Reasons for reduced efficiency

Due to its characteristics, the rolling jack is designed to work with liquids, which provide high lifting capacities. Most often we are talking about oil. A special hydraulic version of this fluid is used here.

In order for the jack to serve for a long time, it is necessary to monitor the presence of oil in it and the condition of the oil seal and valves.

Basically, this design is considered one of the most reliable. She is capable of working with a wide variety of weights. Sometimes the lifting capacity of such a jack can reach several tens of tons. The efficiency is the highest among all representatives of the class of similar equipment.

However, no one is safe from the fact that the hydraulic trolley jack will fail. There may be several reasons for this. The main reason is often the accumulation of large amounts of air bubbles in the work area. This is fatal for any hydraulic device. Very often this leads to the fact that it is necessary to pump the hydraulics. Air bubbles can drastically reduce the efficiency of this type of device.

It is imperative to regularly check the amount of oil in the hydraulic jack system. If its level decreases, then this has a detrimental effect on the entire operation of the device. The free space is quickly filled with air bubbles. At the same time, the work deteriorates sharply. This directly affects the carrying capacity. There are many methods that allow you to troubleshoot such a problem. All of them have a right to exist. Next, we will consider several options for how you can do this. So, you can proceed directly to the instructions.

Some helpful tips

It is imperative to use only hydraulic oil for the hydraulic jack to work properly. This is due to the fact that only it is capable of providing the required viscosity. Simple engine oil has a lower viscosity. It does not work quite correctly even without air ingress.

In production, when it comes to important equipment, people always use only hydraulic specialized oil.

There is a special oil for hydraulic jacks.

It allows any units to work for many years without any breakdowns. It is quite easy to get it today. It is distributed by specialized stores. Of course, it is best to know in advance which oil is best suited for a given hydraulic jack model.

Most often, this information is indicated on the packaging. On the basis of it, one can already draw some definite conclusions. Yes, there are models of ordinary oil that have similar properties with hydraulic, but it is not always suitable in this particular situation. You should definitely focus on the advice and recommendations of the manufacturer.

When purchasing a hydraulic trolley jack, you can always check its compression properties so that you do not get a faulty device that will have to be pumped right away. It is worth immediately determining its compliance with the initial indicators and characteristics. Only then will it be necessary to carry out repairs much less often than in the case of a previously inappropriate unit. Sometimes the figures on the packaging do not correspond to what is actually indicated by the manufacturer. Checking is never superfluous.This is the only way to get a really high-quality device at your disposal.

Pumping scheme of a hydraulic rolling jack.

When pumping, be sure to follow the instructions presented above. This is the only way to achieve a truly good result. If you want to use other methods, then you can always familiarize yourself with them on the sites. There are really no better options. The hydraulic trolley jack has become a real assistant for all car mechanics and tire fitters. He always comes to the aid of his owners. This work of modern technology should not be ignored if today it is widely available to everyone.

So, now we can summarize what was said above. Now every person knows how to pump a hydraulic trolley jack. There is nothing difficult in this process. If you strictly follow the instructions, you can always get in practice the result you need. Hydraulics has always been considered a whimsical thing. It is influenced by many different characteristics.

Instructions

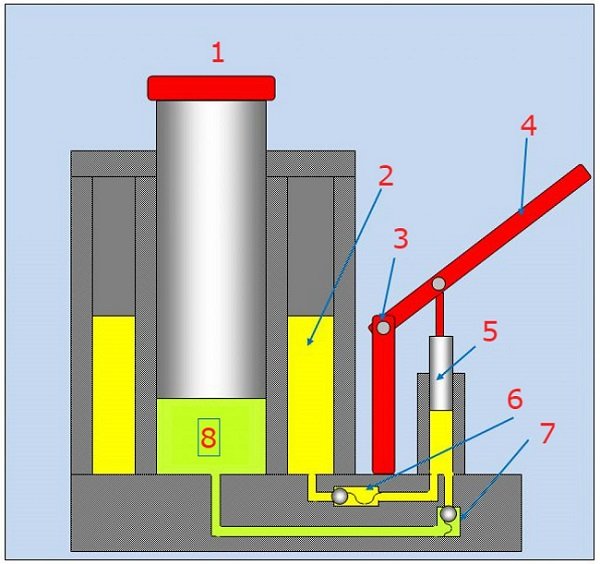

Initially, it is worth deciding what exactly is meant by "pumping" in relation to modern lifting mechanisms. This is a set of actions aimed at displacing air from hydraulic cylinders. In this case, the whole process is reduced to pumping the working fluid with a pump. This is what became the determining factor in the appearance of the name of the procedure, which is one of the most important points in the maintenance of lifting devices.

Those who have at their disposal an old hydraulic jack or a relatively new model of modern lifting equipment with clear signs of airiness, need to know how to quickly cope with such a problem. A large amount of relevant information can now be found on the net. First of all, it should be noted that to effectively restore the device's performance, you will need a standard tool arsenal, as well as about 300 ml of ordinary mineral oil or a special fluid for hydraulic systems.

To effectively pump the bottle-type hydraulic jack, you will need to perform the following steps.

- First of all, it is necessary to find a filler hole, which is sealed as tightly as possible with a rubber stopper. In most cases, it is located at the top of the device. Taking into account the design features of different models, the plug can be recessed into the body or protruding above it.

- Open the oil filling hole by carefully pulling out the plug to avoid damaging it.

- Drain off all working fluid in full. It is worth considering that this measure is relevant in cases where it is required to service an old hydraulic jack, which has been actively operated for a long time without maintenance. To completely remove the remaining oil, unscrew the bypass valve and lower the piston all the way.

- Flush the cylinders using special fluids, as well as kerosene or oil, which will be filled afterwards. To do this, it is necessary to pour the flushing agent through the aforementioned hole, by pumping to raise the piston to the highest point, and then open the valve and lower the stem to the stop. This procedure must be repeated several times.

- Fill the hydraulic cylinder with oil by placing the bottle jack in its working, that is, vertical position. Experienced users and experts advise using a syringe when doing this.

- After the container is filled to the maximum level, the bypass valve is tightened all the way. At the next stage, with up / down movements, the piston of the device is raised to the stop.

- After that, it is necessary to slightly unscrew the valve and manually lower the piston with the filler hole open. This sequence of actions is repeated several times.

- If the described algorithm did not lead to the desired results, and air remains in the system, then you can turn the shut-off valve several turns, raise the piston by hand and lower it sharply. In this case, the use of a pump is excluded. Such manipulations are repeated several times, and with each approach, the length to which the stem extends decreases by 1 cm. As a rule, such drastic measures allow you to quickly get rid of air in the hydraulic system.

Hydraulic slide-type lifts are characterized, first of all, by increased lifting capacity. In this case, the main performance indicator directly depends on the tightness of the system and the pressure created in the working chambers. To maintain the full performance of rolling models, they need to be pumped periodically.

Contamination and air ingress can be a source of problems with this category of hydraulic jacks. There are several ways to remedy the situation. The first option for pumping rolling equipment involves the following steps:

- open the oil filler plug;

- unscrew the overflow valve;

- pump the working cylinder with quick movements;

- screw the valve all the way in and close the filler hole tightly.

Unfortunately, in some situations, the manipulations described above cannot fully squeeze out the air from the hydraulic system. At the same time, many are interested in how to identify its remains in the cylinders of the jack.

In such cases, you will need to find a shut-off needle, which is an integral part of the design of any modern sliding hydraulic jack. It is turned out by 2-3 turns, after which, in manual mode, the piston should be extended several times to the stop and returned to its original position. As a result of such manipulations, as in the situation with bottle models of equipment, the air will be completely squeezed out of the system.

Characteristics of varieties of jacks

Lifts are of various types, each of which has its own distinctive features and characteristics:

- The mechanical jack is the most famous piece of equipment for its light weight, fast working stroke, high lift and low cost. Its disadvantages include low stability, since the mechanical equipment has a small support area.

- An electric lift is a piece of equipment that is controlled by a special small unit and powered by the electrical wiring of the machine. Such a jack can lift up to two tons of weight. Among the disadvantages are its large mass and manual lowering, which takes a lot of time.

- Powered by a compressor or compressed air, the pneumatic jack is lightweight and has a large bearing area.

- Hydraulic equipment is the most popular and is used both in car repairs and during construction work to lift various heavy structures. The lifting capacity of hydraulic jacks is up to 200 tons, and the efficiency reaches 80%. However, this lift also has a drawback - it cannot be transported in a lying position, since the equipment mechanism may fail.

For high-quality operation of equipment, it is necessary to use special oils. Such compositions are divided into several groups and have their own purpose.

The main types of oils:

- flushing;

- transmission;

- motor;

- hydraulic.

To service the jacks, hydraulic compositions are used, the choice of which requires care and responsibility.

The main causes of breakdowns

A rolling jack, which can be repaired at home, can have several causes of breakdowns. The most common of these are: complete or partial failure of the device to lift heavy loads, as well as oil leaks. Each of these problems requires immediate repair.

A rolling jack (repair, oil change, characteristics are described in detail in this article) very often fails as a result of oil leakage. In this case, you will have to completely disassemble the device. Be sure to remove the pistons and check for corrosion. Thoroughly clean all structural elements and remove any contamination. Now check the stem. If you find that it has a curved and broken shape, then you may not even try to repair it yourself. In this case, you will most likely need to purchase a new jack.

Another common reason for the failure of the device is the clogging or breakdown of special valves, which, in fact, are responsible for lowering and raising the mechanism.

Main requirements for hydraulic fluid

The use of hydraulic oil is a very important component in the operation of any machine - from the machine to the jack. Therefore, the choice of oil requires responsibility and care. Each oil must meet certain characteristics.

First of all, this concerns the viscosity of the liquid. The freedom of movement of the moving parts of the machine depends on this indicator. The viscosity value must be optimal. The temperature index or viscosity index is also important. Usually this indicator should be of great importance.

This type of liquid does not undergo oxidation. It is not affected by temperature fluctuations and the chemical composition of the environment. All this ensures long-term and high-quality operation of the hydraulic fluid.

Such oils must have excellent anti-corrosion properties. If this is not the case, the hydraulic drive will fail very quickly.

Another important indicator of a hydraulic fluid is "filterability"

That is, the liquid will pass through the filter and be cleaned of dirty impurities, which is important during the operation of any device. Oxygen and other gases must be easily removed from the working medium

Foam should not form.

The hydraulic fluid must protect the hydraulic system of the machine from premature wear. It must be compatible with the materials used for the hydraulic system.

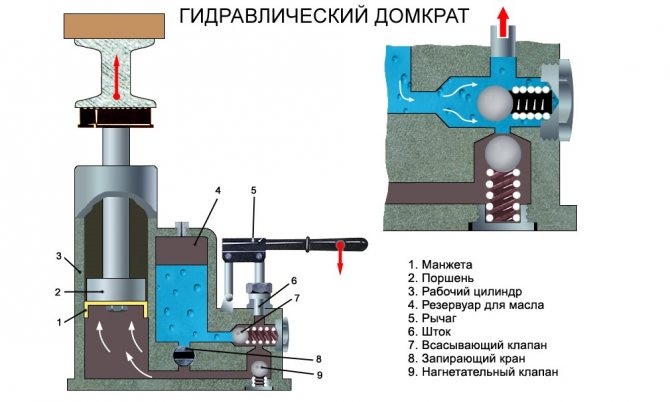

How the hydraulic jack works

The design uses the principle of communicating vessels. A force is applied to the handle of the drive (by means of an electric motor or manually). By means of a lever, the force is supplied to the delivery pump. Oil enters the bottom of the cylinder when the lever is pressed or the electric motor is started. The piston rises. The bypass valve, which consists of pressure and suction valves, keeps the oil pressure at a constant operating level. The suction valve is located at the inlet to the container and does not let the oil back in when the piston is lowered. The pressure pump is installed at the inlet to the cylinder and does not let the oil out during the piston lift.

What is the difference between hydraulic jacks that puts them in first place among other types of lifting equipment:

- work smoothly and quietly due to the fact that the working fluid is not compressed;

- very stable;

- the construction is rigid and durable;

- small size;

- clarity of braking;

- low effort and high efficiency (up to 80%);

- exact stop;

- high carrying capacity.

The hydraulic mechanism can handle objects set very low, lifting them off the floor. This is a great advantage over other types of lifting devices.

- low speed of work;

- low lifting height;

- inconvenience of transportation (must be located strictly vertically to avoid oil leakage);

- the lowering height of the load cannot be adjusted.

In the event of a breakdown, repairs are more complicated and expensive than those of a mechanical counterpart. The hydraulic lifting device works with loads weighing 2 - 200 tons.

Special-purpose devices are capable of lifting very bulky loads to great heights, fixing and holding them.

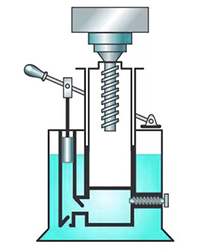

Hydraulic bottle jack single very easy to use, therefore its variations are the most widely used.

The trolley has a low fit and is mounted on wheels. Levers for lifting the load leave the body. Typically, such equipment has a drive handle of sufficient size to reduce the applied forces. A mechanism of this type can only work on hard and smooth surfaces.

The range of application of the jack is much wider than just using it when changing tires on a car. Any experienced car owner knows when to use this device.

But besides the rules of operation, it is important to know how to properly maintain and replace hydraulic material.

Unlike the existing lifting mechanisms, the jack has small dimensions and weight, simple operation, convenience and a high degree of reliability. For every car owner, such a tool is a necessary and very important thing.

There are several main types of jacks:

The control can be manual and by means of an electric drive. Some models can handle loads up to several hundred tons.

Refueling mechanisms

Next, let's look at how to properly pour the recommended oil into the jack. Occasionally, if handled incorrectly, hydraulic fluid may spill out and fill voids with air. This will cause the jack to fail. In this case, an oil change is required.

The rack and pinion mechanism is quite dimensional, it is used not only for lifting the body, but also for repairing old buildings. Before changing the lubricant, the mechanism must be fully lowered. To verify this, residual stress can be relieved by turning the exhaust valve counterclockwise.

The filler neck is usually located on the tank body, usually at the bottom of the cylinder. It is necessary to free the neck from the bolt or plug that reliably protects the oil in the container. Then you need an oiler, the nozzle of which must be inserted into the neck and filled.

There is sufficient hydraulic fluid when it overflows. Now all that remains is to tighten the bolt with effort or insert the plug.

Pouring lubricant into the bottle jack will have to be a little different. But first, you also need to make sure that the mechanism is lowered all the way. You can insure yourself using the same method as in the rack and pinion mechanism.

In a bottle design, the plug should be found on the master cylinder body at the top. To begin with, remove the plug and fill it with an oil can, which is pre-filled with hydraulic oil, removing air from it. In this case, the oil level should be 1/8-inch less than the filler hole.

Changing the oil in the hydraulic jack has its own characteristics. Before pouring, the mechanism should be disassembled and cleaned. Dirt and rust can build up on the piston. Next, you need to inspect the gaskets (they wear out rather quickly), and replace them if the integrity is violated.

Do not open the valves yourself. This can lead to the failure of the entire unit.

Before pouring oil, you need to pump the mechanism, thereby freeing it from air, and drain the old fluid. Then you can start pouring through a special hole. It is tightly closed with a threaded plug.

The required level is indicated by a special line on the body. When the level has reached the mark, the plug is tightened and the mechanism is pumped to get rid of air voids. The piston should be raised to the limit. Then unscrew the lid again and top up and pump again.This is done several times until the liquid begins to pour out. This indicates correct filling. The procedure is easier to do with an assistant.

As you can see, filling and changing the oil in the jack is quite simple, you just need to follow the recommendations that you got acquainted with in this article and it will not be difficult to do this operation yourself.

The most important tool for working with heavy massive structures is the jack. It is used to lift loads when repairing equipment, cars or during various construction work.

The most important tool for working with heavy massive structures is the jack. It is used to lift loads when repairing equipment, cars or during various construction work.

To ensure high-quality and durable operation of the lift, it is necessary to use a special oil for jacks. Correctly selected composition of this element will allow the mechanisms to work with high efficiency and minimal wear.

How to fill in oil correctly

It is the lack of oil in the jack that leads to its poor performance. Fortunately, such a breakdown is easy to fix - you need to add fluid. However, you should know what exactly to top up.

Often the working fluid in the jack is called oil. This is because it is used in jacks, although the device will work even on water.

A high-quality fluid will ensure long-term operation of the mechanism:

- Industrial types of industrial oils. But not types I30A, I40A, I50A - they are too viscous.

- Brake fluid is too hygroscopic, that is, it absorbs water vapor. And water will eventually lead to corrosion and breakage.

- Proprietary Hydraulic Fluids - Manufactured specifically for braking and lifting systems.

- Water is a short-lived jack, but it will work.

Important!

You should also avoid liquids of glycolic, petroleum and mineral origin. The best solution is synthetic oil, which, moreover, does not thicken in the cold. ... After the fluid is selected, it is necessary to perform preparatory work to replace it.

After the fluid is selected, it is necessary to perform preparatory work to replace it.

First, the old liquid is drained. For this, the plug is unscrewed and the device is pumped. The jack is then rinsed with a cleaning fluid available from your hardware store. The solution is poured and drained. Before filling with new oil, there must be no foreign liquid in the jack.

How to unscrew the plug

After that, the jack is set to the lowest position, and the screw-crane turns to the "Drain" position. Oil is poured. The required level is shown by a mark on the jack.

Important!

The oil level should be as accurate as possible. You can not overfill or underfill. ... After the first filling, the plug is closed, and the jack is driven 5-6 times. The plug opens again and oil is poured

It must be repeated several times until the oil stops leaving.

After the first filling, the plug is closed, and the jack is driven 5-6 times. The plug is opened again and oil is poured. It must be repeated several times until the oil stops leaving.

After the final oil filling, a test distillation of the liquid is carried out again to get rid of the air. To do this, the jack is pumped - raised and lowered - until pressure appears. Excess air is discharged through special pipes; oil must be added in its place as it leaves.