Typical dimensions

When visiting a hardware store, you can see a wide variety of grinder attachments. They differ in structure, diameter, thickness. You need to understand how important the technical parameters of the equipment are. If the diameter is larger than the allowable, the following problems may arise:

- A low-power tool will not be able to work effectively with large diameter tooling.

- The linear speed of the cutting edge increases with size. If it is large, the rig may collapse.

- To work with larger rigs, the protective shield must be removed. However, this makes the workflow unsafe for humans.

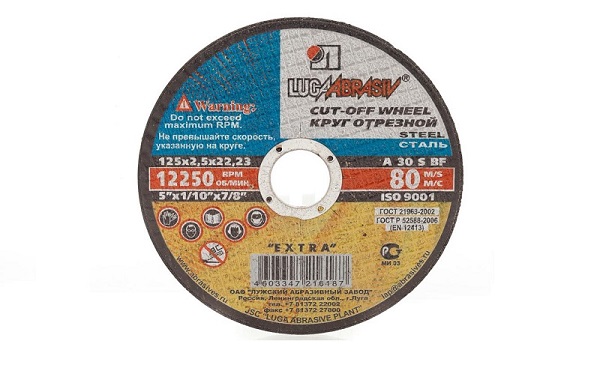

The diameter of the central hole, which is designed to fit on a rotating shaft, is 22.2 mm. Typical dimensions of the outer diameter are 115, 125, 150, 180, 230 mm.

New discs contain all the information necessary for the buyer - diameter, thickness, rotation speed, scope of application of the equipment.

Main characteristics

Grinder attachments vary in size. The most demanded standard cup diameter is 125 mm. Other options are diameters from 110 to 180 mm. The power of the tool used to work with the cup must be at least 1500 watts. Large bits significantly speed up surface treatment, but they are more expensive and require a more powerful aggregate. Small-sized products are used by engravers to process workpieces. The diameter of the bore located at the base of the cup varies from 19 to 22.2 mm.

Working elements - cutters - are made with the addition of small fractions of diamonds to the metal alloy. The mixture is pressed in special molds, which gives it special strength. Coarse diamond grains (200/160 or 160/125 microns) are used for the manufacture of cutters, which are used for rough processing of concrete surfaces, or for roughing. Fine and medium fractions (125/100 and 100/80 microns) are used in the production of finishing attachments.

The advantages of diamond grinding cups for concrete include:

- high strength;

- efficiency;

- durability;

- ease;

- balance.

It is especially important for builders to use the cup without the use of water. The nozzles have special holes on the base that remove air and prevent overheating

Classification

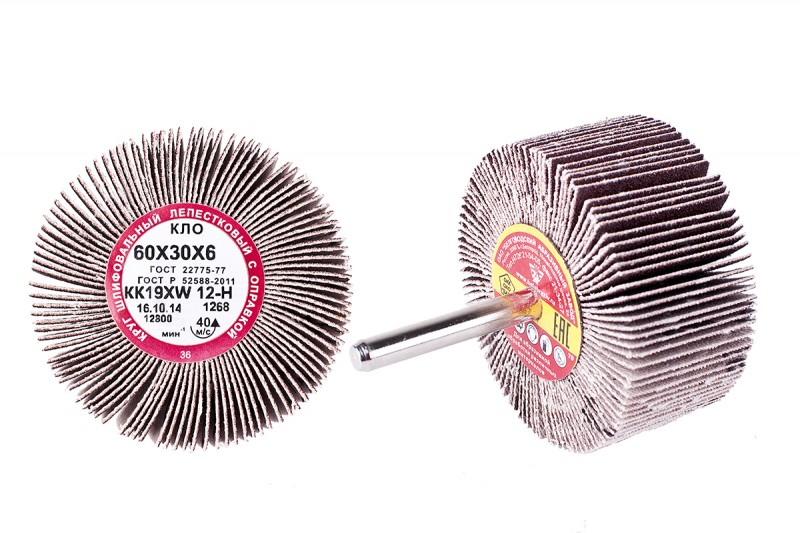

Lobe nozzles are excellent for cleaning iron from paint or rust, grinding seams, welding and removing scoring when metal processing by cutting or stamping. They are also used in the preparation of wood for applying paint or varnish. The principle of operation of different discs is the same - removal of the top cover of the material by means of an abrasive applied to the base. Manufacturers produce a wide variety of abrasive discs exclusively for surface polishing and face grinding, and modifications are also available to clean internal, hidden voids. The petal disc has excellent plasticity.