What engine can be put on the Neva walk-behind tractor?

As practice shows, most often, power units manufactured by the brands Lifan, Robin-Subaru, Patriot and Honda are used to replace a failed standard engine. Among the main advantages of these engines, experts point out endurance, high wear resistance, the ability to work in the most difficult weather conditions and low fuel consumption. Below we will consider the features of the application of engines from each of the listed manufacturers in more detail.

Lifan

This popular brand has become popular for its overhead valve design, which makes them more balanced and reliable.

Another important advantage is the availability of a wide range of engine models, thanks to which the owners of Neva walk-behind tractors can choose an option with optimal technical characteristics.

Motors from the Lifan brand are capable of withstanding significant loads. The operation of each such engine is controlled by an efficient air cooling system. To start a cold Lifan engine, there is a manual fuel pump in its design, which allows the Neva walk-behind tractor to be used with such an engine in almost any weather.

Other advantages of the Lifan brand power units include:

- relatively low cost;

- modern high-tech device;

- versatility;

- availability on sale of all spare parts necessary for repair;

- the right center of gravity.

Each Lifan brand engine is quite easy to self-service. Provided that the correct proportion of the preparation of the fuel mixture is observed, such an engine will serve on the Neva walk-behind tractor for as long as possible, without the need to carry out repair work.

Subaru

The engines of the famous Subaru brand deserve high demand due to the mass of advantages, the availability of useful options for work and high build quality. The motors of this manufacturer were among the first to be installed on Neva walk-behind tractors and agricultural machines of other well-known brands.

The advantages of these motors include:

- durable body that does not lend itself to mechanical damage;

- the presence of special channels in the head and cylinder block prevents overheating of the oil during intense engine loads;

- reliable forged crankshaft and efficient multi-level air purification system;

- cast iron liners, which significantly increase the service life of each engine;

- the presence of an electronic ignition system;

- the use of the most modern technologies and high quality materials in the assembly of engines.

Motors of the Japanese brand Subaru are distinguished by modest fuel and oil consumption. A rigidly mounted crankshaft reduces engine noise. The enlarged reel of the starter is able to quickly overcome the resistance when starting the engine, which significantly speeds up the activation of the Neva walk-behind tractor.

Patriot

The engines of this well-known company are among the most popular engines that the owners of Neva walk-behind tractors choose to re-equip their equipment. Each Patriot motor has a compact size and light weight, which does not wave it to have high power and endurance.

Another important advantage is the high environmental friendliness of the Patriot motors. Engines of this brand are manufactured in compliance with all norms and standards for the amount and composition of emitted exhaust gases

Patriot engines are very easy to do-it-yourself installation. The presence in the kit of all the necessary valves and nozzles allows you to easily install the engine even for a person who has no experience in such events.

Honda

Power units of a well-known Japanese brand have a number of important advantages. They are durable, resistant to wear and tear, and are distinguished by modest fuel and oil consumption.

Among the other advantages of motors from the Honda brand should be highlighted:

- wide range of models, actual capacity from 1.2 to 12 liters. with.;

- the presence in the design of an effective lubrication system that works on the principle of splashing. This feature significantly increases the terms of application of engines on Neva walk-behind tractors;

- high reliability and efficiency of motors;

- the presence of an automatic decompressor in each Honda power unit, which allows the engine to start in all weather conditions.

Even under high loads, the Honda engine does not overheat, which was achieved thanks to the presence of an effective forced air cooling system in its device.

Features of operation

All Agat walk-behind tractors undergo a comprehensive pre-sale factory preparation and testing, therefore they are delivered almost completely assembled, filled with all oils and ready to work. The machines are distinguished by a reasonable, uncomplicated device, so their operation is not particularly difficult, even for beginners.

Compliance with the requirements of preventive and routine maintenance in accordance with the operating instructions can significantly extend the service life of the equipment.

The operating instructions for the Agat L-6.5 walk-behind tractor are here.

Service

Oil for the Agat walk-behind tractor engine is selected strictly in accordance with the operating instructions, depending on the brand of the motor. The gearbox requires TAD-17I or MS-20 oil. Motoblocks consume unleaded AI-92 gasoline. The size and profile of the V-belt: A-1120, 13 mm wide.

First launch, running-in

The first 25 hours of operation of the Agat walk-behind tractor are a running-in period - running-in and grinding in of the main units and mechanisms. The running-in procedure should be carried out in a gentle mode, avoiding high loads. Cultivation should be done gradually in 2-3 steps, starting from 10 cm in one pass. The throttle valve can be opened no more than 3/4 of its full stroke.

The work of the walk-behind tractor at idle speed is possible no more than 10 minutes. On heavy clay soil, the machine can work no more than 2 hours, then a break is needed. After running-in, the oil in the engine and transmission units of the unit is changed.

Major malfunctions, repair

Motoblocks Agat are distinguished by a simple rational design. Possible equipment malfunctions can often be triggered by operating errors. So, uneven rotation of cutters can be caused by sticking of damp earth or ingress of foreign objects into the work area. Also, belt slippage should be avoided.

In the event that the cutters stop rotating when the engine is running, it is necessary to check the clutch cable - it may break. Another reason: the V-belt has jumped off the pulley or has broken.

Motoblocks Forza (9 hp): operating experience

Inexpensive and multifunctional Chinese Forza walk-behind tractors of Perm assembly were generally accepted favorably by most of their buyers - villagers and summer residents. With a rather low quality of metal, these agricultural units nevertheless demonstrate good performance and reliability in seasonal use on small land plots. The hard and tedious work of seedbed preparation is done much easier and faster, without annoying breakdowns and downtime. The design is classic, time-tested and verified, the assembly is of high quality, versatility is high.

9-strong Forza motoblocks are easily aggregated with trailed and mounted agricultural equipment of various types. These are lugs, potato planters on lugs, cultivators of all types, potato diggers with a coupling, hillers and hillers, weeding machines, plows, harrows, carts, mowers. It is possible to equip them with adapters that raise the walk-behind tractor almost to the level of a mini-tractor. After all, with him there is no need to walk from behind and the muscle strength of the technician in the right direction, while experiencing a strong load on the lower back and back as a whole.

Motoblock Forza is equipped with a sufficiently strong steering rod that is resistant to mechanical stress and damage, carrying the controls. It is foldable for easy transport and has two different positioning options to facilitate the workflow. The tiller is equipped with a forward clutch stopper, supplemented with stretch marks for easy adjustment; protection from cutters knives (additional protective wings). Changing speeds is easily done with a toggle switch between the handles.

The operating experience clearly demonstrates that the Forza walk-behind tractors have full interchangeability of any parts and assemblies with the popular, common walk-behind tractors of the "Kaskad" and "Oka" brands. This refers to both gearbox parts (chain, shaft, sprockets) and clutch parts (belts, pulleys, levers). The frame and transmission have a high degree of versatility - it is possible, if necessary, to install absolutely any other single-cylinder engine for motoblocks here.

The volume of engine oil in the crankcase is 0.6 liters. The engine oil must be changed: the first time after 20 hours of operation, then after every 100 hours of the walk-behind tractor. The volume of the transmission oil sump is 1.7 liters. The oil recommended for this unit should be 80W90 viscosity. It is recommended to change the oil after every 100 hours of operation of the walk-behind tractor.

Motoblocks Forza are equipped with two types of air filters: a "wet" filter (in an oil bath) or a paper filter. In order to prevent abnormalities in the operation of the carburetor, it is necessary to regularly

clean the air filter. The filter paper should be cleaned every ten hours of the operating cycle and replaced every 50 hours of operation. Cleaning the "wet" air filter (changing the oil in the glass) must be carried out every 20 hours of operation. It is not worth starting the engine without an air filter: this will speed up the process of its wear at times.

On the network you can find a lot of statements and reviews of the owners of Forza motoblocks with a capacity of nine horsepower. All owners, without exception, note ease of operation, high-quality reinforced gearbox and low fuel consumption of the walk-behind tractor. Any of the presented models starts well, even in cold weather. With cheaper, belt ones, there are, of course, more problems, and they happen more often. So, according to the testimony of one of the users, for three seasons of operation, he changed the belts 4 or 5 times. The Forza walk-behind tractor is really easy and simple to aggregate with a full set of trailed (snow plow attachments, rotary mowers, dump carts) and mounted (lugs, plows, hillers, potato diggers, cutters) equipment - both from UralBenzoTech and from other brands of motor-blocks. Performs such a large amount of work that soon it becomes simply impossible to imagine your farm without him.

Motoblocks Cascade with Lifan engine

The most expensive part of a walk-behind tractor is the engine. And if you look at MB61-22, then it has a Honda GX-22 engine. It has excellent characteristics and a long service life. However, its price tag is high.

Recently, the Chinese company Lifan entered the market. It offers engines identical to Honda's, but at a much lower cost.

Many do not trust the Chinese manufacturer.However, Lifan engines quickly gained confidence and are now in great demand.

All characteristics of this model are identical to MB61-22. At the same time, the price of Cascade walk-behind tractors with a Lifan engine starts at 33 thousand rubles. And this is 8 thousand less. And it makes many owners think about the advisability of overpaying.

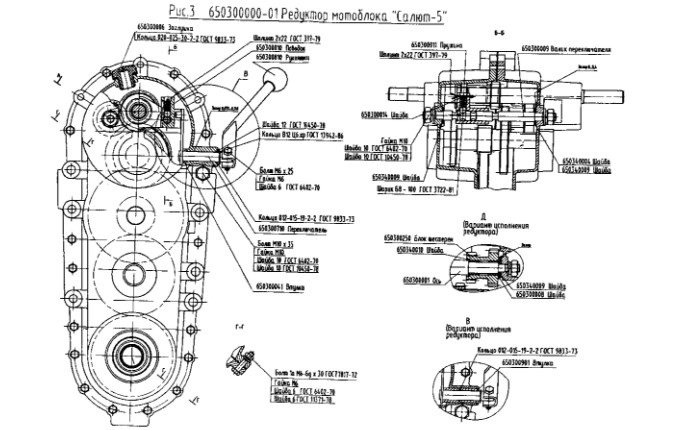

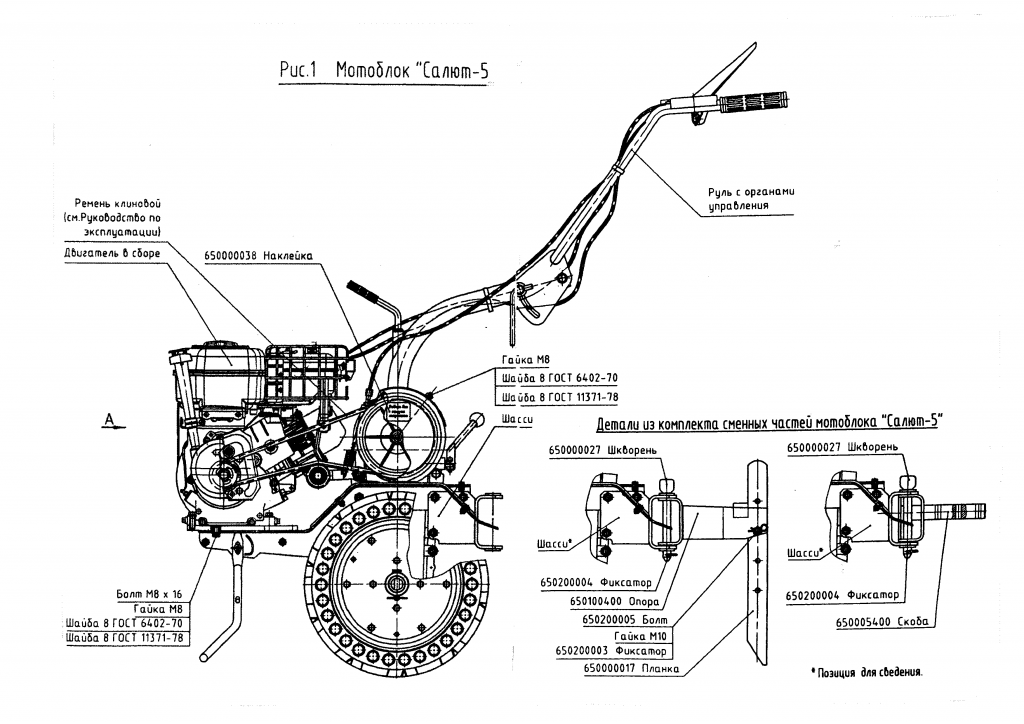

Analogs of this model include Luch, Caliber MK-6 Lifan and Salyut-5.

Advantages and disadvantages

The Japanese brand under the world-famous name Honda takes a special approach to the design and creation of all the equipment it produces. Before starting the production of its own cultivators, the company had to conduct a sufficient volumetric study of the characteristics of the soil in various parts of our planet. Therefore, the cultivator of this company is ideal for gardening lovers from different countries.

The quality and reliability of Honda motor cultivators have been tested by more than one generation of users.

Their main advantages include the following characteristics:

- a high-power motor, which at the same time works almost absolutely silently;

- simplicity in starting the motor: you just need to pull the handle - and the cultivator is ready to work;

- high stability of equipment, the ability to maneuver without making a lot of effort;

- the set contains additional accessories, using which you can change the operating mode of the cultivator from weeding to hilling, from hilling to haymaking, etc.

- high build quality;

- durable parts;

- Convenience during transportation: the cultivator is quite light and small in size, so it is easy to transport it to the dacha and back;

- due to its compactness, it does not require a lot of storage space;

- gasoline engine type - the power and capabilities of such a machine are much higher than that of its electronic counterparts.

Among the disadvantages of Honda cultivators, one can single out only their rather high cost and inefficiency. In addition to the fact that you will have to pay quite an impressive amount of money for the equipment itself, then you will also have to invest a lot in its maintenance and service.

However, according to reviews for this type of technology, over time, the costs will pay off.

Useful experience of owners of MB2 walk-behind tractors - what do they write about the reviews?

What feedback did the Neva MB2 model get from its owners? We study the opinions of members of the forum who have already purchased any of the modifications.

“I bought myself a Neva with a 7-horse Subarov engine. He is now a year old, but I am satisfied with the device. It starts up well, after all, the Japanese engine makes itself felt, but the gearbox buzzes strongly, especially if high revs are given. Cons: inconvenient belt adjustment. Confused by the fact that the engine is supported by four bolts, one of which is not easy to get to. The belt was spinning, so I moved the tension cable farther from the axis. No questions about work! It works properly, those who write that "the walk-behind tractor is jumping" are doing something wrong. Even without weights, it works fine for me, it floats straight. "

“A wonderful walk-behind tractor, mine is already 12 years old - and everything is plowing. I changed the engine last year, but the old one, which is most important, works, it just eats a lot of oil. So I replaced it. I put an ordinary Chinese engine, but what I want to say: good technology is immediately visible. From the very beginning of operation, I did not like the fact that the belt wore out quickly. But this is a consumable, so I have no complaints about the car itself. "

How to choose a walk-behind tractor?

The name of this type of technique speaks for itself. The mechanized unit operates on the basis of an engine that can be gasoline or diesel. The gearbox shaft is supplemented by a right and left motor - attachments are attached to it, which is responsible for expanding the functionality of the device.

Wheels with powerful tires are responsible for the movement of the walk-behind tractor. The accumulated dirt is independently cleared from the wheels while moving on the ground, provided that they are correctly installed based on the direction of their rotation.You can find out how to install the wheels from the instructions for the walk-behind tractor.

A special lever is provided to adjust the lift height and steering angle. A non-separable self-charging battery acts as a battery.

Engine

Between gasoline, electric and diesel engine types, most choose diesel. The choice of 9 liter gasoline motoblocks is often due to the desire to save money on the purchase, because gasoline models are cheaper. However, diesel technology has a number of undeniable advantages:

- The efficiency of her work is higher;

- during the operation of such a device, there is a much lower fuel consumption than gasoline counterparts, so it is safe to say that when purchasing a diesel device, after a short period of time, you will save more than if you buy a 9 liter walk-behind tractor;

- durability: more wear-resistant and reliable parts are used for the diesel engine;

- ideal adaptability for plowing, cultivation and hilling, thanks to the ability to operate at low speeds due to the high tractive effort;

- ease of use: the absence of a carburetor eliminates the need for constant adjustment of the equipment;

- the presence of air or water cooling.

The main parameter when choosing is the power indicator, since the price of the engine for the walk-behind tractor directly depends on it, and the power also affects the efficiency of the equipment.

With belts or gear

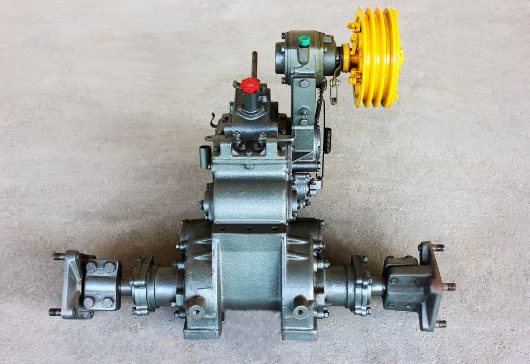

The gearbox is designed to change the angular speed when transferring rotation from the driven pulley to the wheels.

When choosing a motor-cultivator, after evaluating the required power, weight, productivity and design, it is customary to pay attention to the gearbox of the drive of the working mechanisms. This sequence seems illogical to some experienced summer residents and gardeners.

After all, the gearbox is the most vulnerable place of a motor-cultivator and therefore it is extremely important that it be reliable, convenient, productive, repairable with the least material and time costs, and, if a complete replacement is necessary, it should be generally inexpensive

Three types of gearboxes are installed on motor-cultivators: worm gear, chain and gear. Traditionally, worm gearboxes are equipped with lighter and lower-power models, chain ones are heavier and more powerful and gear, respectively, the most powerful. But there are also many exceptions to these rules. Manufacturers are constantly experimenting, systematizing operating experience and meeting customers halfway.

The most popular among users can be safely called a chain reducer. Its advantages include:

- simplicity;

- reliability;

- the ability to reverse (reverse the device).

Most often, chain reducers are made collapsible, which allows you to visually diagnose the condition of the chains and gears, as well as regularly lubricate them. The most common chain reducer breakdowns are: chain stretching or breaking, shearing of gear teeth or drive shaft keys.

Chain or gear

A gearbox is a unit that transmits torque in a box. The type of gearbox affects the durability of the unit, the noise level during operation, and the smoothness of the speed configuration. That, this is a principle knot.

Reducers on walk-behind tractors and motor-cultivators are:

- Worm gearbox Widespread on single-stage gearboxes, which are equipped with light cultivators. The worm gear is low-noise, features smooth operation and low noise level, and the highest efficiency. The defect is fragility.

- Chain reducer Suitable for light and medium tillers and medium / heavy tillers. There is a driving sprocket on the motor axis, and a driven sprocket on the working shaft. They are connected by a chain. By changing the gear ratio, the force on the working equipment is changed, for this reason, of course, to select the force required for each job. You will like the chain reducer more collapsible and non-collapsible. In a collapsible one, you can replace worn parts (asterisks). Unbreakable is replaced completely.The lack of a chain reducer is the noise level.

The chain reducer is echoing, but simply repaired. The gear reducer is the most reliable.

Price

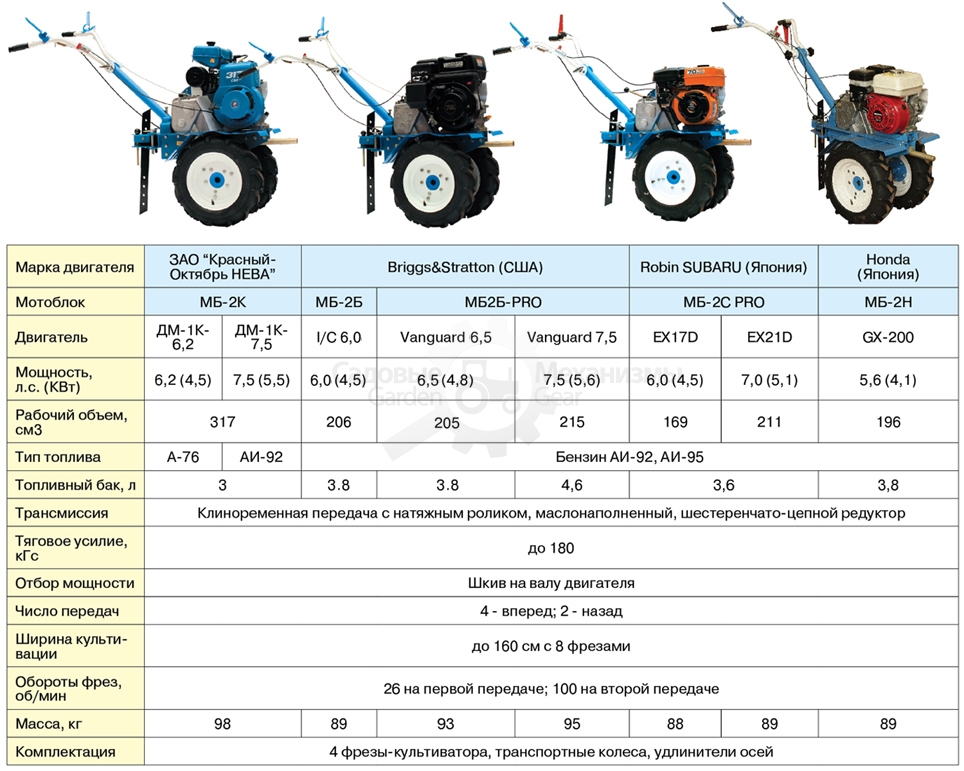

Although the company has released an updated model of the Salyut-100 walk-behind tractor, some modifications of the "old" Salyut-5 can be bought both from the manufacturer (a specialized store at the plant in Moscow) and from dealers. The average price for a new cultivator depends on the installed engine and its power:

- Lifan - 27,200 rubles.

- B&S I / C 6,0 - 5,700 rubles.

- B&S Vanguard 6,5 - 39,400 rubles.

- Honda - 36-38 thousand rubles.

- Subaru - 35,900 rubles.

Of the used options, used Salyut-5 walk-behind tractors with a Lifan engine are most often found, the cost of an average of 23,700 without a hitch. Attachments increase the price by 5-10 thousand, trailers or trolleys - even more.

With other engines "bu" Salyut-5, on average, you can buy at the following price list:

- Kadvi DM-01 - 22 thousand rubles.

- B&S I / C 6.5 - 27.5 thousand rubles.

- B&S Intek I / C 5.5 - 37 thousand rubles.

If you search for offers in different sources and track new ones, not relying only on the current ones, you can find cheaper options.

Motoblock Kipor 610

The KDT-610L agricultural machine is popular and competes in the class of similar equipment from other manufacturers:

- The working shaft of the walk-behind tractor has a hexagonal shape. The Chinese manufacturer has foreseen the occurrence of various situations and provided the possibility of installing a special semiaxis on the shaft. Thanks to this design solution, the owner of the walk-behind tractor was able to change the wheel track width. This solution will be very useful for cultivating land with different row widths. Using universal axle shafts, the wheels are set in the most convenient way at the moment. This elementary solution has saved a lot of time required to cultivate the land on which various crops are planted.

- The experienced owner will appreciate the reliable KDT-610L actuator. The Chinese manufacturer has moved away from the usual kinematic scheme of the walk-behind tractor. A three-strand pulley and, accordingly, three belts are installed here, which made it possible, in addition to power, to add solid reliability to the walk-behind tractor. An important positive point is the installation by the manufacturer of a splined shaft instead of a pulley.

- It is also worth noting the ergonomic control of the walk-behind tractor during operation. Devices that control work and movement are within easy reach of the operator. This condition made it possible to make the work on the walk-behind tractor as comfortable as possible.

- Attachments for Kipor walk-behind tractors are presented quite widely. All of it has a successful design, predetermined by correct engineering solutions. For example, removable wheels can be replaced with wheels with special grousers or with a rotary cutter. It is a device capable of digging up the ground, without hanging additional devices. Also, in addition to widespread devices, you can find really unique ones, for example, a rotary mower.

Motoblocks Kipor have the ability to significantly facilitate work both on a personal plot and on fairly large areas. The owner of the walk-behind tractor will spend much less effort with an excellent result. Considering the availability of accessories and attachments, this puts Kipor much higher than its competitors.

Model range of motoblocks

T-400

The Carver T-400 motor-cultivator is a light, small unit weighing 29 kg, equipped with a 4-stroke 4 hp engine.

It has no gearbox, the torque is transmitted through the belt to the worm gear.

The clutch is set by adjusting the degree of belt tension.

The crankshaft is located vertically, which simplifies the design of the walk-behind tractor and reduces the cost of its production. Ideal for cultivation, plowing and other works in small areas.

The motor-cultivator is designed for processing the surface layer of the soil (soil), on small land plots using cutters. Not intended for use with a cart

Specifications

| Engine model | 168FB-2 (4-stroke petrol), OHV |

| Engine displacement, (see cubic) | 196 |

| Maximum power, hp, (kW) / rpm | 4,0 (3,0)/3600 |

| Capture width | 380 mm |

| Tillage depth | 220 mm |

| Speed | 1 forward, neutral |

| Clutch | Belt |

| The weight | 28 kg |

MT-650M

The Carver MT-650 walk-behind tractor has a compact size and simple design, and is also efficient in operation. It is completed with a 4-stroke engine with an operating power of 6.5 hp. and a volume of 196 cm3, using gasoline as fuel.

It can be used for mowing grass, as a snow blower, as well as for processing soil of various densities.

It has 2 forward gears and a reverse, which increases its maneuverability.

The air oil filter is excellent at handling dusty air.

The model is equipped with 4.00-8 wheels, which provide improved cross-country ability. The gear reducer easily transfers the torque from the motor to the wheels.

The unit weighs 105 kg, can handle a row 80-120 cm wide, as well as go deep into the soil up to 35 cm.

The walk-behind tractor is designed for soil cultivation, mowing grass, snow removal (with the help of an additional snow blower attachment) in small and medium-sized areas, as well as for carrying out a transport function.

Specifications

| Engine model | ZONGSHEN XP140A (4-stroke petrol), OHV |

| Engine displacement, (see cubic) | 196 |

| Power at 3600 rpm | 4.8 kW / 6.5 HP |

| Fuel tank volume, l | 4,8 |

| Capture width | 800-1200 mm |

| Tillage depth | 100-350 mm |

| Speed | 2 forward, neutral, 1 back |

| Clutch | Belt |

| The weight | 97 kg |

MTL-650

The Carver MTL-650 motoblock weighs 91 kg, which allows it to be used for cultivating the soil without weighting agents.

Equipped with a 6.5 hp 4-stroke petrol engine, with a working volume of 196 cc.

Due to the presence of rotary tillers, the unit can plow the ground to a depth of 20 cm, be used as a snow blower or transport goods using a trailer.

The device has 2 gears forward and one reverse, which significantly increases maneuverability.

Wheels on tubeless tires measuring 4.00-8 do not get stuck on wet ground, and a capacious 4.8-liter gas tank makes it possible to work for about 5 hours without refueling.

The processing width of the row can vary from 50 to 100 cm. The unit is equipped with an air-oil filter, which increases the resource of the motor, and also has a transport wheel for ease of movement.

Specifications

| Engine model | 168FB-2 (4-stroke petrol), OHV |

| Engine displacement, (see cubic) | 196 |

| Maximum power, hp, (kW) / rpm | 4.8 kW / 6.5 HP |

| Fuel tank volume, l | 4,8 |

| Capture width | 500-1000 mm |

| Tillage depth | 150-250 mm |

| Speed | 2 forward, neutral, 1 back |

| Clutch | Belt |

| The weight | 83 kg |

MT-900

The CARVER MT-900 walk-behind tractor is a professional model, as it is equipped with a 9 hp engine.

The significant weight of 141 kg allows it to be used without weights, and the large pneumatic wheels will easily overcome off-road conditions.

The unit is equipped with a reverse and two forward gears, thanks to which improved maneuverability is achieved.

Although it should be noted that with such large dimensions as the MT-900, it is difficult to achieve effective maneuvering.

The plowing width varies according to the amount of tillers used. The launch is carried out in manual mode, but additional efforts on the part of the operator are not required.

Equipped with a power take-off shaft allows you to connect additional equipment.

Specifications

| Engine model | 177F (4-stroke petrol), OHV |

| Engine displacement, (see cubic) | 270 |

| Power at 3600 rpm | 6.5 kW / 9.0 HP |

| Fuel tank volume, l | 6.0 |

| Capture width | 800-1200 mm |

| Tillage depth | up to 350 mm |

| Speed | 2 forward, neutral, 1 back |

| Clutch | Gears |

| The weight | 83 kg |