Bosch jigsaw: high price and expensive repairs

And of course Bosch. The power tool of this manufacturer is distinguished by the high quality of components, assembly and a long service life, provided that it is treated with care. He also has a drawback - the price. Moreover, both the product as a whole and the spare parts are expensive.

It should be noted that the Bosch tool practically does not break, but there are some nuances that appear during long-term use. For example, wear on the brushes of the electric motor, failure of the speed controller or the device for holding the saw blade. There are accidents and more complicated ones, failure of a rod or an anchor, but this is, rather, from incorrect handling.

As in the case of Metabo, Bosch jigsaws are best repaired at service centers. There they will install original spare parts and give a guarantee for the repair performed. But this is an expensive pleasure.

After reading the article, the user received theoretical knowledge about jigsaw failures. Now, in the event of a breakdown, he will be able to determine the cause and make the right decision, and maybe even perform minor repairs.

>

Features of cutting straight elements

Despite the fact that this type of work is one of the most common, with a lack of experience, difficulties may arise with how to smoothly saw off any element with a jigsaw. It is recommended to opt for a wide blade, designed for straight cuts, in order to better maintain the marking line. For an even cut, the presence of the "soft start" function plays an important role. In this case, the tool begins to gain momentum gradually, due to which the jigsaw is better controlled at the initial stage of cutting.

In the process of work, you should not use excessive force to move the jigsaw forward, otherwise this will lead to failure of the file or the mechanisms of the tool. A worn-out blade should be replaced immediately, since a dull file will cause an increased load on the electric drive. The workpiece to be sawn must be securely fastened.

For straight cuts, you can use a rip fence or a guide bar.

Sawing with a guide bar

First, the workpiece must be marked. After that? by installing the jigsaw in a special shoe, and then the shoe in the tire, the tool is positioned along the cutting line.

Having installed the file of the tool exactly along the cutting line, the guide bar is fastened.

The tool is started up and driven along the tire. Little depends on the operator. The quality of the saw and the jigsaw itself will affect the quality of the cut much more.

There are busbars with clamps that allow you to make both straight cuts and angled cuts.

There are busbars with clamps that allow you to make both straight cuts and angled cuts.

Sawing with the rip fence

The parallel stop often comes with a jigsaw, but regardless of this, almost all models have a slot in the sole for attaching the parallel stop rod.

It is possible to make a high-quality cut using this device only in the following cases:

- The reference plane along which the shoe will move must be flat and parallel.

- The jigsaw must be of high quality and resistant to sideways movement.

- The rip fence itself, that is, its rod and shoe, must be strong and rigid.

- The operator must firmly press the shoe against the supporting surface when moving the tool.

The most popular jigsaws

Consider the models that are most popular with buyers.

Bosch 900 PEL is the best tool. The 620 Watt 3100 rpm motor makes any work quick and pleasant.

The special holder allows you to easily and in an instant change the file without using a key.

The pendulum mechanism speeds up the whole work process, and in this model it is regulated by four modes. In addition, when cutting in pendulum mode, the degree of wear of the saws is reduced.

To make the cut smooth, a backlight is installed in the jigsaw. There is an outlet for connecting to a technical vacuum cleaner, as well as the possibility of an oblique cut.

Electric jigsaw BOSCH 900 PEL

Electric jigsaw BOSCH 900 PEL

According to buyers, the Makita 4329, Makita 4326 and Bosch 650 tools are the best jigsaws for the home.

Makita 4329. The pendulum stroke is regulated by three positions. The rubberized handle and low weight of the tool allow you to work with it for a long time. The molded sole can be rotated 45 °.

Makita 4329 electric jigsaw

The Makita 4326 jigsaw is equipped with the same engine, but there is no pendulum mechanism. Thanks to this, the tool has a lower price.

The outsole tilts to both sides and is locked with a hex wrench.

A special protective screen will not allow sawdust to obstruct the view during cutting.

The saws in both models are replaced with a key.

Makita 4326 electric jigsaw

The Bosch PST 650 tool has a compact size and low weight, as a result, it is easy and convenient to use. Power 500 watts.

The saws can be changed without a key. The intensity of the blowing off of the sawdust is controlled by a switch on the left side of the tool.

There is an outlet for connecting a vacuum cleaner.

The stamped sole can be tilted up to 45 °.

BOSCH PST 650 electric jigsaw

Fiolent PMZ-600E is the best inexpensive electric jigsaw 600 W, stroke speed up to 2600 strokes / min. The pendulum mechanism is adjustable in three positions.

The file is fixed with one screw. The advantage of such a clamp is that it is possible to install files of different thicknesses. The switch can be locked in the pressed position.

The gearbox housing is made of aluminum, as a result, during operation, it cools faster than others.

Electric jigsaw Fiolent PM3-600E

But the most popular among buyers, nevertheless, are brands such as Bosch and Makita.

Electric jigsaws of the Fiolent brand are in demand due to their low price, good quality and affordable spare parts.

More articles from the section Tool

Go to groups and Odnoklassniki

The most frequent breakdowns, how to avoid them and safety precautions

It is important not only to know how to saw with a jigsaw, but also to try to avoid causes that can lead to tool breakage. Electric motor

Most often, the engine fails in jigsaws. There can be several reasons for the breakdown: burnout of the rotor, stator, wear of the notch on the shaft. To avoid rotor burnout, you need to purchase a tool that will be powerful enough to perform the required tasks. For example, if you need to cut thick workpieces, a 400 W jigsaw will not be enough - the engine simply will not withstand the load and will burn out. An insufficiently high voltage in the network can also lead to this. It is not recommended to set low speed too often: lack of cooling and high currents can lead to burnout of the winding

Electric motor. Most often, the engine fails in jigsaws. There can be several reasons for the breakdown: burnout of the rotor, stator, wear of the notch on the shaft. To avoid rotor burnout, you need to purchase a tool that will be powerful enough to perform the required tasks. For example, if you need to cut thick workpieces, a 400 W jigsaw will not be enough - the engine simply will not withstand the load and will burn out.An insufficiently high voltage in the network can also lead to this. It is not recommended to set low speed too often: lack of cooling and high currents can lead to burnout of the winding.

The notch on the shaft can wear out due to constant shock loads on the tool stem. Shock loads on the rod appear due to improper selection of equipment. Therefore, always follow the guidelines when selecting a saw blade.

Power button. Sometimes the owners of a jigsaw are faced with a malfunction of the power button. Pulling the trigger will close the circuit and start the engine. If metal dust enters the case, the power button may not function properly. To remove dust during operation, you can use a special vacuum cleaner (a household one will not work). The failure of the "trigger" can lead to natural wear and tear of the conductive tracks. I must say that this process is quite lengthy.

Mechanics. Among the mechanical components, the stem may be problematic: this part is subjected to serious mechanical stresses that occur during the sawing process. The blade locking mechanism is the weakest in this system, since it is directly connected to the stem. Do not be afraid of damage to the gearbox if the housing reliably protects the internal mechanisms of the tool from dust.

Jigsaw safety and maintenance

The basic safety rules are necessarily indicated in the operating manual. It is strictly forbidden to perform any work while intoxicated. Before starting work, make sure that the tool is in good working order, the presence of protective glasses and gloves, the stability of the voltage in the network. It is necessary to take care of good lighting of the workplace in advance. Jigsaw work should be carried out in a dry room. There should be no flammable substances nearby.

At the end of the work, the tool is thoroughly cleaned of dust, if possible - blown with air (when the engine is running, the blowing efficiency will be higher). Lubricant is applied to moving parts as needed. Store the instrument in a dry place. Compliance with these simple recommendations will significantly increase the life of the jigsaw.

Additional tips for choosing saws

The quality of the saw blades should be even better than the quality of the jigsaw itself, because it is the blunt teeth that easily bend in different directions that can ruin the work of even the most experienced craftsman.

In addition, it makes sense to choose different saws for different types of sawing:

- For straight cuts, wide blades are suitable, which are more stable and, accordingly, provide a straight line in the end.

- The more important the cleanliness of the cut itself, the thinner the teeth on the blade are selected.

- If it is necessary to achieve a perfectly clean cut line, absolutely without a single chip, choose a blade that has a reverse tooth stroke.

- When you need a quick and rough cut, large saws are used with wide-set cutters.

- Blades without setting are quite productive and convenient for working with thick workpieces.

- If both productivity and quality of sawing are equally important, then saws with teeth installed with a displaced pitch will help (the step is large at the bottom, and as it approaches the front of the part, it gradually becomes smaller).

Characteristics and design features

Features of an electric jigsaw that must be considered in order to choose the right model:

- The motor power affects both the maximum workpiece thickness and the stroke rate.

- Stroke frequency determines productivity, maximum cutting speed

- Sawing depth - the maximum thickness that the device can handle, depending on the material.

- Power type - battery or mains.

- Continuous working time - how many minutes or hours the device can work without interruption.

- Availability of additional functions.

Jigsaw power

The functionality and performance of the entire device directly depends on its heart - the electric motor. Power determines how much force the blade will move, for example a 400W electric jigsaw. will be able to overpower 60 mm of wood and 4 mm of metal, and a 600-watt one will already be able to handle 80-85 mm of wood and 6-8 mm of metal. Power ranges from 300 to 1000 watts. For a home craftsman, it would be wise to choose among devices with an average value of 500-600 watts. Weak devices are useful only for a narrow range of tasks, while more powerful, professional, too heavy and expensive, and also consume a lot of electricity.

File movement frequency

The stroke rate directly determines the speed of the saw - the more often it goes up and down, the faster the material will be cut. For different models, the maximum frequency lies in the range of 2300-3200 strokes per minute, and the most powerful models have a stroke rate of 4000 per minute. Most modern models allow you to adjust the stroke rate: stepwise using a separate regulator or smoothly, as the pressure on the power button is intensified.

The second option is better suited if the master is going to do sawing or curly cutting of the material. Frequency control makes it possible to work with various materials of workpieces, for example, for wood, the frequency should be maximum, for a smoother surface of the cut, and for metals, on the contrary, small, in order to avoid overheating of the file and its breakage.

Another important parameter is the cutting depth.

Cutting depth is a key characteristic of an electric jigsaw. It determines what maximum thickness of the workpiece can be mastered by the device, provided that a blade of the appropriate length is installed in it. By the way, if you cut a 100 mm thick beam with a 100 mm file, the end of the cut can turn out to be sloppy, with bad marks. It is better to have a margin of 5-10 mm in length. The depth depends on the material and is indicated separately for wood and steel. Aluminum blanks, as a rule, can be sawn one and a half times thicker than steel. Household models have a depth of 50-110 mm for wood and 4-6 mm for iron. For professional ones - 150 and 10 mm, respectively

Principles of Correct Operation

After the jigsaw is purchased, the master must learn how to use it. The jigsaw is a simple tool. But even a hammer - which is easier - can be used in different ways.

The master has three degrees of freedom in using a jigsaw. The master must:

- Choose the right tooling (file).

- Set the optimal pumping amplitude and motor rotation speed.

- Use the most appropriate work habits.

Each point can be discussed for a long time, but we will try to highlight the main thing.

Choice of equipment

There are a great many varieties of files produced and sold. They differ in the type of steel from which they are made, in the length and width of the blade, in the shape and size of the tooth:

- The harder the material to be sawed, the smaller the tooth should be on the selected file.

- For a curvilinear cut, you need to choose a narrow file. For straight cutting, as wide as possible.

- The length is selected based on the thickness of the workpiece to be cut.

Especially many different saws are produced for woodworking. For a quick cross-cut, choose a file with large, set teeth. The coarse step allows you to cut very quickly, but we give a lot of chips. For a clean cut, the tooth should be smaller.

Metal cutting saws are very similar to a regular metal hacksaw blade.

Pumping and speed

Inflating can significantly increase the cutting speed. It is usually turned on when you need to quickly cut a large piece of wood in a straight line.In other cases, it does not really help and can even complicate the work or worsen the quality of the cut.

Figured cutting is performed with pumping completely switched off. General recommendations cannot be given here. You need to try different modes. The most correct solution is to first practice on some scraps of material.

Inexperienced craftsmen tend to work with a jigsaw immediately at maximum speed. It is not right.

When cutting plastics, the file can become very hot at high speed and the plastic will begin to melt. Not all metals like high speeds.

How to work

As stated many times, the electric jigsaw is a tool for many applications. However, the variety of situations comes down to only three cases: sawing in a straight line, curved cuts and cutting holes.

Straight cut

This is the simplest case. Draw a line with a pencil and smoothly draw a jigsaw along it. The built-in laser pointer will be more than helpful here. Sometimes a parallel stop can be useful for such work, which is fixed to the jigsaw frame.

The sawing speed can be maximum. Pumping will further increase the cutting speed.

To maintain a straight line, you have to "steer" with a jigsaw all the time. But even the most careful "aiming" gives mediocre results. In this type of work, a jigsaw loses to a circular saw in terms of cut quality and speed.

Curvilinear cut

Such cuts are the native element of electric jigsaws. They were "born" for this.

The main secret of success is not to rush. Mark the part carefully. It is convenient to stick masking tape on the surface of the workpiece and draw lines with a pencil. Guide the jigsaw along the line of the markings, turning it slightly ahead of time. Bends with small radii should be done especially slowly so that there is minimal forward advance for each sawing stroke.

Cutting holes

This is one of those operations in which the jigsaw has no competition. Typical examples: cutting a hole in a worktop for installing a hob or sink, making a hole in the wall of a cabinet for an outlet, and a thousand more similar cases.

To cut a hole in a part, you first need to drill one or more "starting" holes with a drill. A jigsaw file is placed in them and the sawing begins and ends in this hole.

If you have to cut a very large window, it is more convenient to cut it out in parts.

Sawing at an angle to the surface of the part

All the cuts described above can be made not only perpendicular to the surface, but also at an arbitrary angle up to 45 degrees to the plane of the part. The need for such cuts arises, for example, if you need to connect two parts "on the mustache".

Features of cutting round and oval elements

In this section, we will talk about how to properly saw round or oval elements with a jigsaw. First you need to apply markings to the material. In most cases, a hole is drilled in the workpiece, from which the product will be cut. In this case, the diameter of the drill should slightly exceed the width of the saw blade. To cut out curved elements, you must take a narrow file designed for such work.

The jigsaw is brought to the desired path slowly. If you want to cut a circle of the correct shape, you can use an additional device - a circular cutter. To do this, it is necessary to determine the center of the circle and, having fixed the stop-compass there, cut it out.

For such work, it is better to choose a narrow canvas. In the process of cutting, you need to focus on the position of the blade, since the elements that help when performing a straight cut (guide "flies", lasers), in this case, will only knock down the direction.

In some cases, you can do without drilling a hole in the workpiece. For this, the tool is positioned with the edge of the sole behind the marking line.The jigsaw turns on and tilts with careful movements until it touches the work surface. The angle increases until the workpiece has been cut through. After that, the tool stops, the file is removed and set to the standard working position. Exit to the marking is carried out by the method of gradual rounding of the cut line. Any effort on the tool should be avoided.

For cutting non-standard shapes or patterns, the jigsaw is installed using special fasteners or a saw table in a stationary state, with a file upwards. In this case, you will not have to wield a jigsaw, but the workpiece itself, moving it in accordance with the markup. This cutting method provides maximum visibility of the work process, adherence to the cutting line, and control over the workpiece. Tool settings are set according to the material being processed.

Some helpful tips

- The working stroke of the jigsaw file is from bottom to top. On wooden blanks, because of this, chips appear on the surface facing the jigsaw. To avoid them, turn the part face down.

- It is not always convenient to saw the details from the wrong side. In this case, there will be fewer chips if you seal the cutting line with masking tape.

- Another way to avoid chipping is to use files with a special “reverse tooth”. However, with them, the recoil becomes very noticeable and additional physical effort is needed to hold the jigsaw.

- A jigsaw file is a very resilient element. Because of this, during the cut, it bends, which, in turn, leads to a shift of the cutting plane to the side. The thicker the workpiece to be sawn, the greater the drift. To reduce it, use the sharpest saws and feed the jigsaw forward as slowly as possible.

- Thin metal, thin plywood, hardboard can rattle violently during operation. Such details should be put on a sheet of 10-12 mm plywood and this “sandwich” should be cut.

Device and principle of operation

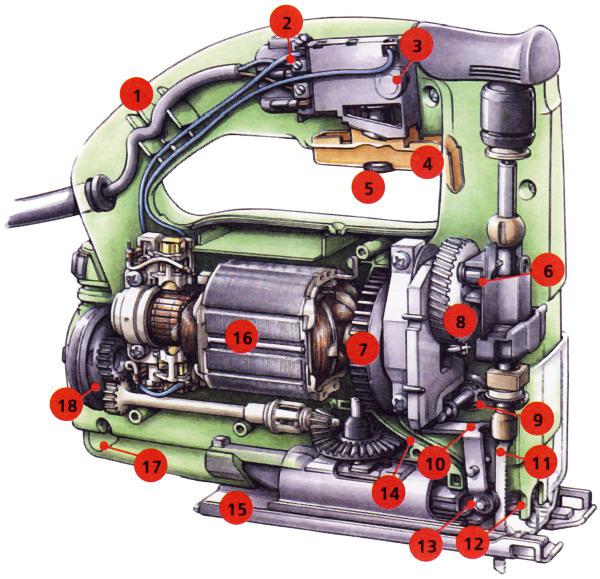

Let's consider in detail the jigsaw device

What a jigsaw consists of

Jigsaw device

Jigsaw device

- Power cord.

- Cord terminals.

- Trigger stopper.

- The trigger.

- Speed selection knob.

- Eccentric hinge.

- Cooling fan.

- Reducer.

- Pendulum action regulator.

- Pendulum mechanism.

- File.

- Protective limiter.

- Saw support roller.

- Air duct.

- Base plate.

- Electric motor.

- Sawdust removal.

- Baseplate adjuster.

In simple jigsaws, the tooling moves only up and down. And when using the pendulum mechanism, even forward and backward. This tool cuts faster. How is vertical movement formed? The motor transfers its rotation to the gear wheel. An eccentric hinge is attached to it, which creates an up and down movement. The base plate presses and holds the tool on the work surface, eliminating hand shake. The sawdust is blown out by a cooling fan and discharged through a special branch pipe.