Advantages of bored piles

- shortening the construction time, since after the installation of the piles there is no need to wait until the concrete gains its design strength;

- the possibility of using in permafrost conditions;

- relatively low cost of work and dynamic tests.

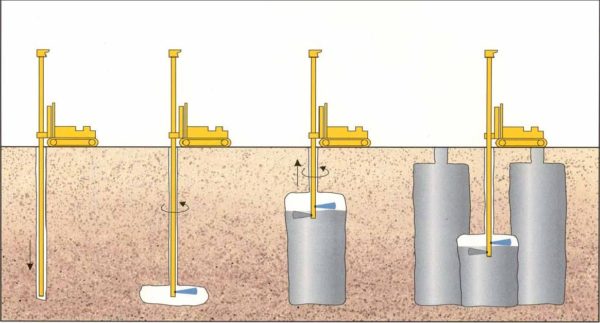

Due to their high strength characteristics, bored piles are used in plastic-frozen soils of the Far North. For their device, wells are drilled mechanically. The diameter of the wells is one to two centimeters less than the minimum cross-section of the pile. Piles are driven in any way to a depth equal to the depth of the drilled well.

Bored piles, bored piles or bored piles can be made with both internal cavities and a solid structure. Naturally, the cost of piles with internal cavities is cheaper than solid ones due to the reduction in the amount of material used. However, the strength characteristics of hollow structures remain at the proper level, which allows them to be used for the construction of bored foundations. The piling technology does not differ from the construction of solid drilled products.

For the strengthening of reservoirs and the construction of retaining walls, rectangular structures, both solid and hollow, are traditionally used. For driving into soft soils, hollow or solid round bored piles are used. They are available with both open and closed ends.

Advantages and disadvantages of leader wells

This technology has both advantages and disadvantages, which we will now consider.

Thanks to the use of this type of drilling, it is possible to install a well in any, even the hardest soil, subject to the technology. Also, by adhering to the technology, you can increase the maximum depth with further pile driving. When performing a pilot well, it is possible to install the pile in an ideal vertical position in the future, in this case there will be no deviations.

If you decide to install a pile in a prepared hole, then the vibration impact on the foundations of neighboring buildings, which destructively affects them, will be significantly reduced. Therefore, it is possible to install piles during leader drilling even a few meters from buildings.

In addition, if you decide to choose this technology, you can significantly save not only time, but also physical effort.

Drilling a leader well to design depth

Despite the large number of serious advantages, there is still one drawback. It lies in the fact that additional financial costs will be needed. This is due to the fact that it will be necessary to use special equipment, as well as to do geodetic research. Therefore, it should be borne in mind that such a procedure will significantly increase the cost of installing piles.

The chief designer makes a decision on the need for leader wells, based on the results of geodetic surveys.

Where leader wells are used

Leader wells are used to reduce the time of the installation of the pile foundation, ensure better safety of the piles, ensure the design parameters of the pile immersion depth, and also reduce the time to overcome the soil layers of increased density. The piles are immersed in wells specially drilled in the places where the piles are installed. Such wells are called leader. The diameter of the leader hole should be 5 cm less than the diameter of the round pile or the diagonal of the square pile.

Rice. 3

: Drilling auger tip

The need to create leader wells is often encountered when arranging pile foundations from driven reinforced concrete piles. This practice is used in the following cases:

- If it is necessary to immerse the pile in the soil, in which there is a deep layer of sandy soil with a thickness of more than 2 meters - such a layer of compacted sand, a reinforced concrete pile cannot pass independently either with the shock or with the vibration method of immersion;

- In case of excessively dense upper soil layers - in such cases, the creation of a leader well makes it possible to avoid damage to the trunk of a reinforced concrete pile during shock contact with dense soil;

- If it is necessary to immerse piles in stony soil, numerous disseminations of rocks located inside stony soil are an insurmountable obstacle for a pile driven in without a previously created leader hole;

- When piles are immersed in permafrost soils, the density of permafrost soil is much higher than the density of ordinary soils, it is impossible to hammer a reinforced concrete pile into the frozen soil using conventional methods;

- If it is necessary to immerse reinforced concrete piles to a depth of more than 9 meters - the deeper the soil layer is, the more compacted it is, since the layers of soil located above are pressing on it. When a reinforced concrete pile is driven below a certain depth, its "failure" (pile failure) occurs and further immersion is possible only into the drilled leader well;

- When driving a pile into dispersed soils, this type of soil is characterized by a minimum density due to the absence of rigid structural bonds, as a result of which, when the pile is immersed, problems arise with its vertical positioning. Leader wells in such cases play a guiding role, they allow the reinforced concrete pile to be loaded perfectly evenly.

The technology of driving piles into leader wells is also used in the device

foundations

,

nearby buildings and structures. The drilling depth of the leader wells should not exceed 90% of the length of the pile part submerged into the ground and is determined by experimental drilling.

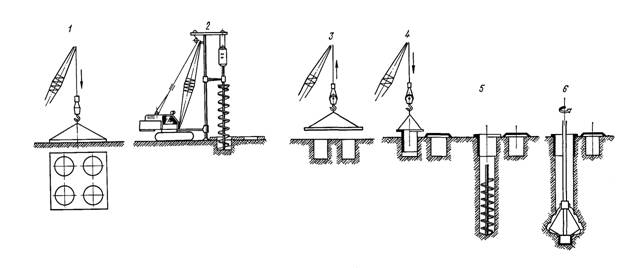

This process involves several sequential stages:

- installation of equipment on the axle in the position indicated in the project;

- further directly the process of drilling wells;

- driving (immersion) of piles (sheet piles) to the declared design level.

It is worth noting that the method of leader drilling of wells has found application in the process of installing sheet piling of a pit, and, in addition, in the process of trenchless laying of a pipeline (that is, when a well is initially made in the ground, and then it is expanded and simultaneously there, into it tighten the pipeline).

When is the leader drilling method used?

Recall that leader drilling is a drilling method that is performed before driving the pile itself.

As a rule, this method is used during pile driving in such cases:

- if there is a geological section of the sand layer, more than 2.5 meters long;

- if the topsoil is too dense (that is, in the case when its telos is destroyed at the beginning of the driving process);

- if it is necessary to increase the depth of the immersion of the piles (usually in dense soil with an undershoot of 2.1-2.5 m);

- if there is no possibility of driving the piles up to the mark declared in the project;

- if there are large deviations in the pile positioning process.

The decision to use the method of pilot borehole drilling (or, as experts call it, the "leader") is made necessarily with the approval of the design organization, while being based on reports on engineering and geological surveys and current conditions.

Depending on which section, the depth of the pile to be driven and the category of soil, the required diameter and depth of the leader is determined.Often, for piles with a cross section of 300x300mm, a diameter of two hundred to two hundred and fifty millimeters is taken, in the case when a section of 350x350mm or 400x400 mm is taken three hundred or three hundred and fifty mm. It should be noted that the depth of the leader well is taken 2-2.5 meters higher than the point of the pile points declared in the project.

In addition, in the process of pilot drilling of wells, the optimal technology is determined: there is the option of a complete selection of soil from wells or partial drilling (softening of the soil with a screw). It is necessary to take into account the fact that when installing the leader, the soil that is drilled out of the well by the augers, the mark indicating the surface of the soil increases quite noticeably, and it must either be removed or a pit must be dug out with the margin necessary in this case.

During the work, it is necessary to correctly plan the coordinated work of technical means (such as a pile driver and a drilling rig, for example) in order to prevent "trampling" of previously drilled wells. In addition, the distance between the wells should be taken into account in order to exclude the possibility of their crumbling in the event of a dynamic load during the operation of pile hammers.

What are the advantages of leader drilling?

As we have already said, this method of drilling bored piles will provide a vertical direction in the process of driving the piles (sheet piles), this will be most in demand in winter. In addition, this method greatly facilitates the achievement of verticality of the piles at the initial moment of driving.

Preliminary (it is called drilling a well by the leader method) drilling will allow the permeability of dense sands, as well as clayey soil of a harder and semi-solid consistency. Leading wells, which are drilled in order to reduce the resistance of soils to the process of driving piles (sheet piles), at the same time serve as a guide for these piles.

A great advantage of this method is the ability to ensure the safety of the pile (sheet pile), as well as the ability to ensure their immersion with a high level of accuracy to the marks that are declared in the project. In addition, the time spent on their loading is noticeably reduced, and the negative impact on nearby buildings is also significantly reduced. It should be noted that in modern conditions of rather dense urban development, this is truly a decisive factor.

The ATM-Aqua company carries out various types of work for the manufacture of piles. We use only the most modern technology and all equipment in our work. ATM-Aqua specialists do their job extremely efficiently and in a short time.

What are we for

If the construction of an object requires the use of piles, then the use of leader wells is almost always recommended. This demand is due to the fact that they allow you to more quickly perform work, do not threaten other objects located in the vicinity.

This method is often used when equipping pile foundations using driven reinforced concrete structures.

If we are dealing with the installation of a pile in the ground, where there is a sandy rock with a thickness of at least 2 meters, the pile cannot independently punch it when using either of the two immersion methods.

In the case when the topsoil is very dense, in order not to damage the pile in the process, you also need to do leader drilling.

Drilling a leader hole with a large auger

This method is especially in demand when we are dealing with rocky soils. In this type of soil, the pile cannot pass without preliminary drilling.

Such a method is definitely needed if it is necessary to install piles in permafrost soil, since its density is much higher than ordinary rock.

If we install a pile to a depth exceeding 9 m, since the soil is compacted at a depth, due to the constant pressure of the upper layers.When we drive a pile to a great depth, sooner or later it will not be able to pass, therefore, you must first make a hole.

Also, this work is required in soft rock conditions. This is due to the fact that the structure will be unstable, and it will not be possible to hammer very deeply, since there will be strong resistance of the rock at a certain level.

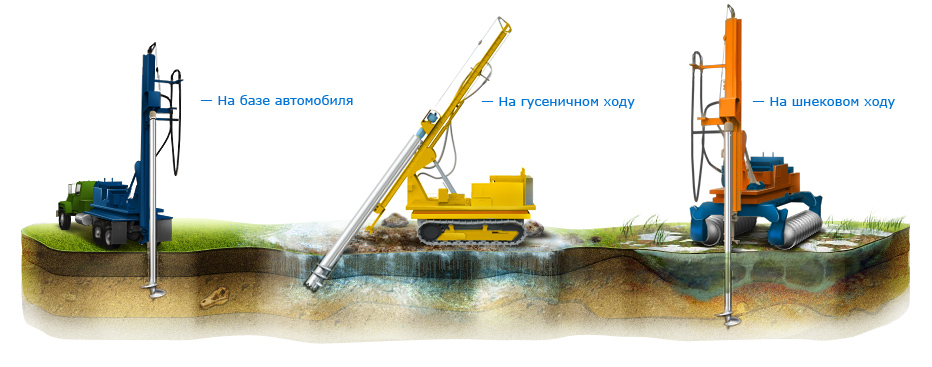

Technique used for drilling wells under piles

Drilling wells for piles provides the necessary strength of the bearing supports. Pile drilling technique involves the use of special equipment. These can be both fully automated devices that are capable of performing a large amount of work, and relatively small mobile drilling rigs that operate on the principle of simple rotary drilling. Often, these rigs are wheeled or crawler mounted and are fully functional piling machines.

In accordance with the technique of performing the work, MBU are divided into some varieties:

- Rigs for drilling with a solid auger, for which they have a special stackable drill string that does not have an internal channel.

- Special rig for CFA drilling. It has an internal cavity that serves to feed the concrete mixture into the well.

The operational parameters of the MBU are constantly growing and optimally meet the needs of modern construction. These rigs can drill wells up to 50 meters deep, which opens up the possibility of sinking the maximum possible composite supports into the ground. The diameter of the piles varies from 100 to 800 mm.

For a pile foundation in private housing construction, hand tools are often used to create wells. This category of products has its own characteristics that are important when choosing a model:

- The diameter of the working blades of these drills is up to 300 mm, so they cannot be used for wells for large piles, and this is not rational - large-sized installations are used in these works.

- Hand drills do not have a fixed handle - instead, the design provides for the extension of the rod as the drill sinks into the ground.

- Drills can create both cylindrical wells and depressions with expansion in the lower part.

When performing drilling operations on a significant scale, specialized drilling equipment is used. This equipment is usually installed on large trucks such as Ural, KAMAZ or KrAZ.

Equipment for drilling wells for piles

A drilling machine for drilling wells for bored piles is a mandatory equipment for performing well creation work. This technique ensures high productivity and reduces the time and money spent on erecting the foundation.

Advantages of leader drilling for reinforced concrete piles

Due to the simplicity and high quality of the result, leader drilling has become widespread in production. The most significant advantages of this technology are the following:

- The ability to load reinforced concrete piles into any type of soil with any technical characteristics.

- Significant increase in pile depth.

- Strict adherence to the verticality of the pile installation, which ensures the high quality of the entire foundation and the achievement of the characteristics laid down in the project.

- Reducing the impact of vibration from pile driving on nearby structures.

Leader drilling is constantly being improved. Now it is difficult to find objects with a pile field at the base, where they can do without additional drilling. Even with good soil, not to mention problem areas. Special equipment ensures the quick execution of the entire range of works with an excellent result in the end.

A well for pile installation is an excellent solution for construction!

According to SP 50-102-2003:

According to clause 7.2.2, when performing calculations of the bearing capacity of suspended driven, pressed in all types and shell piles, immersed without excavation, it is necessary to take into account the working conditions coefficients according to table 7.3.

Table 7.3

clause 9.4. If, according to the results of engineering surveys, it is established that the immersion of driven piles into subsiding soils is difficult, the design should provide for the device of leader wells, the diameter of which in soil conditions of type I should be assigned less than the diameter of the pile section (up to 50 mm), and in soil conditions Type II - equal to it or less (up to 50 mm). In the latter case, the depth of the leader wells should not exceed the thickness of the soil layer subsiding from soaking.

13.8. For piles that receive pull-out loads, it is allowed to provide for their immersion in the leader wells, while the difference between the transverse size of the pile and the diameter of the leader well should be at least 0.15 m.

p. 15.2.11 If it is necessary to punch layers or interlayers of dense soils in the process of driving piles in order to reduce the duration of pile driving, ensure their safety and immersion to specified marks, leader wells are used. In these cases, leader wells are usually arranged 5 cm less than the diagonal of the cross-section of the submerged pile. to a depth of soles of a dense layer.

15.2.12 Leading wells are also recommended to be used when driving piles into water-saturated clay soils, which do not have time to compact during pile driving, which can lead to vertical deformations of the soil and cause flooding of previously submerged piles, destruction of joints of composite piles, destruction of foundation structures of nearby buildings, and structures.

15.2.13 The depth of the leader wells is assigned empirically, but not more than 0.9 of the pile length, and for the leader wells specified in 15.2.12, regardless of their diameter, the depth can be determined from the condition of the stability of their walls by the formula:

Zmid = 2 su / γI, where

where Zmid- ultimate depth of a stable well, m;

withu - undrained resistance of clay soil to shear, kPa;

γI - the calculated value of the specific gravity of the soil, kN / m.

Clause 15.2.26 With appropriate justification by calculation and agreement with the design organization, it is allowed to change the location of screw and screw-on piles with a blind tip during the work process (extraction of piles when meeting with local accumulations of gravel, large boulders, etc. and re-immersion of piles) ...

In such cases (the presence of inclusions), it is allowed to use leader wells with a diameter of at least 0.1d smaller than the diameter of the pile shaft d, and the location of their bottom at least 1 m above the mark of the location of the lower ends of the piles.

p.15.2.27 When installing screwed-in piles with a blind tip in unstable soils, instead of installing leader wells, loosening of the soil with an auger drill (without lifting it while drilling) should be performed within the soil massif (cylinder), the diameter of which is not less than 0.1d less the diameter of the pile shaft d and the elevation of the bottom of the massif at least 0.5 m above the design elevation of the location of the lower ends of the piles.

Sequence of works of leader drilling

Further, the axes of the future pile field are broken down and the places where the pile posts will be inserted are marked, along which drilling will be carried out. Specialists licensed to perform geodetic work are allowed to mark pile foundations.

Rice

After marking the pile field, the leader drilling technology is implemented:

- The drilling machine drives up to the location of the well;

- The drilling mast is brought into working position;

- The well is being drilled to the design depth;

- After complete penetration of the well, the auger auger rises with the reverse (reverse) stroke engaged.

Rice

In a similar way, leader wells are equipped throughout the pile field, after which a pile-driving unit is put into operation to drive or vibrate reinforced concrete piles.

Prices for drilling leader wells

The construction company "Bogatyr" offers its customers one of the lowest prices for leader drilling in Moscow and the region.

We calculate the cost of creating a leader well based on its depth - the base price of one running meter of drilling is 300 rubles (it may vary depending on the type of soil and the amount of work).

It is also necessary to take into account the price for the relocation of construction equipment - in Moscow and the region it is 20 thousand rubles (relocation to neighboring regions is possible, its cost can be clarified by contacting the representatives of the company).

Leader drilling allows piles to be vertically mounted on a site with a dense soil composition. This method is most relevant in winter, since it facilitates the process of driving in the sheet pile during the construction of the foundation.

Leader drilling makes it possible to reduce the resistance of the earth's surface, as well as to set the entire structure to a considerable depth. In addition, vibration and noise levels are reduced during installation.

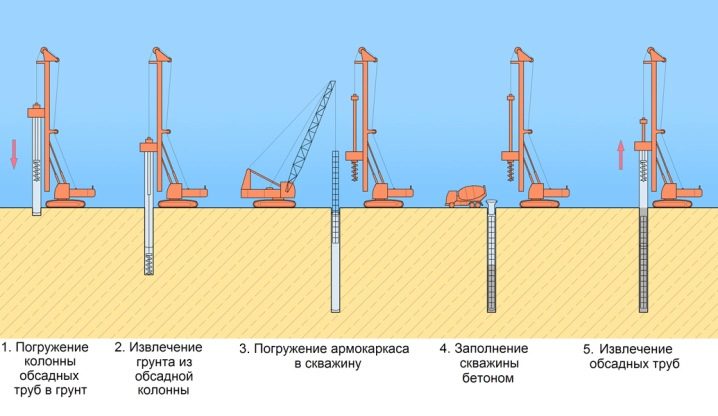

Process steps

To drill a hole with your own hands or with the help of specialists to the required depth, you must strictly adhere to the technology.

A typical work algorithm is as follows:

- installation of drilling equipment and its fixation;

- penetration to the design depth and diameter;

- conservation work using clay solution or casing insertion;

- saturation of the formed cavity with concrete solution.

Experts pay special attention to the fact that both the prepared pit and the concrete poured into it have a short shelf life. According to the generally accepted standard, a maximum of 8 hours should elapse from raising the drill to pouring in the last drop of concrete.

Their requirements are also imposed on preparatory work, which look as follows:

- Fertile soil is harvested (up to 150 mm over the entire area).

- A pile field is planned at a selected elevation.

- A fence from strangers is mounted.

- The site is formatted, and then the flatness of the surface is checked again.

- The pillows for the work itself and the passage of cars are filled up.

- Route lines for drilling systems using reinforced concrete slabs are being prepared.

- Drainage channels are being organized.

- Lighting fixtures are connected (only if you need to drill around the clock or with reduced daylight hours).

- The arrangement of drilling systems and the required materials and products is carried out.

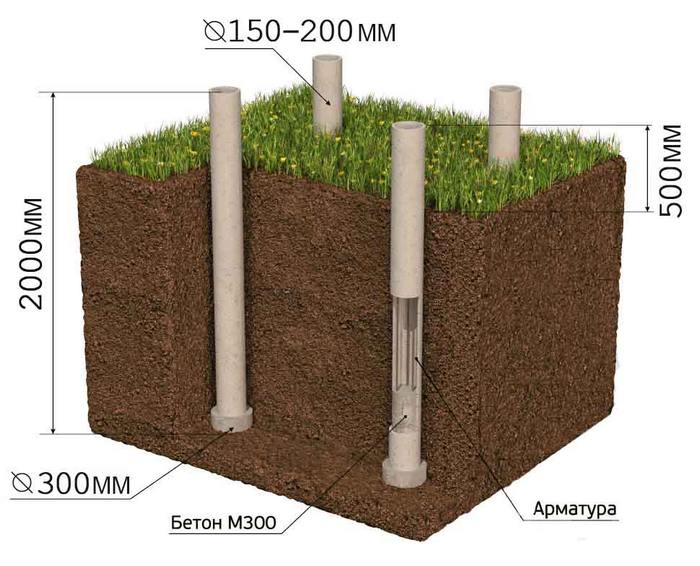

Well sizes

There are circumstances when the soil is removed from the wellbore completely, and for certain cases, drilling is performed, that is, loosening of the soil remaining inside the well.

The auger diameter is selected in accordance with the size of the piles that will be used later. So, with a reinforced concrete pile size of 300 x 300 mm, a drilling tool with a diameter of 200 - 250 mm is used, and for a section of 350 - 400 mm a screw with a diameter of 300 - 350 mm. The well depth is less than the design depth for the sharp end of the pile by 2.0 - 2.5 m.

When designing drilling and piling operations, it is important that the finished wells are not "trampled" when an adjacent well is driven down with a pneumatic hammer. Therefore, it is necessary to distribute the sequence of drilling wells and installing piles

According to the guidelines for the design of pile foundations to SNiP II-17-77 "Pile foundations"

p.2.4. A variety of driven reinforced concrete piles to the structure and method of immersion are:

b) piles immersed in the leader boreholes, and the diameter of the leader borehole should not be less than the size of the cross-section or the diameter of the pile, and the depth should be less than the required pile immersion depth by at least 1 m.

Leading wells are allowed to provide, if necessary, forced drilling of clay soils of solid and semi-solid consistency (for example, subsiding and swelling) in cases where, according to the results of experimental piling or construction experience, it has been established that it is not possible to load piles without leader wells;

Clause 8.13. If the construction organization does not have hammers with impact energy that satisfy the condition of formula (45), then it is necessary in the design to provide for the use of leader wells or underwash during the immersion process. If, for some reason, it is impossible to use these methods in the case under consideration, it is necessary to resolve the issue of the admissibility of using pile foundations from driven piles of shorter length or the transition to the use of bored piles.

Clause 9.3. In the event that, according to the results of engineering surveys, it is established that the immersion of driven piles in subsiding soils is difficult, the design should provide for the device of leader wells, the diameter of which should be set less than the size of the pile section up to 50 mm.

In order to avoid the difficulties associated with driving piles into subsiding soils, they should be driven with a leader wells device.

Leading wells are drilled in the center of the future pile with a diameter not less than 100 mm and no more than the side of the cross-section of the pile minus 50 mm. The length of the leader holes should be less than the pile immersion depth by an amount equal to 3d, where d is the pile diameter, but not less than 1 m. wells. After the device of the leader wells, it is advisable to fill them with water 2 times and hold for at least 1 day. before pile driving.

Clause 13.12. For piles that perceive pull-out loads, it is allowed to provide for their immersion in the leader wells only when the diameter of the well is less than the diameter or side of the pile section by 15 cm or more.

Bored piles

More recently, foundations of this type have been used to lay the foundations of construction projects in the port and bridge areas.

More recently, foundations of this type have been used to lay the foundations of construction projects in the port and bridge areas.

More recently, foundations of this type have been used to lay the foundations of construction projects in the port and bridge areas. But with the development of civilization, the pile method with the grillage penetrated into the household industry. Today there are three main types of bored grillage:

- The belt type cannot be installed in soil with little moisture, unlike the pile type. It should be noted that this is a shallow foundation, the depth of which does not exceed 1 meter.

- The walls of the grillage are able to withstand strong water pressure, so you can safely lay foundations in watered or cohesive soils;

- The installation process is carried out in all climatic conditions using a casing pipe.

Construction process on low-moisture and cohesive soils

Installation of piles and grillage by bored method on soil with a low percentage of moisture is performed using a special drilling device. The mechanism of its work lies in the rotational action of the apparatus of the apparatus, which makes the hole. In order to prevent the collapse of the soil, it is necessary to install a metal pipe.

When the required depth is reached, it is necessary to immerse the frame from the reinforcement and fill everything with a concrete solution. Concrete must be placed vertically by placing pipes. Concrete pipeline to seal the joints of the structure.

The concrete mix is made at the construction site, and the delivery process is centralized. At the end of the action, the pipe is carefully removed from the well. The grillage can be compacted with special vibrators, which help to strengthen the reception funnel.