Hammer

Simple in design, a tool used by man for a long time. The main property of the hammer is the ability to significantly increase the impact force and apply it pointwise.

Hammer is translated into English as Hammer.

To carry out certain work, it is worth using hammers of the appropriate purpose. The right hammer affects not only the speed of work, but also the quality.

The hammer is a traumatic tool, therefore, when working with it, you must follow a number of safety rules:

- Do not play with a hammer and fool around. In general, the most serious injuries occur in these situations;

- Never work with a broken hammer or hammers in which the firing pin is loose and may fall off;

- Never use a chipped or cracked hammer.

Features of hammers with a nail puller

The carpentry hammer is distinguished by the fact that it is combined with a nail puller into one whole. The most comfortable models are with a wooden handle. The wood is capable of absorbing shocks, so the wood handle is the most comfortable to work with.

The carpenter does not have to do with one tool. In his arsenal there should be several types of hand tools. The differences are in the shape of the percussion part and are:

- flat;

- convex;

- corrugated.

The former are used for driving nails and wedges. The second is for working with other tools, for example, with a core or chisel. Still others are used to prevent slipping when hitting.

The opposite side of the striker is flattened and bifurcated. Thanks to the tapering slot, the so-called dovetail, the worker can remove nails with different caps: from small, several millimeters, to large ones exceeding a centimeter.

The new generation professional hammer is endowed with the ability to keep nails from falling, which is very convenient when working with one hand. The steel fastener "sticks" to the tool due to the magnetized part of the striker. Often, special guiding recesses are equipped for a nail in the body of a percussion instrument.

Mallet

straightening hammers for leveling sheet metal roofing

This tool has one very interesting feature. The striking part of the straightening hammer is made with an internal cavity filled with sand or fine shot. Such a structure made it possible to completely extinguish the inertia of the hammer during the impact. When working, it does not bounce off the surface and practically "sticks" to it. Such hammers are called inertia-free. They are made of rubber or polyurethane, and some models are made of metal with replaceable heads from a softer material.

Mallets are intended for plumbing and joinery work, namely for straightening, leveling or fitting large elements made of soft metals or wood. The striking part of the instrument is made of rubber or hardwood such as birch or elm. Rubber can be either black or white. White mallets are preferable, since black rubber strikes can leave dark stripes on light surfaces.

The material of the handle is wood, plastic or metal, usually the handle has the shape of a circle in cross section. Depending on the purpose, mallets can have a different shape of the striking part. Carpentry tools are cylindrical or barrel-shaped, while locksmith mallets have one side wedge-shaped.The advantage of these types of hammers is that they do not leave dents or marks on the work surface.

When choosing a mallet, you need to focus on the type of work performed

If these are more accurate actions, then a tool of small weight from 220 to 450 g is enough for you, if you need a large impact force, then pay attention to a tool weighing from 900 to 1000 g. The price policy of this type of hammer is very different, but you should not choose the most expensive mallet

You will hardly be able to find differences from the tool of the average pricing policy, which means that you will overpay for the “name”.

How to use a hammer

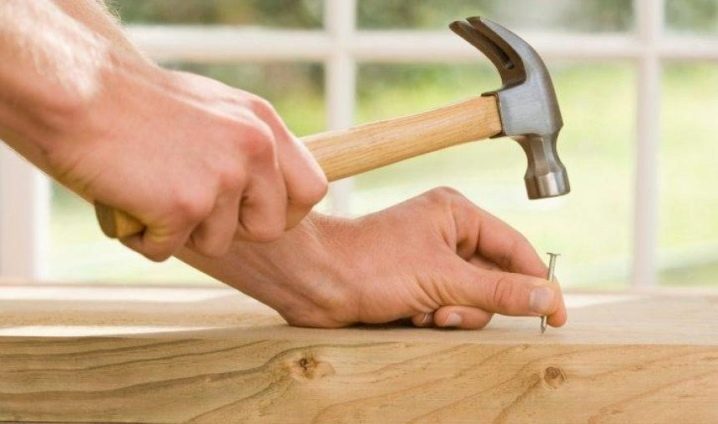

The most popular type of work is hammering nails or dowels into a hard surface.

It is simple to do.

1. Place the nail perpendicular to the surface or at an angle if required.

2. The hammer transmits the force perfectly, so you do not need to swing too much to hammer in the nail.

It is better to do the first blow with a test, only slightly deepening the fasteners.

3. Apply force if the surface is hard.

The swing is short and precise.

4. If necessary, perform several strokes before the nail reaches the desired position.

Fundamental rules

Despite the obvious simplicity of the process, some rules are followed so that nailing does not result in injury.

Before use, it is worth checking the tool: the strength of the connection between the head and the handle, the absence of cracks.

Hold by the base of the handle, not the middle.

In this case, the swing can be made shorter, and the effort can be transmitted more.

The nail is driven in with the center of the striker, not with the edge.

Otherwise, the head will easily slide off the head of the fastener.

Effort is applied not with the palm and hand, but with the whole hand - from the shoulder through the elbow.

Otherwise, the hand will quickly get tired, and the work will have to be interrupted.

You only need to work on a hard surface.

Soft - carpet, carpet, absorb some of the energy, and the effort is wasted.

It is recommended to protect the eyes and ears, as when driving in nails and when chipping material, fragments fly in all directions, which is fraught with eye injuries.

If the nail is very small - wallpaper, for example, and it is difficult to hold it with your fingers, a piece of cardboard is pierced with it and the cardboard is held not by the nail, but by the cardboard.

This makes it easier to avoid injury.

When working with sheets of metal or tin, a thick layer of plywood or wood is placed under it.

It partially dampens shocks and prevents material displacement.

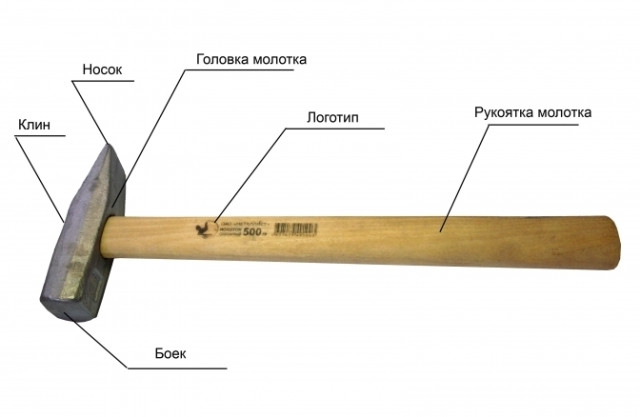

Design features of the tool

The hammer consists of a handle and a head. All the force on impact is transmitted from the human hand to the head. It must be firmly connected to the handle. This is a prerequisite for safe work.

It is strictly forbidden to use hammers with wobbly heads and cracks in the handle.

The head construction consists of:

- Sock.

- Striker.

- Wedge.

- Cheeks.

The toe is the back of the head, which has a wedge-shaped shape. It has a small area, which accounts for the entire force of the impact. The hammer tip is used for crushing and embossing work. Some instrument models are equipped with a swallow tail toe.

Expert opinion

Torsunov Pavel Maksimovich

The main striking part of the tool is the striker. It has the shape of a relatively large area

An important characteristic of the striker is strength. In the process of work, he has to withstand a large number of blows of various strengths.

There is a hole on the head of the hammer called "vsad". A handle is inserted into it. To ensure the strength of the connection of structural elements, an expansion of the seat is made from the center upwards. Some models of the instrument are equipped with a metal collar. Place it around the hole. The non-working, flat part of the milk is called the cheeks.

Carpenter's Power Tools

It's worth starting with an electric saw.There are several types: chain, disc, trimming, circular, electric hawk, jigsaw. The assortment is large and specific. The choice depends on the scope of application, material thickness, type of cut. If the first two are used for normal cuts, then the jigsaw can be used for curly cuts.

For grinding, we use: grinders and electric planers. By the way, an interesting tool is a grinder, which can serve both as a cutting machine and as a grinder.

For drilling, you can use a drill or screwdriver. Everything depends on the power. They will also help to screw the fastening materials into the array. Therefore, the kit should include not only cue balls, but also a set of drills of various diameters.

A router is used for curly elements, it also helps to drill a number of technical holes. The configuration and size of cutters abounds in variety. For finer work, an engraver is used.

Types of hammers

According to its variety, purpose and application, there are a very large number of types of hammers. We will omit such types of hammers as kitchen, medical, shoe and the like, and will try to mention all types of hammers used in construction.

Locksmith hammer

This is a classic hammer with a flat striker on one side of the head and a wedge-shaped striker on the other. The wedge-shaped side is called the spout.

Such a hammer is used almost everywhere and by weight it has the largest range of sizes from 200 g and over 1 kg.

Small, lightweight hammers are used to hammer in small nails. They are used when installing wooden glazing beads, when working with clapboard (clapboard nails) and small clays.

Heavier hammers are used almost everywhere: in everyday life, for bending metal, hammering nails, in a variety of jobs.

Due to its practicality, it is the most common type of hammer.

A bit of theory

When hammering in a nail, we do not think about the most complex physical transformations in the hammer / nail / solid system. The coefficient of efficiency (the ratio of the useful work and the energy expended to drive the hammer) is 70 - 97%. For most modern machines and mechanisms, this is an unattainable limit.

The main part of the energy loss goes to the kickback of the hammer, due to the emergence of elastic forces. The amount of recoil depends on the material of the hammer head and the properties of the material. For a steel tool, energy losses are about 30%, for titanium - in the range of 3 - 5%. But these indicators also depend on other parameters:

- the type and shape of the striking part;

- material and length of the handle;

- tool mass;

- contact angle;

- matching the type of hammer to the operation being performed.

The last item on the list is very important - in mechanical engineering, stone processing, construction, various types of hammers of different levels of versatility are used. Among them, you can choose a tool for all occasions, for domestic and semi-professional use, and highly specialized, "sharpened" for performing one or two operations, but with the highest efficiency.

The two main parts that make up the hammer - the handle and the head - are firmly connected to each other. When moving on a massive head, sufficiently large forces act - when sliding off the handle during an impact, the kinetic energy of the head allows it to fly several tens of meters. If at the junction there is the slightest wobble or cracks appear on the handle, the hammer must never be used. It becomes dangerous for the worker and those around him.

The head consists of several parts:

1. Sock; 2. Hole for the handle (vzad);

3. Wedge; 4. Nail puller;

5. Striker; 6. Cheek; 7. Lever.

The striker, the head striking part, is usually flat, has sufficient area and strength to withstand a significant amount of shock contacts with solid objects without deformation. The impact surface is flat or slightly convex. In cross-section, it is a square, rectangle or circle.

The back of the hammer is generally wedge-shaped. This allows you to develop a significantly greater impact force, by reducing the contact area. Wedge strikes are used when it is necessary to split the material or emboss. The back part can be spherical, depending on the scope of the hammer and its main purpose.

The seat is made in the form of an oval or round through hole, the walls of which slightly expand from the center to the upper part, to prevent possible slipping from the handle. On some types of hammers, a forging is provided around the bore hole in the form of a metal collar, which goes over the top of the handle by a few centimeters. This part of the tool protects the handle from kinking when hitting too hard or inaccurately.

The head is made of hard metal by forging, casting or milling. It is protected from corrosive effects by special types of paint or galvanic coating. Before applying the protective layer, the head is hardened, in most cases selectively. The impact part (firing pin) reaches the highest hardness (up to 52 units on the Rockwell scale). Hardening is carried out by the electric induction method, which makes it possible to accurately control the depth of surface hardening. On the striker, the hardening depth reaches 3 - 5 mm.

The back part (wedge or nose) is hardened up to 36 - 42, and the area of the bore hole - up to 24 - 30 units on the same scale. The shape, weight, dimensions and other characteristics of industrial hammers are determined by GOST 11042-90 and 2310-77, which describe almost all types of hammers and their purpose.

Many manufacturers produce percussion tools according to their own specifications, which take into account most of the requirements given in national standards. The changes concern the use of new alloys, the length and shape of the handles with improved ergonomics, computer-modeled, more accurate surface treatment.

Choosing a carpentry hammer with a wooden handle

The good thing about the all-metal hammer is that you don't have to push the head onto the handle. It is perfectly balanced and ready to go. The steel handle is uncomfortable when hitting. It can slip out of your hand. In addition, metal cannot dampen vibrations. Disadvantages are eliminated by applying impact-resistant plastic or thermoplastic rubber pads to the handle. So the hammer is securely held in the palm of the hand during work and protects the hand from shock loads.

The metal and plastic handles are undoubtedly strong enough. However, the hammer is constantly exposed to significant loads both when hammering in nails and when dismantling. The handles are tested for durability during the operation of the nailer. A new instrument will age and become unusable over time.

The situation is somewhat different with wooden handles. At first, well-processed wood is just as reliable as metal. The wood, which is warm to the touch, does not require additional linings; it fits comfortably in the hand of the carpenter. When working with a tool with a wooden handle, the joints of the worker are maximally protected from vibration effects.

The tree itself dampens blows, as if absorbing them. Hands do not get as tired as when working with metal, plastic and other new materials used by manufacturers.

Another argument for a wooden handled hammer is its low cost. For Russian craftsmen, wood is more familiar than plastic and metal.Therefore, if you need to choose, they give preference to those tools that their distant and not very distant ancestors worked with.

Chisel

No carpenter's toolbox is complete without these tools. There are several types:

- Straight. Used for cutting grooves of various sizes and shapes, leveling the surface. The thickness, width of the blade and chamfer are selected for a specific type of work and quality of wood.

- Semicircular. They are used when you need to make smooth bends, lines. The main characteristics when choosing a tool are the width of the blade and the size of the radius. These parameters divide this view into steep, sloping, caesaric (deep). The first option is used to form a depression, the second is used to smooth lines.

- Corner. The main characteristics are the angle and width of its sides. The degree of inclination is in the range from 45 to 90 °. With this type of tool, the initial contour of the drawing is applied, and with the rest of the types it is already being finalized.

- Cluckars. In this series, there are several more subspecies: straight, semicircular, coal. Like the previous types, they differ in the width of the blade, the size of the radius, and the size of the angle. They are used for work in hard-to-reach places or when it is required to make shallow cuts.

Axe

One of the most ancient tools of labor. Previously, carpenters were called axes by the name of the main tool. The tool itself consists of two parts - a blade and a hatchet. The blade is made by stamping high carbon steel

When choosing an ax for carpentry work, special attention is paid to the following features:

- The weight of the blade should be between 900 and 1100 grams. Lighter weight will force more effort, and more will not allow accurate processing of the array.

- The blade must be sharpened at 35 °. This prevents the tool from getting stuck in the wood. A sharpened blade on one side is used to hew the solid.

- The handle is made of wood, which dampens vibration during operation.

- The optimum length of the ax is 440 mm. The shape of the handle plays an important role, it should fit comfortably in the hand. For each type of work, the angle of the blade to the ax is different. For example, a straight line at 90 ° is used for felling, and an acute-angled one for cutting.

The ax is used for harvesting wood, roughing - removing bark, stripping.

As you can see, this simple carpenter's tool has a number of distinctive features that will allow you to make the material with less effort.

Locksmith hammer

The instrument got its name from a specific profession. Its practicality gives it the right to be considered the most common species. The shape of the hammer head is the presence of a flat striker on one side and sharp points on the other. The wedge-shaped side is called the spout. The weight of the tool, taking into account a wooden or plastic handle, can range from 200 grams to 1 kilogram.

To choose the right tool, you can look through the catalog of locksmith hammers. It is easier to hammer in small nails with small, light tools. To do this, use the narrow part of the striker. When installing glazing beads or securing the lining, this side of the hammer works best for the job.

In such cases, it is a good idea to know how to make the hammer work again. Craftsmen do not always throw out rejected tools. Whenever possible, they try to get him back into work.