Ural with the UMZ-5V engine

The engine of the Ural UMZ-5V walk-behind tractor is a 4-stroke 1-cylinder petrol unit with a volume of 475 cm³. The motor was originally designed for use on self-propelled agricultural machinery and stationary installations. The power unit develops a power of 4.5 liters. with. at 2000 rpm. The plant allows for a short-term increase in power up to 5 liters. with. by increasing the speed.

The engine is equipped with an air cooling system. A fan is used to cool the engine and blows air into a shroud around the cylinder and head. When operating a walk-behind tractor, it is required to regularly inspect and clean the cooling fins from dust and oil. Accumulated dust impairs heat transfer and causes local overheating, which leads to increased engine wear.

The motor is equipped with an automatic speed controller. For this, a centrifugal mechanism is used, which does not allow a rotational speed of more than 2350 rpm. When the speed is exceeded, the throttle valve is displaced, which leads to a drop in the speed. The engine manufacturer prohibits self-adjusting the speed limiter and its use for speed control.

The gas distribution system consists of 2 bottom valves. Because of this, the motor has a low compression ratio of 6 units. The engine uses automobile gasoline A-76 (A-80) as fuel. The fuel supply is located in a tank located above the engine carburetor, the fluid supply is gravity. The fuel supply in the tank is 6 liters, which provides an operating time of up to 4-4.5 hours. The operating time depends on the condition of the engine and the nature of the tasks being performed.

The engine of the Ural walk-behind tractor is equipped with a 2-speed gearbox with crawler gears. The first speed reduces the rotational speed by 6 times and is used to perform work with a high coefficient of resistance (for example, plowing virgin soil). The second speed reduces the revolutions by 2.91 times and is used to operate the product with a trailer or when plowing soft soil. Switching the speeds of the UMB-K Ural walk-behind tractor according to the instructions is performed on the idle engine.

The engine is started by a cord that is wound around the flywheel. Before starting, it is required to set the crankshaft to the end of compression position. The engine can be started in 1 or 2 gears of the geared motor.

The output shaft of the engine is equipped with a 2-strand pulley designed to transmit torque to the auxiliary gearbox and to drive the attachment. On the fan side, there is a second pulley used to drive attachments that require an increased speed of rotation of the working parts. The clutch mechanism consists of belts and tension rollers.

In the transmission crankcase of a walk-behind tractor with an UMZ-5V engine, according to the repair instructions, transmission oil in the amount of 1.5 liters is filled. The filling of the substance is carried out through a hole closed with a plastic stopper.

The standard set of attachments for the walk-behind tractor included a cultivator. For the transportation of goods weighing up to 350 kg, a 2-wheel TOP-350 / 350M trolley was used. When using a single-body plow, an adapter is required to be attached to the frame. The use of the plow is allowed in conjunction with metal wheels equipped with grousers. A mounted potato digger is used in conjunction with the plow.

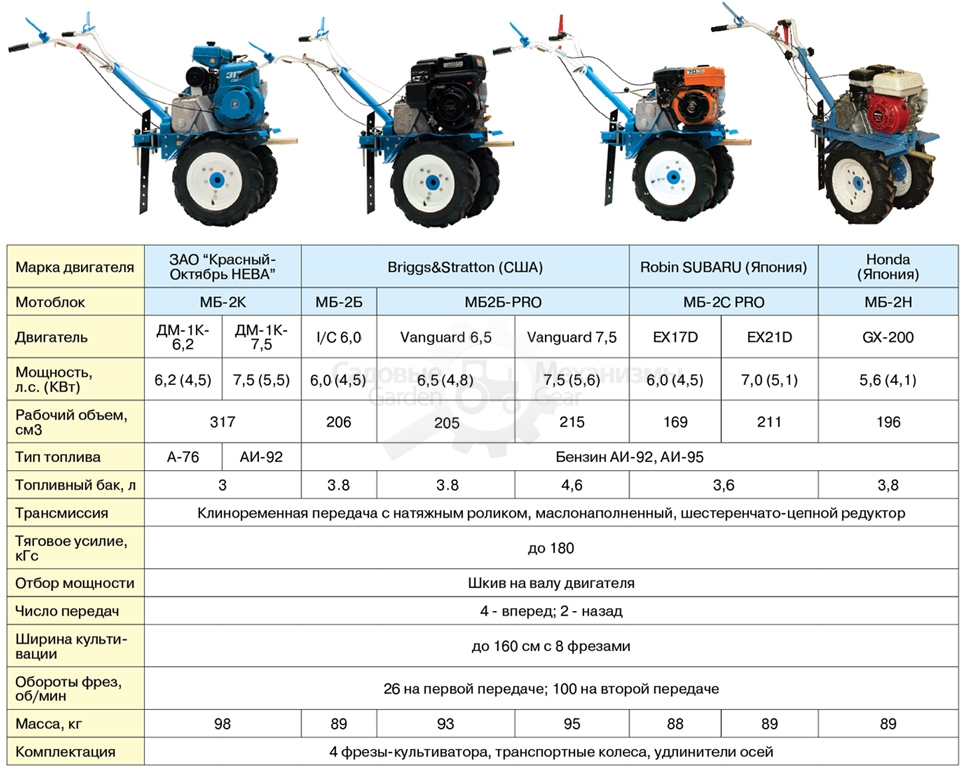

Models

"NEVA MB2 MultiAGRO"

This is a new model that can rightfully be called one of the most successful.The unit stands out from the line for its rich functionality, as well as a good Briggs & Stratton engine, which belongs to a separate Vanguard series. Complemented by an excellent gearbox with original characteristics.

The engine resource is designed for five thousand hours, which is a record among power plants of this class. The walk-behind tractor has two forward gears, one is reverse. The traction force is about 142 N, which makes it possible to work on virgin soil and transport heavy loads.

Set:

- walk-behind tractor "Neva MB-2B-6.5" 1 pc .;

- cutters 4 pcs.;

- wheels (4.6x10) 2 pcs .;

- axle attachments 2 pcs.

"NEVA MB2 B"

6.5 l. with. suitable for a wide variety of jobs. Such a unit is indispensable in subsidiary utilities. This walk-behind tractor is equipped with a four-stroke Vanguard engine, which has a number of original improvements:

- more modern carburetor layout;

- the reducer has several additional stages;

- there are big wheels.

"Neva MB-2N GX200"

It makes it possible to cultivate the soil and clean streets and squares. The power of the unit is enough to cultivate virgin lands.

The petrol engine from the Honda company has a cast iron body, the power is 4.2 kW. The machine is distinguished by increased traction parameters.

"Neva MB2 GX-200"

It cannot rightfully be called a heavy unit. Maneuverability, cross-country ability and power are noticeably higher than average.

The unit is distinguished by its unpretentiousness and high performance. Maneuverability is achieved by locking the wheel. You can put eight cutters, the track width can be up to 172 cm. Can be combined with any attachments.

Specifications:

- the weight of the device is just over one hundred kilograms;

- the fuel tank holds up to 3.2 liters of gasoline (92 or 95);

- there are two gears;

- you can cultivate the soil at a depth of 21 cm;

- shaft turnover in first gear 22-43;

- shaft turnover in the second gear 88-161;

- the gearbox is enclosed in an aluminum housing.

"Neva MB 2S-7,5PRO"

Another popular motoblock model. The machine is distinguished by its ability to work in any weather and temperature. The reducer has a chain and gears, in which there is a double-grooved pulley. The device is very maneuverable, the wheels in it work autonomously. There is a function to turn off one of the wheels. The land can be cultivated with eight cutters, working width 171 cm.

The technique is capable of performing almost any job, characteristics and types of work:

- cleaning the territory;

- transportation;

- harvesting root crops;

- mowing;

- with the Subaru engine;

- the amount of fuel in the container is 3.5 liters;

- total weight 101 kg;

- aluminum body;

- the width of the cultivated soil is 171 cm;

- processing depth 21 cm;

- shaft revolutions 22-43 (1st gear) 88-161 (2nd gear).

"Neva MB 2S-6,5PRO"

This is a classic unit that has proven itself from the very best side. "MB 2S-6.5PRO" is versatile, it can work with any soil. The power is 4.7 kW (6.4 hp). It is possible to put up to eight cutters, the width of the cultivated soil strip can reach 172 cm. It is distinguished by high maneuverability even under high loads.

Main characteristics:

- suitable for transportation;

- processing of all types of soil;

- communal works;

- horse power 6.1 (4.5);

- the tank holds 3.5 liters of gasoline;

- the device weighs about a centner;

- gears are two forward and one is rear;

- gasoline 92 and 95.

"Neva MB 2B-6.5 RS"

This walk-behind tractor is supplied with a gasoline engine from Briggs & Stratton of the I / C series. This is one of the best units that can successfully cope with the most difficult tasks, performing almost any type of agricultural work, soils can be different. Designed for processing medium to large areas. Additionally, the walk-behind tractor has an electric starter and headlights. Differs in increased performance, the engine is 6.21 liters. with. (4.5 kW).

The unit is distinguished by good functionality, reliability, the mechanism can withstand heavy loads.

Main advantages:

- you can work in different gears, the pulley is simply redirected to the second cell;

- there are unblockers, they are provided with a maneuverability mechanism;

- there is a light source that allows you to work at night;

- fuel capacity 3.9 liters;

- weight 98.5 kg;

- two gears - front, one back;

- engine displacement 204 cc cm;

- fuel - gasoline 92 and 95;

- the width of the cultivated strip is 85-128 cm;

- the number of shaft revolutions 22-43 and 88-162;

- immersion in the ground up to 21 cm.

Can be used with:

- public works;

- harvesting;

- transportation of goods;

- irrigation.

How to set the ideal settings yourself

To work, you will need the usual set of tools that are found in almost every garage. To eliminate fuel overflows, you need to correctly set the float in the chamber. This operation can be done using a special template. Experts recommend not using this template, since the number and thickness of the gaskets in the carburetors does not always match. Fans of various improvements often change the factory gaskets for better ones. It happens that the factory setting of the template does not suit everyone. Although the Solex carburettors are the same, the fuel pump can deliver gas in different ways. A lot also depends on whether the return is muffled, so the specialists use a different method.

Checking algorithm:

- The adjusting screw of the mixture quality is tightened by hand to the end;

- Next, unscrew it back five turns;

- We turn on the motor, remove the suction and, with the screw of the amount of the mixture, bring the engine speed to 750 rpm;

- Turning the quality screw, we bring the engine speed to the maximum;

- Using the amount screw, reduce the RPM to 800 rpm;

- Tighten the quality screw a little until instability appears;

- Unscrew the same screw back one turn;

- We turn the number screw until the idle speed reaches 800 rpm (in winter they can be raised to 900).

It is worth remembering that adjusting the carburetor does more than eliminate floating engine rpm. A well-tuned carburetor will consume the minimum amount of fuel at a stable idle speed.

It happens that when unscrewing the screws of quantity and quality, the engine practically does not react. This happens when a large jet of gas flows from the idle hole and the screw is not able to influence it. It is possible that the valve is poorly closed or the nozzle is deformed. It happens that when replacing the jets, a larger diameter is mistakenly chosen than it should be. The plug may be loosely tightened. It is worth conducting a thorough inspection of all elements of the carburetor, this will help to avoid such problems. During cleaning, the jets must not be cleaned with abrasives.

If the solenoid valve is faulty, unscrew it and check for deformation. The bore can also be deformed. If the thread of the bore is torn off, then you will have to replace the carburetor cover with a new one. If no defects are found, simply lubricate the O-ring before screwing in the nozzle.

You can determine if the carburetor needs adjustment by the engine's reaction to pressing the gas pedal. The engine, receiving a balanced fuel mixture, responds to pressing the pedal without hesitation, in a split second. The revs should be smooth at idle. There should be no jerks or failures. If the engine runs smoothly at idle, and when you press the accelerator it starts to be capricious, you need to tighten the quality screw, enriching the mixture.

The quality screw directly affects CO emissions into the atmosphere. Fans of drive are familiar with the situation when a quality screw must be tightened before going to a scheduled inspection. The emission becomes less and the machine passes the inspection quietly, after which the position of the quality screw is returned to its place.Some people wonder why the neighbor's car uses less fuel, although the models of both are identical. It's all about the settings and adjustments of the quality screw.

Setting up the carburetor is a tricky procedure. Don't expect everything to work out right the first time. It may take a couple of weeks for a full cycle to eliminate all deficiencies. It is better to listen to the operation of the engine, promptly reacting to the slightest interruptions in its operation and carry out regular flushing of the carburetor. The main thing when flushing is not to use unnamed Chinese-made flushing agents. And if you fill up with quality fuel, the carburetor will thank you for years of trouble-free operation.

Technical characteristics of the Neva MB-2 walk-behind tractor

- Travel speed at maximum power:

- in first gear - 1.8 km / h;

- on the second - 6.1 km / h;

- reverse - 1.4 km / h.

- Travel speed when changing the V-belt transmission belt:

- in first gear - 3.3 km / h;

- on the second - 12 km / h;

- reverse gear - 2.5 km / h.

- Transport track:

- without axle extensions - 320 mm;

- with axle extensions - 565 mm.

- Turning radius - 1.1 m.

- The ground clearance is 145 mm.

- Operating temperature - -5 ... + 35 ° С.

- The ignition system is electronic non-contact.

- The spark plug for the ignition coil is A-11-1, A-17V.

- Starting system - recoil starter with lanyard.

- The running system is 2x2 wheels.

- Tires - 4x10 model F-106.

- Tire pressure - 1.8-2 kg / cm³.

Working characteristics of the tillage unit:

- number of cutters - up to 8;

- cutter diameter - 36 cm;

- processing depth - 20-32 cm;

- maximum capture width - 120 cm;

- processing speed - up to 0.12 ha / h.

Carburetor

The carburetor of the Neva KMB-5 walk-behind tractor of the float type ensures the preparation of the air-fuel mixture, has a vertical arrangement of the mixing chamber, is attached with 2 screws to the branch pipe through gaskets and bolts to the board. Fuel from a 3.6 liter fuel tank with the tap open through the connecting hose and fitting flows by gravity into the device, then through the fuel valve into the float chamber, sprayed, mixed with air in the mixing chamber and goes to the combustion chamber of the cylinder block.

In case of malfunctions in the power supply system, the carburetor is adjusted by turning the screw 1 and 3/4 turn.

Dimensions (edit)

Overall dimensions of equipment:

- Length - 1640 mm;

- Width:

- without axle extensions - 600 mm;

- with extension cords - 850 mm;

- with a cultivator - 600 mm.

- Height with wheels - 1200 mm.

Features of the internal combustion engine

Neva modifications are completed as follows:

- Neva MB-2K is equipped with a domestic DM-1K engine with a long service life and a low price.

- Neva MB-2B with American Briggs & Stratton engine of different power and performance.

- Neva MB-2S with professional Japanese Robin Subaru or Honda installations.

The engine for the Neva walk-behind tractor is a 4-stroke 1-cylinder carburetor with manual start from the starter and air cooling. To transfer rotation to a gearbox or a hinged mechanism, a three-groove pulley is used. The operation of the motor is regulated by an air damper.

The devices have an overhead valve arrangement, a horizontal crankshaft position and a large torque.

They are characterized by the following features:

- body strength;

- modernized air purification system;

- making a crankshaft from forged steel and installing it on bearings from 2 sides;

- the presence of electronic ignition;

- production of sleeves from durable cast iron;

- installation of special channels for cooling in the block and head;

- the use of metal parts instead of plastic;

- fast start-up due to the large reel in the starter and reduction of compression;

- small size and weight.

The most popular are the American Briggs & Stratton installations. They are distinguished by their durability, wear resistance and great power. The main disadvantage of engines is their high cost.

Reducer

The gearbox for the Neva MB-2 walk-behind tractor is a gear-chain device designed to change the rotational speed of the output shaft or milling cutters and to transfer rotary motion from the driven pulley to the wheels of the walk-behind tractor, change the speed and direction of movement.

Its performance is ensured by the presence of oil in the housing. Parts are lubricated by splashing oil during disassembly.

The kinematic diagram of the device is simple: a chain and 2 sprockets - upper and lower. The lower, or driven, sprocket is located on the working shaft, thanks to which the system starts to move. The gear ratio increases the force on the cutters and provides maximum penetration into the ground.

The transmission serves as a transmitter of energy from the motor to the wheels.

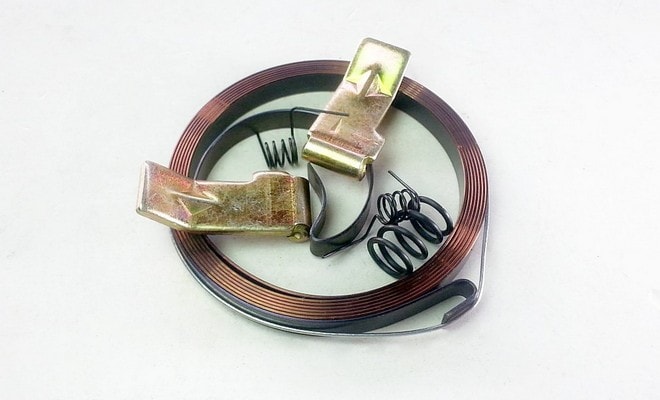

How to repair the starter of a motor cultivator with your own hands

Consider how to repair a walk-behind tractor starter with your own hands. Before you start repairing a recoil starter, you need to find its instruction manual, which contains a diagram of the device. Then you need to prepare a wrench to unscrew the mechanism.

Before starting to dismantle the device, it must be photographed in order to then correctly assemble all the parts and components.

After that, unscrew the washer, which is located in the middle of the body. Having opened the lid, you need to carefully inspect all the parts that are located inside the drum and determine which ones are damaged. It is necessary to inspect small parts very carefully and carefully so as not to accidentally spoil them and not lose them.

In most cases, repairing a kickstarter on a walk-behind tractor consists in updating components that are out of order. For example, replacement of the starter cord is performed if it is torn or frayed.

If a large spring fails, then you need to remove it from the drum. There are usually hooks where the spring is attached. If they are not in the design, then it is necessary to heat the ends of the spring and bend them in the desired direction. If the spring is completely out of order and there is pronounced metal fatigue, then there is no need to try to restore functionality to such a spring. In this case, it is best to replace it with another one. After that, we install the device in its place.

In addition to the manual starter, there is also a spring and electric starter for a walk-behind tractor. The spring mechanism has a simple structure and is easy to start. The device starts up after shifting the handle of the cultivator. The motor accelerates by means of a semi-automatic spring operation. You can replace the manual starter with a mechanical one yourself.

The electric starter of the walk-behind tractor is connected to the battery, from which it receives power. The electric start of the device is carried out using the start button. The battery determines the power of the electric starter and the duration of the operation of the device. Installation of an electric starter is carried out according to the electrical diagram of this design. A walk-behind tractor with an electric starter is distinguished by its strength, reliability, and long service life.

Unfortunately, not all designs of manual cultivators can be converted into spring or electric ones. Therefore, before starting work on replacing the manual mechanism, you need to study the instructions and the capabilities of the walk-behind tractor and find out if such an alteration is possible.

Farmers should be aware that at the beginning of work, all cultivators are working properly. Gradually, on the assembled unit, various components fail. In order to extend the service life of the walk-behind tractor and all its parts and assemblies, it is necessary to regularly inspect the mechanism and properly care for it. All assemblies and components must be periodically lubricated with machine oil and checked for performance. To increase the productivity of the cultivator and extend its service life, constant proper care of this technique is necessary.

About the device

The walk-behind tractor is a tiny (relatively) uniaxial tractor that allows you to operate a wide variety of attachments.This makes it possible to carry out any process in the processing chain. Motoblocks most often have the same dimensions, differing only in small nuances, engine and wheel radius. The width of the tires is also important. This directly affects the speed, duration and quality of work. And all because some walk-behind tractors are designed exclusively for light work (most often they have less weight, they are more compact, most are called a motor-cultivator).

Motor

The choice of this or that means for your site depends on its size. Motoblocks come in different sizes, respectively, the strip of soil processed at a time will also be different. It can be either 50 cm or 1 m or even 1.7 m

It is very important to know in advance the characteristics of a future purchase. Another serious nuance will be the ability to replace spare parts.

For example, gearbox repairs are easier when parts are removable. In this case, the walk-behind tractor will be cheaper to operate than with non-removable parts.

What gasoline is suitable for the Neva MB 2 walk-behind tractor

In order for the walk-behind tractor to work for a long time without complaints, it is recommended to use high-quality fuel. 92 or 95 gasoline is poured here. Experts recommend periodically increasing the octane number if AI-92 is used, which allows you to clean the power plant from deposits. The manufacturer recommends filling high-octane gasoline no more than twice a season, provided that the walk-behind tractor is operated on a regular basis. If this type of technique is used less often, then you can limit yourself to pouring 95 fuel once a season.

This type of special equipment, such as a walk-behind tractor, is very popular among amateur gardeners, as well as commercial agricultural companies. Currently, there are various models and manufacturers of such equipment, but the most popular is the manufacturer Neva and its model MB 2. This unit has proven itself well due to its simplicity and ease of maintenance.

In addition, for this walk-behind tractor, there is a whole mass of attachments and auxiliary equipment on sale, which allows you to operate the device in every possible sense. However, despite the reliability and quality, in order for this device to serve for a long time, it is required to regularly subject the technician to maintenance, as well as to install only high-quality parts and consumables.

Complete sets and attachments

The use of attachments and trailed equipment allows you to expand the functionality of the walk-behind tractor. The following attachments are aggregated to the Neva MB-2 module:

- plows;

- hillers;

- potato diggers;

- seeders;

- lugs;

- and the Neva;

- rotary brushes.

The hiller for the Neva walk-behind tractor processes areas with plants to a depth of 80-120 mm and a width of 250-430 mm.

The motoblock irrigation pump has the following parameters:

- productivity - 12 m³ / h;

- suction depth - 5 m;

- water supply height - 30 m.

Snow blower - attachments for clearing snow. The productivity of such a unit reaches 250 m³ / h, and the working width is 700 mm. When using a blade-blade, the working width is modified up to 1000 mm.

As trailed implements, a transport trolley is used for the Neva walk-behind tractor with a carrying capacity of 150-250 kg.

Hitch

Hitch is a device with which hinged mechanisms are attached to the walk-behind tractor. Its use makes it easier to work with a plow, hiller and other tools, provides a reliable connection.

The devices are U-shaped and can withstand heavy loads.

Cutters

The complete set for the walk-behind tractor includes additional cutters in the amount of 6-8 pieces to increase the width of the soil in 1 pass.

The number of cutters installed depends on the engine power and the purpose of the module.