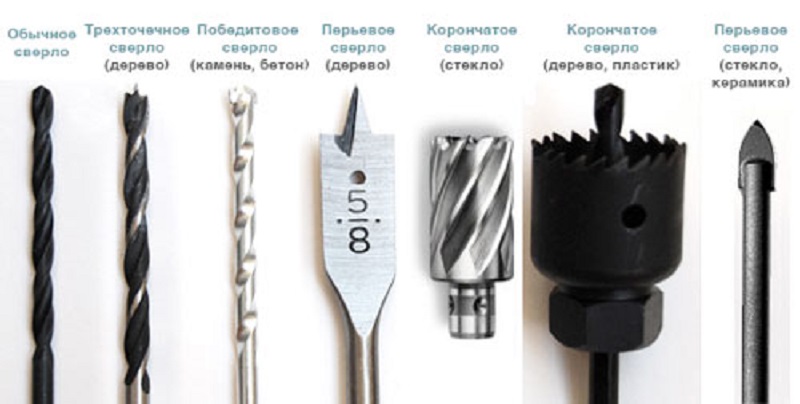

Flat

Drills with a narrow tip. Compared to other drills:

- warp much less often

- simple construction

- low price

Pen drill for metal with indexable inserts

- cannot be used for drilling wide holes

- no chips are ejected from the hole. can remain inside, so the holes must be cleaned and the drill itself must be clean

Spiral

The most common type of drill, optimal for creating holes in metal. It is a metal rod with lateral grooves covering the entire length of the tool. It is these lateral spiral grooves that determine the main property of the drill - the removal of chips from the holes.

According to their purpose, twist drills are divided into several subgroups:

- Cylinder drills, general jobs (manufacturing and home conditions). Their diameter reaches 82 mm.

- Left-hand twist drills - so called because they have the opposite direction of twisting the spiral groove, that is, to the left. This allows the drill to be used to remove stripped bolts or other damaged fasteners. The fasteners are drilled and unscrewed along with the movement of the drill.

- High precision drills. These tools show the highest level of material handling with millimeter tolerances.

Crowns

Designed for drilling large holes. They represent a large metal glass with teeth on the edge. In some cases, instead of teeth, various metal or diamond coatings can be used. To work with high forces, the crowns are made of hard alloys.

Drilling only takes place from the outside, so the middle of the hole simply remains empty.

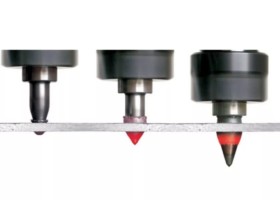

Conical drills

The working surface of this type of drill is smooth and consists of steps. They are used for making holes in thin materials. Due to their shape, they are easily centered at the first moments of drilling, which, of course, is more convenient than with cylindrical drills. Another undoubted plus with one drill you can get holes of different diameters, this is easily adjustable by the depth of immersion of the drill into the material. We drilled one diameter up to the first step, went deeper into the step and increased the diameter.

With such drills, you can not only create a new hole, but also expand the existing one.

Next, we will look at a range of metal drills that can be used to make holes even in high strength materials.

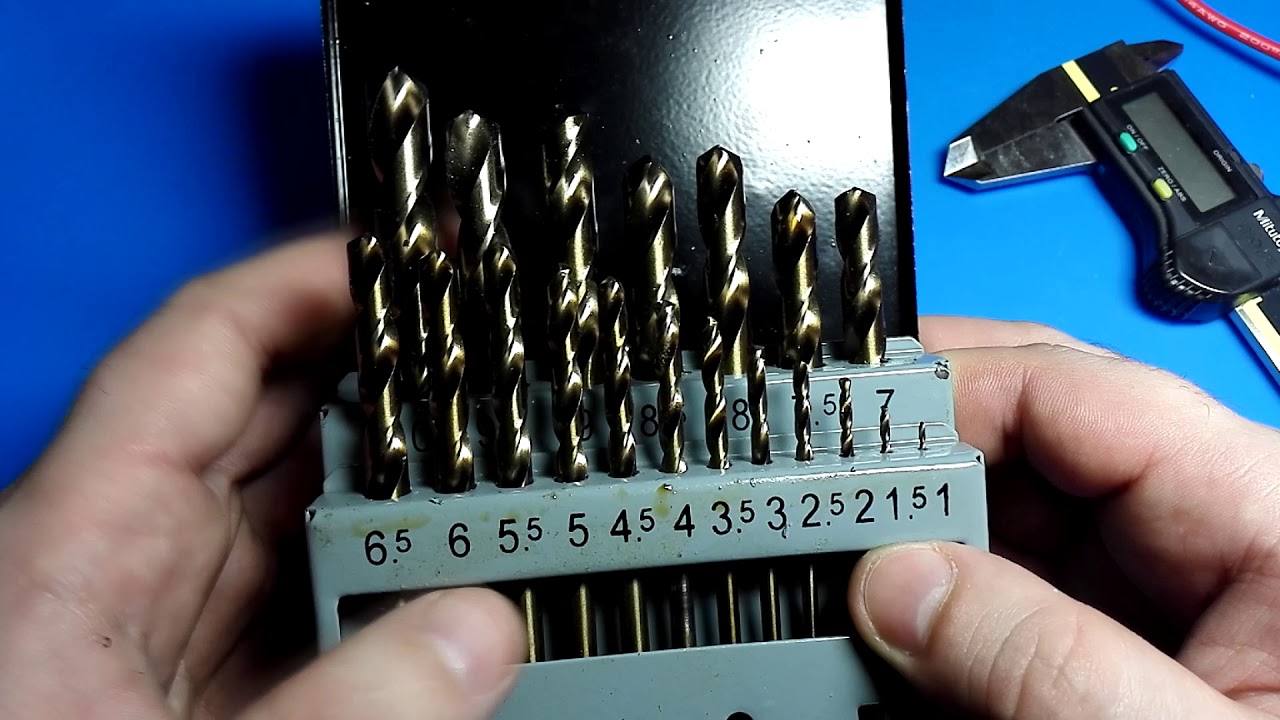

Cobalt drills

Manufactured on the basis of high speed steel or HSS. Moreover, they are additionally alloyed with cobalt. It is he who creates the necessary strength for the drill, resistance to fracture and temperature loads. Cobalt drills handle not only hard materials, but also viscous materials. Of course, the high properties of cobalt drills require more serious costs from the buyer, but in our opinion, these costs are fully justified. The performance of a single cobalt drill is high enough to replace several unalloyed steel drills.

Cobalt drills are hard enough to drill materials without punching the workpiece before starting work.

Carbide drills

The cutting surface of this type of drill is reinforced with special carbide inserts, while the base of the tool is made of CS.Plates are made from carbide alloys with increased hardness and wear resistance. Drill blades are sharpened only once in production and cannot be resharpened. These drills are used for working with especially hard alloys and metals or for thick metal workpieces.

Scope and design features

Tapered (or step) drills have a long working life, which is ensured by the high strength of their cutting edges. Unlike a conventional drill, a taper drill allows you to perform technological operations, which in any other situation would require the use of several tools. It is the versatility that largely explains the high cost of drills in this category.

Step drill device

Conical drills can make holes not only in metal, but also in drywall, wood, plastic, etc. They also successfully cope with dense metal, which cannot be said about any other type of drilling tool.

The sharp tip of the stepped drill not only eliminates the need for a centering tool, but also easily cuts into the structure of even the densest metal. The hole obtained in this case does not need additional processing using a file and a grinder.

Most stepped drills are capable of drilling metal up to 4mm thick

The progressive channels of the stepped drill, located in a spiral, are made in different sizes with a smooth transition. This design enhances the efficiency of the cone drill in thin sheet metal by at least 50%. In addition, when drilling metal parts with a tool with such spiral translational grooves, its smoothness is ensured.

On the working surface of stepped drills, abrasive spraying can be applied, the basis of which is diamond or titanium chips (this does not contradict the requirements of GOST). Such a coating of the cutting surface significantly increases the degree of its strength, which makes it possible to minimize the frequency of its sharpening. Naturally, such an advantage of using a sputtered cone drill can be counted on if the rules for its operation are followed and the permissible load on it is not exceeded.

These drills are made from high quality titanium coated high speed steel

One of the tasks that a cone drill solves is the correction of hole defects obtained with a different type of tool. Such defects include, in particular, torn edges. Step-type drills are practically indispensable in cases where it is necessary to obtain high-quality holes in thin sheet metal, fiberglass products and other polymeric materials.

Considering all of the above, it can be concluded that cone drills are even more versatile than traditional spiral type tools. That is why they will not be superfluous on the production site and in the home workshop. How convenient and effective the cone tool is, the cost of which depends both on the diameter of the working part and on the type of spraying, can be judged by the video processing with its use and from the reviews of specialists.

Drill sharpening tool

In everyday life, we do not use large drills, as a rule, the most common sizes are small and medium - from 0.5 mm to 18 mm. We will sharpen them. Just to begin with, we will collect everything you need for this. Ideally, work on sharpening a drill is best done on a sharpening machine. Every self-respecting owner is simply obliged to have a small emery in the garage. Even if it's not there, it's not scary. We will manage with a grinder or an electric drill attachment. Only first you need to firmly fix the power tool on the plane. The main thing is to get a rotating grinding wheel or emery stone.

One should not forget about safety precautions either. God saves man, who save himself. If you don't already wear glasses, then protect yourself with them. Anything can happen

It is also very important to cool the drill in time when sharpening, because if this is not done, then the steel will lose strength. During sharpening, the drill gets very hot, and for cooling it is necessary to periodically dip it in cold water or liquid oil

The liquid should be poured into a small container and placed within reach near the machine or attached power tool.

How to choose a cone drill

An indirect sign of a quality product will be its price. In addition, by the color of the metal, it will be possible to tell from the material and how strong the gimbal is made.

Stepped products can be divided by color into several quality groups:

- The gray color indicates that the product is made of steel that has not been subjected to additional processing. Such products have low strength.

- Black color indicates superheated steam quenching. The quality will be slightly higher than that of the gray counterparts, but the cost is also different.

- A deep golden color is obtained when the tool has been subjected to high temperature tempering. The procedure allows you to remove excessive stress in the metal, which has a positive effect on the performance of the product.

- If the cone drill has a bright golden color, then on this basis it is possible to identify the presence of a wear-resistant surface consisting of titanium nitride. The type of material is the most

durable, but the cost will be several times higher in comparison with cheap counterparts.

In addition to the quality of the material, the diameter of the purchased tool will affect the final cost.

For example:

- a high-quality step drill for metal 4-32 mm will cost at least 1000 rubles;

- if you do not need to drill large-diameter holes, then you can purchase a 4-20 mm drill, the cost of which, with equal quality, will be about 500-600 rubles.

Video:

What are the best step drills for metal can be determined from reviews on the Internet. Qualitative information can be obtained on specialized forums, where specialists who use tapered products in their daily work communicate.

Tool sharpening

With prolonged use, even high-quality products can become dull. Every home craftsman needs to know how to sharpen a step drill for metal. The procedure is complicated, in addition to theoretical information, you need to master practical skills.

To sharpen the cone gimbal, you must perform the following steps:

- fix the drill in a vice:

- pick up a small grinder with a grinding wheel;

- carefully sharpen the cutting edges that have been damaged.

In this way, it is possible to restore the operability of the cone tool on its own.

Video:

If it is possible to turn to specialists, then you can get a full restoration of the gimbal for little money.

Video:

How to drill

With a well-sharpened tool, it is easy to make high-precision holes in metal sheets up to 4 mm thick.

To perform drilling correctly, it is advisable to adhere to the recommendations:

- the place for drilling is marked with a core;

- the drill during operation is kept in a strictly perpendicular position in relation to the plane of the metal;

- drilling metal at low speeds. The larger the hole diameter is to be made, the slower the cutting tool should rotate. A screwdriver is ideal for this task;

- a small amount of machine oil should be applied to the drill to lower the operating temperature of the tool during operation.

Subject to the requirements, the conical product will last a long time, without sharpening.

Video:

Drill type selection

There are three main types of drills: spiral, stepped and conical (countersinks). The fourth type is somewhat less common - ring cutters, also called core drills.They are designed to create large holes up to 150 mm.

To decide on one

of the types among these options, you need to focus on the following selection criteria:

- Required finished hole diameter.

- Penetration or through hole drilling is required.

- Steel grade, product appearance and other features of the processed metal.

- Required hole depth.

- Characteristics and features of the tool used for work: drill, screwdriver, puncher, etc.

Popular manufacturers

There are a number of manufacturers whose products you can trust. There are few of them, and most of the companies are well-known and well-known.

Popularly, this instrument is often called "carrot" because of its similarity to this vegetable (perhaps, there really is a similarity, very similar in shape).

What is the versatility of this drill? And the versatility lies in the fact that it is tapered-stepped, and has a marking of sections along the length of the barrel.

Designed for drilling holes in plastic, wood, metal and other materials.

I must say right away that it will not take a material of great thickness, but thin materials up to 5 mm are just right. It is very convenient when you need to drill several holes of large diameter, for example 10 mm and 26 mm. This is done with one such cone-step drill without many additional drills and replacing them in the drill chuck.

Let's take a closer look device of step drills

, characteristics, as well as they can be applied.

Drill for a perforator - the necessary "ammunition" for the tool

Choosing the right drill for your rock drill is just as important as buying the tool itself. Correctly selected equipment will not only facilitate drilling in such hard building materials as stone, concrete, brick or, but also make working with such a serious tool easy and safe.

What is the difference between a rotary hammer drill and a conventional drill? ↑

At first glance, the drill used in rock drills is not much different from a conventional concrete drill designed for hammer drills. However, there are significant differences between them. The drill shank has a complex shape, while the conventional drill has a smooth shank. The spiral grooves on drills are quite sharp because they are designed to cut into the material, while in drills they are made to remove dust and debris formed during drilling. Despite the fact that the tip in both cases has a victorious sputtering, which gives it greater strength, the sharpening angles differ, which is explained by the difference in the principles of operation of the drill and the hammer drill.

Often, the master is faced with the question of whether it is possible to use a drill from a drill in a hammer drill and drill wood or metal with it. Yes, you can, but this requires a special adapter, which usually comes with the tool. In this case, do not forget that the perforator in this case should be three-mode, that is, be able to switch to the conventional drill mode. The drill can also be installed in a hammer drill, but it will not work to achieve the same efficiency as when drilling with a hammer drill. In addition, the drill can jam in the chuck, in which case it will have to be disassembled and possibly repaired.

How to choose a drill for a hammer drill - types ↑

The shanks of all perforating drills have the international designation SDS (an abbreviation of the German words Steck, Dreh, Sitzt, literally translated as "sit, turn, sit"). In turn, they are divided into five types: SDS-plus and SDS-max hammer drill bits are the most common, SDS (the same as SDS +), SDS-top (sometimes used in medium rock drills), SDS-quick (used on select Bosch models only).

SDS-plus is used in light and medium hammer drills for household use; the shank diameter is 10 mm.SDS-plus diameters range from 4mm to 26mm (most commonly used are 6mm and 10mm rock drill bit sets). The length can be from 100 to 1000 mm (the working length is somewhat less). The spirals designed to remove cuttings during drilling on SDS + can be different - if the angle of inclination is small, then the drill is designed for not very high-speed, but long-term work. The larger the angle, the higher the speed of work, which means that the load on the tool increases significantly, so you need to make sure that it does not overheat.

The SDS-max drill is designed for heavy-duty tools. Its bore diameter is 18 mm, and the diameter of the drill itself, as a rule, ranges from 20 to 80 mm. The spiral on SDS-max not only removes sludge, but also cools concrete or brick. Such drills can be breaching, and are intended, for example, to destroy walls when creating new doorways, or walk-throughs intended for conventional drilling. There are also SDS-max with bits in the form of crowns, used when drilling holes for switches and sockets, as well as whole typesetting systems with which you can "pass" even the thickest reinforced walls. In the event that the tool itself is purchased for permanent or professional work, it makes sense to stock up on several drills of different diameters.

It is not recommended to install SDS-max drills into SDS-plus sockets, even with an adapter, as this will damage the tool.

How to choose a hammer drill bit set? ↑

The main recommendation when making such a purchase is to pay attention to the manufacturer. Chinese and, unfortunately, Russian drills are significantly inferior in quality to those produced in European countries or Japan - their shanks may not exactly match the tool holder, and the metal is often overheated

Both of these factors lead to breakage of components, and in some cases, the hammer drill.

Accessories for tools of one company, for example, drills for Makita perforators, can be manufactured at Japanese, Korean and Chinese enterprises - if possible, the choice should not be in favor of the latter. Many well-known manufacturers produce accessories not only for professional tools, but also for "home" ones - their price is slightly lower, and the quality is quite suitable for periodic work.

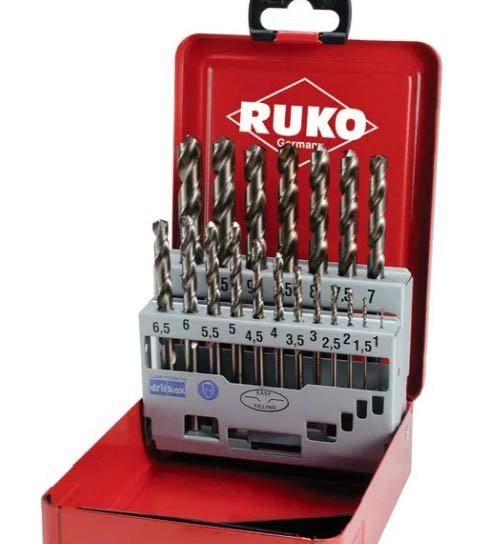

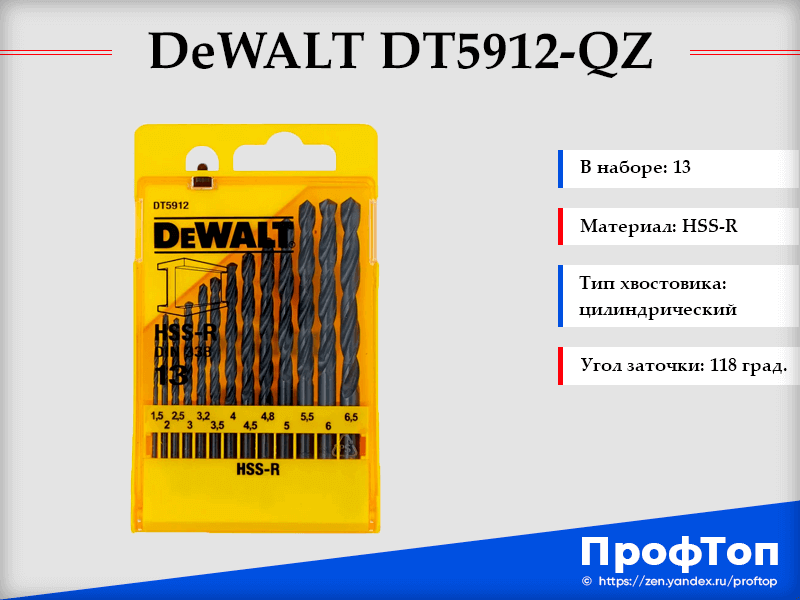

Reliable set of drill bits for metal DeWALT DT5912-QZ, 13 pcs.

- standard sizes - from 1.5 to 6.5 mm with a step of 0.5 mm;

- shank - cylindrical;

- material - HSS-R;

- quantity in a set - 13 pcs., all for metal.

The twist drill set is produced under an American brand, with production facilities located in China. The factory cutting edge sharpening angle is 118 degrees. The cylindrical shank allows you to work with chucks.

To eliminate slippage during drilling, three flat edges are applied to the non-working part. The SDS-plus adapter can be used to work with the hammer drill. Drilling can be done without preliminary punching - the adjustment of the transverse edge allows you to accurately hit the target point.

A set of tools is stored in a plastic cassette. Reinforced core adds strength and reduces the chance of product breakage. Gold-colored oxide coating eliminates the effects of overheating and extends service life. The shank is tapering to reduce breakage.

Recommended for the home workshop and in production as an additional set of standard sizes. Factory sharpening is optimal for steel, cast iron and magnesium alloys. It will also cope with wood, plastic and other materials.

Those who tried to drill with this set note the good workmanship and the availability of standard sizes for household use. Some users noticed that some of the drills are overheated and fragile, so the work requires some accuracy.

DIY metal drill

The only limitation on working with a victorious drill is that we will not be able to sharpen it on a regular grinding abrasive wheel at a normal wheel speed. The fact is that the higher the sharpening speed, the softer the drill material. The victorious drill is very hard, and at normal speed of the emery stone, the drill can easily overheat. Two options - either reduce the speed, or use a diamond grinding wheel.

There are a few basic rules, and the rest comes with experience:

- The victorious drill is sharpened by short-term touches to the circle.

- Be careful not to knock the center of the drill pivot when sharpening.

- The sharpening angle should not be less than 160-170˚.

- Do not cool the drill immediately, once after sharpening, otherwise it may crack.

- Do not overheat the victory drill.

If you follow these simple tips, your winning drill gets a new lease of life. Not from the first, but from the second time, for sure.

Drill shape

The drill is a simple tool and consists of only three elements: the cutting part, the shank and the working surface, which is necessary so that the chips do not accumulate inside the hole, but are immediately taken out.

Although it is a standard tool for working with metal, many people also use it for working with wood, plexiglass, ceramics, plastic, concrete and other materials.

By their design, drills are divided into two groups: the tools of the first group are called flat, and the second - spiral.

Decide which of the two is the best for you before purchasing a drill.

The advantages of flat tools are that they do not react to possible distortions during operation, are cheaper than spiral tools and have a simpler design.

Video:

The disadvantages of such drills are the smaller diameter when sharpening and the absence of automatic chip removal.

One of the varieties of such drills is a conical tool for metal. This drill can be purchased separately or in a set, depending on the need.

The conical type tool is used to work with a drilling machine, or a two-hand drill

If you need to make a hole with a large section, then pay attention to this particular option.

Twist drills are the more popular type of drills. They are more often bought due to their great application possibilities - they are suitable for creating almost any holes and working with different materials.

Such a drill has the shape of a cylinder, and on its "body" there are special grooves-grooves in the amount of one or two pieces.

Due to their presence, the chips do not linger during operation, but are immediately removed from the hole.

Scrolls differ in the type of tail: it can be standard, crown, designed for carving, left-handed, increased accuracy or stepped.

The standard cylindrical device has a diameter of up to 12 mm and can be used both in production and at home.

Private craftsmen most often buy this type of instrument. A core drill is used to create large holes with a diameter of at least 30 mm.

The thread tool allows you to create a thread of the desired cross-section. If you purchase a tool for these purposes, then you need to buy one that will be 1 mm less than the section of the future hole.

The stepped device is the most versatile, since it allows you to make holes of different diameters.

The only limitation on working with it is that it can be used to work only on sheet metal no more than 2 mm thick.

Video:

The tool diameter is large enough and can reach 30 mm.

To buy such a drill is usually more expensive than the others, but the price depends on the size of the section, and for small sections it will be quite acceptable.

Tools with increased precision are the best available. They are acquired in cases where the result should be as high as possible.

The price for such devices depends on the accuracy class to which they belong - it can be class A1 or B1.

How to sharpen a stepped drill

The step drill is a black sheep in the drill family. It allows you to very accurately drill holes of different diameters. And with a very accurate centering. There are different models of stepped drills, but the principle is the same - one drill can make a hole from 4 to 32 mm. They are very easy to sharpen. To restore the cutting edge, simply fix it with a rotating wheel with sandpaper.

So you can extend the life of the drills, and at the same time learn how to sharpen them. Working with a blunt instrument is not solid for a good craftsman.

Cutting tools such as drills are used to make holes in the thickness of the material. The VolgaTools company is engaged in the manufacture of drills and their implementation. Our products are made of high quality materials and are always popular with customers who are satisfied with our drill prices.

Drill types

Products can be divided into drill bits for concrete, metal, wood, glass and tiles. Depending on what kind of work they are intended for and the prices for drills are formed. By design, the drills are a rod with a shank for fastening, a working part, a cutting part and grooves for removing chips. The drilling process occurs due to rotation, feed along the longitudinal axis of the tool. In this case, the drill cuts into the material, and the chips come out.

The following main types of drills are used in industry: spiral, pen, ring, centering, special.

Twist drills with a cylindrical shank are in great demand for hand, power tools and poodles for drilling holes on stationary machines.

For work on metal, drills are made of a screw shape, with a pointed end.

Best concrete drill sets

These drills differ from similar products for other work by soldering on the tip and the angle between the cutting edges. The width of the brazed plate exceeds the diameter of the drill itself. Products can be made in the form of a cone, cylinder or crown.

DeWALT 6956

A set of a well-known American company that manufactures its goods in various countries of the world, including China. The set includes five drills of various diameters: 4,5,6,8,10 mm. Convenient plastic packaging allows you to comfortably carry the tool to the workplace and store it on a workshop or garage shelf.

Advantages of the set:

- Fast and high-quality drilling of concrete and brick products.

- Convenient for clamping cylindrical shank end.

- Great working resource.

- The set contains the most common sizes for work.

- The price matches the excellent quality of the drills.

Cons of the set:

- Not found.

Vira 550105

The set is the fruit of a partnership between a Russian company and a Chinese manufacturer. This set contains twist drills, which are most often used in work. Their diameters are 4, 5, 6, 8 and 10 mm. This consumable tool can be used to drill concrete, brick, stone - hard steel alloy copes with such work without problems.

Advantages of the set:

- Convenient bright packaging.

- Cylindrical end shape, convenient for clamping.

- Compact package dimensions: 166x59x12 mm.

- Light weight: 160 g.

- provide high-quality drilling, do not break under intense load.

Cons of the set:

- Not found.

Makita D-05175

The consumables of the Japanese company are packed in an easy-to-carry box. Information about each drill included in the kit is printed on the body of the package, which allows you to accurately select the correct consumable tool. Carbide tips allow you to work with such durable materials as stone, brick, concrete.

Advantages of the set:

- The set includes drills of various diameters: 4, 5, 6, 8, 10 mm.

- Compact package dimensions: 155x57x12 mm.

- Minimum weight: 157 g.

- Classic shank end, cylindrical, suitable for different drilling tools.

Cons of the set:

- The lack of proper control in production leads to the release of crooked drills, especially products of 6 mm sin this.

- Comments are expressed about the poor presentation: traces of rust are visible on the instrument.