Concrete moisture meter

The moisture meter for concrete is a compact and simple device for measuring the moisture content of concrete products and other materials.

Features of the moisture meter:

- to measure, it is enough to put the device on the surface;

- humidity measurement is based on changing the frequency of radio waves penetrating into the product up to 30 mm deep;

- examinations can be performed either on an ongoing basis or at set intervals.

The moisture meter is able to measure the moisture content of solids (concrete, mortar screed, plaster, brick), both in laboratories and on production sites.

Non-destructive testing provides measurements not of the humidity itself, but of the parameter associated with it, with its subsequent translation into the humidity value.

The moisture meter for concrete can be divided into two types according to the principle of operation:

1. Needle, measuring electrical resistance, depending on humidity, between contact rods embedded in the material.

2. Non-contact, providing indications using attenuation of electromagnetic waves.

How to determine the strength of concrete with a Kashkarov hammer

Everyone knows that the strength of concrete and reinforced concrete products is the basis of the strength and reliability of the entire structure. Large construction companies and factories have laboratories that monitor the quality of concrete products. But if, for example, the foundation is flooded, and its technical characteristics are in doubt. What to do then, how can you check the strength of the poured concrete solution?

There are several options. One of them is the use of Kashkarov's hammer. What is it, what does it consist of, why is it called a hammer, and how should you work with it? This is all we will talk about in this article.

As an addition to the material, let us turn your attention to the site

Tool design

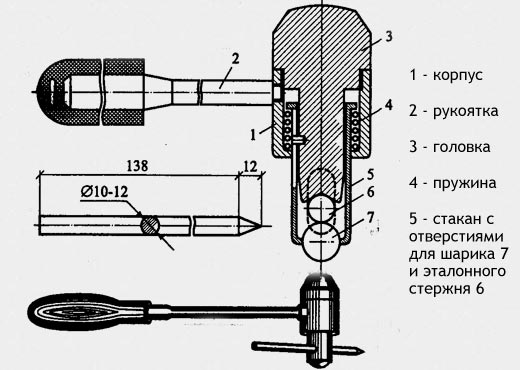

This tool is very similar to a hammer, which is why it is called that. There are two main parts in its design:

True, the story is unusual. Its back (wide) side is the same as that of a simple hammer. But the sock (sharp tip) is a complex design. First, it is collapsible. Secondly, it includes:

- The cup is the toe-side cavity in the bike.

- A spring inserted into a glass.

- A metal rod called a reference. It is removable and inserted into the glass, supporting the spring.

- A metal ball at the end of a reference rod called an indenter.

How to use the Kashkarov hammer correctly

For the tests to pass correctly, you need to know how to use the tool. The first step is to prepare the test plane. It must be cleaned of paint and other materials, it must be flat, without shells and large roughness.

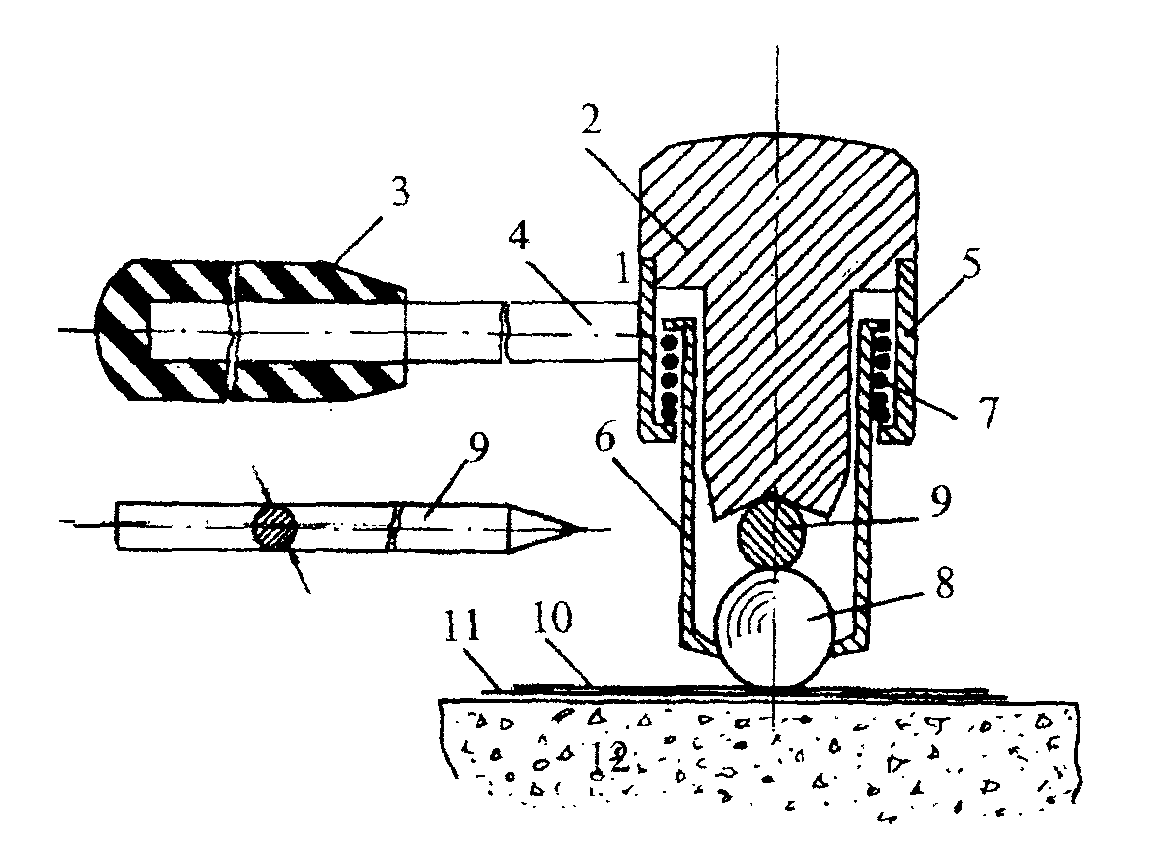

Copy paper is laid on the concrete, and a white sheet on top. The sharp end of the bike hits the concrete with a medium impact. Not very strong, but not weak either.

It is very important that the lanyard hits the concrete plane at an angle of 90 °. This is not easy to do, so experts recommend using an additional conventional hammer for this process. That is, Kashkarov's hammer is installed vertically, and on its back side you need to hit with an ordinary hammer

That is, Kashkarov's hammer is installed vertically, and you have to hit the back of it with an ordinary hammer.

Please note that to measure the indicators, you need two valleys formed during the impact. One on the concrete plane, the other on the indenter. It will be difficult to measure the size of the resulting dent on concrete, therefore, copy and plain paper is placed under the hammer.

It is on them that all the necessary measurements are carried out.

It will be difficult to measure the size of the resulting dent on concrete, so copy and plain paper is placed under the hammer. It is on them that all the necessary measurements are carried out.

After that, comparisons are made between the dents on the ball and on the concrete. The average value of their sum is taken as the basis for determining the strength of the test material. Now this indicator is weighed against the tabular value.

It should be noted that dents are measured by an angular scale. In this case, the measurement accuracy should be no more than 0.01 mm. In order to more accurately determine the strength characteristics of concrete, it is better to carry out several test blows in a small area. In this case, the largest size of the depressions is taken into account. One reference rod can withstand up to four tests on one plane, after which it must be replaced with a new one.

The Kashkarov hammer is a tool designed to determine the strength of reinforced concrete products or monolithic reinforced concrete. Consists of a replaceable metal rod with a known strength (reference rod), an indenter (ball), a glass, a spring, a body with a handle and a head. ... ... Wikipedia

Hammer - This term has other meanings, see Hammer (disambiguation). Primal stone hammer ... Wikipedia

Hammer (disambiguation) - Hammer: The Wiktionary has an article "hammer" Hammer is a small hammer, a percussion tool used to hammer nails, smash objects, and other work. Kashkarov's hammer is a tool designed to determine strength ... ... Wikipedia

KP Kashkarov's hammer - - is based on the presence of a relationship between the strength of concrete and the value of an indirect indicator, which is the ratio of the diameters of the imprints left by the impact of the CM on the concrete and the reference rod. [Recommendations for the definition ... ... Encyclopedia of terms, definitions and explanations of building materials

Equipment for the production of concrete - Heading terms: Equipment for the production of concrete Autoclave Pass-through autoclave Dead-end autoclave Bucket Barosmesitel ... Encyclopedia of terms, definitions and explanations of building materials

Advantages and disadvantages

Kashkarov's hammer has both pros and cons. The advantages of using this tool include, first of all, the ease of measurement. Even a beginner in the construction business can cope with such a study.

There is no need to destroy the sample for testing, that is, the study can be carried out directly on the finished product

This is especially important if the research items are large. Also, the pluses include the cost of the device. Such a tool can be purchased for use in everyday life, for example, erecting a monolithic house for yourself

Such a tool can be purchased for use in everyday life, for example, building a monolithic house for yourself.

But Kashkarov's hammer also has significant drawbacks. The error of the device is 12 to 20 percent, which is quite a lot. Modern electrical sclerometers provide more accurate results. The strength of concrete is determined only in the surface layers (1 cm deep). As you know, these layers are often susceptible to destruction due to carbonization. In addition, the device is practically insensitive to the strength of the coarse aggregate and its grain size composition.

How to determine the strength of concrete?

In the production of materials and construction, methods are used to test concrete for strength:

- destructive;

- non-destructive straight lines;

- non-destructive indirect.

They allow, with varying accuracy, to control and assess the actual strength of concrete in laboratories, on sites or in structures that have already been built.

Destructive methods

Samples are cut or drilled out of the finished assembled structure, which are then destroyed on a press. After each test, the values of the maximum compressive forces are recorded, and statistical processing is performed.

This method, although it gives objective information, is often unacceptable due to its high cost, laboriousness and causing local defects.

In production, research is carried out on a series of samples prepared in compliance with the requirements of GOST 10180-2012 from a working concrete mixture. Cubes or cylinders are kept in conditions as close as possible to factory conditions, then tested on a press.

Non-destructive straight

Non-destructive methods for controlling the strength of concrete involve testing the material without damaging the structure. Mechanical interaction of the device with the surface is carried out:

- at separation;

- tearing off with chipping;

- chipping off the rib.

In pull-off tests, a steel disc is glued to the surface of the monolith with an epoxy compound. Then, with a special device (POS-50MG4, GPNV-5, PIV and others), they tear it off together with a fragment of the structure. The resulting value of the effort is converted using formulas into the desired indicator.

When detached with chipping, the device is attached not to the disk, but to the concrete cavity. Petal anchors are inserted into the drilled holes, then part of the material is removed, the breaking force is recorded. To determine the brand characteristics, conversion factors are used.

Non-destructive indirect methods

Clarification of the grade of the material by non-destructive indirect methods is carried out without the introduction of devices into the body of the structure, the installation of anchors or other labor-intensive operations. Apply:

- ultrasound examination;

- shock impulse method;

- rebound method;

- plastic deformation.

In the ultrasonic method for determining the strength of concrete, the speed of propagation of longitudinal waves in the finished structure and the reference sample is compared. The UGV-1 device is installed on a flat surface without damage. Plots are called according to the test program.

The data is processed excluding outliers. Modern devices are equipped with electronic bases that carry out primary calculations. The error in acoustic studies, subject to the requirements of GOST 17624-2012, does not exceed 5%.

When determining the strength by the shock pulse method, the impact energy of a spherical metal striker on the concrete surface is used. A piezoelectric or magnetostrictive device converts it into an electrical impulse, the amplitude and time of which are functionally related to the strength of the concrete.

The device is compact, easy to use, gives results in a convenient form - in units of measurement of the desired characteristic.

When determining the grade of concrete by the rebound method, the device - the sclerometer - records the amount of reverse movement of the striker after hitting the surface of the structure or a metal plate pressed against it. Thus, the hardness of the material is established, associated with the strength of the functional dependence.

The method of plastic deformation involves measuring the dimensions of a track on concrete after being hit by a metal ball and comparing it with a reference print. The method was developed for a long time. The most often used in practice is the Kashkarov hammer, into the body of which a replaceable steel rod with known characteristics is inserted.

A series of blows are applied to the surface of the structure. The strength of the material is determined from the ratio of the obtained diameters of the indentations on the bar and the concrete.

Mechanical methods for studying the indicators of concrete mixture

Concrete types table.

The oldest and most popular method for determining the compressive strength of a material is called the reference material method. To conduct a study, control samples are made from a concrete mixture, which are cubes with a side length of 20 cm. For testing, cubes must have a holding period of at least 28 days. Then the finished samples are placed under a press and compressed until they are completely destroyed. The load indicators at which the destruction occurred are recorded, and then, with their help, the strength of the monolith is calculated.

Non-destructive testing of concrete is carried out with special mechanical devices. In this case, methods are used that determine the properties of a monolith when exposed to certain tools. The readings of devices are taken into account during such manipulations as chipping, separation, plastic deformation and some others.

Methods for checking concrete using Fizdel and Kashkarov hammers

The principle of operation of the testing mechanisms is based on the indicators of the depth of penetration of the device into the thickness of the surface layer of the concrete monolith. As an example, consider the Fizdel hammer, when struck, holes remain on the surface of the material. The diameters of the holes determine the strength characteristics of the concrete.

The device of the Kashkarov hammer.

Then 10-12 medium-strength impacts on the surface of the area selected for testing are carried out. Hammer prints should be at least 3 cm apart.

After that, using a caliper and a special ruler, the diameters of the holes are measured. Each measurement is made with an accuracy of tenths of a millimeter, first in one direction of the hole, then in a strictly perpendicular direction. Based on the information received and the data on the diameter of the imprints of laboratory samples taken as a standard, a calibration curve is drawn up, which makes it possible to determine the compressive strength of concrete.

In addition, the strength characteristics of the monolith can be determined with the help of Kashkarov's hammer. The principle of operation of this tool, like that of Fizdel's hammer, is based on the properties of plastic deformation. Structurally, Kashkarov's hammer is a device into which, in addition to the working body, a control rod is also inserted. Due to this, the device leaves not a single, but a double print. One is located on the surface of the investigated object, and the other - on the control rod. Analysis of indentations and left hole diameters allows calculations of concrete compressive strength.

Investigation of the properties of concrete using a sclerometer and pistols

Concrete strength ratio table.

Tools that are used to determine the strength characteristics of a concrete monolith based on the properties of elastic rebound are equipped with a rod striker, or striker. An example of such tools is the pistols of Borovoy and TsNIISK, the KM sclerometer and the Schmidt hammer.

Studies determine the magnitude of the rebound force of the striker, which, during testing, is reflected on the scale of the mechanism. As a rule, the force of the spring energy during the experiment should have a constant value.

The rod striker is released independently when the tool comes into contact with the surface. The KM sclerometer has a built-in striker with a certain mass value. With the help of a spring with a given stiffness, a blow is made on a metal striker pressed against the test surface.

Methods for controlling the strength of concrete, based on the indicators of separation with spalling, make it possible to determine the characteristics of a monolith not on the surface, but in the body of an element. For research, areas without metal reinforcement are used.

Methods for establishing the strength of concrete.

Special anchors are installed in the thickness of the concrete, with the help of which the strength characteristics of concrete are then studied in a non-destructive way.

To date, the described methods of non-destructive testing of concrete strength are considered the most accurate, since they use for calculations a dependence in which only 2 parameters can change: the size of the fractions of the concrete solution filler and its type. At the same time, the disadvantages of non-destructive testing of concrete strength are high labor intensity combined with the impossibility of using these methods with high material reinforcement. In addition, during the tests, partial damage to the surface of the monolith under study occurs.

Comparative table of concrete strength control methods

| Non-destructive method | Description | Peculiarities | disadvantages |

|---|---|---|---|

| Chipping off | Calculation and evaluation of anchor pull-out forces | Availability of standard calibration dependencies | Inability to measure structures with saturated reinforcement |

| Chipping a rib | Determination of the breaking force of the corner of a concrete structure | Ease of application of the method | Not applicable for concrete less than 2 cm |

| Tearing off discs | Evaluation of the breakout force of a disc from a metal | Suitable for high structural reinforcement. | The need to label discs. The method is rarely used |

| Impact impulse | Striker impact energy measurement | The diagnostic tool is the Schmidt hammer. Compactness and simplicity of measuring equipment | Poor estimation accuracy |

| Elastic rebound | The path of the impact striker is measured with a Schmidt sclerometer | Availability and ease of diagnosis | Requirements for surface preparation of test areas are high |

| Plastic deformation | Estimation of the parameters of the imprint of the impact of a special ball with a Kashkarov hammer | Uncomplicated equipment | Low accuracy of diagnostic results. |

| Ultrasonic | Measurement of vibration indicators of ultrasound transmitted through concrete | Ability to assess deep concrete layers | High quality control surface required |

Why and when control is exercised

Let's consider this topic in more detail. Knowledge of the issue can be useful not only for specialists, but also for ordinary people who build with their own hands on a personal plot.

Without controlling the quality of the concrete used for construction, one cannot be sure that the dam is reliable.

Of course, pouring a concrete path near the house, there is no need to check the quality and strength. But, for example, if during the construction of a summer cottage you used a purchased concrete mix, and then the house shrank, or cracks began to appear on the foundation, one of the reasons may be poor-quality concrete.

After making sure of this, you can collect money for repairs from the supplier. To do this, you need to know what is concrete control for determining strength, and how it is carried out.

What are the guidelines for assessing strength

This interstate standard is used to control the quality of concrete.

The quality of concrete is checked by both the construction supervision authorities and the manufacturers (construction organizations) themselves. For this there is GOST - concrete quality control is carried out in accordance with its requirements. Document number: 18105-2010. The entire document is called “Concrete.

Rules for the control and assessment of strength ". It is interstate and operates on the territory of the entire commonwealth, including Ukraine, which recently left the CIS. Let's consider the requirements of this document in more detail, but without delving too much into the terms. It defines the methods and schemes for laboratory control of concrete.

When is the control carried out

The concrete is checked when it reaches the design strength - that is, usually after 28 days from the moment the mixture was prepared.

- But for prefabricated and prefabricated monolithic structures, tests are also carried out during the delivery or acceptance of products (called the incoming concrete control).

- Indeed, often at the time of transfer, the stone does not yet gain the necessary characteristics. This is the so-called transfer strength.

- For monolithic structures, control can also be carried out at the time of removing the formwork or loading the structure - this strength is called intermediate.

- Moreover, if, when checking at an earlier date, it is determined that the material has gained more than 90 percent of the design strength, then it is allowed to no longer carry out assessments. At the same time, the product or structure is considered to be of high quality.

- Also, the quality of concrete is determined during various examinations in order to determine the cause of damage or destruction of buildings and structures.

High precision models

When testing the strength of concrete, a high precision instrument can be very useful. Devices of this type are usually used by professional builders. Also, modifications are actively used in the laboratory. The models are equipped with special electrode sensors. They process the density and moisture content of the sample. It should also be noted that they can operate at elevated temperatures. The probes in the devices are of the channel type. The minimum allowable temperature of the meters is approximately -10 degrees.

Contactors in devices are used with expanders. The control units are used with a microprocessor. If we consider electronic devices, they often have modules installed. The concrete calculator is calculated using the controller. Maps are used to store data. The data processing accuracy is quite high. In this case, the maximum error rate is 0.2%. The catchers are used with and without transmitters.

Features of determining the strength of concrete

In the field of construction and production of materials, measures are being taken to test concrete for strength. Control methods include:

- straight (non-destructive);

- destructive;

- indirect.

With their help, it is possible to conduct research and control the strength of concrete on construction sites, in laboratory conditions and on constructed buildings. The accuracy and implementation principle of each method is different.

Destructive

In the mounted concrete structure, samples are drilled out or cut out with special tools, in the future they are destroyed on the press. Each test ends with the fixation of the compressive forces and statistical processing. This method has increased information content, but it is often neglected due to its high cost, laboriousness and local damage.

In production conditions, diagnostics are carried out on samples that are prepared taking into account the standards of GOST 10180 from a concrete mixture of a working type. Cylindrical or cubic products are kept in conditions close to real ones, after which they are examined using a press.

Non-destructive

In this case, the strength is determined without directly affecting the concrete structure. The interaction of the device with the surface is carried out when:

- chipping ribs;

- separation;

- detachment with chipping.

In diagnostics, a disc made of steel is fixed on the surface of a monolithic structure by tearing off, a substance based on epoxy resin is used for fixing. Then, with a special device, it is opened together with a part of the surface. GPNV-5, POS-50MG4 or PIV are used as a tool. The resulting value of the effort is transformed into the desired parameter, for which they use mathematical formulas.

If the shear pull method is used, the fixture is anchored into the concrete cavity rather than the steel disc. Petal-type anchors are inserted into the drilled holes, after which a part of the concrete is removed, and the destructive force is fixed. To determine brand parameters, conversion factors should be used.

Rib chipping is used for those structures where there are external corners - columns, floors, beams. In this case, the GPNS-4 device is used, it is fixed to the protruding element with an anchor, then gradually loaded. Depth and force are determined during fracture. Strength is determined by the formula, taking into account the characteristics of the aggregate. It should be noted that the method is not suitable if the thickness of the protective layer does not exceed 20 mm.

Indirect

Indirect non-destructive methods are used to clarify the grade of concrete. Their distinctive feature is the absence of the need for the penetration of the tool into the body of the structure, installation of anchors and the implementation of other labor-intensive procedures. The most expedient methods have proven themselves:

- shock impulse;

- plastic deformation;

- rebound;

- ultrasound examination.

In the latter case, the strength of concrete is determined by comparing the intensity of propagation of ultrasonic waves in the reference product and the finished structure. The UGV-1 tool is fixed on a flat surface, then sections of the structure are called, and the resulting information is processed. Modern tools have electronic bases, thanks to which the calculation of the primary type is carried out. If you comply with the requirements of GOST 17624 for acoustic diagnostics, then the error will be no more than 5%.

The study of strength by a shock impulse involves the use of the impact energy of a spherical striker on the outer cavity of concrete. A magnetostrictive or piezoelectric device transforms energy into a pulse, its time and amplitude directly depend on the strength index. The device has a compact size, it is easy to use and quickly shows the result in the required unit of measurement.

To determine the strength of concrete by the rebound method, you can use a special tool - a sclerometer, it determines the indicator of the back movement of the striker after impact contact with a surface or a fixed metal plate. This method determines the hardness of the material, which is functionally dependent on strength.

The method of plastic deformation makes it possible to measure the mechanical trace on the surface of the material after being hit by a ball made of metal. The print parameters are compared with the reference values. The method has been actively used for decades. Previously, the Kashkarov hammer was used, where a steel rod with established characteristics is located in the body.