Preparation of drawings and manufacture of the apparatus

Having figured out how to make a tractor with your own hands, they get to work. According to the specification of the drawing, the necessary units and parts are selected. Those elements that cannot be found ready-made are made independently.

A DIY mini tractor at home is created from the following elements:

- engine;

- the frame on which the structural units are attached;

- running gear and brake hydraulic system;

- attachments;

- driver's seat;

- lanterns.

Engine selection

On a homemade tractor, you can use a Moskvich engine. It was designed specifically for homemade agricultural machinery, so its power is only 4 liters. with. However, this may be sufficient for working in a small area. In addition, it is easy to repair. The ideal option is the engine from the walk-behind tractor. Usually, a front axle with a frame and steering from the same walk-behind tractor is installed along with it.

Unit power frame

To install the engine, 2 pipes are welded on top. The frame elements are fastened with welded seams, because the bolted joints may not withstand the load.

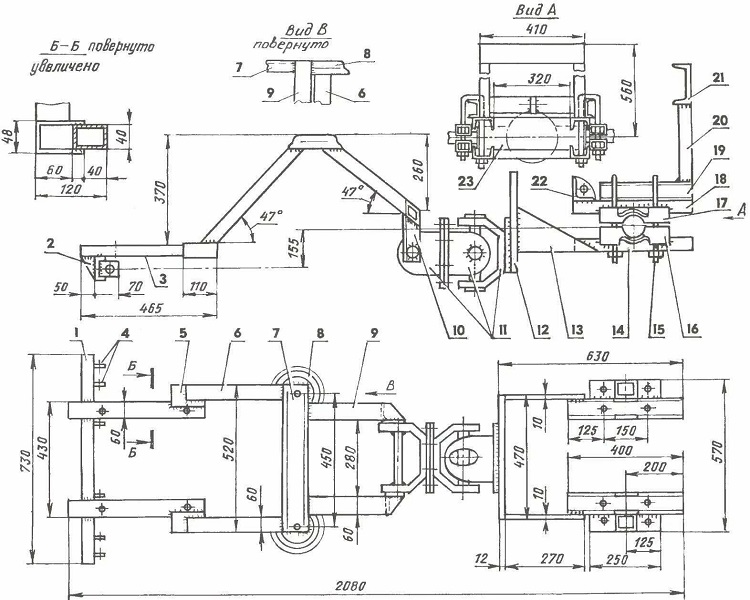

The hitch between the frames is made of 2 forks and a hinge. For this, bearings and a trunnion from Kamaz are used. Thanks to this connection, the rear half has the ability to move both horizontally and vertically.

Installation undercarriage

To install the bridges, vertical posts with reinforcing corners are welded onto the frame. The front axle is not a leading one, so there you can use the structure from any car.

For the rear axle, a cast rod with a diameter of 50 mm is prepared. To float the bridge on a bumpy road, a hinge is installed in the middle. Ears are fixed at the edges of the bar. They are needed in order to put on KAMAZ trunnions with hubs with the help of greaves. Then wheels are put on them. Hydraulics are taken from any vehicle. The brake system is installed on the rear wheels, you can take it from a UAZ car.

Fixing the hinge

Their fixation is carried out with 3 points. One is attached to a special plate on the frame, the other to the attachments, and the third to the hydraulic motor drive. Through it, the torque will be transmitted to the attachment.

Steering column and driver's seat

A system from a Moskvich car is used as a steering control. Instead of native rods, Zhiguli ones are taken, and the hubs are selected from Zaporozhets. A special lever is installed between the rods and the column.

“>

Assembly technique

Before you start assembling a mini tractor, you need to determine what tasks the machine will perform. Most often, the unit is used for loosening the soil, mowing grass, digging ditches. Then you will need the appropriate attachments. It will also be necessary to consider the power and performance of a tractor that will be able to do the job.

The tractor will consist of the following units:

- frame;

- motor;

- cardans of the main transfer;

- chassis: suspension, axles, wheels;

- brake disc system;

- steering unit;

- driver's seat;

- unit for hanging.

The assembly of the mini-tractor is carried out as follows. The walk-behind tractor is installed on a self-made frame. The brake system must be drum, and the steering column can be taken from an old Zhiguli car. If a Neva walk-behind tractor is used to make a fracture, then it is desirable that it be with a coupler, then it will be able to transport loads and carts. When assembling the structure and welding units, it is necessary to observe safety measures.Welding should only be carried out with protective goggles or a helmet.

Care must be taken when working with a tool such as a metal cutter. Protect your eyes and body from metal swarf

Work should be done indoors or outdoors, away from other people, and especially from children, to avoid injury to others. If you yourself do not know how to weld, then it is better to call a specialist welder who will carry out all the welding work to create a homemade product.

If you need a durable machine with high power characteristics, then it should be created on the basis of a walk-behind tractor with high performance and a powerful motor. This will increase the efficiency of the machine and the service life. In this case, you can use the Centaur walk-behind tractor with a diesel engine, which has a power of 9 hp.

When choosing a walk-behind tractor, you should consider the body structure. Determine how it will connect to the motor unit. In the manufacture of the body and frame, it is necessary to use profiled strong pipes and steel corners. If a powerful motor is installed on the tractor, then the body can be made from a trailer to a car. It is necessary to find out how it will be mounted to the walk-behind tractor. Before starting work, once again check the strength of all connections and assemblies, and then test how the structure functions.

A self-made mini-tractor can be used to work in a summer cottage, in a garden, in small farms. The cost of such a unit will be small compared to the price of a new mini-tractor, which is sold in specialized agricultural machinery stores.

Completion of assembly

- The brake system can be removed from cars or motorcycles and installed without modification.

- The fuel tank is selected for specific tasks. On average, a 10-liter tank will suffice. If necessary, the size of the container can be increased.

- If you plan to work in the field at night, you should install a path lighting system on a homemade breaker tractor. For this, headlights, wiring, battery and generator are mounted.

- The driver's seat must be adjusted for the stiffness of the suspension, otherwise the driver will feel every unevenness in the terrain.

- The cab will help to create an aesthetic look for the assembled agricultural equipment, as well as protect it and the driver from weather conditions. Finishing is done based on your own tastes and preferences.

The use of a homemade tractor is allowed only after it has been fully tested in various conditions. Otherwise, the manifestation of shortcomings is possible at the most crucial moment.

It is difficult to overestimate the attractiveness of a home-made tractor breakage from the Oka. The cost of spare parts and components required for the manufacture of a tractor is quite low. The total costs can be recouped in one growing season. This solution is suitable for novice farmers who do not have the funds to purchase factory-made agricultural machinery.

Frame design

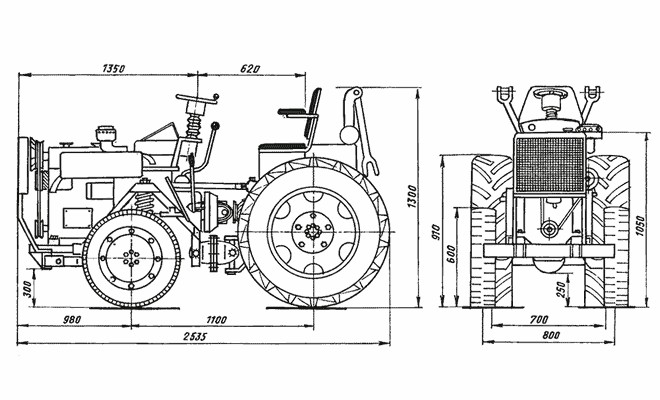

To make a mini-tractor with a breaking frame with your own hands, you need to connect 2 semi-frames by welding. The dimensions of the front half-frame are 900x360 mm, the rear one is 600x360 mm. Details are made of profile channel # 8.

The parts are connected to each other at an angle of 45º. On the front frame, 2 pieces of square pipe are mounted. It will act as a subframe for mounting the motor. After that, planes are welded for mounting other parts.

A stand is installed on the rear half-frame and reinforced with corners from the side. A metal plate is welded to the rear pillar for mounting the hinge. For the plate, take metal with a thickness of 12 mm. A sheet with a thickness of 3 mm is mounted to the upper part of the half-frame.

Thus, a platform is created for the driver's seat. The semi-frames are connected using a cardan shaft. It consists of two steel forks connected by a hinge.The forks are mounted to the traverses of the semi-frames. The pivot requires thrust bearings. They can be taken from a KamAZ truck. Half-frames must move both horizontally and vertically. Therefore, the chassis is mounted on a rigid hitch.

A hub is attached to the semi-frame in front. This will create an additional horizontal deflection angle and offset of the frame components. So that the frame sections do not move too far, a gear wheel is fixed to the front, and stops are mounted to the rear.

Advantages and disadvantages of manual assembly

Perhaps the main advantage of a homemade mini tractor is the unconditional savings in money, compared to purchasing full-fledged units in a store, such as Uralets, Kubota, Bulat 120, Yanmar, Belarus 132n, Scout.

At the same time, its performance indicators will not differ much from the factory options, because the design uses a sufficiently powerful motor, which is quite enough for processing land holdings up to ten hectares.

Advantages

The costs of manufacturing a mini tractor pay off in almost one calendar year, because most of the components are taken from old equipment, or the cost of purchasing them is minimal. Many adapt other equipment for a mini tractor, such as a walk-behind tractor, which further simplifies the assembly process.

In addition, homemade units have other advantages:

- Relatively high degree of immersion in the soil. If everything is correctly foreseen, the depth of digging will be identical to that shown by purchased analogs. Be that as it may, it is still better than digging up the garden by hand.

- Sufficiently high mobility, as a result of rather modest dimensions. The use of such units is advisable precisely in small gardens and summer cottages, where large tractors cannot turn around.

- Due to the fact that you are making a mini tractor yourself, there is a possibility of additional modernization of the unit. You can remove components, changing them to other, more powerful ones, or add new devices.

- In the mini tractors sold, such an opportunity is absent, moreover, in the operating instructions it is directly written that making any changes to the configuration is strictly prohibited.

disadvantages

Among the shortcomings, the following points can be noted:

- Relatively complex assembly process. Here we are talking not only about direct work, but also about certain difficulties in the selection of the necessary components. Many of them have to be adjusted on a lathe, which in itself presents additional complexity.

- The likelihood of breakdowns, because a homemade version is made mainly from old parts and spare parts.

In principle, the pros and cons are about equal in importance, but there is one small digression here. Today's realities are such that the issue of price is becoming dominant, overshadowing other arguments.

Design features and dimensions

Of course, this technique can also be bought in the store. But the costs in this case are often prohibitively high. And what is most offensive, for the largest land, where powerful machines are required, the purchase costs rise sharply. In addition, for those interested, enthusiastic about technology, the preparation of an all-wheel drive 4x4 mini-tractor in itself will be pleasant.

First, they determine what kind of work is to be performed on the site. Then the appropriate attachments are selected, the optimal placement and methods of attaching it are determined. It is customary to divide home-made mini-tractors into the same parts as their "shop" counterparts:

- frame (the most significant detail);

- movers;

- power point;

- Gearbox and gear unit;

- steering block;

- auxiliary (but not less important) parts - clutch, driver's seat, roof and so on.

As you can see, most of the parts from which homemade mini-tractors are assembled are taken ready-made from other equipment. Can be used as a basis for both cars and other agricultural machines. But the number of possible combinations of components is not that great. Therefore, it makes sense to focus on ready-made combinations of parts. As for the dimensions, they are chosen at their discretion, but as soon as these parameters are fixed in the drawing, it becomes extremely imprudent to change them.

Most experts believe that it is best to use a structure with a break frame. And experienced craftsmen prefer this option. Walk-behind tractors are taken as a basis.

Steering

To make a tractor with your own hands, you first need to complete the design of the control system. The steering column is mounted to the front frame with screws. To turn the steering wheel to match the movement of the unit, you need to change the position of the worm gear. We must mount it the other way around. A notch should be made in the adjusting screw nut and a hole drilled in the crankcase cover.

The hydraulics can be removed from an old non-working tractor. The oil tank and pump are located next to the motor. The hydraulics are installed at the rear, where there is space for attachments.

If the machine will be used not only for loosening soil and other agricultural work, but also for clearing snow, then the front linkage must also be mounted. To lift the attachment, a cylinder is mounted. It is also taken from a mini-tractor.