt is tensioned, driving the gearbox shaft.

This gearbox shaft, on which the cutting elements (soil milling cutters) are located, rotates around its axis, cutting off the soil crust, at the same time crushing and mixing it. Similar translational movements are carried out by the movement of the walk-behind tractor along the surface of the earth.

The set includes four rotary tillers, which must be positioned in pairs, on each side of the shaft. By the way, it is possible to install six cutting elements at once, which improves the quality of soil cultivation.

Mole

The scope of this and other motoblocks, such as the Cayman, Patriot, Texas, Foreman, Crossser, Viking, Forza, can be significantly expanded if additional attachments are attached to it. It is attached to the unit through a special bracket located at the back of the walk-behind tractor.

Such equipment will have to be purchased separately, but thanks to it, an expanded scope of work opens up:

- transportation of goods of various weights;

- processing of inter-row spaces of beds;

- hilling and weeding of beds;

- making hay for livestock;

- planting and digging potato tubers;

- using a pump, you can water the beds, etc.

In other words, with the help of the Krot, Sadko, Don, Hooter, Profi, Plowman, Champion walk-behind tractor, you can carry out virtually the entire list of agricultural work. This circumstance makes him an indispensable assistant for a villager who uses his garden to the fullest.

Fuel supply problems

If attempts to start the walk-behind tractor were unsuccessful, this means that there are malfunctions in the engine or starting system. In order to determine the source of the breakdown, you first need to check the spark plugs.

If the spark plugs are dry, this means that the fuel mixture is not entering the engine cylinders. There may be several reasons for this:

- there is no fuel in the tank;

- the fuel supply valve is closed;

- the hole in the gas tank plug is clogged;

- foreign objects have entered the fuel supply system.

To fix problems with the fuel supply, you must:

- Fill the tank of the walk-behind tractor.

- Open the fuel cock.

- Clean the drain hole located in the fuel filler cap.

- Remove the fuel cock, drain the fuel tank and rinse it with clean gasoline. After that, remove the connecting hose on the side of the carburetor and blow it out together with the carburetor nozzles without disassembling the latter using the fuel pump.

Friendship Refinement 4

Many Western manufacturers of chainsaws produce tuning kits for their saws to increase power, and in service centers there is a separate price list with a list of possible modifications. It is mainly found in service centers of gasoline-powered tools in the USA and Germany.

It is possible to carry out modernization, replace components, in order to improve performance, it is also possible for saws of the Friendship family.

Examples of what can be done:

- Install turbocharged boost to increase the rate of flow of the fuel mixture;

- Install a more modern carburetor;

- Increase the compression of the fuel mixture;

- Put on an electric starter;

- Waste the internal combustion engine and put an enlarged piston;

- Install a decompression valve;

- Leave one piston ring to reduce cylinder stroke resistance.