Maintenance and basic malfunctions MB-23

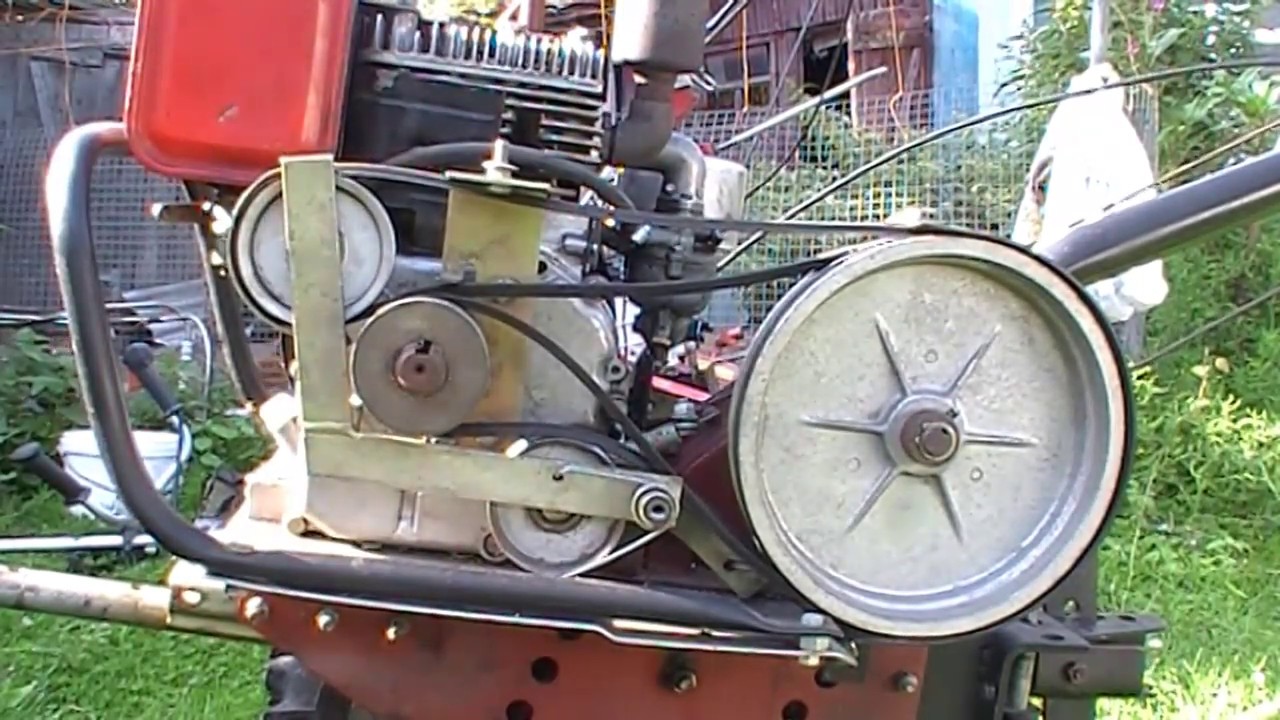

Drive belt, pulley

During the operation of the walk-behind tractor, problems sometimes arise in the operation of the V-belt transmission.

The work of the V-belt transmission is carried out due to the drive belt and two pulleys - the wheels that transmit the movement to the drive belt.

One of the main malfunctions, according to the reviews of the owners of Neva MB23 walk-behind tractors and their modifications, is incomplete disengagement of the clutch. There may be several reasons for such a malfunction:

- belt tension when the clutch is pressed is more than normal;

- belt tension when the clutch is pressed is less than normal;

- the strap has delaminated.

The method of eliminating excessive or insufficient tension is as follows: you need to set the normal belt tension when the clutch lever is pressed so that the deflection of the upper part of the belt does not exceed 8-10 mm, if a force of 5 kgf is applied to the middle part of the belt between the pulleys (5 kilogram-forces ).

If the belt delaminates, replace the worn belt with a new one.

If there is a malfunction in the operation of the pulleys, it is necessary to adjust them. If the axis of rotation does not coincide with the axis of inertia, the pulleys are balanced, thereby normalizing the operation of the belt drive.

Carburetor adjustment

It is advisable to keep the factory adjustment during the entire period of operation of the walk-behind tractor.

The sequence of adjusting the carburetor under operating conditions:

- screw in the screws for adjusting full and low throttle up to the stop, and then unscrew by 1.5 turns, then start and warm up the engine for about 10 minutes;

- put the engine control lever at minimum speed, while not allowing the engine to stop;

- set the minimum idle speed (with a stable engine);

- adjust the idle speed to the maximum value with the idle screw, and then adjust the minimum idle speed;

- the last two manipulations are repeated two more times until the engine runs stably and without interruptions.

After 100 hours of operation of the walk-behind tractor, you need to change the oil in the gearbox,

Ignition, candles, spark

The reason for the ignition breakdown on Neva MB23, MB23S, MB23N walk-behind tractors is often the following:

- malfunction of the ignition coil (magneto)

- malfunction of candles

The ignition on the walk-behind tractor is configured as follows:

- the flywheel of the engine unfolds until the contacts inside the magneto open;

- the flywheel turns until the piston is compressed;

- flywheel check (before knocking - this is triggered by the overrunning clutch);

- check the flywheel to the reverse mark (counterclockwise)

- the minimum distance between the breaker contact and the cam should be 0.25 mm, and the maximum 0.35 mm;

- the cam is fixed with a screw above it.

Spark plugs fail for the following reasons:

- oily (it is necessary to remove the remaining oil);

- covered with carbon (cleaning will help);

- out of order (replacement is needed, not cleaning).

Ideally, you need to change the candles at every change of season, that is, at least twice a year (spring-summer and autumn-winter).

If the engine does not start due to a lack of spark, the cause may be either the spark plug or the magneto. If the problem is in the magneto (ignition system), cleaning the contacts, replacing the capacitor, adjusting the clearances between the contacts can help. A defective spark plug just needs to be replaced. Also, the reason for the absence of a spark may be that fuel does not come from the carburetor (purging the fuel line and cleaning the plugs from grease will help).

Walk-behind tractor device

Depending on the specification, Neva MB1 may have some differences, but the principle of building the device is the same:

- Engine. Mid-range cars are equipped with a four-stroke gasoline unit with a power of several horsepower as standard. For work in difficult conditions can be supplied with a diesel engine.

- Transmission. A set of several mechanisms connected to a common unit. This includes the gearbox, gearbox, clutch and, in some models, the differential.

- The undercarriage, consisting of a frame, where the rest of the mechanical "stuffing" of a powerful axle and a pair of independent wheels is attached.

- Control is carried out using handles. Structurally, gas, clutch and gear shifting are located on them, which greatly facilitates the work.

The compact arrangement of nodes, high ergonomic performance, low dead weight and the ability to effortlessly change the specialization of the walk-behind tractor made it one of the most popular types of agricultural machinery, among which the Neva MB-1 stands out due to its wide functionality, well-thought-out engineering and technical component and reasonable cost.

main parameters

The main property of the walk-behind tractor is reliability and quality. Technical characteristics of the model Neva MB-23 9 liters. with. allow you to evaluate the walk-behind tractor as a design with high performance.

Basic components for the MB-23 model:

- frame;

- reducer;

- transmission;

- engine;

- cutters;

- coupling clevis.

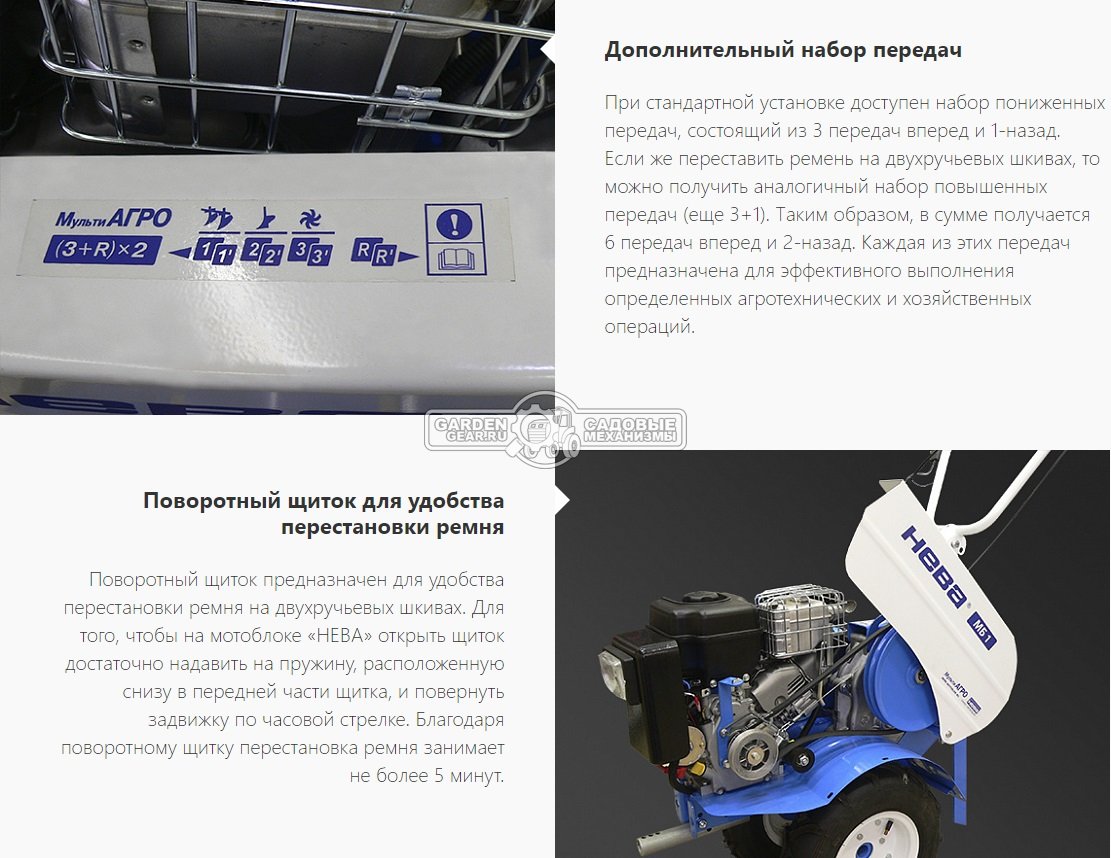

The maximum speed for the walk-behind tractor is set using a gearbox that has 3 speeds for moving forward and one for reverse. Often in the process of work, it becomes necessary to change the speed of movement of the unit. To increase the rear speed on the Neva walk-behind tractor, you should use the reinstallation of the drive belt.

The universal mobile device has additional equipment:

- plow;

- hiller;

- cutters;

- potato digger;

- segment and rotary mowers;

- trailer.

The working volume of the motor is 306 cm³, the power is 10 liters. with. The ignition system of the walk-behind tractor helps the device to work flawlessly in all weather conditions.

Before starting plowing, the equipment is run-in. The user observes all the rules specified in the instructions. If there is a problem, how to make a reverse speed on a walk-behind tractor in order to plow heavy soil, replace the gear pair mounted in the wheel reducers. Mounting the cogwheel increases the speed by 1.5 times. The second option is possible - installation of tires of large diameter (704 mm).

Cost of new and used models

- MB-1C-6.0 - 39570 rubles.

- MB-1S-6.0-FS - 45,780 rubles.

- MB-1C-6.5 - 41,740 rubles.

- MB-1C-7.0 - 37,370 rubles.

- MB-1B-6.0 - 41,530 rubles.

- MB-1B-6.0-FS - 44,400 rubles.

- MB-1B-6.5 - 39,150 rubles.

- MB-1B RS 950 - 39,000 rubles.

- MB-1H GP-200 - 41,520 rubles.

The cost of used MB-1 models is usually 4-7 thousand rubles less than new units and depends on the wear of the walk-behind tractor and attached attachments.

Old Soviet models Neva MB-1 can be bought in a "second-hand" condition, their average cost is:

- MB-1 of the 1986 model - 18,940 rubles.

- MB-1D - 28,000 rubles.

- MB-1R sample of 1991 - 16388 rubles.

- MB-1R sample 1994 - 15,400 rubles.

Again, the price of used models of the old model depends on the condition and completeness of the walk-behind tractor.

Attachments

The manufacturer tried to equip his walk-behind tractor with a large number of attachments. For soil cultivation, milling cutters are used, in this case there are eight of them, but in the basic version there are only four. If necessary, additional equipment is purchased separately. With a hitch and a plow, an additional lug is purchased. All of them are necessary to give high-quality traction to the ground during operation, this is the only way to compensate for the impressive mass of equipment.

Potato digging attachments are a useful accessory when you have a large area. It helps you plant your garden in less time with minimal effort.Planting is done evenly, a fixed distance is maintained between the rows. This device is available in two types:

- fan-shaped;

- vibrational.

The soil is lifted and then sieved, leaving the tubers on the surface. Vibrating ones have their own advantage - they have the best efficiency. The structure is equipped with a vibrating grate and a ploughshare that lifts the ground and spreads it out. After that the soil is sifted through the grate and the potatoes remain clean. Of the attachments, mowers can be distinguished, which are also supplied for sale in different versions:

- segment;

- rotary.

Segment knives are made of hardened steel and move horizontally, so this equipment is best suited for work on a flat surface. The main field of application is shrub shearing and cereal harvesting. As for rotary mowers, they have become more demanded by the user, since they have increased productivity. The knives are extremely durable, they are mounted on discs that rotate at high speed. Thanks to this design, it became possible to remove small shrubs and grass.

If necessary, a snow blower can be installed on the walk-behind tractor, which was developed specifically for the "Neva MB-1". SMB-1 has a simple operating principle, while it demonstrates high efficiency. The auger directs the snow to the middle, and the direction of discharge is set by the swivel screen. The harvesting height is adjusted by means of the installed runners.

If you need to clear the area from debris, then a rotary brush is placed on the walk-behind tractor. The grip extends to 900 mm. The walk-behind tractor can be used as a small vehicle; for this, pneumatic wheels are left on it and a cart with a carrying capacity of no more than 40 kg is hooked through an adapter. The braking system is provided as standard. Certain attachments help carry out agricultural work. These are not only load carriers, but also a plow, rippers, hiller.

Unit repair

The owner studies the device of the walk-behind tractor and fixes malfunctions in a timely manner. When the engine is running, ignition may occur, black smoke comes out of the muffler, carbon deposits form on the spark plug.

In this case, it is necessary to disassemble the air filter and clean it. If the spark is gone, the engine does not start, and the spark plug is wet, the reasons for the failure in the ignition system are determined. The owner of the walk-behind tractor cleans the electrodes, rinses and dries the parts. It is necessary to disassemble, observing the following rules:

- drain the oil from the crankcase;

- put out the filler plug;

- disconnect the hose and air filter.

Next, you should dismantle the rest of the engine. Before starting the assembly of the engine, the parts are cleaned of dirt, the units to be installed are washed. When adjusting the crank mechanism, check the suitability of the oil scraper rings for operation.

Piston rings are changed only in a complex manner.

Motor-cultivator Neva MK-200 - characteristics, instructions, video

Power motor-cultivator "Neva" MK-200 - refers to products of small-sized agricultural machinery, with the help of which you can cultivate cultivated soil, loosening it, leveling it on individual garden and backyard plots, in farms, as well as some other agrotechnical operations.

The manufacturer of Neva motor-cultivators is the Krasny Oktyabr plant, the city of St. Petersburg. This is a specialized enterprise for the production of agricultural moto-machinery. The first Neva walk-behind tractor was released in 1984.

The power cultivator is distinguished by a powerful gearbox in an aluminum casing, a reliable motor and a large number of technical solutions that facilitate the work and make it convenient and efficient. MK-200 has 2 forward and 1 reverse speeds specially selected for various types of work. For convenience, the gearshift lever is located on the steering wheel.The gear change mechanism has an original design with a spring "closer".

Only for cultivators Neva (model MK-200) there is a disconnection of one of the drive shafts, which makes it easy to turn around even with 6 cutters.

A feature of this design is gear shifting with the obligatory disengagement of the clutch. The front wheel makes it easy to move the NEVA cultivator around the garden, and is also part of the original parking position design for easy installation of the cutters and saving storage space.

At MK, single-cylinder 4-stroke engines are used as a power plant, running on pure motor gasoline with an octane rating of at least 92 and on the corresponding brands of motor oils.

The use of gasoline and a brand of engine oil that does not meet the recommendations set out in the Engine Operator's Manual can damage the engine components and render it inoperative.

The MK transmission gearbox uses gear oils of the brand and analogs of which are indicated in the Neva MK200 Operation Manual with the GX 160 Honda engine

Gearbox oil - transmission oil SAE85W-90 API GL-5 (it is allowed to use TM-5 oil GOST 17479.2-85). Refueling volume l., 1.15.

Engine Oil - Use 4-stroke engine oil or an equivalent highly refined oil that meets US automotive industry standards for classifications SG, SF. The oil class is indicated on the package. An SAE 10W-30 grade oil is recommended for use over a wide temperature range. If you want to use a “SINGLE VISCOSITY” oil, select the oil with the appropriate viscosity grade based on the average temperature in your area.

Belt - А44 13х1120Li 1150Ld

The use of other brands of gear oils or an insufficient filling volume will lead to accelerated wear of the gearbox parts.

The first 20 hours of operation with a new MK are defined as the running-in period. During this period, you should not use the engine at high speeds, and MK for heavy work for a long time.

At the end of the running-in period, the optimal engine operating mode should be selected, corresponding to the load for each type of work performed.

The MK-200 motor cultivator is equipped with high-quality and reliable engines that ensure long-term operation of your product, try not to work with the MK at unreasonably high speeds, which reduce the engine's service life, especially when there is no load on the transmission.

Specifications

| Walk-behind tractor type according to GOST 28523-90 | Average |

| Dimensions of the walk-behind tractor (no more) | Length: 1740 mm Width: 650 mm Height: 1300 mm

Length of 1991 models: 1640 mm Width of 1991 models: 600 mm Height of 1991 models: 1220 mm |

| Dry weight (no more) | 100 kg 1991 Models: 86 kg |

| Tractive effort on transport wheels with a load of 20 kg (not less) | 170 kGs |

| Forward speed when changing the belt at engine speed 3600 rpm | First gear: 3.01 km / h Second gear: 11.45 km / h Reverse: 2.57 km / h

1991 models: First gear: 3.3 km / h Second gear: 12 km / h Reverse: 2.5 km / h |

| Product performance at ambient temperature | -25 ° C to +35 ° C Models 1991: -5 ° C to +35 ° C |

| Angle of lateral static stability (not less) | 15 degrees 1991 Models: 13 degrees |

| Power take-off shaft (BОM) in accordance with GOST 28524-90 | Side pulley for V-belt transmission, located perpendicular to the longitudinal axis of symmetry of the walk-behind tractor. |

| Running system | Uniaxial, wheel arrangement 2 × 2 |

| Ground clearance | 140 mm 1991 Models: 145 mm |

| Clutch | Permanently off, switching mechanism - tension roller for V-belt |

| Reducer | Mechanical, gear-chain, with a shut-off mechanism for one of the gearbox shafts |

| Number of gears | Four gears - forward Two gears - reverse |

| Tire | Pneumatic - 4.0 × 10; 4.5 x 10; 16 × 6.50-8 Cast - 5.0 × 12 |

| Track | Variable, step-adjustable |

| Track width | Normal: 320 mm With extensions: 570 mm With extensions 1991 models: 565 mm |

| Turning radius | 1.1 m |

| Cultivator cutter diameter | 360 mm |

| Capture width | 6 cutters: 1.26 m 4 cutters: 0.81 m

2013 models: 6 cutters: 1.27 m 4 cutters: 0.86 m 1991 models (8 cutters): 1.2 m |

| Tillage depth | up to 20 cm |

| Steering gear | Rod, with the possibility of intermediate rudder settings in the vertical and horizontal planes |

| Engine | 4-stroke, carburetor, gasoline, single-cylinder with forced air cooling and manual start |

DM-1-01 engine and its modifications

Motoblock Neva is equipped with an economical 6 hp engine. with. Working fuel is used: gasoline grades AI-80, AI-92 according to TU-38.001165-2003. The carburetor is equipped with an air filter for easy starting at low temperatures. The automatic decompressor reduces the starting force. Stable operation is ensured by non-contact electronic ignition.

The engine consists of parts:

- crank mechanism;

- gas distribution systems;

- fuel mechanism;

- air supply and elimination of processed gases.

Ignition of the walk-behind tractor is necessary to ensure uninterrupted sparking in the candle.

Before starting work, the engine is de-mothballed. The fuel tank is filled with gasoline in the amount of 2 liters, a cold (cold) engine is started.

Some users do not know how to increase the RPM. Excessive load without warming up the engine leads to rapid wear of the pairs of the piston group and, as a result, causes them to jam.

Gearbox features

Thanks to the increased number of gears, the user can select the appropriate speed for any agricultural operation. has a higher gear ratio, which allows you to increase the capabilities of the unit, using less power.

The gearbox of the Neva walk-behind tractor is equipped with a silicone sealant, which provides a reinforced coating of the body. A feature of the gearbox device of the Neva walk-behind tractor is that the components necessary to change the gears are mounted on its outer part of the body.

Reducer MultiAgro - mechanical, gear, chain, has a streamlined shape that reduces resistance in the process of plowing the soil. The oil level in the gearbox ensures successful operation of the unit and protects the engine from premature wear.

A sectional diagram of a classic gearbox and MultiAgro shows the main differences between the gearboxes.

To date, MultiAgro is produced in three modifications for different models of Neva walk-behind tractors:

- MB-1 MultiAgro - (3 + 1) x2 gears, without unlocking the axle shafts;

- MB-2 MultiAgro - (3 + 1) x2 gears, with unlocking of the right and left axle shafts;

- MB-2 MultiAgro - (4 + 2) x2 gears, with unlocking of the right and left axle shafts.

Before filling with fuel, you must familiarize yourself with the rules for handling the gearbox. The user is obliged to navigate the price and quality of the fluid in order to cope with the oil change in the gearbox of the Neva walk-behind tractor.

It is necessary to pay attention to the degree of viscosity of the material and special additives. The Multi Agro gearbox is filled with ZIC 10w40 gear oils of API-SM / CF standard

The technical data of Super T-3 85W-90 lubricant should be reviewed before filling the gearbox.

Reducer MultiAgro and classic. Comparison

On the basis of the MultiAgro gearbox, models of Neva MB-1, MB-2 and MB-23 walk-behind tractors have been produced since 2017. Thus, the model range can be divided into 2 classes: with classic and MultiAgro gearboxes. Comparison by main parameters is shown in the table below.

What is the advantage of the MultiAgro reducer against the usual one:

- Increased number of forward gears. This allows you to find the most suitable speed for your job and increase productivity.

- The gearbox is located on the steering column, while the classic version provides only direct shifting with a lever mounted directly on the gearbox itself.

- The steering wheel has a more ergonomic shape, which reduces the stress on the back and arms (based on feedback from owners of multi-speed models).

- During operation, the steering column can be rotated 30 degrees to the left or right. This allows the operator to follow the machine from the side while working, bypassing the plowed strip of land.

- In models MB-2 and MB-23, unlocking of both the left and right wheels is available, while on motor cultivators with a conventional gearbox, only the left wheel is unlocked. This function allows the user to easily control the machine and maneuver when driving with a cart.