Jigsaw operation

Prepare the necessary rigging before work.

Setting up the device

- Take the blade replacement bracket. Loosen the mounting bolt. Insert the correct file and tighten the bolt. The file is replaced in the same way.

- If you have the function of quickly changing the file, then turn the lever of the corresponding unit.

- Adjust the stroke rate. The harder the material, the lower the frequency. The tree is sawn at maximum speed. Metal - half as much. For plastic, the speed is 2.5 times less than the maximum. The tiles are processed at a low speed.

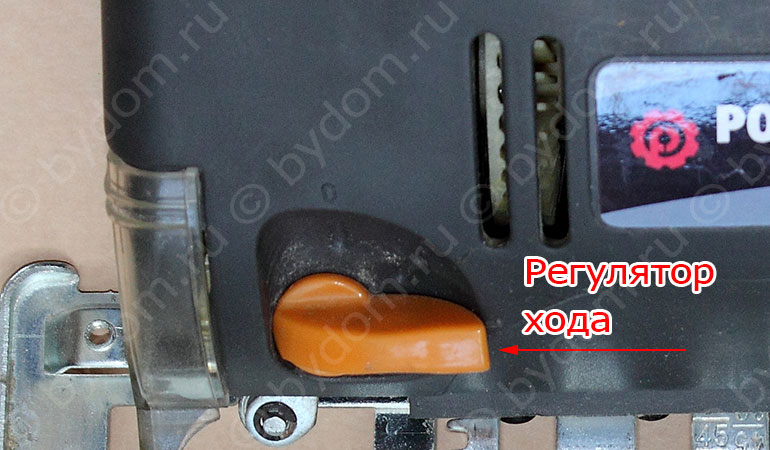

- Install the pendulum stroke. It is used for thick pieces of wood. There are three positions of the regulator: 1 - thickness 30–40 mm; 2 - thickness 40-50 mm; 3 - more than 50 mm.

Jigsaw work

- Secure the part to the workbench.

- Install the device with the cutting end to the workpiece. Turn on. Without pressing on the canvas, guide it along the drawn line. If you use excessive force while sawing, the blade may break.

- Change dull equipment immediately so that there is no heavy load on the engine and the device does not fail.

- Use a straight edge and staff to make a long cut parallel to the edge. Measure the desired distance. Place the rail along the cutting line, fix it on the workpiece with a clamp. Move the tool parallel to the staff.

- For tilt sawing, loosen the platform attachment. Set the angle to the desired value. Tighten the mount.

- To cut a straight circle, connect the guide to the center. It is included in the tool kit. Clip it in the middle. Guide the jigsaw around the center.

- When cutting patterns, secure the jigsaw to the table. Then you will see the whole drawing. You will be able to guide the part along the desired path with both hands.

- To work with thin metal, place plywood underneath so that the workpiece does not deform.

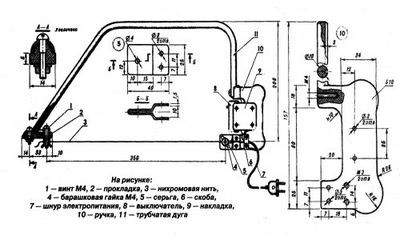

How to fix the jigsaw on the table

If you convert a regular jigsaw into a desktop version, then its capabilities will expand.

- Take a countertop with a thickness of 12-15 mm. Drill four holes in it and in the jigsaw platform.

- Place the worktop on a base that is at least 22 mm thick. Screw on the jigsaw.

- If it has a branch pipe for blowing out sawdust, you can connect a vacuum cleaner. To do this, make a round hole at the back of the table base and route the hose from the vacuum cleaner.

- Now you can saw.

How to work with a jigsaw

- Make cuts along and across the grain. If the file goes only along, then replace it. If the defect is repeated in both cases, you need to adjust the guide assembly.

- For some, the problem is solved by adjusting the video.

- To do this, loosen it and slide it forward or backward.

- For others, adjusting the guide nuts. They are bolted. Loosen them and set the desired position.

- Make control cuts. Repeat the adjustment if necessary.

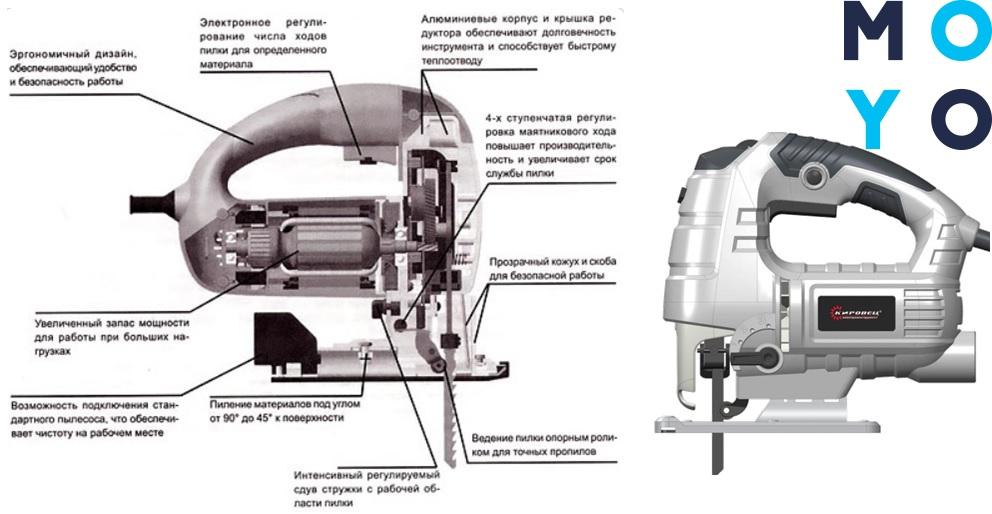

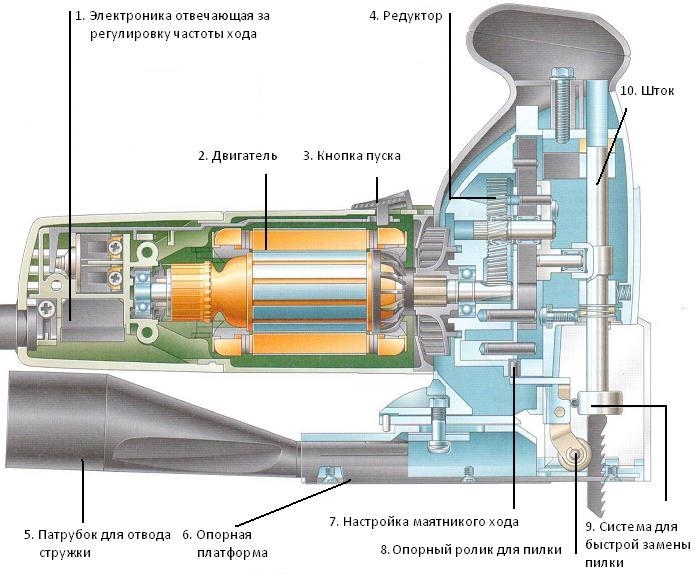

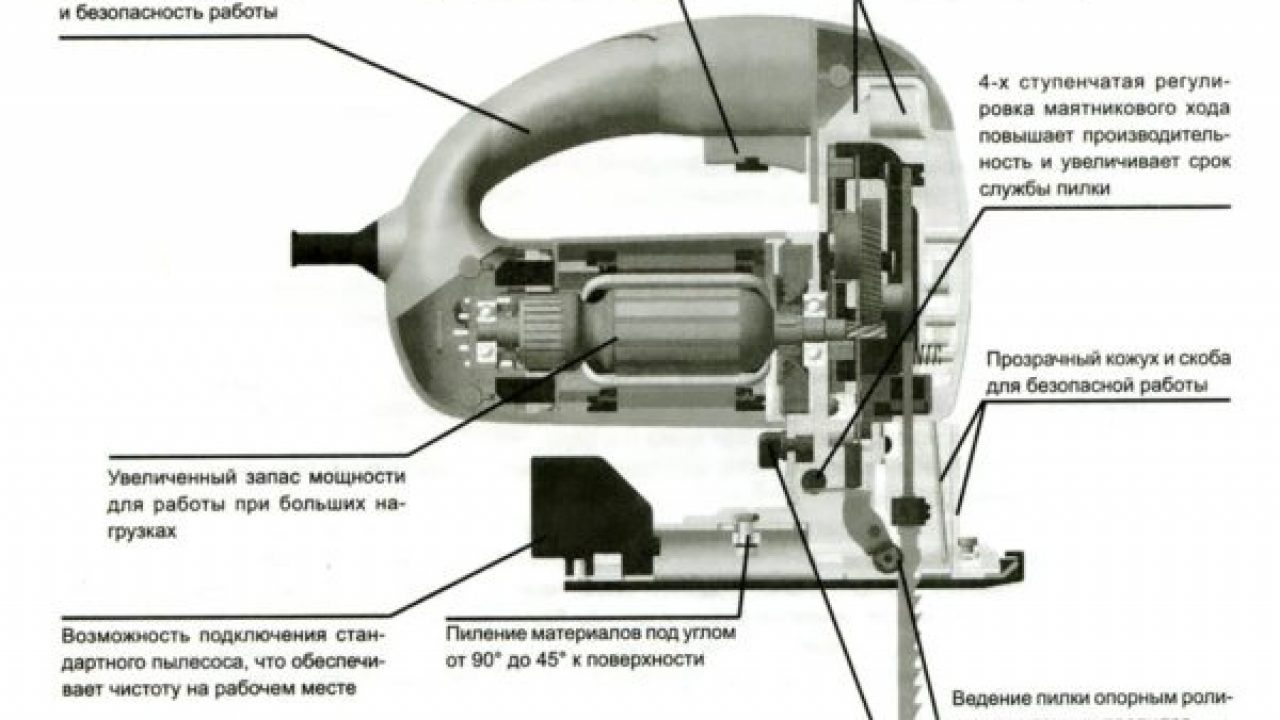

Device

To make the right choice of a jigsaw, you need to understand how it works, what elements it has, and what is their difference. Below is a schematic sectional view.

| Number | Description |

| 1 | Start button |

| 2 | Adjusting the speed of the electric motor |

| 3 | Stock |

| 4 | Reducer |

| 5 | File clamp |

| 6 | Support roller |

| 7 | Electric motor |

| 8 | Brushes |

| 9 | Support bearing |

| 10 | Shavings outlet |

Let's analyze the purpose of each element:

- Start button. Closes the electrical circuit and turns on the electric motor. Many jigsaws are equipped with a soft start system that allows you to adjust the engine speed by pressing the start button.

- Adjusting the speed of the electric motor.With this regulator, you can determine the maximum number of revolutions of the electric motor when the start button is fully pressed.

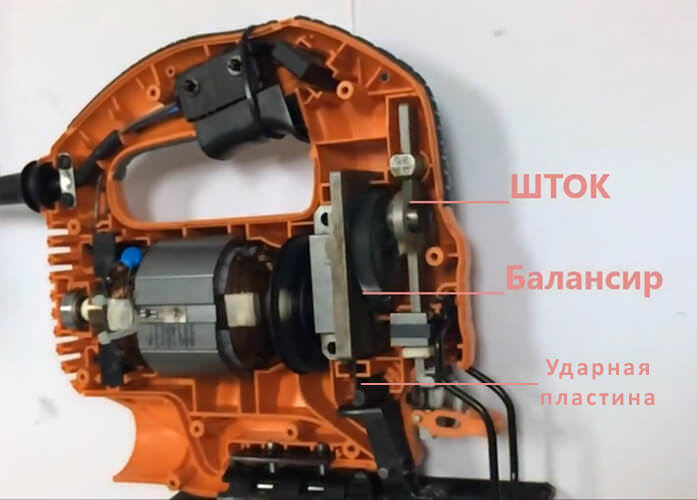

- Stock. A metal rod that determines the forward motion of the jigsaw's saw blade.

- Reducer. A mechanical device that converts the rotational movement of an electric motor into a pendulum movement of a rod.

- File clamp. A device that allows you to rigidly attach the saw blade to the stem. There are different fastening standards and, accordingly, types of saw shanks.

- Support roller. The roller on which the file rests during movement.

- Electric motor. The electric motor is the basis of the power tool and in the case of a jigsaw, it sets in motion the rotating parts of the gearbox, which at one time transmits the translational movement of the stem.

- Brushes. Graphite brushes transmit electricity from the stationary current-carrying wires to the rotating elements of the electric motor. They are not durable, so over time they wear out and the engine, without receiving electricity, stops working. In this case, you just need to replace the brushes. This is one of the most common problems with any power tool.

- Support bearing. Despite its seeming insignificance, the support bearing has a very important role - it is the support of the electric motor. It is he who often fails in the cheapest models of jigsaws. This is due to the fact that the bearing is fixed in a plastic case and during prolonged operation of the jigsaw under load, it heats up to temperatures at which the surrounding plastic begins to melt, which leads to deformation of its seat and displacement of the electric motor and further jamming.

- Chip removal branch pipe (dust collector). The jigsaw is equipped with a system for removing dust and chips from the sawing area in the form of a special branch pipe that must be connected to the vacuum cleaner's hose. During operation, a large amount of sawing products (dust and shavings) are formed, which are recommended to be removed.

- Support platform (or "sole"). In this diagram, it is not indicated, but it will be discussed separately below.

The main components of the jigsaw are discussed above, but the various functional parts that may optionally be present on various models are not touched upon. These include:

- The flashlight serves as an illumination for the cutting area;

- Laser level, allows you to cut more accurately;

- The chip blowing system allows a directed air flow to remove sawed products (dust and chips) from the cutting area for a better view of the cutting area.

and etc.

BOSCH GST 700 manual jigsaw for home use

- power - 500 W;

- cut up to 70 mm;

- adjustable stroke frequency;

- low vibration.

The optimal device for homework. Power - 500 W. Adjustable speed, from 1450 to 3200 movements per minute. Stroke length - 20 mm. The cutting depth depends on the material: wood, plastic - 70 mm, aluminum - 10 mm, steel - 6 mm. Equipped with a 4-stage pendulum stroke. The handle is made in the form of an upper bracket. The sole is steel, it can be tilted up to an angle of 45 degrees. This allows you to make cuts with a predetermined slope in relation to the upper plane of the material.

The tool has a connection for a vacuum cleaner in order to quickly remove sawdust. This ensures clean work with the device in residential premises, offices without taking out furniture and subsequent cleaning. Sold for 4000-5200 rubles.

BOSCH GST 700 has compact dimensions and low weight of 2 kg, it is the smallest in the review - 225x202x80 mm. It is pleasant to work with the tool, there is practically no vibration, the handle fits well in the palms. Power is sufficient for most jobs. Saws dry wood easily. With damp it is worse - it heats up quickly even on a 50 mm board, you have to give time to cool down. Quick-detachable files, fixed with a hexagon.

The main purpose of the model is amateur use.The device is rather semi-professional. Will help in carpentry, joinery, construction, repair. You can saw finishing materials, drywall.

Users love the vibration and runout free, adjustable travel, inclined sole, deep cut, good value for money. There are complaints about the too tight start key.

Pros:

- good power;

- works almost without vibrations;

- sawing wood - up to 70 mm;

- regulation of the stroke frequency;

- inclined sole;

- reliable;

- easy change of files;

- optimal price-quality ratio.

8 SIMPLE FEATURES WHEN CHOOSING ELECTRICAL

1. WIRE OR BATTERY

The manual jigsaw can be powered from the mains, or in a cordless version. These types differ in weight and weight distribution: for cordless jigsaws, the center of gravity is shifted back, since a large, heavy battery is installed there.

This is important for artisans who are accustomed to balancing a networked instrument.

Modern wireless models by all criteria can easily be compared with network models, the only limitation in operation is the battery capacity.

2. HANDLE SHAPE: STAPLE, SAME D-SHAPED AND MUSHROOM

For straight cuts in the horizontal plane, a tool with a staple handle will be convenient. Models with a mushroom body are considered good for a curved cut, but they are inherently more versatile and have a more reliable grip. You can hold on with one or two hands: the body and the protruding handle. Sawing vertical material with a mushroom jigsaw will not tire your hands as much as with a D-handle tool, since you are holding the jigsaw not by the handle, but by the body, the grip is as close to the center of gravity as possible.

3. CUTTING DEPTH AND MOTOR POWER

Manufacturers indicate the parameter for three main materials: wood, steel, aluminum. A household-class machine has enough power of 500 W to cope with 80 mm of wood, cut steel up to 5 mm.

The requirements for a professional tool are higher: the power consumption of the electric motor is from 800 W, the cutting depth of wood is 140 mm, steel is 35 mm.

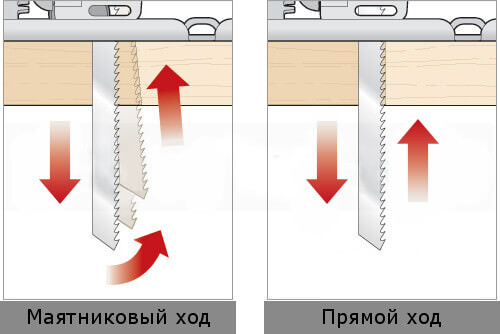

4. PENDULUM STROKE

The pendulum motion allows for a more aggressive and faster cutting of the workpiece due to the swing of the file. The blade is pushed forward during the reciprocating motion and digs harder into the material.

Do not rush to turn on the pendulum to the maximum: not all materials can be cut accurately with it, for example, strong chips will remain on the laminated chipboard if you work with the maximum pendulum stroke.

5. SPEED ADJUSTMENT

This is extremely important because materials require a different approach. The instructions indicate the ratio number of strokes per minute and graduations on the adjusting wheel. When sawing wood, laminate, chipboard, the stroke rate is set to the maximum. If the blade overheats or the tool becomes difficult to operate, reduce the speed. Saw metal and tiles at a low speed. To cut plastic, the speed is selected individually, but it should be remembered that the material melts easily when heated.

6. FITTING THE SAW

The quick-release fastening of the consumables is becoming more popular with manufacturers, and the prices for such samples are becoming affordable, but a significant part of jigsaws are still equipped with screw fastening, a hex wrench is included.

7. SOLE QUALITY

The support sole of the jigsaw can be cast or stamped. The platform can change the angle of inclination relative to the material: 0, 15, 45 degrees. This mobility has its drawbacks: it is advisable to periodically check the settings for the perpendicularity of the file and sole. Make sure the angle is 90 degrees and tighten the screws.

Burrs or damage may appear on the sole of the jigsaw during operation. Therefore, the part must be inspected from time to time.

8. REMOVING SAWDUST

The jigsaw is designed to blow air onto the saw blade, cooling it down and blowing dust off the workpiece.If the hole gets clogged for some reason, it will be inconvenient to cut due to the large amount of sawdust. The presence of a dust extraction branch pipe will allow you to connect a construction vacuum cleaner, which will collect all debris and dust.

How to control the pendulum stroke?

And so, we have already figured out that your electric jigsaw has such a function, so now you just have to understand what exactly it gives and how you can use it.

In fact, everything is extremely simple. If you do not turn on the pendulum function, then the jigsaw file will only move up and down in translational movements. This is what allows us to cut wood, but unfortunately, not as fast as we would like.

Now let's imagine that you turned on, well, let's say the first is the pendulum stroke on an electric jigsaw. The saw will not only move up and down, but also swing to the side, against its cutting edge and back. Thus, the cut will no longer be straight, but at a sharper angle, which will slightly speed up the cutting process itself.

The higher the number on the pendulum adjuster, the sharper the angle of inclination of the cutting edge stroke. Accordingly, the speed will increase significantly, since in one forward motion, the saw will be able to cut at least twice as much as in the standard mode without pendulum motion.

Top 10 best jigsaws

The top jigsaws include models that have proven themselves in terms of power, ease of use and other parameters.

Bosch GST 65B

The Bosch jigsaw tops the list. Its main advantages are a small degree of vibration, reliable fixing of the sole, low weight and dimensions. All this makes it very convenient for household chores. Hand fatigue during work is minimized, thanks to the structure of the body and the fastening of the sole, and the blowing function allows you to follow the cutting line. The model performs well when working with wood, plywood and metal, so it can be considered versatile.

The Bosch GST 65B jigsaw is suitable for sawing various building materials

Bosch PST 10.8 LI

Another model from the same manufacturer. Its main advantage is that it runs on battery power. Other advantages follow from this - low weight, smooth acceleration of the engine, adjustable sole. An interesting additional feature of this model is LED backlighting. In combination with battery power, this allows you to work outdoors in poor lighting. And if you need to replace, for example, a jigsaw blade for wood with a blade for metal, then this can be easily done using the quick fix mechanism.

Cordless jigsaw Bosch PST 10.8 LI with built-in LED light

Makita 4329

The Makita electric jigsaw is distinguished from other models by its minimal vibration. After using this model, you will not want to pick up another jigsaw. Among other advantages, it is worth noting the presence of three modes of pendulum movement, a rubberized handle and the ability to adjust the base plane. The minus of the tool is the long-term replacement of the blade.

The Makita 4329 jigsaw is equipped with three pendulum modes

AEG BST 18X

Cordless jigsaw with very extensive functionality. Nice bonuses of the model - the presence of a screen for face and eye protection operator, electronic brake and die-cast aluminum sole. At the same time, the model is relatively inexpensive, and the only thing that can be attributed to its disadvantages is its large weight compared to other cordless jigsaws. So for a more comfortable use, you may need a jigsaw table.

Cordless jigsaw AEG BST 18X with electronic brake function

Dewalt DW 349

Powerful tool with convenient manual platform adjustment. The speed is regulated by a simple switch, there is an LED light and a sawdust blowing function. The jigsaw also comes with a special soleplate to protect the material being cut.

Dewalt DW 349 electric jigsaw with integrated sawdust blow-off function

Dewalt 331K

A very reliable jigsaw with a closed motor, a lot of settings and the ability to adjust the tilt of the blade without a key. As with the previous model, the sole is equipped with a special soft overlay.

Dewalt 331K jigsaw with closed motor

Ryobi CJS 180L

A jigsaw with a lot of possibilities, but unfortunately not very powerful. Differs in light weight, the presence of a laser pointer and a protective fence. The battery and charger for this model will have to be purchased separately. Can be used as a tabletop jigsaw.

The Ryobi CJS 180L jigsaw features low power and light weight

Interskol MP-100E

The Interskol jigsaw is interesting because it is a domestic model. The main advantage is the low price. Other advantages include high resistance to loads, cast gear housing, hinged engine cover for more convenient cleaning.

Electric jigsaw of domestic production Interskol MP-100E

Bosch GST 14.4 V-LI Professional

An excellent representative of cordless jigsaws. In this model, the jigsaw holder is designed in such a way that the blade can be replaced in one motion. There is a backlight, sawdust blowing function. The main advantage is the long battery life.

The Bosch GST 14.4 V-LI Professional jigsaw has a long operating time without recharging

Makita JV100DWE

Very compact jigsaw with the ability to adjust the pendulum stroke. An excellent household jigsaw with low power, but great efficiency.

Makita JV100DWE jigsaw - compact model for home use

Parts that make up the jigsaw

-

- Engine housing. The most demanding part of the tool in terms of strength, since it is in it that the engine is located, the rotary movement of which is converted by means of a shaft and a gearbox into a reciprocating movement of the slide. In turn, the main cutting part of the jigsaw is attached to the slider - a saw blade or a saw.

- Reducer. Sometimes it is made of plastic, which not only reduces the strength of the tool, but also impairs its heat transfer. As a result, such a tool will heat up faster and is more likely to fail quickly. Therefore, a metal gear housing is preferred.

- Sole. This element of the device plays an important role in making accurate high-quality material cuts. Inexpensive models often use a stamped plate made of metal or, worse, plastic. With such a tool, you should not rely on high-quality work. The most preferred option is a die-cast metal sole. In addition to the material from which it is made, the reliability of its attachment to the jigsaw also plays a role. The fastening must be reliable and free of play.

- Lever.

Types of jigsaw handles

- In the form of a staple. An example of such jigsaws can be Makita model 4327, Makita 4329. Convenient to use for cutting work, where many curly cuts are not required.

- D-shaped. Representatives of this class are Hitachi models CJ 110 MV and CJ 120 V. With such a handle, large smooth cutting lines are easily given.

- Mushroom. BOSCH uses these handles in the GST 120E and GST135CE jigsaws. The mushroom-shaped handle allows for the best possible performance of curly cuts, in which, for turns, you need to constantly change the grip of the tool by the operator's hand.

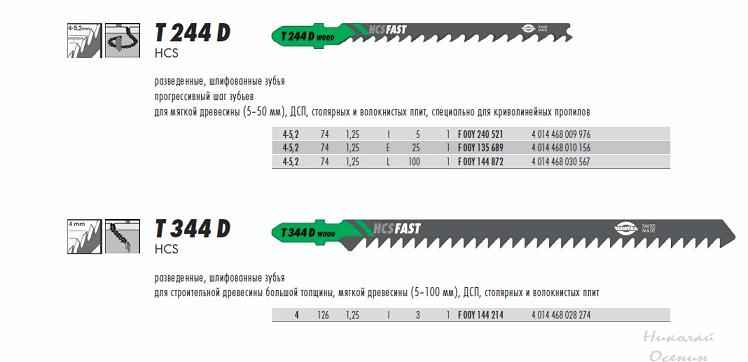

A hacksaw blade or file. As for the choice of jigsaw blades, it is also an important point to ensure the quality of the cut at the proper level. The basic principle in the selection of a saw blade is as follows: for different types of work and different materials, you need to use only the appropriate saw blades. This extends the service life of both the file and the tool itself.

Saw blades differ in:

- The material from which they are made.

- Tooth pitch.

- The way of sharpening and routing.

- The shape of the blade and teeth.

Classification of paintings:

- Made of high carbon steel (HCS mark) - themselves flexible enough to handle soft materials.

- High Speed Tool Steel (HSS) for stronger materials.

- Made of bimetal (BiM) - a combination of the flexibility of the blade itself and the hardness of its teeth (or spraying). Accordingly, the blade is HCS, the teeth are HSS.

- Made of durable material, HM / TC allows you to work with fiberglass and even roof tiles.

- With a wave-like edge. Used to work with non-ferrous metals.

- For ceramics, glass and other hard materials, files with diamond or other dusting are used; tipped with hard alloys.

- Special canvases for tiles.

Anti-splinter device.

To avoid chipping of the material being cut and to get a clean cut, various anti-splinters are used. For example, Makita 4351FCT; "Boshevskie" models GST 85PE, GST 120E (BE), GST 135BCE (CE). The choice of the appropriate blade and the optimal speed of its movement contributes to the reduction of chips.

Other important technical characteristics and control features of jigsaws include (vary by manufacturer and model):

- adjustment of the speed of the file;

- limiting the starting current at start;

- multistage pendulum motion;

- the ability to quickly change the file without additional tools;

- tool-free tilt adjustment of the base plate for bevel cuts;

- sawdust removal system and connection to a vacuum cleaner;

- illumination of the working area.

When buying a tool, pay attention to these features of jigsaws, choosing the best option for yourself

Jigsaw. Appointment. Choice.

Jigsaw. Appointment.

The jigsaw, along with an electric drill and an angle grinder ("grinder"), can be safely attributed to the number of the most popular and versatile hand-held power tools. It can be used to perform both straight longitudinal and curly cuts in sheet materials made of wood, metal, ceramics and plastic. Moreover, the design of modern jigsaws allows you to do this efficiently and quickly, accurately following the previously made markings.

Jigsaws are especially widespread as tools for woodworking.

The working element of the jigsaw is a small file with a length of only 50-120 mm. It reciprocates along the vertical axis with an amplitude of 25-26 mm and a frequency of 500-3000 vibrations per minute, forming a narrow (~ 1 mm) cut in the material being processed.

Depending on the materials for which they are used, jigsaw files differ in the type of steel from which they are made, in their dimensions and the design of the cutting teeth. For example, for woodworking the "pitch" of the teeth is within 2-4 mm, and for metal - 0.7-1.5 mm, rarely - 3 mm. The length of files for wood and cardboard is 50-120 mm, for metals - 50-75 mm.

The jigsaw saw is driven through a special gearbox by a collector motor. In order to speed up the cutting process and increase the service life of the file, in addition to movements along the vertical axis, pendulum vibrations are also communicated to it, when the cutting blade is retracted from the material when moving down, and cutting is performed only when it moves up. So that the cutting speed does not depend on the load on the saw, the effective power of the electric motor is set by a special electronic regulator.

Almost all jigsaws are designed to be operated with one hand. For this, a convenient handle with an on / off button is located above the motor and gearbox. And the file attachment point with protective glass and the file itself are in the lower corner of the front end of the jigsaw.

To ensure high cutting accuracy, the entire tool structure rests on a smooth base plate.It frees the hand from the need to hold the jigsaw on weight, maintains a constant distance to the work surface and allows you to set the cutting angle (up to 45 °). That is, the cutting plane can be not only vertical, but also inclined.

In many models of jigsaws, there is an illumination of the working area and automatic blowing off of sawdust, as well as a branch pipe for connecting to a suction device (vacuum cleaner).

The capabilities of jigsaws largely depend on the power of the electric motor used in them. And if tools with a power of 700 W are able to successfully cut a wooden sheet with a thickness of 100-110 mm, steel - 10 mm, and from non-ferrous metal - up to 30 mm, then a power of 400 W allows you to work with wood only 50 mm thick, with steel 3 mm thick, with non-ferrous metal - up to 10 mm.