The basis of the mini tractor is the frame

The practice of many shows that a channel is perfect for creating a base. From number five to number nine. The channel should be chosen because it is very rigid in torsion and bending. Self-made mini tractors with a breaking frame, made of high-quality channel bars, are able to survive for a long time, being subjected to daily high loads.

The practice of many shows that a channel is perfect for creating a base. From number five to number nine. The channel should be chosen because it is very rigid in torsion and bending. Self-made mini tractors with a breaking frame, made of high-quality channel bars, are able to survive for a long time, being subjected to daily high loads.

Of course, the channel does not have to be used to create the entire structure. You can use profiles of a different type in those places of your future mini tractor that do not imply special hard loads. For example, you can create a canopy over the seat using a 10mm rod. It is also suitable for creating the frame of the wings.

Fracture node for a mini tractor, also known as the articulated joint of the half frames. To create it, you can use the cardan from the main gear of the truck. To simplify the task of controlling a mini tractor during plowing, at the design stage, we recommend thinking about installing a steering with hydraulic cylinders.

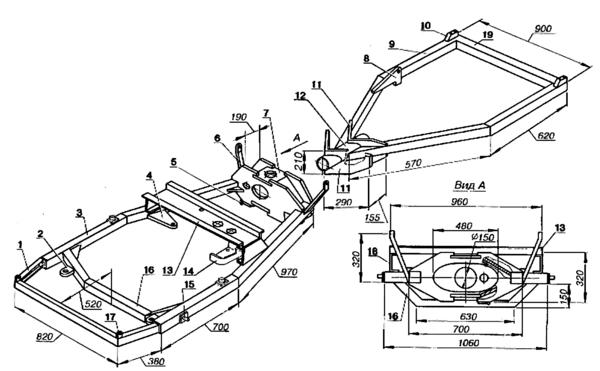

Homemade tractor frame: 1 - bumper (StZ, channel 80x80); 2 - engine mounting lug (StZ, sheet s20): 3 - spar of the front half-frame; 4 - steering cylinder mounting bracket (StZ, sheet s20); 5 - lug of the mower hinge (StZ, sheet s20); 6 - cab mounting rack (2 pcs.); 7 - body, central hinge unit (StZ, sheet s20); 8 - bracket for mounting the hydraulic cylinder for lifting the body and trailed device (StZ, sheet s20); 9 - spar of the rear semi-frame: 10 - body attachment point (StZ, sheet s20); 11 - connecting plates 12 - hinge unit body, special (steel 20, pipe 150 × 1 (1); 13 beam for fastening the transfer case and the cab floor (from GA3-66); 14 - bracket for fastening the transfer case (from GAZ-06) ; 15 knot of the blade hinge; 16 - transverse beam (StZ. Pipe 80x80x6): 17 - eyelet for fastening the hydraulic cylinder of the blade (StZ, sheet s20); 18 - rack (20 steel, channel 100 × 46); 19 - cross member.

Homemade tractor frame: 1 - bumper (StZ, channel 80x80); 2 - engine mounting lug (StZ, sheet s20): 3 - spar of the front half-frame; 4 - steering cylinder mounting bracket (StZ, sheet s20); 5 - lug of the mower hinge (StZ, sheet s20); 6 - cab mounting rack (2 pcs.); 7 - body, central hinge unit (StZ, sheet s20); 8 - bracket for mounting the hydraulic cylinder for lifting the body and trailed device (StZ, sheet s20); 9 - spar of the rear semi-frame: 10 - body attachment point (StZ, sheet s20); 11 - connecting plates 12 - hinge unit body, special (steel 20, pipe 150 × 1 (1); 13 beam for fastening the transfer case and the cab floor (from GA3-66); 14 - bracket for fastening the transfer case (from GAZ-06) ; 15 knot of the blade hinge; 16 - transverse beam (StZ. Pipe 80x80x6): 17 - eyelet for fastening the hydraulic cylinder of the blade (StZ, sheet s20); 18 - rack (20 steel, channel 100 × 46); 19 - cross member.

This is interesting: The design of the steering of a homemade mini tractor: introducing the question

Safety engineering

Regardless of which mechanism was the main one when assembling a mini-tractor, one must understand that this is a rather dangerous device. There are no instructions for homemade equipment, and therefore the first safety measure is a careful selection of the design. It is recommended to read the comments to the drawings and to the descriptions, with the reviews of those who have already tried to use them. You need to refuel the mini-tractor only with the fuel for which the engine is designed. A similar rule applies to lubricating oils.

If the unit has a gasoline engine, do not allow oil to get into the fuel. It is also impossible to fill in fuel to the very edge. If it splashes out while driving, serious problems can arise. It is strictly forbidden to use open fire when refueling a mini-tractor, and ideally at any time when people are near it.

If the canister is leaking, it should be discarded. There is no need to create fuel reserves in excess of the required volumes. Places for refueling and starting the engine must be at least 3 m apart. To avoid a fire, do not start the engine in the immediate vicinity of trees, bushes, or on dry grass. If the engine starts poorly or starts with strange noises, it is best to postpone the work and find the problem that has arisen.

Do not drive a mini-tractor on garden tools, collide with walls, branches and stones. Only people who understand it should operate the mechanism. Even if headlights are installed, it is advisable to work mainly during the day.

You can find out how to assemble the transmission and brakes on a breakdown mini-tractor by watching the video below.

Wheelbase

The frame of the minitractor is installed on wheels, and they should be selected, depending on what exactly you are going to do with your tractor. Either you will be mainly transporting goods and then you need discs with a rim diameter from 13 to 16. Or you will be working in the field, in which case the rim diameter should vary from 18 to 24 inches. The pivot point of the breakaway mini tractor provides enough maneuverability to keep you comfortable on any type of soil, working, planting or harvesting.

What is a fracture tractor

In terms of design and dimensions, the fracture is nothing more than an ordinary mini-tractor. Usually, this technique is produced on the basis of a walk-behind tractor. There is a home-made tractor with a factory-made break frame or assembled at home from old spare parts. There is also a third variant of fracture. The unit is assembled from a walk-behind tractor, and spare parts are used from a special conversion kit for sale.

In terms of productivity and a number of characteristics, a home-made tractor is inferior to a factory-made break. But the homemade product also has its advantages:

- Competently assembled equipment in functionality is capable of surpassing powerful factory mini-tractors, and the cost of a home-made unit is many times less.

- The functionality of the fracture tractor can be significantly expanded to suit your requirements. Craftsmen adapt those mechanisms to the technique that help to perform the necessary work.

- The expenses incurred during the self-assembly of the tractor will pay off in 1 year. And if there are many spare parts from old equipment at home, then the unit will cost the owner practically free of charge.

The disadvantage of a homemade tractor can be considered the lack of the necessary spare parts. If you have to buy all of them, then there will be no savings. Then it is better to immediately purchase a factory-made mini-tractor.

How to choose an engine and transmission

What is the difference between homemade mini tractors with a breaking frame and purchased copies, in the first place? That's right, because almost no one has the opportunity to choose the most suitable engine for them. People take what is closest and cheapest. As a result, the most common engines on which the modern "break" is driven are:

- "UD2".

- "UD4".

In addition, on some examples, diesel engines with two or one cylinder come across.

- Some craftsmen manage to get the M-67 engine.

- If you have the opportunity to install "MT-9", then this will be the best option, because it has more volume.

Just be aware that in this case your 4x4 car will require an increase in the transmission ratio. This is the only way to achieve acceptable wheelbase traction. It is also highly desirable to provide a suitable cooling system for the engine even before the first start and breakdown of the engine. The fact is that standard forced air cooling, which could help the engine to cope with the tasks facing the mini tractors, is simply not provided there. As a solution to the problem, you can put a fan with a guide casing on the toe of the crankshaft. But for this you will have to make an adapter, which means that you will need to get a drawing for it as well.

If you have the opportunity to get hold of a motor from a Moskvich or a Zhiguli for free, then you can get a very good minitractor.Because this is a great way to tie together the clutch, engine and transmission with the transfer case.

Most often, to create a rear axle, bridges with shortened semi-axles from cars or trucks are used. The operation is quite simple and will only require a lathe and an idea of what exactly you are doing. If you have the opportunity, then at the same stage you should select the gear ratio for the gearbox.

Additional equipment for a 4x4 tractor with a breaking frame

For productive work, the mini-tractor must be equipped with a power take-off shaft (PTO) - mounted and trailed units (plows, mowers, reapers) are connected to it. The PTO can be taken from an old tractor or decommissioned military equipment.  If you intend to use a mini-tractor in winter, you can equip it with a cab. Otherwise, a tarpaulin canopy is sufficient. For the convenience of working in the dark, install the headlights and dimensions.

If you intend to use a mini-tractor in winter, you can equip it with a cab. Otherwise, a tarpaulin canopy is sufficient. For the convenience of working in the dark, install the headlights and dimensions.

Did you know? The first tractors appeared in the middle of the 19th century and were steam tractors.

Homemade mini-tractors with a 4x4 drive and with a breaking frame are indispensable helpers in farm fields. Such a unit can be assembled during the winter months when there is no field work.

And the low cost of assembly and maintenance makes it an almost uncontested choice for small farms.

What is a breaking frame of a tractor

The breaking frame is also called articulated frame. In fact, these are two semi-frames connected to each other using a hinge joint. This scheme, especially when combined with all-wheel drive, provides the vehicle with greater maneuverability. Homemade tractors with a breaking frame have a number of undeniable advantages:

- the turning radius of the equipment is reduced. The mini-tractor turns 360 degrees literally on the spot;

- the tractor shows good cross-country ability in areas with difficult terrain. The floating frame changes the balance of the machine for the better, thus providing more reliable grip on the ground;

- The evenly distributed load allows the mini-tractor to deliver maximum power while consuming a minimum of fuel.

A homemade mini-tractor with a breaking frame is more difficult to assemble than an all-metal-based technique. But the result will exceed all expectations. In terms of functionality, compact machines on a break-through frame are practically not inferior to heavier factory tractors.

Features of collecting device

Assembling such a complex device like a tractor will require significant time and financial investments.

In addition to purchasing parts and assemblies of the unit, you must take into account that you will need some tools. If you do not have them, then you can ask your friends for help or use the rental.

What tools will be needed

Since many parts will have to be fitted to each other, and some even made on their own, a lot of tools will be needed:

Required materials for construction

The device consists of several units, some can be completely taken from other equipment, some will have to be redone:

- composite frame;

- engine;

- undercarriage, including suspension, axles and wheels;

- assembly with brake discs;

- steering mechanism;

- seat;

- mechanism for attaching attachments.

Important! To create a homemade fracture, it is inappropriate to use new materials and parts, it is better to use "second-hand machine". The ideal option would be to purchase an old passenger car: "Zaporozhets", "Moskvich" or "Zhiguli", then there will be no need to dock the engine with the chassis and transmission

The final stage

The mini tractor is almost ready to go with the finishing touches left. The brakes and clutch must be installed. These assemblies can be taken from a car or motorcycle. In the second case, the brake and clutch cables must be connected to the pedals.

The fuel tank is installed. For a mini-tractor, a capacity with a capacity of 8-10 liters of fuel will be enough.

Considering that the tractor's suspension is rigid, the driver's seat must be sprung. Otherwise, you will feel every bump while moving.

It is recommended to install headlights and side lights on the tractor. This will make it easier to work in the evening and at night. For the electrical equipment to work, you will have to mount the wiring diagram. It usually consists of a battery, starter and alternator.

The mini-tractor can be equipped with a cab and trim elements. It is not difficult to do this, so each person is guided by his own taste. If the technique will not be used in winter, then it is quite possible to do without sheathing. It will be enough to install a tarpaulin awning.

How to make a tractor with a breaking frame with your own hands

The assembly of the tractor begins with the manufacture of the frame, the phased installation of the remaining units on the base, the installation of the hydraulic system and electrical wiring. Let's take a closer look at each stage.

Frame and body

The components of the frame are welded from metal channels (depending on the planned capacity of the unit, a channel from No. 5 to No. 9 is used) and connected to each other by a hinge mechanism (for this purpose, cardan shafts from trucks are often used).  On the rear half-frame, if necessary, mount a reinforced vertical rack for attachments.

On the rear half-frame, if necessary, mount a reinforced vertical rack for attachments.

For a body that does not bear the same stresses as the frame, a less expensive material can be used. The frame, for example, can be welded from a metal bar.

From above, the frame and the place of its articulation will then be covered with a metal sheet.

Steering and seat

It is strongly recommended to equip the steering system with a hydraulic drive: it will be very difficult to drive the tractor on sticky ground in the field with muscle strength alone. The hydraulic system can be removed from any other agricultural equipment.  Since the suspension on the tractor is stiff, the seat should be made soft and, possibly, cushioned - you will have to spend quite a lot of time in it.

Since the suspension on the tractor is stiff, the seat should be made soft and, possibly, cushioned - you will have to spend quite a lot of time in it.

Engine

Ulyanovsk engines (UD-2, UD-4) are often used for homemade equipment, but there are a lot of alternatives, ranging from the option described above with a passenger car and ending with engines from motorcycles, motoblocks and forklifts.

Important! When using a motorcycle engine, you will have to think about additional forced air cooling - the tractor loads cannot be compared with its normal operation. You will also need to set the gear ratio so that at a speed of about 4 km / h the engine speed is about 2000 rpm.

These indicators are optimal for arable work.

It will also be necessary to set the gear ratio so that at a speed of about 4 km / h the engine speed is approximately 2000 rpm. These indicators are optimal for arable work.

Wheels

The axles (both rear and front) are taken from cars or trucks, before that the axle shafts are shortened to the required length. An independent suspension can be installed on the front axle (for example, from the "Zaporozhets"), the rear axle is better left rigid.  The wheels are chosen depending on the primary tasks of the unit. If his main work will take place in the field and on rough terrain, then it is better to use wheels with a diameter of 18-24 inches. If it will be mainly used for transport tasks, then wheels of a smaller diameter - from 13 to 16 inches, will do.

The wheels are chosen depending on the primary tasks of the unit. If his main work will take place in the field and on rough terrain, then it is better to use wheels with a diameter of 18-24 inches. If it will be mainly used for transport tasks, then wheels of a smaller diameter - from 13 to 16 inches, will do.

It's interesting: Step-by-step instructions on how to make a homemade tracked tractor (video)